Abstract

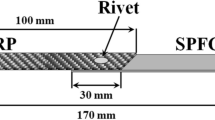

The Lap-joint configuration and the vacuum assisted forming method were put forward to meet the demands of the compression bending strength and the strong connection between the steel and FRC. The bending mechanic tests of the Lap-joint bending specimens carried out, the fabricate processing stability, limit carrying capacity and failure modes were analyzed. The experimental results show that the fabricate processing of the Lap-joint is stable; the bending stiffness is 19.5 N/mm, and the limit bending moment reaches 318 N∙m. The main failure modes are the failure of core material at junction of sandwich plate and steel, and the bending failure in the position of the inner and outer surface.

Similar content being viewed by others

References

Theotokoglou EE, Moan T. Experimental and Numerical Study of Composite T-joints[J]. Journal of Composite Materials, 1996, 30 (2): 190–209

Earl JS, Dulieu-Barton J M, Shenoi R A. Determination of Hygrothermal Aging Effects in Sandwich Construction Joints Using Thermoelastic Stress Analysis[J]. Composite Science and Technology, 2003, 63: 211–223

Liu WJ, Huang JY. Analysis of Load Transfer Capacity of Adhesive Joint of Composite Material[J]. Basic Sciences Journal of Textile Universities, 2008, 21(1): 113–116

Jun C, Joachim LG. Design and Testing of Joints for Composite Sandwich/Steel Hybrid Ship Hulls[J]. Composites Part A, 2004, 35: 1091–1105

Zhang S, Wang D, Li ZN. Numerical Calculation of Damage Accumulation and Bearing Strength Experimental Verification for Composite Single Bolted Joint[J]. Acta Materiae Compositae Sinica, 2006, 123(12): 163–168

Zhu X, Xu SQ, Zhu XJ. Fiber Reinforced Plastic and Metal Parts of the Joint Structure[P]. China: 99245150.7, 2000. 09

Kharghani N, Guedes SC. Experimental and Numerical Study of Hybrid Steel-FRP Balcony Overhang of Ships under Shear and Bending[J]. Marine Structures, 2018, 60: 15–33

Helmuth T, Aage L. Design and Test of Lightweight Sandwich T-joint for Naval Ships[J]. Composites Part A, 2005, 36: 1055–1065

Mei ZY, Tan D, Yang K. The Design and Mechanical Characteristic Research of Swallow -tailed Slot Joint of FRC/Steel[J]. Materials Science and Technology, 2012, 20(1): 144–148

Wang J. The Effects of Local Bend in Composite Structure’ s Joints[J]. Helicopter Technique, 2006, 2: 5–9

Shenoi RA, Read P, Jackson CL. Influence of Joint Geometry and Load Regimes on Sandwich Tee Joint Behavior[J]. Journal of Reinforced Plastic and Composites, 1998, 17(8): 725–740

Stickler PB, Ramulu M. Investigation of Mechanical Behavior of Transverse Stitched T-joints with PR520 Resin in Flexure and Tension[J]. Composite Structure, 2001, 52: 307–314

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the Open Foundation of Hubei Key Laboratory of Theory and Application of Advanced Materials Mechanics (Wuhan University of Technology) (No.TAM201802) and the Open Project Program of Key Laboratory of Inorganic Functional Materials and Devices, Chinese Academy of Sciences (No. KLIFMD201606)

Rights and permissions

About this article

Cite this article

Ren, L., Zeng, H. & Sun, J. Preparation of FRC/Steel by Lap-joint and Its Mechanical Properties. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 33, 888–891 (2018). https://doi.org/10.1007/s11595-018-1909-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-018-1909-6