Abstract

Purpose

The probability of agglomerate-to-wall collision was quantified using a unique image processing technique applied to high-speed microscopic images. The study aimed to investigate the effects of flow rate and particle size on the percentage of colliding agglomerates detected within an in-house powder dispersion device.

Method

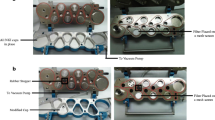

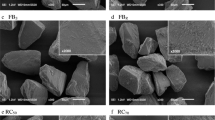

The device consists of a swirl chamber and two tangential inlets in various configurations, designed to emulate the geometric features of commercial devices such as the Aerolizer® and Osmohaler®. The test cases were conducted with constant flow rates of 30 SLPM and 60 SLPM. Four powder samples were tested, including carrier Respitose® SV010 (median volume diameter 104 µm, span 1.7) and mannitol of three constituent primary particle sizes (3 µm, 5 µm and 7 µm; span 1.6 – 1.9).

Results

At the lower flow rate of 30 SLPM, collision frequencies were significantly different between powders of different constituent particle sizes, but the effects of powder properties diminished on increasing the flow rate to 60 SLPM. At the higher flow rate, all powders experienced a significant increase in the proportion of colliding particles.

Conclusion

Analysis of collision events showed that the probability of collision for each agglomerate increased with agglomerate diameter and velocity. Experimental data of agglomerate-to-wall collision were utilised to develop a logistic regression model that can accurately predict collisions with various powders and flow rates.

Similar content being viewed by others

Data Availability

Data analysed during this study are included in the published article (and its supplementary information files). Further raw data generated during the current study are available from the corresponding author on reasonable request.

References

Islam N, Cleary MJ. Developing an efficient and reliable dry powder inhaler for pulmonary drug delivery Б─⌠ A review for multidisciplinary researchers. Med Eng Phys. 2012;34(4):409–27.

Misra A, Shahiwala A, SpringerLink. Novel Drug Delivery Technologies Innovative Strategies for Drug Re-positioning. 1st ed. 2019. xxiv+431. Singapore: Springer Singapore; 2019.

Ye Y, Ma Y, Zhu J. The future of dry powder inhaled therapy: Promising or discouraging for systemic disorders? Int J Pharm. 2022;614: 121457.

Chen L, et al. Investigation of dry powder aerosolization mechanisms in different channel designs. Int J Pharm. 2013;457(1):143–9.

Coates MS, et al. Effect of design on the performance of a dry powder inhaler using computational fluid dynamics. Part 2: Air inlet size. J Pharma Sci. 2006;95(6):1382–92.

Coates MS, et al. Effect of Design on the Performance of a Dry Powder Inhaler Using Computational Fluid Dynamics. Part 1: Grid Structure and Mouthpiece Length. J Pharma Sci. 2004;93(11):2863–76.

Friebel C, Steckel H, Müller BW. Rational design of a dry powder inhaler: device design and optimisation: Device design and optimisation. J Pharma Pharmacol. 2012;64(9):1303–15.

Lee H-J, et al. Spiral mouthpiece design in a dry powder inhaler to improve aerosolization. Int J Pharm. 2018;553(1):149–56.

Ngoc NTQ, et al. Experimental investigation of design parameters on dry powder inhaler performance. Int J Pharm. 2013;457(1):92–100.

Selvam P, et al. A novel dry powder inhaler: Effect of device design on dispersion performance. Int J Pharm. 2010;401(1–2):1–6.

Zhou QT, et al. Effect of Device Design on the Aerosolization of a Carrier-Based Dry Powder InhalerБ─■a Case Study on Aerolizerб╝ Foradileб╝. AAPS J. 2013;15(2):511–22.

Bosquillon C, et al. Influence of formulation excipients and physical characteristics of inhalation dry powders on their aerosolization performance. J Control Release. 2001;70(3):329–39.

Buttini F, et al. Effect of Flow Rate on In Vitro Aerodynamic Performance of NEXThaler (R) in Comparison with Diskus (R) and Turbohaler (R) Dry Powder Inhalers. J Aerosol Med Pulm Drug Deliv. 2016;29(2):167–78.

Chodosh S, et al. Effective delivery of particles with the HandiHaler (R) dry powder inhalation system over a range of chronic obstructive pulmonary disease severity. Journal of Aerosol Medicine-Deposition Clearance and Effects in the Lung. 2001;14(3):309–15.

Chougule M, Padhi B, Misra A. Development of spray dried liposomal dry powder inhaler of Dapsone. AAPS PharmSciTech. 2008;9(1):47–53.

Donovan MJ, et al. Dry powder inhaler device influence on carrier particle performance. J Pharm Sci. 2012;101(3):1097–107.

Mitchell JP, Nagel MW. Cascade impactors for the size characterization of aerosols from medical inhalers: Their uses and limitations. J Aerosol Med Deposition Clearance Effects Lung. 2003;16(4):341-+.

Shur J, et al. Effect of Device Design on the In Vitro Performance and Comparability for Capsule-Based Dry Powder Inhalers. Aaps Journal. 2012;14(4):667–76.

