The paper describes advances in a promising area for the development of Samsonov’s scientific school at the Igor Sikorsky Kyiv Polytechnic Institute. The main results are provided to refine the mechanisms whereby crystals nucleate and grow from melts of eutectic alloys and acquire their microstructure and phase composition and the mechanisms whereby reinforced composite materials with isotropic and anisotropic microstructure are strengthened for extreme applications involving high-speed heating and cooling, impact interaction, cyclic loading, and corrosive environments. The mechanical properties of reinforced composite materials in a wide temperature range are presented. Areas for application of the reinforced ceramics are identified.

Similar content being viewed by others

References

P. I. Loboda, “Grigorii Samsonov: Research and teaching career at the National Technical University Kiev Polytechnic Institute,” Powder Metall. Met. Ceram., 47, Nos. 1–2, 7–12 (2008).

P. I. Loboda, Directionally Solidified Borides [in Ukrainian], Praimdruk, Kyiv (2012), p. 395.

S. Otani, T. Aizawa, and Y. Yajima, “Floating zone growth of LaB6 crystals from the CaB6-added feed rods,” J. Cryst. Growth, 234, 431–434 (2002).

O. Shigeki and I. Yoshio, “Preparation of WB2–x single crystals by the floating zone method,” J. Cryst. Growth, 154, 81–84 (1995).

S. Otani, “Preparation of HfB2 and ZrB2 single crystals by floating zone method,” J. Cryst. Growth, 186, No. 4, 582–586 (1998).

S. Otani and Y. Ishizawa, “Floating zone growth of TiB2 single crystals using SHS rods,” Int. J. Self-Propag. High. Temp. Synth., 3, No. 1, 93–97 (1994).

S. Otani, T. Tanaka, and Y. Ishizawa, “Crystal quality and high temperature hardness of LaB6 crystals prepared by the floating zone method,” J. Alloys Compd., 202, No. 1–2, 25–28 (1993).

S. Otani, S. Honma, and Y. Ishizawa, “Preparation of (La, Ce)B6 single crystals by the traveling solvent floating zone method,” in: Proc. 11th Int. Symp. Boron, Borides and Related Compounds, Tsukuba, Tokyo (1994), pp. 114–117.

T. Tanaka, S. Okeda, and Y. Ishizawa, “Single crystal growth of a new YB50 family compound: YB44SiB1.0,” J. Solid State Chem., 133, No. 1, 10–17 (1997).

S. Otani, S. Honma, Y. Yajima, and Y. Ishizawa, “Preparation of LaB6 single crystals from a boron-rich molten zone by the floating zone method,” J. Cryst. Growth, 126, Nos. 2–3, 466–470 (1993).

S. Otani, M. M. Korsukova, and T. Mitsuhashi, “Floating zone growth and high-temperature hardness of NbB2 and TaB2 single crystals,” J. Cryst. Growth, 194, 430–433 (1998).

S. Otani, M. M. Korsukova, T. Mitsuhashi, and N. Kieda, “Floating zone growth and high-temperature hardness of YB4 and YB6 single crystals,” J. Cryst. Growth, 217, 378–382 (2000).

Yu. N. Taran and V. I. Mazur, Structure of Eutectic Alloys [in Russian], Metallurgiya, Moscow (1978), p. 312.

W. Kurz and P. R. Sahm, Directional Crystallization of Eutectic Materials [in German], Springer-Verlag, Berlin (1975).

R. Elliott, Eutectic Solidification Processing, Butterworth, London (1983).

D. M. Karpinos, Composite Materials [in Russian], Naukova Dumka, Kyiv (1975), p. 360.

A. I. Somov and M. I. Tikhonovksii, Eutectic Compositions [in Russian], Metallurgy, Moscow (1987), p. 304.

Y. Paderno, V. Paderno, and V. Filippov, “Some peculiarities of eutectic crystallization of LaB6–(Ti, Zr)B2 alloys,” J. Solid State Chem., 154, No. 1, 165–167 (2000).

Y. Paderno, V. Filipov, V. Paderno, and A. Sayir, “Submicron size single crystal MeIVB2 (Me = Ti, Zr, Hf) fibers,” J. Eur. Ceram. Soc., 25, No. 8, 1301–1305 (2005).

