Abstract

The Scanning Habitable Environments with Raman and Luminescence for Organics and Chemicals (SHERLOC) is a robotic arm-mounted instrument on NASA’s Perseverance rover. SHERLOC has two primary boresights. The Spectroscopy boresight generates spatially resolved chemical maps using fluorescence and Raman spectroscopy coupled to microscopic images (10.1 μm/pixel). The second boresight is a Wide Angle Topographic Sensor for Operations and eNgineering (WATSON); a copy of the Mars Science Laboratory (MSL) Mars Hand Lens Imager (MAHLI) that obtains color images from microscopic scales (∼13 μm/pixel) to infinity. SHERLOC Spectroscopy focuses a 40 μs pulsed deep UV neon-copper laser (248.6 nm), to a ∼100 μm spot on a target at a working distance of ∼48 mm. Fluorescence emissions from organics, and Raman scattered photons from organics and minerals, are spectrally resolved with a single diffractive grating spectrograph with a spectral range of 250 to ∼370 nm. Because the fluorescence and Raman regions are naturally separated with deep UV excitation (<250 nm), the Raman region ∼ 800 – 4000 cm−1 (250 to 273 nm) and the fluorescence region (274 to ∼370 nm) are acquired simultaneously without time gating or additional mechanisms. SHERLOC science begins by using an Autofocus Context Imager (ACI) to obtain target focus and acquire 10.1 μm/pixel greyscale images. Chemical maps of organic and mineral signatures are acquired by the orchestration of an internal scanning mirror that moves the focused laser spot across discrete points on the target surface where spectra are captured on the spectrometer detector. ACI images and chemical maps (< 100 μm/mapping pixel) will enable the first Mars in situ view of the spatial distribution and interaction between organics, minerals, and chemicals important to the assessment of potential biogenicity (containing CHNOPS). Single robotic arm placement chemical maps can cover areas up to 7x7 mm in area and, with the < 10 min acquisition time per map, larger mosaics are possible with arm movements. This microscopic view of the organic geochemistry of a target at the Perseverance field site, when combined with the other instruments, such as Mastcam-Z, PIXL, and SuperCam, will enable unprecedented analysis of geological materials for both scientific research and determination of which samples to collect and cache for Mars sample return.

Similar content being viewed by others

1 Introduction

Since ancient times, Mars has been at the forefront of astronomical observations as we struggle to understand our place in the universe. It was named for the god of war and was once thought to be a harbinger of death and plague. Telescopes trained on Mars by such observers as Giovanni Schiaparelli and Percival Lowell led imaginations to popularly envision an inhabited and vegetated Mars. However, with more advanced telescopic observations and dawn of the space age, it was clear that Mars has a cold, dry environment that appeared to be devoid of life. As we continued to explore Mars it was obvious from orbiter and rover observations that the Mars of the past was a very different place. All indications, including results from NASA’s Mars Science Laboratory (MSL; Curiosity rover), indicate that Mars had periods of stable liquid water on its surface and that habitable environments existed during a significant period of its history (e.g. Carr and Head 2003; Perron et al. 2007; Grotzinger et al. 2014). Orbital and in situ observations show evidence of volcanism and hydrothermal environments that could provide energy for life (Squyres et al. 2007; Ruff et al. 2020). Mars also had access to organic carbon through both in situ synthesis at hydrothermal vents and through meteoritic infall (Schock and Schulte 1998; Flynn 1996; Benner et al. 2000; Cady et al. 2018). All of this occurred at a time when life started on Earth, leading astrobiologists to ask the question, did life also originate on Mars? And, if not, why not?

To address these questions, understand its potential habitability, and to look for evidence of past life, NASA launched the Perseverance rover to Mars in 2020 (Farley et al. 2020). The Mars 2020 mission has four science goals:

-

A.

Explore an astrobiologically relevant ancient environment on Mars to decipher its geological processes and history, including the assessment of past habitability.

-

B.

Assess the biosignature preservation potential within the selected geological environment and search for potential biosignatures.

-

C.

Demonstrate significant technical progress towards the future return of scientifically selected, well-documented samples to Earth.

-

D.

Provide an opportunity for contributed Human Exploration and Operations Mission Directorate (HEOMD) or Space Technology Program (STP) participation, compatible with the science payload and within the mission’s payload capacity.

1.1 SHERLOC Overview

SHERLOC (Scanning Habitable Environments for Raman and Luminescence for Organics and Chemicals) is a robotic arm-mounted instrument onboard the Perseverance rover that will operate in Jezero crater on Mars (Fig. 1). SHERLOC enables high-sensitivity detection, characterization, and spatially resolved correlation of trace organics/biosignatures and minerals in geological materials at the Martian surface and near sub-surface (i.e. within boreholes). Using a deep ultraviolet (DUV) laser, SHERLOC obtains native fluorescence emissions from aromatic organic species and Raman scattered photons from molecules that allow identification of functional groups of organics, chemicals, and minerals. SHERLOC also acquires high spatial resolution color and gray scale images of natural and abraded samples on the surface in order to better understand the geologic history of Mars and help spatially correlate measurements made by SHERLOC and the other scientific instruments onboard Perseverance. SHERLOC’s spectroscopic methodology enables a new science investigation for organic analysis on Mars where the fine-scale spatial distribution of organics within the context of minerals an be preserved to assess organic provenance; a capability previously relegated to laboratory instruments.

SHERLOC is designed to operate from the end of the rover’s a robotic arm in a single arm deployment activity. Each spectral map obtained is approximately the size of a postage stamp. The robotic arm places SHERLOC over the target without surface contact, thus avoiding contamination of the instrument, rover contamination of the surface, or cross-sample contamination. SHERLOC consists of a combined Raman and fluorescence spectrometer that analyzes photons generated through the interaction of a 248.6 nm pulsed laser beam with surface material. Perseverance will mark the first time that Raman spectroscopy will be attempted on the surface of another planet and will capitalize on the synergistic benefits of utilizing multi-wavelength Raman spectroscopy, with SHERLOC using a DUV excitation source and SuperCam (Maurice et al. 2021; Wiens et al. 2021) using a 532 nm source.

To simplify operations and avoid contacting the surface, several SHERLOC subsystems were included to aid the spectroscopy investigation. This includes an Autofocus Context Imager (ACI) for focusing the spectrometer at standoff distance of ∼50 mm, an internal scanning mirror to avoid complex and sub-millimeter arm movements, and an optical design that focuses the laser to an ∼100 μm beam on the target. In addition, both backscattered spectroscopic elements (Raman and fluorescence) are detected on the same CCD through a common optical path. The instrument has knowledge of where the laser was pointing within the ACI’s grayscale image, thus providing an ability to correlate spectroscopic signals with the physical features of a target’s surface. In addition, onboard spectral analysis enables autonomous retargeting of regions of interest for additional spectral measurements; providing an increased capability to locate minute, “needle-in-a-haystack” features of importance without multiple sols of planning and complex arm retargeting (a sol is a Martian day; duration 1.027 Earth days). All of these measurements are capable with a single, non-contact arm placement on either a natural surface or, preferably, an abraded surface for which dust and weathering products have been removed.

After selection of the initial Mars 2020 science payload, it was noted that there arose a need for an arm-mounted imager that could perform engineering tasks to document rover health, such as wheel imaging, rover undercarriage inspections, and Education and Public Outreach (EPO) activities. The ACI inherits many components derived from MSL’s Mars Hand Lens Imager (MAHLI; Edgett et al. 2012; Grotzinger et al. 2012) hardware. A Mars 2020 Project-wide trade study was performed to determine the best way to integrate these needs within the rover payload. The options included modifying SHERLOC’s ACI capabilities to generate MAHLI-like images. Given the spectroscopy-driven requirements on the ACI design, including a fixed focal length, it was infeasible to incorporate increased capability with the proposed hardware without significant complexity or reduction in spectroscopy performance. However, given the ACI’s heritage based on MAHLI hardware, it was determined that the SHERLOC design could be modified to operate a second camera head, and hence the Wide Angle Telegraphic Sensor for Operations and eNgineering (WATSON) camera was integrated to the SHERLOC investigation. The shared infrastructure approach had only moderate impact to turret space, arm cabling mass and volume, and flight system resources. As an almost direct re-flight of MAHLI hardware, it enables all of the capabilities of the MSL MAHLI (Edgett et al. 2012) to be performed as well. WATSON and the higher resolution ACI, together, enable the most versatile and capable set of rover arm-mounted imagers ever flown to the surface of Mars.