Mitchell J, Newman S, Chan HK. In Vitro and In Vivo Aspects of Cascade Impactor Tests and Inhaler Performance: A Review. AAPS PharmSciTech. 2007;8(4):12.

Longest PW, et al. Aerodynamic Factors Responsible for the Deaggregation of Carrier-Free Drug Powders to Form Micrometer and Submicrometer Aerosols. Pharm Res. 2013;30(6):1608–27.

Chan HK. Dry powder aerosol delivery systems: Current and future research directions. Journal of Aerosol Medicine-Deposition Clearance and Effects in the Lung. 2006;19(1):21–7.

de Boer AH, et al. Design and in vitro performance testing of multiple air classifier technology in a new disposable inhaler concept (Twincer (R)) for high powder doses. Eur J Pharm Sci. 2006;28(3):171–8.

Singh G, et al. From laminar to turbulent flow in a dry powder inhaler: The effect of simple design modifications. Int J Pharm. 2022;616: 121556.

Meng HQ, Chen L, Chen DH. Effect of carrier size and surface morphology on the aerosolization of formulation in a capsule-based dry powder inhaler. Yaoxue Xuebao. 2019;54(9):1673–9.

Ruzycki CA, Javaheri E, Finlay WH. The use of computational fluid dynamics in inhaler design. Expert Opin Drug Deliv. 2013;10(3):307–23.

Kourmatzis A, et al. Effect of an upstream grid on the fluidization of pharmaceutical carrier powders _ Elsevier Enhanced Reader.pdf. Int J Pharm. 2020;578:119079.

Lowe A, et al. Fragmentation dynamics of single agglomerate-to-wall impaction. Powder Technol. 2021;378:561–75.

Mahmoudi S, et al. Fluidisation characteristics of lactose powders in simple turbulent channel flows. Exp Thermal Fluid Sci. 2019;103:201–13.

Singh G, et al. Extending the range of back-lit imaging in two-phase flows using an interrogation-window based method. Measurement. 2021;176: 109155.

Singh G, et al. Effect of inflow conditioning for dry powder inhalers. Int J Pharm. 2021;608: 121085.

Kousaka Y, et al. DISPERSION MECHANISM OF AGGREGATE PARTICLES IN AIR. J Chem Eng Jpn. 1979;12(2):152–9.

Voss A, Finlay WH. Deagglomeration of dry powder pharmaceutical aerosols. Int J Pharm. 2002;248(1):39–50.

Kou X, et al. Powder dispersion mechanisms within a dry powder inhaler using microscale particle image velocimetry. Int J Pharm. 2016;514(2):445–55.

Tong ZB, et al. Discrete Modelling of Powder Dispersion in Dry Powder Inhalers - A Brief Review. Curr Pharm Des. 2015;21(27):3966–73.

Tong ZB, et al. CFD-DEM investigation of the dispersion mechanisms in commercial dry powder inhalers. Powder Technol. 2013;240:19–24.

Wong W, et al. The use of computational approaches in inhaler development. Adv Drug Deliv Rev. 2012;64(4):312–22.

Tong ZB, et al. Numerical study of the effects of particle size and polydispersity on the agglomerate dispersion in a cyclonic flow. Chem Eng J. 2010;164(2):432–41.

Han R, Papadopoulos G, Greenspan BJ. Investigation of powder dispersion inside a SPIROS® dry powder inhaler using particle image velocimetry. Powder Technol. 2002;125(2–3):266–78.

Tong ZB, et al. Numerical investigation of the de-agglomeration mechanisms of fine powders on mechanical impaction. J Aerosol Sci. 2011;42(11):811–9.

Hebbink G et al. Effect of Loaded Dose on Delivered Dose in Dry Powder Inhalers. Available from: https://dfepharma.com/media/tdupjbfj/effect-of-loaded-dose-on-delivered-dose-in-dpi-1.pdf.

Singh G, Kourmatzis A, Masri AR. Volume measurement of atomizing fragments using image slicing. Exp Thermal Fluid Sci 2020;115:10102.

Kourmatzis A, Pham PX, Masri AR. Characterization of atomization and combustion in moderately dense turbulent spray flames. Combust Flame. 2015;162(4):978–96.

Kourmatzis A, Pham PX, Masri AR. A two-angle far-field microscope imaging technique for spray flows. Meas Sci Technol. 2017;28(3): 035302.

Davis J, Goadrich M. The relationship between Precision-Recall and ROC curves. In The 23rd international conference on Machine learning - ICML '06. 2006. Pittsburgh, Pennsylvania: ACM Press.

Funding

This work was funded by the Australian Research Council under Grant Number LP190100842.

Author information

Authors and Affiliations

Contributions

All authors have contributed equally.

Corresponding author

Ethics declarations

Conflict of Interest statement

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Azeem, A., Singh, G., Li, L. et al. Quantifying Agglomerate-to-Wall Impaction in Dry Powder Inhalers. Pharm Res 40, 307–319 (2023). https://doi.org/10.1007/s11095-022-03446-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-022-03446-0