H. Deng, E. Dickey, Y. Paderno, et al., “Crystallographic characterization and indentation mechanical properties of LaB6 –ZrB2 directionally solidified eutectics,” J. Mater. Sci., 19, 5987–5994 (2004).

Y. Paderno, V. Paderno, N. Shitsevalova, and V. Filippov, “The peculiarities of the structure formation in directionally crystallized eutectics EuB6–MeB2,” J. Alloys Compd., 317–318, 367–371 (2001).

P. I. Loboda, “Features of structure formation with zone melting of powder boron-containing refractory materials,” Powder Metall. Met. Ceram., 39, Nos. 9–10, 480–486 (2000).

P. I. Loboda, V. Ya. Shlyuko, and V. V. Kovylyaev, “Mechanism of primary purification in zone melting of boron-containing powder materials,” Powder Metall. Met. Ceram., 40, Nos. 3–4, 187–199 (2001).

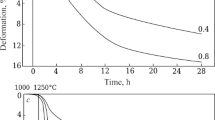

P. I. Loboda and Yu. I. Bogomol, “The thermal stability of the directionally reinforced boride ceramics microstructure,” Ceramics, 69, 117–124 (2002).

P. Loboda, I. Bogomol, M. Sysoev, and G. Kysla, “Structure and properties of superhard materials based on pseudo-binary systems of borides produced by zone melting,” J. Superhard Mater., 28, No. 5, 28–32 (2006).

P. I. Loboda, H. P. Kysla, S. M. Dub, and O. P. Karasevska, “Mechanical properties of the monocrystals of lanthanum hexaboride,” Mater. Sci., 45, No. 1, 108–113 (2009).

P. I. Loboda, G. P. Kysla, Yu. I. Bogomol, and M. A. Sysoev, “Effect of crystallographic orientation of the α-matrix and fiber diameter on the properties of controlled eutectic alloys,” Metallofiz. Noveish. Tekhnol., No. 28, 147–155 (2006).

P. I. Loboda, V. Ya. Shlyuko, and V. V. Kovylyaev, “Mechanism of primary purification in zone melting of boron-containing powder materials,” Powder Metall. Met. Ceram., 40, Nos. 3–4, 187–199 (2001).

P. I. Loboda, “Features of structure formation with zone melting of powder boron-containing refractory materials,” Powder Metall. Met. Ceram., 39, Nos. 9–10, 480–486 (2000).

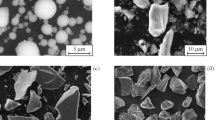

I. Bogomol, T. Nishimura, O. Vasylkiv, et al., “Microstructure and high-temperature strength of B4C–TiB2 composite prepared by a crucibleless zone melting method,” J. Alloys Compd., 485, Nos. 1–2, 677–681 (2009).

I. Bogomol, O. Vasylkiv, Y. Sakka, and P. Loboda, “Mechanism of nucleation and growth of directionally crystallized alloys of the B4C–MeB2 system,” J. Alloys Compd., 490, Nos. 1–2, 557–561 (2010).

I. Bogomol, T. Nishimura, O. Vasylkiv, et al., “High-temperature strength of directionally reinforced LaB6–TiB2 composite,” J. Alloys Compd., 505, No. 1, 130–134 (2010).

I. Bogomol, T. Nishimura, O. Vasylkiv, et al., “High-temperature strength of directionally solidified B4C–ZrB2 composite,” World J. Eng., 7, No. 2, 314–320 (2010).

I. Bogomol, T. Nishimura, Yu. Nesterenko, et al., “The bending strength temperature dependence of the directionally solidified eutectic LaB6–ZrB2 composite,” J. Alloys Compd., 509, No. 20, 6123–6129 (2011).

I. Bogomol, S. Grasso, T. Nishimura, et al., “Hard polycrystalline eutectic composite prepared by spark plasma sintering,” Ceram. Int., 38, No. 5, 3947–3953 (2012).

I. Bogomol, “Chapter 10. Directionally solidified ceramic eutectics for high-temperature applications,” in: J. Low and Y. Sakka (eds.), MAX Phases and Ultra-High Temperature Ceramics for Extreme Environments, IGI Global (2013), pp. 303–322, DOI: https://doi.org/10.4018/978-1-4666-4066-5.ch010.

