Abstract

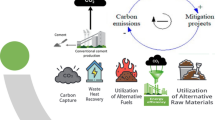

As the demand for automotive materials grows more stringent in environmental considerations, it becomes imperative to conduct thorough environmental impact assessments of dual-phase automotive strip steel (DP steel). However, the absence of detailed and comparable studies has left the carbon footprint of DP steel and its sources largely unknown. This study addresses this gap by establishing a cradle-to-gate life cycle model for DP steel, encompassing on-site production, energy systems, and upstream processes. The analysis identifies and scrutinizes key factors influencing the carbon footprint, with a focus on upstream mining, transportation, and on-site production processes. The results indicate that the carbon footprint of DP steel is 2.721 kgCO2-eq/kgDP, with on-site processes contributing significantly at 88.1%. Sensitivity analysis is employed to assess the impact of changes in resource structure, on-site energy, CO2 emission factors, and byproduct recovery on the carbon footprint. Proposals for mitigating carbon emissions in DP steel production include enhancing process gas recovery, transitioning to cleaner energy sources, and reducing the hot metal-to-steel ratio. These findings offer valuable insights for steering steel production towards environmentally sustainable practices.

Similar content being viewed by others

References

Akhshik M, Panthapulakkal S, Tjong J, Sain M (2019) The effect of lightweighting on greenhouse gas emissions and life cycle energy for automotive composite parts. Clean Technol Environ Policy 21(3):625–636

Avinal A, Ergenekon P (2022) Life cycle impacts of induction furnace technology for crude steel production: case study. Energy Sources Part A Recover Utilization Environ Eff 44(4):9974–9987

Bahlawan H, Morini M, Spina PR, Venturini M (2021) Inventory scaling, life cycle impact assessment and design optimization of distributed energy plants. Appl Energy 304:117701

Bzowski K, Rauch L, Pietrzyk M (2018) Application of statistical representation of the microstructure to modeling of phase transformations in DP steels by solution of the diffusion equation. Procedia Manuf 15:1847–1855

Chen W, Zhang Q, Wang C, Li Z, Geng Y, Hong JL, Cheng Y (2022) Environmental sustainability challenges of China’s steel production: Impact-oriented water, carbon and fossil energy footprints assessment. Ecol Ind 136:108660

Costa P, Altamirano-Guerrero G, Salinas-Rodriguez A, Salas-Reyes A, Goodwin F (2022) Dilatometric study of continuous cooling transformation of intercritical austenite in cold rolled AHSS-DP steels. J Market Res 19:4360–4370

Fang X, Sun W, Li W, Ma G, Wang P, Zuo C (2024) Process-based life cycle inventory framework for assessing the carbon footprint of products from complex production paths: case of dual-phase automotive strip steel. J Clean Prod 447:141551

Fu W, Sun W, Huo X (2024) Design and thermodynamic investigation of a waste heat-assisted compressed air energy storage system integrating thermal energy storage and organic Rankine cycle. Energ Technol 12(2):2300838

Gonçalves M, Monteiro H, Iten M (2022) Life cycle assessment studies on lightweight materials for automotive applications - an overview. Energy Rep 8:338–345

Gul E, Riva L, Nielsen HK, Yang H, Zhou H, Yang Q, Skreiberg Ø, Wang L, Barbanera M, Zampilli M, Bartocci P, Fantozzi F (2021) Substitution of coke with pelletized biocarbon in the European and Chinese steel industries: an LCA analysis. Appl Energy 304:117644

Hagedorn W, Gramlich A, Greiff K, Krupp U (2022) Alloy and process design of forging steels for better environmental performance. Sustain Mater Technol 34:e00509

Huang Z, Ding X, Sun H, Liu S (2010) Identification of main influencing factors of life cycle CO2 emissions from the integrated steelworks using sensitivity analysis. J Clean Prod 18(10–11):1052–1058

Jhaveri K, Lewis GM, Sullivan JL, Keoleian GA (2018) Life cycle assessment of thin-wall ductile cast iron for automotive lightweighting applications. Sustain Mater Technol 15:1–8

Li F, Chu M, Tang J, Liu Z, Wang J, Li S (2021) Life-cycle assessment of the coal gasification-shaft furnace-electric furnace steel production process. J Clean Prod 287:125075

Li Y, Lv M, Li R, Liu Z (2022) Life cycle assessment of melting reduction treatment for iron and steel waste slag: a case study in Tangshan, China. Resour Conserv Recycl Adv 15:200108

Liang T, Wang S, Lu C, Jiang N, Long W, Zhang M, Zhang R (2020) Environmental impact evaluation of an iron and steel plant in China: normalized data and direct/indirect contribution. J Clean Prod 264:121697

Liu S, Sun W (2023) Attention mechanism-aided data-and knowledge-driven soft sensors for predicting blast furnace gas generation. Energy 262:125498

Liu Y, Li H, Huang S, An H, Santagata R, Ulgiati S (2020) Environmental and economic-related impact assessment of iron and steel production. A call for shared responsibility in global trade. J Clean Prod 269:122239

Liu Z, Cheng S, Liu P (2022) Prediction model of BOF end-point temperature and carbon content based on PCA-GA-BP neural network. Metall Res Technol 119:1–11

Liu Z, Cui Y, Wang J, Yue C, Agbodjan YS, Yang Y (2022) Multi-objective optimization of multi-energy complementary integrated energy systems considering load prediction and renewable energy production uncertainties. Energy 254:124399

