Abstract

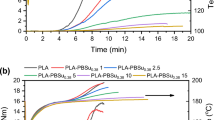

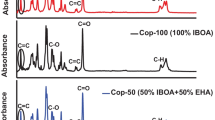

The influence and development of structural modifications through a reactive process between polylactic acid (PLA) and an epoxy-functional copolymer were investigated, resulting in complex long chain branching (LCB) structures in the copolymer architecture. Structural modifications result in improvements in properties of PLA such as the glass transition temperature (Tg) which increases up to 6 °C and the percentage of crystallization (χc) that increases up to 324%. Some of these improvements were reflected in thermal stability increases up to 25 °C. The formation of complex structures of the processed materials were assessed by calorimetric, thermogravimetric and rheological studies.

Similar content being viewed by others

References

Bioplastics E (2018) Bioplastics - facts and figures. European Bioplastics. Institute for Bioplastics and Biocomposites, Hannover

Bioplastics E (2017) Bioplastics market data 2017. European Bioplastics. Institute for Bioplastics and Biocomposites, Hannover

Han T, Xin Z, Shi YQ, Zhao SC, Meng X, Xu H, Zhou S (2015) Control of thermal degradation of poly(lactic acid) using functional polysilsesquioxane microspheres as chain extenders. J Appl Polym Sci 132 (20). Artn 41977. https://doi.org/10.1002/App.41977

Hao Y, Liu Z, Zhang H, Wu Y, Xiao Y, Li Y, Tong Y (2019) Effect of reactive group types on the properties of poly(ethylene octane) toughened poly(lactic acid). J Polym Res 26. https://doi.org/10.1007/s10965-019-1764-y

Zheng L, Geng Z, Zhen W (2019) Preparation, characterization, and reaction kinetics of poly (lactic acid)/amidated graphene oxide nanocomposites based on reactive extrusion process. J Polym Res 26. https://doi.org/10.1007/s10965-019-1722-8

Peng N, Ju Y, Lv R, Na B, Liu Q, Wang B (2016) Toughening biodegradable polylactide with nanopores. J Polym Res 23. https://doi.org/10.1007/s10965-016-1156-5

Zhou Y, Luo L, Liu W, Zeng G, Chen Y (2015) Preparation and characteristic of PC/PLA/TPU blends by reactive extrusion vol 2015. https://doi.org/10.1155/2015/393582

Zhang N, Zeng C, Wang L, Ren J (2012) Preparation and properties of biodegradable poly(lactic acid)/poly(butylene adipate-co-terephthalate) blend with epoxy-functional styrene acrylic copolymer as reactive agent. J Polym Environ 21. https://doi.org/10.1007/s10924-012-0448-z

Frenz VS, Dietrich, Villalobos M; Awojulu AA, Edison M, Van der Meer R (2008) Multifunctional polymers as chain extenders and compatibilizers for polycondensates and biopolymers. Paper presented at the technical conference; 66th, Society of Plastics Engineers: plastics encounter at ANTEC 2008; 2008, Milwaukee, WI,

Blasius WG, Deeter GA, Villalobos MA (2004) Oligomeric chain extenders for processing, post-processing and recycling of condensation polymers, synthesis, compositions and applications. United States Patent

Zhu S, Avakian RW (2012) Heat resistant pla-abs compositions. WIPO Patent,

Karayan V, Villalobos M (2004) Cesa-extend a user friendly technology to enhance reprocessing and recycling of condensation plastics. Paper presented at the global plastics environmental conference 2004, Detroit

Jiji A, Sharika T, Soney CG, Sabu T (2017) Rheological percolation in thermoplastic polymer nanocomposites. Rheol: Open Acess 1(1):1–15

Al-Itry R, Lamnawar K, Maazouz A (2014) Reactive extrusion of PLA, PBAT with a multi-functional epoxide: Physico-chemical and rheological properties. Eur Polym J 58:90–102. https://doi.org/10.1016/j.eurpolymj.2014.06.013

Hale W, Keskkula H, Paul DR (1999) Compatibilization of PBT/ABS blends by methyl methacrylate glycidyl methacrylate ethyl acrylate terpolymers. Polymer 40(2):365–377. https://doi.org/10.1016/S0032-3861(98)00189-X

Gu LL, Xu YW, Fahnhorst GW, Macosko CW (2017) Star vs long chain branching of poly(lactic acid) with multifunctional aziridine. J Rheol 61(4):785–796. https://doi.org/10.1122/1.4985344

Xu H, Fang H, Bai J, Zhang Y, Wang Z (2014) Preparation and characterization of high-melt-strength polylactide with long-chain branched structure through γ-radiation-induced chemical reactions. Ind Eng Chem Res 53(3):1150–1159. https://doi.org/10.1021/ie403669a

Bai J, Fang H, Zhang Y, Wang Z (2014) Studies on crystallization kinetics of bimodal long chain branched polylactides. CrystEngComm 16(12):2452–2461. https://doi.org/10.1039/c3ce42319k

Chen CQ, Ke DM, Zheng TT, He GJ, Cao XW, Liao X (2016) An ultraviolet-induced reactive extrusion to control chain scission and long-chain branching reactions of polylactide. Ind Eng Chem Res 55(3):597–605. https://doi.org/10.1021/acs.iecr.5b04094

Carrasco F, Cailloux J, Sanchez-Jimenez PE, Maspoch ML (2014) Improvement of the thermal stability of branched poly(lactic acid) obtained by reactive extrusion. Polym Degrad Stab 104:40–49. https://doi.org/10.1016/j.polymdegradstab.2014.03.026