1.1.1 SHERLOC Organics/Mineral/Chemical Detection

A major NASA goal is to identify whether there is life elsewhere in the universe (NASA 2020). Life on Earth requires energy, liquid water, nutrients, and organic carbon, but the exact prescription for the origin of life on Earth has been lost to billions of years of geologic processing, chemical weathering, and biological processes. Soon after it formed, Mars likely also had the ingredients necessary to support an origin of life and, as such, is a prime candidate for the search for life elsewhere in the solar system. Mars has preserved a rock record—including sedimentary rocks that carry signals of very ancient environments—that is older than the oldest rocks on Earth (cf. Harrison 2020). Early Mars had energy in the form of impact melting and magmatism and it hosted nearly a dozen different types of aqueous, potentially habitable, environments during its first billion years (e.g., Murchie et al. 2009; Grotzinger et al. 2014). Organic material and nutrients would also have been present either through in situ synthesis of outgassed volatiles, such as N2/H2/CO/CO2 (Chang et al. 1983), or through infall of meteorites and interplanetary dust particles (IDPs) (Flynn 1996; Flynn and McKay 1990). The chosen landing site at Jezero crater includes potential records of past hydrothermal, lacustrine, weathering, and diagenetic environments (Ehlmann et al. 2008, 2011; Glotch et al. 2010; Wray and Ehlmann 2011; Michalski et al. 2013). If Mars had life, Jezero is an ideal location to search for Martian biosignatures. SHERLOC will contribute to this investigation by providing micron-to-millimeter scale microscopy in combination with mineral and organic detection and characterization, putting any potential Martian biosignatures in their proper geologic and textural context.

To assess the presence of potential biosignatures, the SHERLOC spectrometer is used to detect classes of organics, minerals, and chemicals. Figure 2 shows spectral examples of detectable organics using DUV Raman, and for aromatic species, the fluorescence spectra. These classes of organics are found in life as we know it but a number of them have also been found in meteorites. We also show examples of organics that may be present as a result of predicted degradation paths resulting in oxidized organics. It should be noted that the DNA and RNA spectral features represent the capability to detect organic complexity versus subunits or condensed carbon; while not a definitive biomarker, detection of complex organics would certainly be classified as a potential biosignature. For mineral detection Fig. 3 shows examples of some mineral classes that are observable with SHERLOC. The majority of these would be indicative of an aqueous past and are key source and sinks for elemental cycling necessary for life. In addition, we have demonstrated that SHERLOC can detect silicate minerals such as the olivines and pyroxenes in the SaU 008 martian meteorite (Table 1, Fig. 43). It should be noted that increasing iron or manganese content in a sample will attenuate the spectral response through UV absorption of signal. Mineral specificity for carbonates and sulfates has also been demonstrated and an in-depth review can be found in Razzell Hollis et al. (2020b).

Example spectra of organics detectable using SHERLOC DUV Raman (Left) and native fluorescence (right). These spectra were collected on the lab breadboard instrument that was used to set the SHERLOC performance requirements and are representative of what can be achieved using SHERLOC on Mars (The lab breadboard, MOBIUS, is described in detail in Bhartia et al. 2014; Abbey et al. 2017; Sapers et al. 2019; Razzell Hollis et al. 2020b)

Example spectra of minerals detectable using SHERLOC. These spectra were collected on the lab breadboard and are representative of what can be achieved using SHERLOC (Razzell Hollis et al. 2020b). The O2 and N2 lines are terrestrial atmospheric interferences that will not be observed on Mars

The next sections provide an overview of the Jezero crater site and its potential for organic preservation, background regarding the spectroscopy SHERLOC performs and how it detects organics and minerals, a discussion of the key subsystems and components and how they were tested and integrated to form SHERLOC, a demonstration of operations and performance, the methodology to operate, command, and calibrate SHERLOC on the surface of Mars, the SHERLOC data processing plan, and the efforts that were put into maintaining a level of required instrument cleanliness. Table 1 is a summary of the SHERLOC instrument, its component characteristics and performance values.

1.2 Jezero Crater Field Site

After an exhaustive site selection process (Grant et al. 2018), Jezero crater was chosen to be the destination of the Perseverance rover (Stack et al. 2020) Jezero crater (18.4∘ N, 77.7∘ E) is an ∼45 km diameter impact structure in the Nili Fossae region of Mars. Orbital data provide spectral and geomorphic evidence for a complex geological evolution that includes a history of fluid-rock interaction both inside and outside of the crater. The pre-Jezero basement rocks include primitive igneous crust marked by spectral signatures of low-Ca pyroxene (Mustard et al. 2008; Ehlmann et al. 2008), polymict megabreccias from the ∼3.96 Ga Isidis impact (Werner 2008), and Fe- and Mg-smectite-bearing rocks which suggest pronounced alteration by regional groundwater flow (cf. Mangold et al. 2007). Two valleys formed by fluvial incision enter Jezero crater from the west and north, and one exits the crater to the east (Fassett and Head 2005; Schon et al. 2012; Goudge et al. 2012). The complex history of Jezero crater includes the events that made it possible for such valleys to breach the crater rim (e.g., some combination of superposition and deep erosion of the crater rim). Jezero today is partly filled and rocks exposed at the surface include spectrally diverse olivine- and carbonate-bearing rocks, a high-Ca pyroxene-bearing unit, and fluvial-deltaic deposits bearing very little detectable pyroxene (Ehlmann et al. 2008; Horgan et al. 2020). The deltaic sediments and inlet and outlet valleys are key indicators that Jezero records the site of an ancient paleolake. Some investigators have proposed that the crater fill materials also include lava (Schon et al. 2012; Goudge et al. 2015). This complex history makes Jezero crater a relevant target for questions of Martian habitability, and for its potential to return quality petrologic and astrobiological samples.

Lithologic materials of the Jezero crater floor, for instance, consist of two primary phases: a light-toned unit that carries spectral signatures of olivine and carbonate, and a dark-toned, fracture-bearing unit that has spectral signatures consistent with high-Ca pyroxene (Horgan et al. 2020). Light-toned crater fill deposits have been interpreted as fine-grained detrital sediment deposited in a paleolake (Schon et al. 2012), as aeolian deposition within a potentially dry crater (Horgan et al. 2020), or as exposures of a regional mantling unit, perhaps tephra, that occurs throughout the Isidis-Nili Fossae region (Goudge et al. 2015; Kremer et al. 2019). Dark-toned crater floor deposits have been interpreted as having resulted from mafic lava flows (Schon et al. 2012; Goudge et al. 2015), pyroclastic air fall (Golder et al. 2020), or detrital (aeolian or fluvial) sedimentary deposition. A better understanding of the origins of these crater floor units is critical to reconstructing the age and time-line of deposition within Jezero crater, defining times of active deposition and erosion, and exploring the extent to which the Jezero system may have recorded perennial versus ephemeral lacustrine sedimentary environments. Potentially mineralized fractures that cross-cut crater floor materials (Miklusicak et al. 2020) may also provide a glimpse into later, diagenetic fluid flow in the subsurface of Jezero crater.

A second critical region of the Jezero landing site includes distinct deposits along the crater’s western rim that have been interpreted as resulting from fluvial-deltaic deposition (e.g., Fassett and Head 2005; Goudge et al. 2015; Goudge et al. 2017). Deltaic deposition served as a critical element in the selection of Jezero crater as the Mars 2020 landing site, as it records strong evidence that the crater, at least at one time, hosted a water-rich lacustrine environment that would have received chemical nutrients (as well as potential organic materials) from a broader region of the Martian surface. Strata in the deltaic deposits are of particular interest as both potential sinks for organic deposition (e.g., fluvial overbank deposits, prodelta muds, etc.) and to provide critical input to reconstruct the depositional history of Jezero crater (e.g., periods of increased or decreased fluvial input to a lake). Such reconstructions will produce distinct hypotheses for identifying circumstances of the spatial and temporal extent of habitability and the identification of lithologies with the greatest astrobiological potential for sample return.

A third critical region of Jezero crater consists of a spatially discrete carbonate-bearing unit that is located along the western margin of the crater, near the edge of the western delta. This unit exhibits the strongest spectral signatures for Mg-carbonate in the Jezero system and has been interpreted as either resulting from weathering of an ultramafic tephra deposit, widespread in the Isidis region (Kremer et al. 2019), or as lacustrine carbonates deposited in ancient shoreline environments of a former lake (Horgan et al. 2020). This so-called marginal carbonate unit is particularly intriguing as an astrobiological target. Groundwater alteration of mafic to ultramafic igneous rocks, for instance, would provide an aqueous environment of circum-neutral pH that might be conducive to microbial habitability. Similarly, lacustrine shoreline deposits may provide a locus for authigenic carbonate formation, such as in spring deposits and shoreline groundwater seeps that may be highly conducive to both microbial growth and organic preservation.