M. Kruger, G. Hasemann, I. Bogomol, and P. Loboda, “Multiphase Mo–Si–B alloys processed by directional solidification,” Mater. Res. Soc. Symp. Proc., 1516, 1684–1689 (2013), DOI: https://doi.org/10.1557/opl.2012.1684.

I. Bogomol, P. Badica, Y. Shen, et al., “Room and high temperature toughening in directionally solidified B4C–TiB2 eutectic composites by Si doping,” J. Alloys Compd., 570, 94–99 (2013).

G. Hasemann, I. Bogomol, D. Schliephake, et al., “Microstructure and creep properties of a near-eutectic directionally solidified multiphase Mo–Si–B alloy,” Intermetallics, 48, 28–33 (2014).

P. I. Loboda, T. O. Soloviova, Yu. I. Bogomol, et al., “Effect of the crystallization kinetic parameters on the structure and properties of eutectic alloy of the LaB6–TiB2 system,” J. Superhard Mater., 37, No. 6, 394–401 (2015).

J. Llorca and V. M. Orera, “Directionally solidified eutectic ceramic oxides,” Progr. Mater. Sci., 51, 711–809 (2006).

J. I. Pena, M. Larson, R. I. Merino, et al., “Processing, microstructure and mechanical properties of directionally solidified Al2O3–Y3Al5O12–ZrO2 ternary eutectics,” J. Eur. Ceram. Soc., 26, 3113–3121 (2006).

J. Llorca and R. N. Singh, “Influence of fiber and interfacial properties on fracture behavior of fiberreinforced ceramic composites,” J. Am. Ceram. Soc., 74, No. 11, 2882–2890 (1991).

P. B. Oliete, J. I. Pena, A. Larrea, et al., “Ultrahigh-strength nanofibrillar Al2O3–YAG–YSZ eutectics,” Adv. Mater., 19, 2313–2318 (2007).

R. L. Ashbrook, “Directionally solidified ceramic eutectics,” J. Am. Ceram. Soc., 60, Nos. 9–10, 428–435 (1977).

P. L. Kennard, R. C. Bradt, and V. S. Stubican, “Mechanical properties of the directionally solidified MgO–MgA12O4 eutectic,” J. Am. Ceram. Soc., 59, Nos. 3–4, 160–163 (1976).

J. Yi, A. S. Argon, and A. Sayir, “Internal stresses and the creep resistance of the directionally solidified ceramic eutectics,” Mater. Sci. Eng., 421, 86–102 (2006).

C. Chen, W. Zhou, and L. Zhang, “Oriented structure and crystallography of directionally solidified LaB6–ZrB2 eutectic,” J. Am. Ceram. Soc., 81, No. 1, 237–240 (1998).

I. Gunjishima, T. Akashi, and T. Goto, “Characterization of directionally solidified B4C–TiB2 composites prepared by a floating zone method,” Mater. Trans., 43, No. 4, 712–720 (2002).

Y. Waku, N. Nakagawa, T. Wakamoto, et al., “A ductile ceramic eutectic composite with high strength at 1.873 K,” Nature, 389, 49–52 (1997).

P. I. Loboda, “Technique for producing pure single crystals and reinforced ceramic composites from powders of refractory compounds,” in: Physical and Technical Problems of Modern Materials Science [in Russian], Akademperiodika, Kyiv (2013), pp. 413–439.

V. E. Panarin, M. V. Kindrachuk, P. I. Loboda, et al., Development and Implementation of a New Class of Eutectic Composites in Innovation Technologies of Mechanical Engineering Enterprises [in Ukrainian], Motor Sich, Zaporizhia (2016), p. 264.

Kh. S. Bagdasarov, E. I. Givargizov, L. N. Demianets, et al., Modern Crystallography. Volume 3. Formation of Crystals [in Russian], Nauka, Moscow (1980), p. 401.

Acknowledgement

The author is grateful to department staff for the fruitful cooperation and the material for the paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 57, Nos. 1–2 (519), pp. 17–34, 2018.

Rights and permissions

About this article

Cite this article

Loboda, P.I. Structure and Properties of Reinforced Ceramic Materials Produced by Directional Solidification. Powder Metall Met Ceram 57, 13–26 (2018). https://doi.org/10.1007/s11106-018-9951-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-018-9951-7