Abstract

In this study, austenite formation from hot-rolled (HR) and cold-rolled (CR) ferrite-pearlite structures in a plain low-carbon steel was investigated using dilation data and microstructural analysis. Different stages of microstructural evolution during heating of the HR and CR samples were investigated. These stages include austenite formation from pearlite colonies, ferrite-to-austenite transformation, and final carbide dissolution. In the CR samples, recrystallization of deformed ferrite and spheroidization of pearlite lamellae before transformation were evident at low heating rates. An increase in heating rate resulted in a delay in spheroidization of cementite lamellae and in recrystallization of ferrite grains in the CR steel. Furthermore, a morphological transition is observed during austenitization in both HR and CR samples with increasing heating rate. In HR samples, a change from blocky austenite grains to a fine network of these grains along ferrite grain boundaries occurs. In the CR samples, austenite formation changes from a random spatial distribution to a banded morphology.

Similar content being viewed by others

References

G.R. Speich, V.A. Demarest, and R.L. Miller: Metall. Trans. A., 1981, vol. 12A, pp. 1419-28.

N.C. Law and D.V. Edmonds: Metall. Mater. Trans. A, 1980, vol. 33A, pp. 33-46.

M. Hillert, K. Nilsson, and L.-E. Törndahl: J. Iron Steel Res. Int., 1971, vol. 209, pp. 49-65.

C.I. Garcia and A.J. Deardo: Metall. Mater. Trans. A, 1981, vol. 12A, pp. 521-30.

R.R. Judd and H.W. Paxton: Trans. TMS-AIME, 1968, vol. 242, pp. 206-14.

D. San Martín, T. de Cock, A. García-Junceda, F.G. Caballero, C. Capdevilla, C. García de Andrés (2008) Mater. Sci. Technol 24: 266-72.

D.Z. Yang, E.L. Brown, D.K. Matlock, and G. Krauss: Metall. Trans. A, 1985, vol. 16A, pp. 1385-92.

C.I. Garcia and A.J. Deardo: Metall. Trans. A, 1981, vol. 12A, pp. 521-30.

J.J. Yi, I.S. Kim, and H.S. Choi: Metall. Trans. A, 1985, vol. 16A, pp. 1237-45.

T. de Cock, C. Capdevila, F.G. Caballero, and C. García de Andrés (2006) Scripta Mater 54: 949-54.

V.I. Savran, Y. Van Leeuwen, D.N. Hanlon, C. Kwakernaak, W.G. Sloof, and J. Sietsma: Metall. Mater. Trans. A, 2007, 38A: 946-55.

J. Huang, W.J. Poole, and M. Militzer: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 3363-75.

M. Mazinani and W.J. Poole: Metall. Mater. Trans. A, 2007, vol. 38A, pp. 328-39.

R.A. Grange: 2nd Int. Conf. on the Strength of Metals and Alloys, ASM, Materials Park, OH, 1970, pp. 861-76.

R. Petrov, L. Kestens, and Y. Houbaert: ISIJ Int., 2001, vol. 41, pp. 883-90.

L. Kestens, A.C.C. Ries, W.J. Kaluba, and H. Houbaert: Mater. Sci. Forum, 2004, vol. 467-470, pp. 287-92.

V. Andrade-Carozzo and P.J. Jacques: Mater. Sci. Forum, 2007, vols. 539–543, pp. 4649–54.

D. Quidort and Y.J.M. Brechet: ISIJ Int., 2002, vol. 42, pp. 1010–17.

F.S. LePera: J. Met., 1980, vol. 32, pp. 38-39.

J.R. Vilella (1938) Metallographic Techniques for Steels, ASM, Materials Park, OH, p. 36.

M. Onink, C.M. Brakman, F.D. Tichelaar, E.J. Mittemeijer, S. van der Zwaag, J.H. Root, N.B. Konyer (1993) Scripta Metall. Mater., 29: 1011-16.

G.R. Speich and A. Szirmae: Trans. TMS-AIME, 1969, vol. 245, pp. 1063-74.

C.C. Chang: Characterization of Solid Surfaces, P.F. Kane and G.G. Larrabee, eds., Plenum Press, New York, NY, 1974, pp. 534–37.

Oh C-S, H.N. Ham, C.G. Lee, T-H. Lee, and S-J. Kim: Met. Mater. Int., 2004, vol. 10, pp. 399-406.

C-M. Li, F. Sommer, and E. Mittemeijer: Z. Metall., 2000, vol. 91, pp. 5-9.

C.R. Brooks (1992) Principles of the Austenitization of Steels, University Press, Cambridge, UK, p. 101.

Y.L. Tian and W. Kraft: Metall. Trans. A, 1987, vol. 18A, pp. 1403-14.