1.3 Biosignature/Organic Preservation Potential at Jezero

The current Martian surface is an inhospitable place for most organic molecules due to high UV flux and an oxidizing component present within the ubiquitous dust that is present on the surface (Hecht et al. 2009; Moores and Schuerger 2012; ten Kate et al. 2006). However, organic material has been identified in Gale crater by the Sample Analysis at Mars (SAM) investigation (Mahaffy et al. 2012) on MSL (e.g., Glavin et al. 2013; Freissinet et al. 2015; Stern et al. 2015; Eigenbrode et al. 2018), as well as in Martian meteorites (Steele et al. 2016). SAM observed 150-300 ppb of chlorobenzene, and chlorinated alkanes at lower abundances (Glavin et al. 2013; Freissinet et al. 2015), as well as thiophene and methythiophene in samples of lacustrine mudstones (Eigenbrode et al. 2018). In addition, the Martian meteorites (e.g., Allan Hills (ALH84001)) are well-studied samples from Mars in which hydrocarbon compounds, including polycyclic aromatic hydrocarbons (PAHs), have been identified in more than a dozen different meteorites (Grady et al. 1997, 2004; Grady 2006; Steele et al. 2006, 2012a,b). Steele et al. (2016) tabulated all of the bulk analyses from shergottites to calculate that igneous rocks on Mars could possess between ∼18 ± 26 ppm reduced carbon. Given this evidence, it is highly likely that organic molecules are preserved just beneath the Martian surface in Jezero crater (Carrier et al. 2019).

2 The SHERLOC Investigation Objectives

2.1 Science Objectives

The SHERLOC investigation, along with other payload elements, such as Planetary Instrument for X-ray Lithochemistry (PIXL), SuperCam, Mastcam-Z, RIMFAX, and Mars Environmental Dynamics Analyzer (MEDA) (Allwood et al. 2020; Wiens et al. 2021; Maurice et al. 2021; Bell et al. 2020; Hamran et al. 2020; Rodriguez-Manfredi et al. 2021) will provide critical data to decipher the evolutionary history of Jezero crater, reconstruct the environmental history of the Jezero lacustrine systems, and identify samples most likely to preserve potential biosignatures. The observations that acquire these data map directly to the SHERLOC investigation objectives (Table 2).

SHERLOC will be used to assess the habitability potential and aqueous history at Jezero crater through identification of key minerals using Raman spectroscopy. Observations of clay minerals, carbonates, sulfates, and halides in sedimentary units has shown that Mars hosted nearly a dozen different types of aqueous (alkaline, acidic, and saline lakes, hydrothermal deposits etc.) and other potentially habitable environments during its first billion years (Ehlmann et al. 2008; Glotch et al. 2010; Wray and Ehlmann 2011; Michalski and Niles 2012; Elhmann et al. 2011; Murchie et al. 2009). Some minerals are particularly indicative of environmental conditions such as serpentine (alkaline, reducing), sulfate (acidic, oxidizing), and carbonates (alkaline). Other phases are useful as environmental indicators, although only when they are found in mineral assemblages in which multiple phases collectively allow derivation of fluid geochemistry. By collecting point mineralogical data over an extended spatial scale in conjunction with textural evidence, it is possible to discern whether aqueous minerals formed in sediments, hydrothermal precipitates, volcanic materials, or resulted from secondary overprinting by weathering or diagenesis. Measurements on these scales can identify many important features including evidence for aqueous activity, alteration features, sedimentary laminae, or melt pockets, and can contribute to the analysis of detrital grains in sediments or individual clasts in conglomerates or breccias. These detailed textural observations will be made possible by SHERLOC’s ability to image from the micron to the multi-millimeter scale; this range is an important size-step in the continuum of contextual investigations that make up the 2020 mission.

Furthermore, by identifying minerals with Raman spectroscopy, SHERLOC will also be able to assess the availability of key elements and energy sources for life. Life on Earth is driven by oxidation-reduction reactions that form and transform organic matter and mineral substrates containing key elements such as C, H, N, O, P and S. The abundance and diversity of these substrates in a sedimentary environment are key measures of habitability and analysis of these substrates in a given environment can identify sedimentary rocks that reflect the detrital component, a precipitated residue of the dissolved component, or post-depositional (diagenetic) alteration processes (Fries et al. 2011). Transformation of minerals by biology or diagenesis has distinctive signatures that can be observed in assemblages of astrobiologically important minerals (e.g., carbonates, nitrates, phosphates, sulfates, etc.). The presence of such minerals, especially in association with organics, or when they otherwise imply some degree of chemical or morphologic disequilibrium, is an important component in evaluating potential biogenicity.

SHERLOC data will also be used to ascertain whether there are potential organic biosignatures preserved in Martian rocks and outcrops by combining Raman spectroscopy with fluorescence spectroscopy (Bhartia et al. 2012b, 2014; Abbey et al. 2017). Potential biosignatures that can be identified and spatially resolved using these synergistic techniques are key organics such as hopanes, steranes, and organic macromolecules. This especially strong interrogative power will help identify samples to be obtained for return to Earth. SHERLOC’s operational modes can determine the organics and minerals present over scales that match the mineralogy and morphology of most biosignatures resulting from microorganisms (Bhartia et al. 2010). It is capable of correlating detected classes of organics with morphology (widths and shapes) to determine whether morphological candidates for microfossils, filaments, or stromatolitic layering are potentially biogenic (Allwood et al. 2006) (Fig. 4). For finer-scale features, SHERLOC’s micro-mapping mode is a platform for non-destructive, sub-picogram sensitive organic detection (Bhartia et al. 2010), providing an in situ capability unprecedented for a flight instrument.

Example of SHERLOC science via analysis of a Strelley Pool Formation Stromatolite sample using the laboratory breadboard MOBIUS instrument (see Bhartia et al. 2014; Abbey et al. 2017). The chert signature observed is highly attenuated by the edge filter but is observable in this sample. Colors blend in the map and organics are green and yellow as they are mixed with the chert signature (sample courtesy of A. Allwood)

SHERLOC will further provide organic and mineral analyses that will be essential for selective core sample extraction and caching. By generating maps of organic molecules and mineral features co-located with corresponding contextual information in the form of micron-to-millimeter scale imaging, the team will be able to identify the most compelling samples that need to be acquired for sample return. In addition, its autofocus and intrinsic depth of field enables organic/mineral analysis of the near-subsurface by observing the inside walls of the extracted cores (i.e. boreholes) where organic material can be protected from the oxidizing nature of the surface.

Table 3 lists the SHERLOC investigation goals associated with the Spectroscopy element of the investigation. All of the SHERLOC scientific objectives and observations described above include options for operations at any time of the Martian day. The inherent Martian UV flux, coupled to the limited spectroscopic field of view, with internal instrument baffling, and the speed that the spectrometer Charged Coupled Device (SCCD) for spectroscopy is read, enables day-time spectroscopic observations. The only notable exception, based on MSL MAHLI experience, might be some hardware inspections (e.g., rover deck) and rare science objectives (e.g., borehole walls), that might be best imaged at night using onboard illuminators (Minitti et al. 2014; Yingst et al. 2016).

2.2 Geologic Photography at 10-100 μm Scales

SHERLOC’s two robotic arm deployable cameras, WATSON and ACI, will provide high spatial resolution (10.1 μm/pixel via ACI; 13.1 to > 100 μm/pixel via WATSON), color (WATSON) and grayscale (ACI) images of rocks and regolith in natural and robotically-disturbed (e.g., abraded, cored, broken by wheels) states. WATSON will, furthermore, obtain images of landscapes, rocks hidden from view of other Perseverance cameras (e.g., beneath ledges, etc.), and provide the contextual spatial resolution bridge between SHERLOC and PIXL observations and those of the rover’s mast-mounted instruments (e.g., Yingst et al. 2016).

Close-up photography of geological materials, including fossil biosignatures, is a field almost as old as photography itself (e.g., Deane 1861; Woodward 1903; Kerp and Bomfleur 2011). Photography is used in the geosciences for a wide range of purposes designed to illustrate, instruct, document, and provide new data for study—including examination of changes that occur on various time scales and images used to construct three-dimensional models of geological materials (e.g., Stow 2005; Maley 2005; Remondino et al. 2010; Rodrigues 2015; Fonstad and Zettler-Mann 2020).

