Abstract

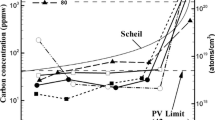

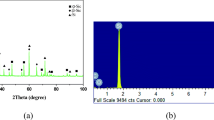

This paper presents a simple and cost-effective method for the production of micro-sized silicon carbide whiskers at high yield and the effect on heat transfer enhancement for the whisker laden fluids. For SiC whisker synthesis, the starting powder mixture is obtained by milling short carbon fibers with the white ashes of rice hulls. Calcination in argon, together with the subsequent purification process, results in a high yield of SiC whiskers, which possess a diameter of 200–400 nm and a length of several tens of microns. The formation of the whiskers is discussed according to VS growth mechanism. Convective heat transfer performance in small channel tubes is then studied for fluid systems mixed with those micro-sized SiC whiskers at different concentrations. The heat transfer coefficient of SiC containing fluid can be significantly improved in comparison to the base fluid.

Similar content being viewed by others

References

Zhang P, Liang J, Wang K Y, et al. The formation of fibrous SiC in SiC/Al2O3 composites from the silica-carbon-aluminum system. Int J Refract Met Hard Mater, 2012, 35: 196–201

Li J, Shirai T, Fuji M. Rapid carbothermal synthesis of nanostructured silicon carbide particles and whiskers from rice husk by microwave heating method. Adv Powder Technol, 2013, 24: 838–843

Li Q, Wang C A, Tie S. Synthesis of bamboo-like SiC whiskers from waste silica fume. Cryst Res Technol, 2014, 49: 290–297

Li S, Zhang Y, Han J, et al. Fabrication and characterization of SiC whisker reinforced reaction bonded SiC composite. Ceram Int, 2013, 39: 449–455

Wang Z, Li S, Wang M, et al. Effect of SiC whiskers on microstructure and mechanical properties of the MoSi 2SiCw composites. Int J Refract Met Hard Mater, 2013, 41: 489–494

Xu K, Chen G, Wu F, et al. Effect of SiC whiskers addition on microstructure, microhardness and wettablility of Sn-Ag-Cu solder. City: IEEE, Year. 310–312

Mani M K, Viola G, Reece M J, et al. Mechanical and magnetic characterisation of SiC whisker reinforced Fe-Co alloy composites. Mater Sci Eng: A, 2014, 592: 19–27

Deng D, Luo X, Chen S, et al. The active-to-passive oxidation transition mechanism and engineering prediction method of C/SiC composites. Sci China Tech Sci, 2013, 56: 1403–1408

Yang X, Zhang M, Wang Y, et al. Analyzing trap generation in silicon-nanocrystal memory devices using capacitance and current measurement. Sci China Tech Sci, 2012, 55: 588–593

Song Q, Zhang Y, Zhang Y, et al. Investigation of surface morphology and ion activation of aluminium implanted 4H-SiC. Sci China Tech Sci, 2012, 55: 3401–3404

Maxwell J. A Treatise on Electricity and Magnetism., Vol. 1 Clarendon Press. 1873.

Zhu H, Li C, Wu D, et al. Preparation, characterization, viscosity and thermal conductivity of CaCO3 aqueous nanofluids. Sci China Tech Sci, 2010, 53: 360–368

Zhou M, Xia G, Chai L, et al. Analysis of flow and heat transfer characteristics of micro-pin fin heat sink using silver nanofluids. Sci China Tech Sci, 2012, 55: 155–162

Lu H, Wang B, Zhang H, et al. Analysis of solid particle clusters in coherent structures of turbulent channel flow. Sci China Tech Sci, 2013, 56: 2525–2530

Wang L, Lin G, Chen H, et al. Convective heat transfer characters of nanoparticle enhanced latent functionally thermal fluid. Sci China Ser E-Tech Sci, 2009, 52: 1744–1750

Lu Y, Li X, Li Q, et al. Numerical simulation and experimental investigation of natural convection heat transfer of molten salt around fine wire. Sci China Tech Sci, 2013, 56: 1651–1656

Xu J, Yang M, Xu J, et al. Vertically oriented TiO2 nanotube arrays with different anodization times for enhanced boiling heat transfer. Sci China Tech Sci, 2012, 55: 2184–2190

Xuan Y, Roetzel W. Conceptions for heat transfer correlation of nanofluids. Int J Heat Mass Tran, 2000, 43: 3701–3707

Xuan Y, Li Q. Heat transfer enhancement of nanofluids. Int J Heat Fluid Fl, 2000, 21: 58–64

