Abstract

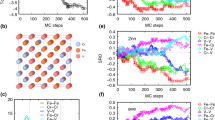

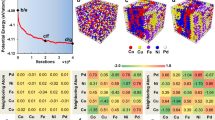

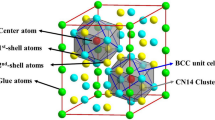

Attributing to the attractive mechanical properties, e.g., high yield strength and fracture toughness, the atomic and electronic basis for high entropy alloys (HEAs) are under extensive studies. In the present work, the local atomic arrangement of body-centered-cubic (BCC) equiatomic HEAs are revealed by the CN14 cluster-plus-glue-atom model and the 32 atoms special quasirandom structures. Moreover, the cluster-plus-glue-atom model is utilized to generate ordered and disordered configurations. The bonding lengths among the same and different alloying elements are comprehensively compared in term of their partial pair correlation function (PCF). According to the specific (well-defined) position of each partial PCF of the BCC structure, the order–disorder/random configurational transitions are revealed by the absence of partial PCF peaks. Here, the WMoTM1TM2 (TM = Ta, Nb, and V) BCC equiatomic refractory HEAs are selected as a case study. Through mixing various groups of alloying elements, the atomic-size differences not only result in the lattice mismatch/distortion but also yield the formation of weak spots. Their bonding-charge density captures the electron redistributions caused by the coupling effect of the lattice distortion and valance electron differences among various elements, which also presents the physical nature of the loosely-bonded weak spots and the tightly-bonded clusters. It is worth mentioning that both the PCF and the negative enthalpy of mixing can be utilized to characterize the clusters or the short range ordering in the HEAs. The microstates revealed by the cluster-plus-glue-atom model are in line with the novel small set of the ordered structures method reported in the literature.

Similar content being viewed by others

References

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes, Adv. Eng. Mater., 2004, 6, p 299-303

Z. Li, K.G. Pradeep, Y. Deng, D. Raabe, and C.C. Tasan, Metastable High-Entropy Dual-Phase Alloys Overcome the Strength-Ductility Trade-Off, Nature, 2016, 534, p 227-230

B. Gludovatz, A. Hohenwarter, D. Catoor, E.H. Chang, E.P. George, and R.O. Ritchie, A Fracture-Resistant High-Entropy Alloy for Cryogenic Applications, Science, 2014, 345, p 1153-1158

Y. Zou, H. Ma, and R. Spolenak, Ultrastrong Ductile and Stable High-Entropy Alloys at Small Scales, Nat. Commun., 2015, 6, p 7748

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, and Z.P. Lu, Microstructures and Properties of High-Entropy Alloys, Prog. Mater Sci., 2014, 61, p 1-93

Z. Zhang, M.M. Mao, J. Wang, B. Gludovatz, Z. Zhang, S.X. Mao, E.P. George, Q. Yu, and R.O. Ritchie, Nanoscale Origins of the Damage Tolerance of the High-Entropy Alloy CrMnFeCoNi, Nat. Commun., 2015, 6, p 10143

O.N. Senkov, J.D. Miller, D.B. Miracle, and C. Woodward, Accelerated Exploration of Multi-Principal Element Alloys with Solid Solution Phases, Nat. Commun., 2015, 6, p 6529

M.C. Troparevsky, J.R. Morris, P.R.C. Kent, A.R. Lupini, and G.M. Stocks, Criteria for Predicting the Formation of Single-Phase High-Entropy Alloys, Phys. Rev. X, 2015, 5, p 011041

F. Kormann, A.V. Ruban, and M.H.F. Sluiter, Long-Ranged Interactions in BCC NbMoTaW High-Entropy Alloys, Mater. Res. Lett., 2017, 5, p 35-40

S. Maiti and W. Steurer, Structural-Disorder and Its Effect on Mechanical Properties in Single-Phase TaNbHfZr High-Entropy Alloy, Acta Mater., 2016, 106, p 87-97

Y. Zhang, G.M. Stocks, K. Jin, C. Lu, H. Bei, B.C. Sales, L. Wang, L.K. Beland, R.E. Stoller, G.D. Samolyuk, M. Caro, A. Caro, and W.J. Weber, Influence of Chemical Disorder on Energy Dissipation and Defect Evolution in Concentrated Solid Solution Alloys, Nat. Commun., 2015, 6, p 8736

W.Y. Wang, S.L. Shang, Y. Wang, F. Han, K.A. Darling, Y. Wu, X. Xie, O.N. Senkov, J.S. Li, X.D. Hui, K.A. Dahmen, P.K. Liaw, L.J. Kecskes, and Z.-K. Liu, Atomic and Electronic Basis for the Serrations of Refractory High Entropy Alloys. NPJ Comput. Mater., 2017 (in press)