Dean KM, Petinakis E, Meure S, Yu L, Chryss A (2012) Melt strength and rheological properties of biodegradable poly(lactic acid) modified via alkyl radical-based reactive extrusion processes. J Polym Environ 20(3):741–747. https://doi.org/10.1007/s10924-012-0461-2

Barletta M, Moretti P, Pizzi E, Puopolo M, Tagliaferri V, Vesco S (2017) Engineering of poly lactic acids (PLAs) for melt processing: material structure and thermal properties. J Appl Polym Sci 134(8). Artn 44504. https://doi.org/10.1002/App.44504

Zhao Z-G, Yang Q, Coates P, Whiteside B, Kelly A, Huang Y-J, Wu P-P (2018) Structure and property of microinjection molded poly(lactic acid) with high degree of Long chain branching. Ind Eng Chem Res 57(33):11312–11322. https://doi.org/10.1021/acs.iecr.8b01597

Tuminello WH (1999) Determining molecular weight distributions from the rheological properties of polymer melts. In: Proc. 71st Soc. Rheol. Meeting, Madison, Wisconsin

Pattamaprom C, Larson RG, Sirivat A (2008) Determining polymer molecular weight distributions from rheological properties using the dual-constraint model. Rheol Acta 47(7):689–700. https://doi.org/10.1007/s00397-008-0264-5

Cao X, Mohamed A, Gordon SH, Willett JL, Sessa DJ (2003) DSC study of biodegradable poly(lactic acid) and poly(hydroxy ester ether) blends. Thermochim Acta 406(1–2):115–127. https://doi.org/10.1016/S0040-6031(03)00252-1

McKee MG, Unal S, Wilkes GL, Long TE (2005) Branched polyesters: recent advances in synthesis and performance. Prog Polym Sci 30(5):507–539. https://doi.org/10.1016/j.progpolymsci.2005.01.009

Phuong VT, Coltelli M-B, Cinelli P, Cifelli M, Verstichel S, Lazzeri A (2014) Compatibilization and property enhancement of poly(lactic acid)/polycarbonate blends through triacetin-mediated interchange reactions in the melt. Polymer 55(17):4498–4513. https://doi.org/10.1016/j.polymer.2014.06.070

Tiwari A, Hihara LH (2009) Thermal stability and thermokinetics studies on silicone ceramer coatings: part 1-inert atmosphere parameters. Polym Degrad Stabil 94(10):1754–1771. https://doi.org/10.1016/j.polymdegradstab.2009.06.010

Van Gurp M, Palmen J (1998) Time-temperature superposition for polymeric blends. Rheol Bull 67(1):5–8

Garcia-Franco CA, Harrington BA, Lohse DJ (2005) On the rheology of ethylene-octene copolymers. Rheol Acta 44(6):591–599. https://doi.org/10.1007/s00397-005-0441-8

Trinkle S, Walter P, Friedrich C (2002) Van Gurp-Palmen plot II – classification of long chain branched polymers by their topology. Rheol Acta 41(1):103–113. https://doi.org/10.1007/s003970200010

Cailloux J, Santana OO, Maspoch ML, Bou JJ, Carrasco F (2015) Using viscoelastic properties to quantitatively estimate the amount of modified poly(lactic acid) chains through reactive extrusion. J Rheol 59(5):1191–1227. https://doi.org/10.1122/1.4928071

Nam GJ, Yoo JH, Lee JW (2005) Effect of long-chain branches of polypropylene on rheological properties and foam-extrusion performances. J Appl Polym Sci 96(5):1793–1800. https://doi.org/10.1002/app.21619

Cailloux J, Santana OO, Franco-Urquiza E, Bou J, Carrasco F, Maspoch M (2014) Sheets of branched poly(lactic acid) obtained by one-step reactive extrusion-calendering process: Physical aging and fracture behavior. J Mater Sci 49. https://doi.org/10.1007/s10853-014-8101-y

Rahalkar RR (1989) Correlation between the crossover modulus and the molecular weight distribution using the Doi-Edwards theory of reptation and the rouse theory. Rheol Acta 28(2):166–175. https://doi.org/10.1007/BF01356977

Baimark Y, Cheerarot O (2015) Effect of chain extension on thermal stability behaviors of polylactide bioplastics. Orient J Chem 31(2):635–641. https://doi.org/10.13005/Ojc/310204

George KA, Chirila TV, Wentrup-Byrne E (2010) Carbodiimide-mediated synthesis of poly(l-lactide)-based networks. Polymer 51(8):1670–1678. https://doi.org/10.1016/j.polymer.2010.02.009

Cooper TR, Storey RF (2008) Poly(lactic acid) and chain-extended poly(lactic acid)-polyurethane functionalized with pendent carboxylic acid groups. Macromolecules 41(3):655–662. https://doi.org/10.1021/ma0707180

Ohya Y, Maruhashi S, Ouchi T (1998) Graft polymerization of l-Lactide on Pullulan through the Trimethylsilyl protection method and degradation of the graft copolymers. Macromolecules 31(14):4662–4665. https://doi.org/10.1021/ma980377d

Corneillie S, Smet M (2015) PLA architectures: the role of branching. Polym Chem-Uk 6(6):850–867. https://doi.org/10.1039/c4py01572j

Acknowledgements

Eduardo Martínez-Mercado acknowledges financial support from CONACyT and Universidad Iberoamericana to carry out his experimental work and his graduate studies.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Martínez-Mercado, E., Ruiz-Treviño, F.A., González-Montiel, A. et al. Long chain branched structures of polylactic acid through reactive extrusion with styrene-acrylic copolymers bearing epoxy functional groups. J Polym Res 26, 260 (2019). https://doi.org/10.1007/s10965-019-1938-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-019-1938-7