S. Chattopadhyay and M. Sellars: Acta Mater., 1982, vol. 30, pp. 157-70.

C. Lesch, P. Alvarez, W. Bleck, and J.G. Sevillano: Metall. Mater. Trans. A, 2007, vol. 38A, pp. 1882-90.

I. Nikitin and M. Besel: Scripta Mater., 2008, vol. 58, pp. 239-42.

T. Hasegawa and T. Yakou: Acta Metall., 1982, vol. 30, pp. 235-43.

T. de Cock, C. Capdevila, J.P. Ferrer, F.G. Caballero, J.A. Jiménez, C. García de Andrés (2008) Mater. Sci. Technol., 24: 832-36.

V.N. Gridnev, V.G. Gavrilyuk, and Y.Y. Meshkov (1971) Metall. Sci. Heat Treat.13: 20-22.

Acknowledgments

The authors would like to acknowledge the Natural Sciences and Engineering Research Council of Canada (NSERC) for their financial support. We are grateful to J.D. Embury for valuable discussions and suggestions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 29, 2010.

Appendix

Appendix

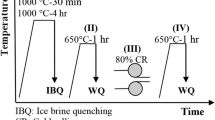

To examine the effect of different factors on the deviation from linearity in the dilation curves observed before austenite formation, see Section III–B; additional investigations were carried out. Cold rolling can introduce residual stresses that are concentrated on the surface of the samples.[30] Relieving residual stresses imposed by cold rolling can occur prior to austenite formation in the CR steel. It can also contribute to the dimensional changes in the samples.[31] However, reduction of residual stresses via thinning the samples down to half thickness by polishing shows no sign of change in the deviation. Furthermore, dilatometry of 80 pct CR prespheroidized samples (annealed for 24 hours at 963 K [690 °C] before cold rolling) revealed a dilation response similar to that of the CR sample. Thus, spheroidization was then ruled out to contribute to dilation changes. A 80 pct CR Ti-added IF steel with the chemical composition given in Table A1 was used to supplement the dilation study during heating for a case where no cementite is present, i.e., any effect from pearlite can be excluded. The initial microstructure consists of elongated ferrite grains. To examine the start temperature of ferrite-to-austenite transformation, a sample was heated into the single austenite phase region at 1 K/s, and an Ac1 temperature of 1193 K (920 °C) was measured. As shown in Figure A1, a thermal cycle was then employed to investigate the dilation before phase transformation. It includes a heating stage (solid black line), fast He quenching (black dashed line), and reheating stage of the sample (gray line). The CR sample was heated first at 1 K/s to 1123 K (850 °C) followed by rapid He quenching down to 473 K (200 °C) and immediate reheating at 1 K/s to 1123 K (850 °C). The contraction in the dilation curve in the first heating path is evident in Figure A1 (similar to the CR low-carbon steel in Figure 2). The relative change length (ΔL/L o) is approximately 0.11 pct, which is similar to the CR low-carbon steel, i.e., 0.1 pct. However, in the next reheating stage, the dilation curve shows no sign of contraction. Microstructural observations at 873 K (600 °C) and 1123 K (850 °C) showed that the microstructure changed from the CR to a completely recrystallized one during the first heating stage. Thus, a reduction in dislocation density and texture changes from an alpha fiber to a gamma dominant texture[10,32] that occur during ferrite recrystallization remain as possible explanation for the deviation. A reduction in specific volume of 0.37 pct for 80 pct cold-drawn steel wires during annealing and before austenite formation was reported by Gridnev et al.[33] With an assumption of isotropic change in length during dilation, one can estimate ΔL/L o through ΔL/L o ≈ ΔV/3V o for a small relative volume change in which ΔL is the length change, L o is the initial length, ΔV is the volume change, and V o is the initial volume of the sample. Thus, the value for ΔL/L o concluded from the work by Gridnev et al.[33] is ≈0.12 pct, which is in good agreement with the observations made in this study, i.e., 0.1 pct for the low-carbon steel and 0.11 pct for the IF steel. Gridnev et al.[33] attributed this observation to annihilation of point and line defects as well as microcracks. De Cock et al.[10,32] also showed that the reduction in dislocation density during recrystallization can account for the amount of dilation (≈0.05 pct) that is observed during heating of 80 pct CR low and ultralow carbon steels before austenitization at 10 K/s. Thus, it is concluded that the deviation from linear thermal expansion is related to recrystallization of the sample during heating and is consistent with the volume change caused by a reduction in the average dislocation density.

Rights and permissions

About this article

Cite this article

Azizi-Alizamini, H., Militzer, M. & Poole, W.J. Austenite Formation in Plain Low-Carbon Steels. Metall Mater Trans A 42, 1544–1557 (2011). https://doi.org/10.1007/s11661-010-0551-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-010-0551-5