C. Pang, Q. Wang, R. Zhang, Q. Li, X. Dai, C. Dong, and P.K. Liaw, β Zr-Nb-Ti-Mo-Sn Alloys with Low Young’s Modulus and Low Magnetic Susceptibility Optimized Via a Cluster-Plus-Glue-Atom Model, Mater. Sci. Eng., A, 2015, 626, p 369-374

E. Ma, Tuning Order in Disorder, Nat. Mater., 2015, 14, p 547-552

Y. Wu, H. Wang, Y. Cheng, X. Liu, X. Hui, T. Nieh, Y. Wang, and Z. Lu, Inherent Structure Length in Metallic Glasses: Simplicity Behind Complexity, Sci. Rep., 2015, 5, p 12137

Z. Zhang, H. Sheng, Z. Wang, B. Gludovatz, Z. Zhang, E.P. George, Q. Yu, S.X. Mao, and R.O. Ritchie, Dislocation Mechanisms and 3D Twin Architectures Generate Exceptional Strength-Ductility-Toughness Combination in CrCoNi Medium-Entropy Alloy, Nat. Commun., 2017, 8, p 14390

Y.D. Wu, Y.H. Cai, X.H. Chen, T. Wang, J.J. Si, L. Wang, Y.D. Wang, and X.D. Hui, Phase Composition and Solid Solution Strengthening Effect in TiZrNbMoV High-Entropy Alloys, Mater. Des., 2015, 83, p 651-660

T. Egami, Atomic Level Stresses, Prog. Mater Sci., 2011, 56, p 637-653

P. Murali, T.F. Guo, Y.W. Zhang, R. Narasimhan, Y. Li, and H.J. Gao, Atomic Scale Fluctuations Govern Brittle Fracture and Cavitation Behavior in Metallic Glasses, Phys. Rev. Lett., 2011, 107, p 215501

D. Ma, A.D. Stoica, and X.L. Wang, Power-Law Scaling and Fractal Nature of Medium-Range Order in Metallic Glasses, Nat. Mater., 2009, 8, p 30-34

C. Jiang and B.P. Uberuaga, Efficient Ab Initio Modeling of Random Multicomponent Alloys, Phys. Rev. Lett., 2016, 116, p 105501

A. Zunger, S.H. Wei, L.G. Ferreira, and J.E. Bernard, Special Quasirandom Structures, Phys. Rev. Lett., 1990, 65, p 353-356

A. van de Walle, P. Tiwary, M. de Jong, D.L. Olmsted, M. Asta, A. Dick, D. Shin, Y. Wang, L.Q. Chen, and Z.K. Liu, Efficient Stochastic Generation of Special Quasirandom Structures, CALPHAD, 2013, 42, p 13-18

Y. Qiu, Y.J. Hu, A. Taylor, M.J. Styles, R.K.W. Marceau, A.V. Ceguerra, M.A. Gibson, Z.K. Liu, H.L. Fraser, and N. Birbilis, A Lightweight Single-Phase AlTiVCr Compositionally Complex Alloy, Acta Mater., 2017, 123, p 115-124

R.S. Berry and B.M. Smirnov, Configurational Transitions in Processes Involving Metal Clusters, Phys. Rep., 2013, 527, p 205-250

S. Shang, Y. Wang, W.Y. Wang, H. Fang, and Z.-K. Liu, Low Energy Structures of Lithium-Ion Battery Materials Li(MnxNixCo1−2x)O2 Revealed by First-Principles Calculations, Appl. Phys. Lett., 2013, 103, p 053903-053905

W.Y. Wang, S.L. Shang, H.Z. Fang, H. Zhang, Y. Wang, S. Mathaudhu, X. Hui, and Z.K. Liu, Effect of Composition on Atomic Structure, Diffusivity and Viscosity of Liquid Al-Zr Alloys, Metall. Mater. Trans. A, 2012, 43, p 3471-3480

H.Z. Fang, W.Y. Wang, P.D. Jablonski, and Z.K. Liu, Effects of Reactive Elements on the Structure and Diffusivity of Liquid Chromia: An Ab Initio Molecular Dynamics Study, Phys. Rev. B, 2012, 85, p 014207

W.Y. Wang, H.Z. Fang, S.L. Shang, H. Zhang, Y. Wang, X. Hui, S. Mathaudhu, and Z.K. Liu, Atomic Structure and Diffusivity in Liquid Al80Ni20 by Ab Initio Molecular Dynamics Simulations, Phys. B, 2011, 406, p 3089-3097