High spatial resolution imaging (in this case, 10.1 to ∼100 μm/pixel) of geological materials on Mars began with the 31 μm/pixel grayscale robotic arm deployable Microscopic Imager (MI) cameras onboard the MER rovers, Spirit and Opportunity (Herkenhoff et al. 2003, 2019). The Phoenix Mars Scout lander included a Robotic Arm Camera (RAC; Keller et al. 2008) as well, which provided sand grain-scale views (∼50 μm/pixel) of regolith particulates (Goetz et al. 2010). MSL’s Chemistry Camera (ChemCam) Remote Microscopic Imager (RMI) provides sub-millimeter per pixel grayscale close-up views of rocks and regolith from a mast-mounted instrument (Le Mouélic et al. 2015). In addition, the robotic arm-mounted MAHLI onboard Curiosity (Edgett et al. 2012) routinely obtains images in the 16 to 100 μm/pixel range; it is capable of 13.9 μm/pixel but rarely is it practical for the camera to be positioned close enough to a target to obtain images at that scale (Yingst et al. 2016). Together, Minitti et al. (2013) and Yingst et al. (2016) described the many versatile uses of the MAHLI; Edgett and Newsom (2018) noted examples of changes detected (sand grain motion) during single MAHLI imaging sessions; and Garvin et al. (2017) and Caravaca et al. (2020) described methods for three dimensional Structure from Motion (SfM) model construction from MAHLI data. All of the capabilities and uses of the MSL MAHLI are achievable with the SHERLOC WATSON camera.

All ACI images will be obtained at ∼10.1 μm/pixel in gray scale. ACI will enable three primary tasks: (1) determine the best focus position for the spectrometer, (2) correlate the laser position with the target surface to provide morphological context of SHERLOC spectra and chemical maps, and (3) place the high resolution chemical maps in context with the rest of the target. In addition, the ground-based data processing pipeline also uses the imaging data to correct for arm drift during prolonged measurements. The resulting imaging system also provides additional science capabilities such as range-finding with ∼0.2 mm accuracy from a safe standoff from the surface, 10.1 μm/pixel views of rock and regolith texture and structure, ability to generate of 3D surface relief maps via MAHLI heritage Z-stacks. The ACI was built with the MAHLI heritage UV Light Emitting Diodes (LEDs) which will enable high-resolution imaging of mineral fluorescence, if present, in a sample (Fig. 5).

2.3 Deep UV Laser Induced Native Fluorescence Spectroscopy

Native fluorescence was first observed in Acuña et al. (2009) and since then, the variety of compounds that exhibit native fluorescence has been determined to be extensive. Most fluorescent compounds incorporate aromatic ring structures but there are some exceptions (Borkman and Kearns 1966). In simple terms, fluorescence provides insight on the electronic states of a molecule. It requires that a molecule absorbs an incident photon such that a bound electron can jump from an S0 to an S1 or S2 state. Once excited, vibrational, rotational, and molecular collisions cause the excited electron to non-radiatively lose energy until, typically, it reaches the lowest vibrational level of the S1 excited energy state. The gap between the lowest energy level of S1 and various levels of the S0 ground state will dictate the emission wavelength produced when the electron returns to S0 (Fig. 6a). This excitation energy is lost through thermal energy or by emission of a photon that is less energetic than the initial absorbed photon; all of this can occur within in hundreds of picoseconds of the incident excitation. The wavelength of this emitted photon provides information about the gap between electronic levels. Typically, as the physical size of a compound increases the emitted photon is of a lower energy (longer wavelength); the shift from the excitation wavelength to the emission wavelength is known as the Stokes shift.

(a) Jablonski diagram illustrating electronic (S) and vibrational (v) energy levels of a molecule, and the transitions involved in each scattering process (Raman) or emission (fluorescence). (b) the Morse potentials and vibrational wavefunctions for ground and excited electronic states involved in resonant Raman scattering. (c) the change in nuclear geometry for electronic excitation of unsubstituted benzene

Native fluorescence is a complimentary mode of detection to Raman, and resonance Raman. One primary benefit are cross-sections that are 105 to 108 times larger than Raman. Additionally, when excitation is below 250 nm, native fluorescence enables observation of the full range of fluorescence emissions from the full range of aromatic organics including benzene, the simplest aromatic organic – which has an emission at 260 nm (Asher and Johnson 1984) - to polyaromatic hydrocarbons (PAHs) such as anthracene, which can absorb a 248 nm photon and emit at 374 nm (Bhartia et al. 2008). As a result, the full spectral shape of simple and complex aromatic organics is characterizable and provide a very sensitive method for determining molecular size. Indeed, DUV native fluorescence can be used to detect and differentiate astrobiologically relevant organics (aromatic amino acids, PAHs, and biosignatures) from mineral backgrounds (Bhartia et al. 2008). It was subsequently demonstrated that DUV native fluorescence enables detection of microbes at the single cell level on natural basalt samples, demonstrating spatially resolved detection of picograms of carbon (Bhartia 2012; Bhartia et al. 2010, 2012a). Salas et al. (2015) demonstrated that the high radiance of a laser is necessary to observe these weak emissions and employed the technique in instruments for in situ measurements that observe trace organic and microbial detection in the ocean subsurface on the walls of igneous boreholes. More recently, laser-induced DUV native fluorescence was demonstrated to detect and locate and spatially resolve the stochastic nature of microbes and organics, including PAHs, in situ in Greenland ice (Malaska et al. 2020).

The sensitivity of laser-induced DUV native fluorescence enables detection of exceedingly trace amounts of organics. While classification is possible, and further enabled with spatially resolved maps, the specificity is limited by the broad emission peaks and spectral variances that are typically observed and interpretable. However, as described by (Bhartia et al. 2014) and others (Bhartia et al. 2012b; Hug et al. 2018), native fluorescence can be used to detect regions of interest, followed by DUV resonance Raman to further interpret an unknown substance. Given that even resonance Raman is inherently orders of magnitude weaker, it is not an ideal broad area search tool for in situ analysis due to resource (i.e. power, data volume, laser lifetime etc.) constraints, however the specificity of the spectrum provides a higher level of organic differentiation. Fusion of these data can be used to extract additional information (Bhartia et al. 2012b). Thus, combining these two complementary methods leverages both techniques to enable detection and characterization of organics and the mineral matrix.

Typically, only organic molecules fluoresce when excited at 248.6 nm, especially between the 260 to 370 nm region where SHERLOC observations occur. However, as there is evidence of some mineral fluorescence from some astrophysical environments (Garstang 1957; Bowen 1960; Hartman and Johansson 2000; Johansson et al. 2000), SHERLOC data analysis will include study of the elemental data obtained by PIXL on the same target (Allwood et al. 2020) to assess the probability of mineral interference. Additionally, the deep UV Raman analysis will provide confirmation of fluorescence features as organics.

2.4 Deep UV Raman Spectroscopy

Raman spectroscopy is a form of molecular vibrational spectroscopy that is highly sensitive to the chemical structure, environment, and photochemical properties of molecules in a target or sample. In contrast to infrared (IR) spectroscopy, which involves the direct excitation of molecular vibrations by absorption of IR radiation, Raman spectroscopy probes these vibrations using the Raman effect, a phenomenon where incident light is inelastically scattered by molecular vibrations, and the change in photon energy corresponds to the change in vibrational energy. Any given molecule may have several Raman-active vibrational modes of different energies, depending on chemical structure, which leads to a typical spectrum of several Raman peaks between 10 and 4000 cm−1. Because of its sensitivity to vibrations of the C-C and C=C bonds (in the 1000-1800 cm−1 range) that make up the backbone of organic molecules, the Raman spectrum in this range is sometimes referred to as the “molecular fingerprint” region. Laboratory Raman spectroscopy can be used to study isotope effects, molecular orientation/anisotropy, crystallinity, and surface adsorption (Asher and Murtaugh 1988; Toyama et al. 1999; Chennaoui Aoudjehane et al. 2012; Le Ru and Etchegoin 2008; Razzell Hollis 2016; Fries et al. 2011; Fries and Steele 2018).

In the next few paragraphs, we briefly explain the principles behind Raman spectroscopy, but we recommend Raman Spectroscopy by Long (1977) for a more detailed and authoritative description. A molecule absorbs an incident photon and its energy is briefly raised to a virtual state between the electronic ground state (\(S_{0}\)) and electronic excited state (\(S_{1}\)), which exists for ∼1 fs before relaxing back to the ground state through re-emission of the scattered photon (illustrated in Fig. 6). Typically, the molecule returns to its original vibrational state, meaning that the scattered photon has the same energy as the incident photon (elastic scattering); this process is Rayleigh scattering. Roughly 1 in 107 scattering events result in the molecule relaxing back to a different vibrational state, such that the scattered photon loses energy (inelastic scattering). The wavelength shift is characteristic of a vibrational mode in the molecule. Finally, the more coherent the excitation source is, the finer the scattered photons are and the more readily a molecular identification can be made which is why lasers are commonly used for Raman spectroscopy.