Liu SH, Sun WQ, Li WD, Jin BZ (2023) Prediction of blast furnace gas generation based on data quality improvement strategy. J Iron Steel Res Int 30:864–874

Lu Q, Zhang B, Yang S, Peng Z (2022) Life cycle assessment on energy efficiency of hydrogen fuel cell vehicle in China. Energy 257:124731

Ma S, Ding W, Liu Y, Ren S, Yang H (2022) Digital twin and big data-driven sustainable smart manufacturing based on information management systems for energy-intensive industries. Appl Energy 326:119986

Ma S, Zhang Y, Lv J, Ren S, Yang H, Wang C (2022) Data-driven cleaner production strategy for energy-intensive manufacturing industries: case studies from Southern and Northern China. Adv Eng Inform 53:101684

Park H, Woo Y, Jung HS, Kim G, Bae JW, Park MJ (2021) Development of dimethyl ether synthesis processes using by-product gas from a steel-making plant: single-vs. two-step processes. J Clean Prod 326:129367

Raugei M, Morrey D, Hutchinson A, Winfield P (2015) A coherent life cycle assessment of a range of lightweighting strategies for compact vehicles. J Clean Prod 108:1168–1176

Ren L, Zhou S, Peng T, Ou X (2021) A review of CO2 emissions reduction technologies and low-carbon development in the iron and steel industry focusing on China. Renew Sustain Energy Rev 143:110846

Roy P, Defersha F, Rodriguez-Uribe A, Misra M, Mohanty A (2020) Evaluation of the life cycle of an automotive component produced from biocomposite. J Clean Prod 273:123051

Suer J, Traverso M, Ahrenhold F (2021) Carbon footprint of scenarios towards climate-neutral steel according to ISO 14067. J Clean Prod 318:128588

Sun W, Shao Y, Zhao L, Wang Q (2020) Co-removal of CO2 and particulate matter from industrial flue gas by connecting an ammonia scrubber and a granular bed filter. J Clean Prod 257:120511

Sun W, Wang Q, Zheng Z, Cai J (2020) Material–energy–emission nexus in the integrated iron and steel industry. Energy Convers Manage 213:112828

Sun W, Wang Q, Zhou Y, Wu J (2020) Material and energy flows of the iron and steel industry: status quo, challenges and perspectives. Appl Energy 268:114946

Tong Y, Zhang Q, Cai J, Gao C, Wang L, Li P (2018) Water consumption and wastewater discharge in China’s steel industry. Ironmak Steelmak 45(10):868–877

Tong Y, Cai J, Zhang Q, Gao C, Wang L, Li P, Hu S, Liu C, He Z, Yang J (2019) Life cycle water use and wastewater discharge of steel production based on material-energy-water flows: a case study in China. J Clean Prod 241:118410

Voraberger B, Wimmer G, Salgado UD, Wimmer E, Pastucha K, Fleischanderl A (2022) Green LD (BOF) steelmaking—reduced CO2 emissions via increased scrap rate. Metals 12(3):466

Wang J, Sun W (2024) Decomposition of the site-level energy consumption and carbon dioxide emissions of the iron and steel industry. Environ Sci Pollut Res 31(11):16511–16529

Wang J, Wang Q, Sun W (2023) Optimal power system flexibility-based scheduling in iron and steel production: a case of steelmaking–refining–continuous casting process. J Clean Prod 414:137619

Wang J, Wang Q, Sun W (2023) Quantifying flexibility provisions of the ladle furnace refining process as cuttable loads in the iron and steel industry. Appl Energy 342:121178

Yang H, Ma L, Li Z (2023) Tracing China’s steel use from steel flows in the production system to steel footprints in the consumption system. Renew Sustain Energy Rev 172:113040

Yu R, Cong L, Hui Y, Zhao D, Yu B (2022) Life cycle CO2 emissions for the new energy vehicles in China drawing on the reshaped survival pattern. Sci Total Environ 826:154102

Zhang W, Xu J (2022) Advanced lightweight materials for automobiles: a review. Mater Des 221:110994

Zhang H, Sun W, Li W, Wang Y (2022) Physical and chemical characterization of fugitive particulate matter emissions of the iron and steel industry. Atmos Pollut Res 13(1):101272

Zhang Y, Zhang F, Yu H, Yang N, Zhao Y, Yang J, Yu H (2022) Performance evaluation of the practical application of cleaner production management system: a case study of steel enterprise. J Clean Prod 379:134468

Zhang H, Zhao F, Hao H, Liu Z (2023) Comparative analysis of life cycle greenhouse gas emission of passenger cars: a case study in China. Energy 265:126282

Zhou X, Cheng Z, Ren K, Zhai Y, Zhang T, Shen X, Bai Y, Jia Y, Hong J (2022) Environmental sustainability improvement in chloromethanes production based on life cycle assessment. Sustain Prod Consum 34:105–113

Funding

This work was supported by the National Natural Science Foundation of China (52334008).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Data collection, visualization, and analysis were performed by X Fang, W Li, and W Sun. The first draft of the manuscript was written by X Fang, and W Sun and G Ma commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fang, X., Sun, W., Li, W. et al. Life cycle assessment of carbon footprint in dual-phase automotive strip steel production. Environ Sci Pollut Res 31, 26300–26314 (2024). https://doi.org/10.1007/s11356-024-32940-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-024-32940-8