G. Kresse and J. Furthmuller, Efficient Iterative Schemes for Ab Initio Total-Energy Calculations Using a Plane-Wave Basis Set, Phys. Rev. B, 1996, 54, p 11169-11186

G. Kresse and J. Furthmuller, Efficiency of Ab Initio Total Energy Calculations for Metals and Semiconductors Using a Plane-Wave Basis Set, Comput. Mater. Sci., 1996, 6, p 15-50

G. Kresse and D. Joubert, From Ultrasoft Pseudopotentials to the Projector Augmented-Wave Method, Phys. Rev. B, 1999, 59, p 1758-1775

Y. Wang and J.P. Perdew, Correlation Hole of the Spin-Polarized Electron Gas, with Exact Small-Wave-Vector and High-Density Scaling, Phys. Rev. B, 1991, 44, p 13298-13307

M. Methfessel and A.T. Paxton, High-Precision Sampling for Brillouin-Zone Integration in Metals, Phys. Rev. B, 1989, 40, p 3616-3621

P.E. Blochl, O. Jepsen, and O.K. Andersen, Improved Tetrahedron Method for Brillouin-Zone Integrations, Phys. Rev. B, 1994, 49, p 16223-16233

P.N.H. Nakashima, A.E. Smith, J. Etheridge, and B.C. Muddle, The Bonding Electron Density in Aluminum, Science, 2011, 331, p 1583-1586

W.Y. Wang, K.A. Darling, Y. Wang, S.-L. Shang, L.J. Kecskes, X.D. Hui, and Z.-K. Liu, Power Law Scaled Hardness of Mn Strengthened Nanocrystalline Al-Mn Non-equilibrium Solid Solutions, Scr. Mater., 2016, 120, p 31-36

W.Y. Wang, J.J. Han, H.Z. Fang, J. Wang, Y.F. Liang, S.L. Shang, Y. Wang, X.J. Liu, L.J. Kecskes, S.N. Mathaudhu, X. Hui, and Z.K. Liu, Anomalous Structural Dynamics in Liquid Al80Cu20: An Ab Initio Molecular Dynamics Study, Acta Mater., 2015, 97, p 75-85

W.Y. Wang, Y. Wang, S.L. Shang, K.A. Darling, H. Kim, B. Tang, H.C. Kou, S.N. Mathaudhu, X.D. Hui, J.S. Li, L.J. Kecskes, and Z.-K. Liu, Strengthening Mg by Self-Dispersed Nano-lamellar Faults, Mater. Res. Lett., 2017, doi:10.1080/21663831.2017.1308973

K. Momma and F. Izumi, VESTA 3 for Three-Dimensional Visualization of Crystal, Volumetric and Morphology Data, J. Appl. Crystallogr., 2011, 44, p 1272-1276

Z.W. Wu, M.Z. Li, W.H. Wang, and K.X. Liu, Hidden Topological Order and Its Correlation with Glass-Forming Ability in Metallic Glasses, Nat. Commun., 2015, 6, p 6035

X.J. Liu, Y. Xu, X. Hui, Z.P. Lu, F. Li, G.L. Chen, J. Lu, and C.T. Liu, Metallic Liquids and Glasses: Atomic Order and Global Packing, Phys. Rev. Lett., 2010, 105, p 4

S.L. Shang, A. Saengdeejing, Z.G. Mei, D.E. Kim, H. Zhang, S. Ganeshan, Y. Wang, and Z.K. Liu, First-Principles Calculations of Pure Elements: Equations of State and Elastic Stiffness Constants, Comput. Mater. Sci., 2010, 48, p 813-826

Z.-K. Liu, First-Principles Calculations and CALPHAD Modeling of Thermodynamics, J. Phase Equilib. Diffus., 2009, 30, p 517-534

O.N. Senkov, G.B. Wilks, D.B. Miracle, C.P. Chuang, and P.K. Liaw, Refractory High-Entropy Alloys, Intermetallics, 2010, 18, p 1758-1765

S. Guo and C.T. Liu, Phase Stability in High Entropy Alloys: Formation of Solid-Solution Phase or Amorphous Phase, Prog. Nat. Sci., 2011, 21, p 433-446

L.J. Santodonato, Y. Zhang, M. Feygenson, C.M. Parish, M.C. Gao, R.J.K. Weber, J.C. Neuefeind, Z. Tang, and P.K. Liaw, Deviation from High-Entropy Configurations in the Atomic Distributions of a Multi-Principal-Element Alloy, Nat. Commun., 2015, 6, p 5964

M.G. Poletti and L. Battezzati, Electronic and Thermodynamic Criteria for the Occurrence of High Entropy Alloys in Metallic Systems, Acta Mater., 2014, 75, p 297-306