The selection rule for Raman scattering dictates only those vibrational modes that involve a change in the molecule’s polarizability, \(\alpha \), at equilibrium, are Raman active and contribute to the Raman spectrum. Compare this to the selection rule for IR absorption, which requires that vibrational modes involve a change in dipole moment to be IR active. Consequently, Raman spectra tend to be dominated by the vibrational modes of easily polarized bonds like C-C and C=C, which usually lack inherent dipole moments and thus are weak in IR. Because of this, Raman and IR spectroscopy are considered complementary techniques that probe different aspects of a sample’s molecular vibrations. Traditional Raman scattering cross-sections tend to be very small compared to fluorescence and Rayleigh scattering – typically 10−30 cm2 sr−1 per molecule (Asher and Murtaugh 1988) – necessitating the use of high-power lasers as an excitation source.

One of the most important considerations in Raman spectroscopy is the choice of excitation wavelength. The difference in intensity between Raman scattering and other photophysical phenomena; fluorescence, for example, can be ∼1010 times stronger than Raman, meaning that the Raman spectrum may be impossible to detect if the frequency of the scattered light coincides with a strong fluorescence peak (Asher and Johnson 1984; Tarcea et al. 2007). To emphasize the importance of wavelength, an excitation just above the DUV, at 262 nm, can lead to obscuration by fluorescence (Christensen et al. 2008). Additionally, scattered intensity is generally proportional to the fourth power of the scattered frequency, which for Raman depends on the excitation frequency, \(f_{L}\), and the frequency of the vibration, \(f_{v}\). This means that, for the same laser power, a typical C=C Raman peak at 1600 cm−1 will generate ∼25x more signal under 248.6 nm excitation as compared to the more common 532 nm excitation. However, including the resonance term (Asher 1993), the observed increase can be as high 100 to 200x greater (Nagli et al. 2008). While the majority of commercial Raman instruments operate in the visible to near-IR range (\(\lambda \)ex = 400–1000 nm), the development of commercial deep UV lasers (\(\lambda \)ex <250 nm) has triggered greater interest in UV Raman spectroscopy in recent decades, especially as UV Raman spectra occur in a relatively fluorescence-free spectral range (Asher 1993; Storrie-Lombardi et al. 2001; Tarcea et al. 2007; Hug et al. 2009; Tuschel et al. 2010; Bhartia et al. 2012b; Bhartia et al. 2014; Beegle et al. 2015). In addition to the increase in signal from high-frequency excitation, the use of an excitation frequency that coincides with the absorption band of a molecule can increase scattering cross-sections a further 10–1000x. This phenomenon, known as molecular resonance, is exploited in resonant Raman spectroscopy to increase signal and achieve a greater spectral sensitivity to chemical and environmental perturbations of molecular structure (Asher and Johnson 1984). Pre-resonance refers to the tendency for scattering cross-sections to increase faster than the fourth power rule as excitation wavelength approaches the electronic transition energy (Johnson and Asher 1987).

The origin of resonant Raman is the virtual state coinciding with a real vibrational energy level of the electronically excited state. This leads to strong electron-phonon coupling between vibrational excitation and electronic excitation, described by the Franck-Condon overlap between original state (e.g. \(S_{0}\), \(v_{0}\)) and excited state (\(S_{1}\), \(v_{1}\)), shown in Fig. 6b. Strong overlap between \(v_{0}\) and \(v_{1}\) only occurs when the electronic transition involves a net change in nuclear geometry \(Q\) (the equilibrium positions of atoms in the molecule), as illustrated in Fig. 6c, and only applies to vibrational transitions that explore a similar change in nuclear geometry. This tends to result in the selective enhancement of those vibrational modes associated with the part of the scatterer that absorbs light (known as the chromophore), which for organic molecules under visible or UV excitation is usually a conjugated \(\pi \)-system such as an aromatic ring. Because of the sensitivity of resonance to changes in nuclear geometry, resonant Raman spectroscopy is a powerful tool for studying how chemical and environmental factors perturb the structure of the chromophore and/or its excited state. Vibrational overtones, transitions between \(v_{0}\) and \(v_{2}\), are also frequently observed under resonant conditions as a second, weaker, set of Raman peaks at slightly less than twice the Raman shift of the fundamental transition (Long 1977). While resonance provides many advantages for detection and identification of chromophores at low concentration, quantitative analysis may be complicated by the absorption of incident and/or scattered light by the chromophore (Pelletier 2003; Wu et al. 2006; Razzell Hollis et al. 2020b).

A number of laboratory studies have been conducted using SHERLOC analog instruments to demonstrate the application of UV Raman spectroscopy to planetary science and astrobiology. The use of DUV excitation (248.6 nm) provides resonance with many organic molecules that possess at least one aromatic ring, a list that includes several molecules of biological significance (such as the nucleobases of RNA and DNA, and certain amino acids), as well as many compounds that are formed by abiotic processes and have been found in meteorites (such as polyaromatic hydrocarbons and carbonaceous material) (Kubasek et al. 1985; Wu et al. 2001; Sephton et al. 2002; Frosch et al. 2007; Czaja et al. 2009; Höhl et al. 2016). Raman scattering cross-sections for these molecules under UV are of the order of 10−25 cm2 sr−1, meaning that a detectable Raman spectrum can be obtained with a relatively low-power laser, even when the aromatic organic material is at low concentration (Asher and Murtaugh 1988; Abbey et al. 2017). Saturated aliphatic compounds, which lack the conjugated \(\pi \)-system that acts as a chromophore, are still detectable. However, with only pre-resonance or without resonance enhancement, they typically have a higher limit of detection than aromatics (Trulson and Mathies 1986; Bhartia et al. 2014; Beegle et al. 2015; Abbey et al. 2017). The resonant enhancement of certain molecules and vibrational modes under UV can be very useful when dealing with complex samples such as biological material, leading to cleaner spectra dominated by a more manageable number of key molecules that are easier to classify (Asher and Johnson 1984; Nelson et al. 1992; Hug et al. 2009; Sapers et al. 2019). We have also demonstrated the ability to conduct quantitative analysis of concentration from Raman spectral intensities, provided that self-absorption and the shape of the annular laser spot are considered (Razzell Hollis et al. 2020b). Mineralogy can also be mapped at the sub-mm scale, as many Mars-relevant minerals (carbonates, borates, sulfates, some silicates) may be distinguished by the positions of key peaks in the 800–1200 cm−1 range (Abbey et al. 2017; Razzell Hollis et al. 2020a). SHERLOC also avoids the complication of spectra dominated by background fluorescence, as the 248.6 nm excitation ensures that Raman peaks between ∼800 and 4000 cm−1 occur in a narrow spectral range (252–275 nm) that is spectrally separated from fluorescence that occurs at >275 nm (Asher and Johnson 1984; Tarcea et al. 2007; Bhartia et al. 2008, 2014; Hug et al. 2009; Beegle et al. 2015). Analysis of complex organic systems is possible with UV Raman, where deconvolution of the Raman spectra can be used to identify multiple organic species, including cells themselves when present in a sample (Sapers et al. 2019). We have developed a model that accounts for these physical parameters (Bhartia et al. 2014). This model was vital in driving the SHERLOC optical design requirements and operation methodology and was used to evaluate successful performance of the completed instrument.

2.5 SHERLOC Sensitivity Model

The advantage of DUV fluorescence spectroscopy is its high sensitivity in detecting the presence of aromatic organic compounds when compared to other forms of spectroscopy, including mass spectroscopy. In environments such as Mars, where organics are rare, the low detection limit can result in identification of rocks/surfaces that should be cored and cached for sample return as well as a way to document the concentration of organics to identify potential contamination sources when these samples are analyzed in terrestrial laboratories. However, while fluorescence can detect, the advantage of DUV resonance Raman is its chemical specificity such that organic classification and mineral identification are enabled.

In the development of the instrument concept, a photon budget model (Bhartia et al. 2010; Hug et al. 2012; Bhartia et al. 2014; Abbey et al. 2017; Razzell Hollis et al. 2020b) was used to define the performance of the SHERLOC instrument in order to detect aliphatic organics at <1x10−3 wt/wt in a 100 μm spot; the most challenging case of mission objectives. Initially the model included known terms such as laser power, Raman cross sections and ambient light levels as well as estimates for instrument performance such as optical throughput. This enabled requirements to be placed on individual subsystems to use as requirements in their design. As the instrument went through design, development and characterization, the model was modified to include the measured performance of key subsystems, including the laser energy at the sample, the optical throughput (illumination and detection), detector quantum efficiency, dark noise and end to end electronics read noise in order to ensure that the instrument requirements were all satisfied with margins.

