Abstract

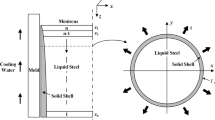

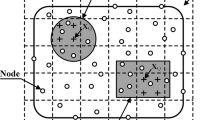

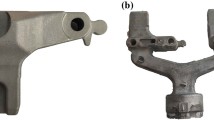

To study the effect of nonuniform heat transfer on the grain structure of shells in molds, a micro and macroscopic model coupling heat transfer with dendritic growth was established based on the measured heat flux. Dendritic growth was modeled by using a cellular automaton technique and by considering solutal transport. The quasi-instantaneous nucleation model was introduced to address heterogeneous nucleation, which might occur at the mold wall and in the bulk of the liquid. The temperature field of the billet under the measured heat flux in the mold was calculated, and the initial solidification process and grain structure evolution of four domains at different angles from the inner arc were simulated. The effect of circumferential nonuniform heat transfer on the grain structure of the chill zone and columnar grains of the shell was discussed in detail. The relationship between the distribution of the primary dendrite spacings in different domains and locally measured heat flux was analyzed.

Similar content being viewed by others

References

X. Liu and M. Zhu: ISIJ Int., 2006, vol. 46, pp. 1652–59.

X. Wang, L. Tang, X. Zang, and M. Yao: J. Mater. Process. Technol., 2012, vol. 212, pp. 1811–8.

J.O. Kristiansson: J. Therm. Stresses., 1984, vol. 7, pp. 209–26.

L. Cai, X. Wang, N. Wang, and M. Yao: Metall. Mater. Trans. B., 2020, vol. 51B, pp. 236–46.

B.G. Thomas and L.F. Zhang: ISIJ Int., 2001, vol. 41, pp. 1181–93.

W. Guo, L. Zhang, and M. Zhu: Steel Res. Int., 2010, vol. 81, pp. 265–77.

C. Li and B.G. Thomas: Metall. Mater. Trans. B., 2004, vol. 35B, pp. 1151–72.

F. Du, X. Wang, M. Yao, and X. Zhang: J. Mater. Process. Technol., 2014, vol. 214, pp. 2676–83.

L. Beltran-Sanchez and D.M. Stefanescu: Metall. Mater. Trans. A., 2004, vol. 35A, pp. 2471–85.

M.F. Zhu and D. Stefanescu: Acta Mater., 2007, vol. 55, pp. 1741–55.

A. Karma: Phys. Rev. Lett., 2001, vol. 87, p. 115701.

A. Karma and W. Rappel: Phys. Rev. E., 1998, vol. 57, pp. 4323–49.

M. Yamazaki, Y. Natsume, H. Harada, and K. Ohsasa: ISIJ Int., 2006, vol. 46, pp. 903–8.

S. Luo, M.Y. Zhu, and S. Louhenkilpi: ISIJ Int., 2012, vol. 52, pp. 823–30.

W. Wang, C. Ji, S. Luo, and M. Zhu: Metall. Mater. Trans. B., 2018, vol. 49B, pp. 200–12.

Y. Man, H. Yin, and D. Fang: ISIJ Int., 2004, vol. 44, pp. 1696–704.

H. Yin and M. Yao: J. Mater. Process. Technol., 2007, vol. 183, pp. 49–56.

L. Beltran-Sanchez and D.M. Stefanescu: Metall. Mater. Trans. A., 2003, vol. 34A, pp. 367–82.

P. Thevoz, J.L. Desbiolles, and M. Rappaz: Metall. Mater. Trans. A., 1989, vol. 20A, pp. 311–22.

C.A. Gandin, M. Rappaz, and R. Tintillier: Metall. Trans. A., 1993, vol. 24, pp. 467–79.

M. Rappaz and C.A. Gandin: Acta Metall. Mater., 1993, vol. 41, pp. 345–60.

Y. Natsume and K. Ohsasa: ISIJ Int., 2014, vol. 54, pp. 415–21.

W.L. Wang, S. Luo, and M.Y. Zhu: Metall. Mater. Trans. A., 2015, vol. 46A, pp. 396–406.

M. Hu, C. Sun, H. Fang, and M. Zhu: Eur. Phys. J. E, 2020, vol. 43, art. no. 16.

W.D. Huang, X.G. Geng, and Y.H. Zhou: J. Cryst. Growth., 1993, vol. 134, pp. 105–15.

S.Z. Lu and J.D. Hunt: J. Cryst. Growth., 1992, vol. 123, pp. 17–34.

X.F. Zhang and J.Z. Zhao: J. Cryst. Growth., 2014, vol. 391, pp. 52–8.

W. Wang, P.D. Lee, and M. Mclean: Acta Mater., 2003, vol. 51, pp. 2971–87.

Acknowledgments

This work is supported by the National Natural Science Foundation of China (51974056/51474047/51704073); the Fundamental Research Funds for the Central Universities and the Key Laboratory of Solidification Control and Digital Preparation Technology (Liaoning Province) are also gratefully acknowledged. Part of this work was performed using computational resources from Supercomputing Center of Dalian University of Technology.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted July 31, 2021; accepted October 22, 2021.

Rights and permissions

About this article

Cite this article

Wei, J., Wang, X., Cai, L. et al. Microstructure Simulation of the Nonuniform Shell for the Round Billet Continuous Casting. Metall Mater Trans B 53, 273–283 (2022). https://doi.org/10.1007/s11663-021-02364-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02364-7