Y. Zhang, Y.J. Zhou, J.P. Lin, G.L. Chen, and P.K. Liaw, Solid-Solution Phase Formation Rules for Multi-component Alloys, Adv. Eng. Mater., 2008, 10, p 534-538

R. Feng, M. Gao, C. Lee, M. Mathes, T. Zuo, S. Chen, J. Hawk, Y. Zhang, and P. Liaw, Design of Light-Weight High-Entropy Alloys, Entropy, 2016, 18, p 333

S. Chen, L. Yu, J. Ren, X. Xie, X. Li, Y. Xu, G. Zhao, P. Li, F. Yang, Y. Ren, and P.K. Liaw, Self-Similar Random Process and Chaotic Behavior in Serrated Flow of High Entropy Alloys, Sci. Rep., 2016, 6, p 29798

J. Antonaglia, X. Xie, Z. Tang, C.W. Tsai, J.W. Qiao, Y. Zhang, M.O. Laktionova, E.D. Tabachnikova, J.W. Yeh, O.N. Senkov, M.C. Gao, J.T. Uhl, P.K. Liaw, and K.A. Dahmen, Temperature Effects on Deformation and Serration Behavior of High-Entropy Alloys (HEAs), JOM, 2014, 66, p 2002-2008

R. Carroll, C. Lee, C.-W. Tsai, J.-W. Yeh, J. Antonaglia, B.A.W. Brinkman, M. LeBlanc, X. Xie, S. Chen, P.K. Liaw, and K.A. Dahmen, Experiments and Model for Serration Statistics in Low-Entropy, Medium-Entropy, and High-Entropy Alloys, Sci. Rep., 2015, 5, p 16997

M.C. Gao, J.-W. Yeh, P.K. Liaw, and Y. Zhang, High-Entropy Alloys: Fundamentals and Applications, Springer, Cham, 2016

S. Chen, X. Xie, B. Chen, J. Qiao, Y. Zhang, Y. Ren, K.A. Dahmen, and P.K. Liaw, Effects of Temperature on Serrated Flows of Al0.5CoCrCuFeNi High-Entropy Alloy, JOM, 2015, 67, p 2314-2320

S. Chen, X. Yang, K. Dahmen, P. Liaw, and Y. Zhang, Microstructures and Crackling Noise of AlxNbTiMoV High Entropy Alloys, Entropy, 2014, 16, p 870-884

M. Widom, W.P. Huhn, S. Maiti, and W. Steurer, Hybrid Monte Carlo/Molecular Dynamics Simulation of a Refractory Metal High Entropy Alloy, Metall. Mater. Trans. A, 2013, 45A, p 196-200

M. Widom, Prediction of Structure and Phase Transformations, in eds. by M.C. Gao, J.-W. Yeh, P.K. Liaw, Y. Zhang (Springer, Cham)

Y. Wang, S. Curtarolo, C. Jiang, R. Arroyave, T. Wang, G. Ceder, L.Q. Chen, and Z.K. Liu, Ab Initio Lattice Stability in Comparison with CALPHAD Lattice Stability, CALPHAD, 2004, 28, p 79-90

Acknowledgments

The present work was financially supported by the National Natural Science Foundation of China (Grants 51690163, 50871013, 51271018, 51271151, and 51571161), the United States National Science Foundation (Grant DMR-1006557), and the US Army Research Laboratory (Project No. W911NF-08-2-0084). WYW acknowledges the support from the project of SKL-AMM-USTB (Grant Number 2016-Z07) and the Fundamental Research Funds for the Central Universities in China (Grant Number G2016KY0302). PKL would like to acknowledge the Department of Energy, Office of Fossil Energy, National Energy Technology Laboratory (DE-FE-0008855 and DE-FE-0024054, and DE-FE-0011194), the US Army Research Office project (W911NF-13-1-0438), the National Science Foundation (DMR-1611180), and the Department of Materials Science and Engineering, National Tsing Hua University, Taiwan, for their support. First-principles calculations were carried out on the LION clusters at the Pennsylvania State University supported by the Materials Simulation Center and the Institute for CyberScience and the clusters at the Northwestern Polytechnical University. Calculations were also carried out on the CyberStar cluster funded by NSF through Grant OCI-0821527and the XSEDE clusters supported by NSF through Grant ACI-1053575.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, W.Y., Wang, J., Lin, D. et al. Revealing the Microstates of Body-Centered-Cubic (BCC) Equiatomic High Entropy Alloys. J. Phase Equilib. Diffus. 38, 404–415 (2017). https://doi.org/10.1007/s11669-017-0565-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11669-017-0565-4