In brief, the sensitivity of the measurement is a function of the interaction volume that is collectable on the CCD, the fluorescence or Raman cross section, the concentration of organics and the number of UV photons. The interaction volume can be modeled as a cylinder with diameter of the laser beam and a height defined by the lesser of the value of the depth of field or the penetration of UV light into and out of a mineral matrix. Measurements of the depth of penetration into mars relevant samples, indications that the depth of field of the optical system (∼500 microns) is on order of the depth of penetration (Carrier et al. 2019). Based on the measured SHERLOC beam parameters, the focused laser spot has an effective area at ∼7540 μm2 (using the 1/\(e^{2}\) definition), which encompasses ∼95% of total intensity. For a typical laser pulse energy of 8 μJ at start of mission in Jezero crater, we predict the dosage received by the sample will be 0.1 J/cm2 per pulse. For a 5-pulse survey acquisition, the total dosage is 0.5 J/cm2, and for a 400-pulse detailed acquisition, the dosage is 40 J/cm2.

Using these values, we modeled the 3D distribution of laser intensity at the sample and determined that for a non-attenuating, non-subsurface-scattering sample, SHERLOC has an interrogation volume of ∼20 nL (∼0.02 mm3). Given the detection limit of ∼10 parts per million and assuming a sample density similar to that of basalt, we will be able to detect the Raman scattering from as little as 0.5 ng of condensed carbon, or approximately 4 picomoles of a small organic compound such as adenine. For samples that are rich in organics and/or minerals that have strong absorption in the UV, attenuation of both incident laser light and Raman-scattered light will reduce the interrogation volume and increase the minimum concentration required for detectable Raman signal.

We have also considered that the DUV laser can lead to photolytic sample degradation (the low peak power avoids thermal alteration). Based on laboratory degradation studies and modeling of ambient UV in Jezero crater (Razzell Hollis et al. 2020c), the UV dosage received by the sample during operation of the SHERLOC laser is estimated to be comparable to 0.01–2 sols of exposure to solar UV radiation, depending on the number of laser pulses used per point. For longer exposures, e.g. detailed scan activities, the SHERLOC laser can induce photo-chemical degradation in organic materials (Razzell Hollis et al. 2020c). However, the extent of degradation and its impact on observed Raman and fluorescence spectra will depend on the organic in question, with more mature material (e.g. macromolecular carbons and carbonaceous material) expected to be highly resilient under UV exposure. Organic material may also be protected by the surrounding mineral matrix, as some certain minerals (such as clays) have been shown to inhibit UV-induced degradation of key biosignatures like DNA (Fornaro et al. 2018).

3 Instrument Accommodation

3.1 Instrument Overview

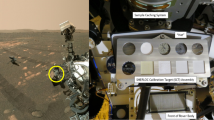

The SHERLOC instrument consists of three hardware units: (1) the SHERLOC Body Assembly (SBA) mounted within the rover chassis which houses the command and data handling, power distribution and scanner control units; (2) the SHERLOC Turret Assembly (STA) mounted on the robotic arm that houses the laser, scanner, spectrometer, imagers (ACI and WATSON) and local control electronics; and (3) the SHERLOC Calibration Target (SCT) mounted to the front of the rover chassis below the elbow bracket that includes spectral standards and HOEDM soft materials.

The SHERLOC instrument contains two electrically separated subsystems: Spectroscopy and Imaging. These subsystems have independent data and power connections to the rover and functions are interlaced through the commanding architecture. The Spectroscopy and ACI are optically co-boresighted for execution of spectral activities. Figure 7 shows the block diagram for SHERLOC.

3.2 Hardware Locations

The SBA is mounted within the rover chassis directly on the rover avionics mounting panel (RAMP). The thermally-controlled environment within the RAMP reduces the overall allowable flight temperature (AFT) range for electronics to -40 ∘C to +50 ∘C. This enables the electronics to avoid the Mars seasonal and diurnal thermal swings without additional thermal control.

The STA is mounted on the turret at the end of the robotic arm with PIXL, the corer, the gas Dust Removal Tool (gDRT), and the facility contact sensor (Moeller et al. 2021). The robotic arm environment is much more severe than that inside internal the rover. The non-operational AFT range from -95 ∘C to +50 ∘C; therefore the STA includes survival heaters and operational heaters to reduce the AFT range within the specification and capabilities of the hardware.

The SCT is mounted to the front of the rover chassis below the robotic arm elbow bracket. The SCT position allows the five degrees of freedom robotic arm to access the calibration targets with both the Spectrometer/ACI and WATSON subsystems.

3.3 Harnessing

The SBA and turret assembly harness, ADLIR (Acquisition & Data Lines between Instrument and Rover), are connected through an impedance-controlled harness that is composed of >12 m of round wire and flex cabling. The harness contains all intra-instrument data, power, and sensor signals. Mitigations in the harnessing and system design were included early in the SHERLOC design phase to avoid the type of issues observed on MSL for both MAHLI and the Alpha Particle X-Ray Spectrometer (APXS) regarding sensitivity of signal to external noise sources picked up through their harness (Gellert et al. 2015). For the spectroscopy subsystem, the development of the turret power regulation board (TPRB) use of temperature cycling resistant electronics (TRCE) chip-on-board (CoB) technology was implemented to provide low-noise regulated power at the turret assembly for sensitive electronics. The analog scanner electronics are housed in the turret assembly to avoid noise feedback in the pointing control circuitry allowing for higher spatial resolution observations of SHERLOC targets. Additionally, the spectroscopy subsystem communication used a SpaceWire interface to ensure optimal data transfer limits greater than those observed on MSL. During SHERLOC development, the Los Alamos National Laboratory (LANL) demonstrated >10 megabits per second using flight hardware, allowing for no data storage being required in the spectroscopy electronics, leading to a simpler design. However, both the ACI and WATSON images are limited to 5 megabits per second per low-voltage differential signaling (LVDS) line, and the camera head readout rates are limited to 2.5 megapixels per second, as these electronics remain mostly unchanged from the MSL MAHLI design (Edgett et al. 2012).

3.4 Vibration Isolation System

Due to the vibrational environment on the turret caused by the adjacent percussive corer, the SHERLOC instrument is isolated from the turret feed structure by a hexapod canister-spring isolation system (Fig. 8). The design of the six struts uses preloaded springs exclusively operating under compression to attenuate natural frequencies thus reducing the energy transfer to the instrument. This results in a fully constrained, quasi-kinematic isolation system. Additionally, the isolation system includes flexure joint interfaces to ensure no stress is applied to the SHERLOC chassis during installation or drilling and coring operations to maintain optical alignments in all configurations.

3.5 Ground Sensing Methods

Unlike arm mounted instruments on MSL, instrument specific contact sensors were descoped from the Perseverance design and replaced with a facility contact sensor mounted to the rear of the turret feed structure (Moeller et al. 2021). The purpose of the facility contact sensor is to provide direct measurements relative to the rover coordinate system for accurate placement of the turret tools and instruments, including SHERLOC, along the axis of approach of turret instrumentation.

However, when that is not available, knowledge of the position of a proximity science (SHERLOC, PIXL) target in three-dimensional space can be determined from surface relief products derived from stereo pair imaging by Perseverance’s engineering stereo cameras (Maki et al. 2020). Also, based on MSL MAHLI experience (Minitti et al. 2013; Robinson et al. 2013; Yingst et al. 2016), deployment of WATSON for range finding via autofocus imaging of a small portion of a geological target can also provide additional, reliable information. While the MSL MAHLI camera head was enveloped by a contact sensing device (Edgett et al. 2012), a similar capability is not included for WATSON. Except for some early testing, the MAHLI contact sensor was not engaged operationally nor accidentally during > 3100 sols of Mars surface operations so the need for such a contact sensor has not been demonstrated and it was removed.

3.6 Positioning

SHERLOC is placed into operating position by the Perseverance’s robotic arm. The accuracy of the placement is governed predominately by the thermal environment, accuracy of the rover engineering camera models, and the mechanical accuracy of the robotic arm. SHERLOC operations will be also constrained for placement by the results of the facility contact sensor assessment of the target (relative placement) and for optimal placement, within a restricted thermal range of operations (nominally 10 ∘C). Nominally, this gives an XY placement accuracy (lateral location relative to the surface) of < ± 6 mm and Z placement accuracy (distance from the ground aligned to the optical axis) of < ± 5 mm and < ±2 mm XYZ with thermal constraint. Relative unconstrained thermal operations are limited to placement accuracies of ±11 mm for XY and ±7 mm for Z.