Yi C, Liu Y, He Z, et al. Passive scalar characteristics along inertial particle trajectory in turbulent non-isothermal flows. Sci China Tech Sci, 2012, 55: 2593–2600

Song J, Wang F, Cheng L. Experimental study and analysis of a novel multi-media plate heat exchanger. Sci China Tech Sci, 2012, 55: 2157–2162

Masuda H, Ebata A, Teramae K, et al. Alteration of thermal conductivity and viscosity of liquid by dispersing ultra-fine particles. Netsu Bussei, 1993, 7: 227–233

Singh D, Timofeeva E, Yu W, et al. An investigation of silicon carbide-water nanofluid for heat transfer applications. J Appl Phys, 2009, 105: 064306

Inaba H, Haruki N, Horibe A. Flow drag and heat transfer reduction of flowing water containing fibrous material in a straight pipe. Int J Therm Sci, 2000, 39: 18–29

Ding Y, Alias H, Wen D, et al. Heat transfer of aqueous suspensions of carbon nanotubes (CNT nanofluids). Int J Heat Mass Tran, 2006, 49: 240–250

Yang Y, Zhang Z G, Grulke E A, et al. Heat transfer properties of nanoparticle-in-fluid dispersions (nanofluids) in laminar flow. Int J Heat Mass Tran, 2005, 48: 1107–1116

Gharagozloo P E, Kolade B, Eaton J K, et al. Nanofluid convection in microtubes. Journal of heat transfer, 2010, 132: 092401–092401

Nakano H, Watari K, Kinemuchi Y, et al. Microstructural characterization of high-thermal-conductivity SiC ceramics. J Eur Ceram Soc, 2004, 24: 3685–3690

Saito M, Nagashima S, Kato A. Crystal growth of SiC whisker from the SiO (g)-CO system. J Mater Sci Lett, 1992, 11: 373–376

Gao Y, Bando Y, Kurashima K, et al. SiC nanorods prepared from SiO and activated carbon. J Mater Sci, 2002, 37: 2023–2029

Li Z, Li H, Chen X, et al. Large-scale synthesis of crystalline β-SiC nanowires. Appl Phys A 2003, 76: 637–640

Li Z, Shi T J, Tan D X. Long b-Silicon Carbide Necklace-Like Whiskers Prepared by Carbothermal Reduction of Wood Flour/Silica/Phenolic Composite. J Am Ceram Soc, 2010, 93: 3499–3503

Yang Z X, Wu Y J, Zhu F, et al. Helical nanocables with SiC core and SiO2 shell. Physica E: Low-dimensional Systems and Nanostructures, 2005, 25: 395–398

Hao Y-J, Wagner J B, Su D S, et al. Beaded silicon carbide nanochains via carbothermal reduction of carbonaceous silica xerogel. Nanotechnology, 2006, 17: 2870

Yang W, Miao H, Xie Z, et al. Synthesis of silicon carbide nanorods by catalyst-assisted pyrolysis of polymeric precursor. Chem Phys Lett, 2004, 383: 441–444

Mazdiyasni K, Zangvil A. Effect of impurities on SiC whisker morphology. J Am Ceram Soc, 1985, 68: C-142–C-144

Tang C, Fan S, Dang H, et al. Growth of SiC nanorods prepared by carbon nanotubes-confined reaction. J Cryst Growth, 2000, 210: 595–599

Lee J-G, Cutler I B. Formation of SiC from rice hulls. Am Ceram Soc, Bull, 1975, 54: 195–198

Markovska I, Lyubchev L. A study on the thermal destruction of rice husk in air and nitrogen atmosphere. J Therm Anal Calorim, 2007, 89: 809–814

Huang S, Jing S, Wang J, et al. Silica white obtained from rice husk in a fluidized bed. Powder Technol, 2001, 117: 232–238

Souza M d, Magalhães W, Persegil M. Silica derived from burned rice hulls. Materials research, 2002, 5: 467–474

Chaudhary D, Jollands M. Characterization of rice hull ash. J Appl Polym Sci, 2004, 93: 1–8

Wei J, Li K-Z, Li H-J, et al. Growth and morphology of one-dimensional SiC nanostructures without catalyst assistant. Mater Chem Phys, 2006, 95: 140–144

Yang G, Cui H, Sun Y, et al. Simple catalyst-free method to the synthesis of β-SiC nanowires and their field emission properties. J Phys Chem C, 2009, 113: 15969–15973

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, P., Liang, J., Yin, L. et al. The synthesis of micro-sized silicon carbide whiskers and the application for heat transfer enhancement. Sci. China Technol. Sci. 57, 2371–2378 (2014). https://doi.org/10.1007/s11431-014-5704-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-014-5704-0