Operations can be performed in a single placement activity while meeting science requirements. The MSL robotic arm observed jitter of <7 microns root mean squared (RMS) providing a highly stable environment for spectral collection and imaging. For Perseverance, the robotic arm is bigger thus necessitating a new jitter measurement which will take place early in the mission. For extended spatial operations, SHERLOC will capitalize on the nudge capability of the robotic arm (steps of ∼3 mm) to generate spectral and imaging mosaics.

3.7 Data and Power Interfaces

The SHERLOC power and data architecture leverages the functions of the Mars 2020 rover. Communication, command, and control use a command-reply handshake over LVDS with the Rover computing elements (RCEs) thus requiring the rover to be awake during all SHERLOC operations. Power is applied directly to the unit from the Rover Power Avionics Module (RPAM) which independently controls power to the SHERLOC spectroscopy and imaging subsystems and thermal zones for warm up, decontamination and survival heating. Additionally, SHERLOC is monitored by 13 flight system platinum resistance thermometers (PRTs) spread throughout the instrument to assess instrument temperature during flight.

4 SHERLOC Body Assembly (SBA)

The SBA houses the command and data handling and power electronics for the Spectroscopy and Imaging subsystems and serves as the interface between the SHERLOC turret assembly the rover’s onboard computers (Fig. 9). To maintain the flight heritage of the SHERLOC imaging system, the SBA contains two distinct LVDS command and power interfaces to the Perseverance rover - one for imaging for the Digital Electronics Assembly (DEA), and one for the spectroscopy for the Command & Data Handling (C&DH)/Power Distribution Unit (PDU). The SBA’s mass is 2.90 kg and it has an enveloped volume of 220 mm x 89 mm x 200 mm excluding connectors and cabling.

4.1 Power Distribution Unit (PDU)

The PDU consists of six converters and dual electromagnetic interference and electromagnetic compatibility (EMI/EMC) filters to distribute power to the spectroscopy subsystem and accepts 22-36 V unregulated rover bus power. The PDU provides regulated power isolated from the bus to the C&DH unit, the Scanner Servo Electronics (SSE) in the SBA, and to the Turret Power Regulation Board (TPRB) located in the STA, and main bus power for the Laser Power Supply (LPS) in the STA. Figure 10 shows the converter and power distribution configuration for the PDU.

4.2 Command and Data Handling (C&DH)

The block diagram of the spectrometer C&DH within the body unit is shown in Fig. 11. It incorporates a LEON3 processor running at 50 MHz, along with boot ROM (Read Only Memory), 6 MB of nonvolatile MRAM (Magnetoresistive Random Access Memory), and 250 MB of SDRAM (Synchronous Dynamic Random Access Memory), all of which are EDAC (Error Detecting and Correction) protected. The processor interfaces to the spectrometer electronics (SE) via 10 Mbit SpaceWire, and through a ProASIC3 FPGA (Field Programmable Gate Arrays) to the RCE, scanner, and SE discrete signals. Regulated power for the C&DH is supplied from the PDU.

The processor runs the VxWorks operating system, which is stored along with the application in redundant banks of MRAM. Two copies of both the operating system and application are stored in two banks of MRAM, either of which can be booted based on discrete command from the RCE. There are two rover interfaces (the same as those used on MSL), one to each of two redundant RCEs for commands and telemetry. The RCE interface consists of LVDS clock, data and frame signals. The command interface from the RCE runs at 2 Mbits/s and the telemetry interface from the C&DH to the RCE operates at 8 Mbits/s.

The C&DH manages the synchronization of the functions required to perform spectroscopy. Coordination of scanner motion and spectral collection are optimized to improve overall timing of operations. Scanner motion is commanded during the read portion of active spectral collection before proceeding to the next step in the map. Each active spectrum is preceded by a dark collection, where the spectrum is acquired without laser firing, for background removal for ground or flight processing. Under nominal operating conditions, this process runs at ∼10 Hz. The maximum number of spectra that can be collected in a single operation is 1296. Results accumulate in the SDRAM and are transmitted to the RCE when commanded.

The C&DH software includes a suite of algorithms to decimate spectral maps into decisional data sets or to retarget chemical specific regions of interest. Decisional data sets are those data acquired by the instrument which must be downlinked immediately to help make key decisions for the very next tactical operations plan to be created by the rover team operating on Earth. They can be generated by downlinking laser data only, spectrally binning maps in up to 6 spectral channels, or spatially binning maps to macro pixel(s) based on spatial binning masks stored in NVM or in situ loaded masks. For region of interest selection, initial pre-processing of data is critical to properly retarget chemical signatures. The SHERLOC algorithm suite includes onboard background subtraction, bad pixel removal, laser normalization, and cosmic ray removal. Cosmic rays will cause large spurious spikes obfuscating results and therefore are removed using the statistical analysis method described by Uckert et al. (2019). Preprocessed data are then ranked and positions ordered based on a weighted sum of up to 6 spectral channels. The resulting ranked position list is used to retarget the center to the Nth ranked position. Algorithm parameters are stored in nonvolatile MRAM and can be changed by command. Single data sets can be reprocessed for multiple times for targeting different chemical features as time permits in the operations timeline.

4.3 Scanner Servo Electronics (SSE)

The SSE is a part of the scanner subsystem and serves as the interface between the scanner and the control (C&DH) and power (PDU) systems. The SSE converts control and power signals for distribution to the scanner subsystem located on the turret and positional feedback to the scanner through the servo control loop.

4.4 Digital Electronics Assembly (DEA)

The shared DEA (Fig. 24b) performs all interfacing functions with the rover to operate the WATSON and ACI imagers. The DEA, described previously by Edgett et al. (2012) and Malin et al. (2017), contains flight software to operate the imagers and perform onboard data compression (including focus stacking). The DEA hardware is equivalent to that of the Mars 2020 Mastcam-Z DEA (Bell et al. 2020, this journal) and has 128 megabytes of SDRAM and 8 gigabytes of non-volatile NAND flash memory for data storage.

5 SHERLOC Turret Assembly (STA)

The SHERLOC Turret Assembly houses the optical, mechanical, thermal and instrument head electronic hardware for the Spectroscopy and Imaging subsystems (Fig. 12). In addition to the optics, the STA contains only critical electronics that are required to be in proximity to hardware. The spectroscopy subsystem electronics includes the spectrometer electronics and turret power regulation board (SE/TPRB), the spectrometer CCD (SCCD) and control electronics, the scanner sensor feedback electronics (SDE), and the high voltage power supply to run the DUV laser (LPS). The imaging electronics on the STA include the context imager FPA (CHE), and the WATSON FPA (WCHE). In addition, to minimize impacts and resources to the flight system, the ACI and WATSON imagers have a command switchable interface for the command, data, and telemetry, and simultaneous power signals from the DEA via a multiplexer (MUX). The STA mass is 6.83 kg and has an enveloped volume of 352 mm x 176 mm x 276 mm excluding connectors and cabling.

5.1 SHERLOC Spectroscopy Subsystem Optical Design

SHERLOC science goals require a DUV laser to excite a target, and a spectrometer that senses the Raman and fluorescence spectral regions as it measures the laser-induced spectral signatures from that target. In addition, the motorized objective lens and the context imager of the ACI provides a means to focus the laser and spectrometer and generate images at a pixel scale of less than 1/10 the laser diameter. These three co-boresighted optical paths comprise the SHERLOC optical system (Figs. 13 and 14).

Block diagram of the SHERLOC optical path. The LIF/LIF2, LPF were provided by Semrock, M7 was from Alluxa, the beam dump, grating, aperture stops were fabricated at JPL and coated by Aktar. The remaining lenses and curved mirrors were custom fabrications to meet the deep UV surface figure and RMS requirements with margin (provided by Optimax)

Guided by the focus position established by acquisition of the ACI image, SHERLOC uses a tip/tilt fine steering mirror to step a focused DUV laser spot across the target, generating Raman scatter and fluorescence emission from each step position. SHERLOC’s laser emission starts in its neon-copper laser, where the primary emission at 248.6-nm is output as a Laguerre-Gaussian beam with an M2 of 34. Also emitted is an orange spontaneous-emission spectrum from the glow discharge and a number of weak laser lines, including a particularly strong, non-lasing line at 252.9 nm. These longer-wavelength spectral features must be attenuated significantly, so that they do not influence the spectroscopy. To this end, the first optical elements after the laser’s output coupler are steep edge laser-injection filters (LIFs) (Semrock). These filters strongly (>99.995%) reflect light less than 251 nm and transmit (on average, about 97%) longer wavelengths. A series of three such filters reflect the 248.6-nm line and attenuates longer wavelengths, while turning the laser beam by 90∘ into the main structure of the SHERLOC instrument. Just before entering SHERLOC, an uncoated fused silica beamsplitter reflects a tiny fraction of the laser signal onto a silicon carbide photodiode (sglux SG01XL). This detector acts as a reference measurement that allows continual assessment of the laser’s pulsed output. The laser signal that transmits through the beamsplitter is then expanded by two aspheric lenses lens that collimate the beam to its full diameter, critically filling the instrument’s 12.5-mm aperture stop. The collimated output of this aspheric beam expander then reflects off of two mirrors that are coated to reflect the 248.6 nm laser line (M2 and M3), then off the LIF edge filter, off the scanner mirror, and out the common-path ACI objective, which transmits nearly 90% of the laser signal and focuses the laser to an approximately 100-μm spot on the target. The scanner is then actuated to articulate the laser spot across the target field, thereby inducing a Raman and fluorescence signal at every desired pixel on the target’s context image.

The target’s laser-induced Raman and fluorescence signals are collected along the same optical path back into the instrument, through the ACI objective and off the scanner mirror. However, this excited signal has a slightly longer wavelength than the exciting laser line, so it is transmitted through the LIF and along SHERLOC’s spectrometer optical path. The next filter is a long-pass filter (LPF) (Semrock) that reflects the spectral signal onto an off-axis paraboloidal (OAP) mirror. This OAP mirror focuses the spectral signal through the spectrometer’s slit, a 100-by-200-μm laser-drilled aperture. This slit limits the spectroscopy aperture. The spectroscopy signal then continues to be collimated by another OAP mirror, after which it is reflected off a fold mirror (M5) and directed onto the instrument’s diffraction grating. This unique grating was written via electron-beam lithography (EBL) at the JPL Microdevices Laboratory (MDL) at a very high groove density of 4200 grooves/mm. The zeroth-order diffraction is dumped into an angled port (which was used to aid instrument alignment and designed to minimize stray light), and the first-order beam is diffracted with high efficiency (nearly 60%) onto a convex aspheric mirror, and then onto a concave spherical mirror that focuses the spectral signal across the long axis of the 512-by-2048 pixel e2v 42-10 SCCD.

The SHERLOC spectroscopic analysis takes place on the SCCD. The target’s spectral signal is read out in three binned regions, one for the Raman signal from 253 to 274 nm and two for the fluorescence regions that range up to 354 nm. In the Raman region, 16.2 nm of the spectrum are diffracted across each of the SCCD’s 13.5-μm pixels. The instrument samples a narrow line source (e.g., the 253.65-nm Hg line) with an instrument line function of <5 pixels Full Width at Half Maximum (FWHM) in the Raman region. The optical design specifies a spectral resolution of 310 pm in this region, and the performance measured was 269 pm. Spectra are diffracted across the SCCD as a curved line, called a spectral smile (Fig. 15). To optimize for the photon-starved Raman signals, the smile is registered to the pixel grid by clocking the SCCD by ∼9∘. This orients the Raman spectral region along pixel rows and minimizes the number of rows binned to generate the spectrum. The fluorescence spectral region curves across the SCCD into the opposite corner. As it is many orders brighter than Raman, binning more rows has a negligible effect on SNR. Data are read in a binned, columnar fashion, since signal is distributed so that wavelength corresponds to SCCD column.

To mitigate ghost reflections and other stray light within the instrument, a physical aperture shaped like the spectral smile is located just before the SCCD. In addition, a baffle is located around the grating periphery to obscure edge effects and other artifacts of the multilayer EBL process. All aperture masks in SHERLOC, including the laser pinhole, instrument aperture stop, spectrometer slit, grating mask, and SCCD smile mask are coated with the same Acktar black broadband-absorbing coating.

5.1.1 Deep UV Laser

Deep UV Laser Overview

The SHERLOC NeCu DUV laser tube was manufactured by Photon Systems, Inc (PSI). A commercial-off-the-shelf (COTS) laser design manufactured by PSI was modified specifically for the SHERLOC instrument to meet launch, cruise, landing, extreme operating and non-operating ambient temperature, and vibration conditions of a Mars rover mission.

For accurate accumulation of Raman and fluorescence spectra on Mars, the stability of the laser emission linewidth and wavelength are essential. The SHERLOC NeCu laser emits at a wavelength of 248.6 nm and, since it is an electronic transition, has a line width and stability less than 0.07 cm−1. The laser is operational without survival heaters or any temperature regulation or control at ambient temperatures from -135 ∘C to +70 ∘C. In addition to the ambient temperature requirements, the NeCu laser was subject to several additional mandatory requirements including:

-

(1)

emission wavelength below 250 nm to enable spectral separation of the Raman and fluorescence spectral emission regions;

-

(2)

beginning of life output energy ≥ 9 μJ per pulse with pulse repetition rate of 80 Hz in 40 μs-wide pulses with a peak power less than about 200 mW to avoid photochemical or thermal damage of organic target materials;

-

(3)

stable emission linewidth and position and independent of ambient temperature, to enable accurate Raman spectroscopy without added system size and mass associated with the need for additional spectral calibration components;

-

(4)

unpolarized to enable Raman detection of crystalline materials of unknown orientation;

-

(5)

insensitive to hard radiation (rad-hard);

-

(6)

able to survive the severe shock and vibration expectations through the entire mission envelope, particularly including launch, landing, and during drilling/coring operations;

-

(7)

low mass and volume (<280 cm3 and < 450 g); and

-

(8)

start-up time < 1 μs to eliminate power consumption before use.

The NeCu laser is a transverse discharge sputtered Cu hollow cathode laser which was first demonstrated in 1974 at the University of Budapest (Csilliag 1974) and Colorado State University. The transverse excited hollow cathode sputtered copper laser tube is a simple, coaxial, robust design with grounded anode invar tube body and internal construction consisting mostly of invar, beryllium oxide, titanium, OFHC (Oxygen-Free, High thermal Conductivity) copper bore, deep UV grade fused silica laser mirrors and windows hermetically sealed with indium and filled with a neon buffer gas. This all-metal, welded, and brazed construction leads to a robust traveling wave tube (Fig. 16). A photograph of the NeCu laser as mounted on the SHERLOC STA is shown in Fig. 8.

Hollow Cathode Laser

Figure 17 shows a cross-section view of the structure of the laser. When a negative voltage between -550 V and -800 V is applied to the laser, it causes an electrical breakdown of the low-pressure neon buffer gas (∼12Torr) where the discharge avalanches to a stable operation at a sustaining voltage of ∼380VDC and current between 20-30A. This process takes 1 μs after application of voltage. The electrons are accelerated inwardly across the Faraday dark space, into the negative glow region undergoing multiple ionizing collisions with neon (Ne) neutrals and producing neon ions (Ne+). This production of Ne+ results in an initial bombardment into the Cu cathode wall via the acceleration back through the Faraday dark space. These highly energetic Ne+ ions begin generating neutral Cu atoms via the sputtering process that is enhanced as Cu+ ions are created in the negative glow region and, in turn, are themselves are accelerated into the Cu wall, efficiently creating even more Cu atoms (de Hoog et al. 1977; McNeil et al., 1975 and 1976). These Cu+ wall collisions combined with the relatively low Cu work function produce secondary electrons bootstrapping the process. These sputtered Cu atoms diffuse back into the negative glow region and are autoionized creating the highly excited upper laser state via charge transfer reaction with the Ne+ metastable ions. One of the unique features of this laser is the (annular ring) Laguerre-Gaussian laser mode which is a result of the nonuniform distribution of Cu++; higher density at or near the wall of the 3 mm copper bore produces a smoke ring like laser gain region. The process, including stabilization of the copper ion density in the hollow cathode, takes less than 10 μs, independent of ambient temperature.

The fundamental lifetime limit of the hollow cathode laser of the NeCu25 type is about 500 million laser pulses at current levels of 25 to 30A, due to erosion of the copper cathode. For SHERLOC, the required number of pulses is a convolution of the instrument throughput and collection efficiency. Assuming 9 μJ/pulse, the required number of pulses to be available for use on Mars is ∼21M. Given the >14 μJ/pulse laser, the SHERLOC flight laser will easily enable acquisition of > 2.7 million spectra, which is >7 times the lifetime of the prime mission.

Tube Construction and Testing