Abstract

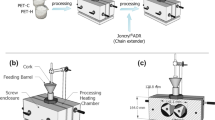

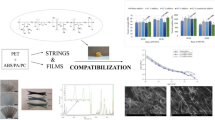

In this study, PBT/recycled-PET blends were developed using a twin-screw extruder. A commercial chain extender (Joncryl ADR 4468) was also used to melt mix with PBT/recycled-PET blend systems. Firstly, Joncryl at different loadings was extruded with recycled-PET to explore the influence of branching on melt behavior and crystallization of PET. The effect of blending recycled-PET with PBT on the final properties was then explored at different blending ratios (25w/75w, 50w/50w and 75w/25w). Similar blends were subsequently prepared while incorporating chain extender. Melt behavior, phase miscibility, crystallization behavior, solid viscoelastic properties, tensile and impact properties of the blends were eventually analyzed using differential scanning calorimeter (DSC), melt flow indexer (MFI), dynamic mechanical analyzer (DMA), and tensile and Izod notched impact testing, respectively. The results showed that the addition of chain extender increased the melt viscosity of PET and at the low contents enhanced the PET’s crystallization rate. On the other hand, the blends of PBT/recycled-PET are fully miscible in the amorphous region whereas the crystalline phases are immiscible subsequent to a fast cooling. The PBT and PET molecules could also co-crystallize and be fully miscible in crystalline phases upon slow cooling of the melt. Blending recycled-PET with PBT didn’t suppress the tensile properties of PBT, however it could enhance the PBT’s ductility and reduce its impact strength. The chain extender didn’t influence the mechanical properties much.

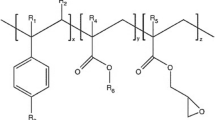

Graphical Abstract

Similar content being viewed by others

References

Utracki LA (2013) Commercial polymer blends. Springer, Dordrecht

Kannan G, Grieshaber SE, Zhao W (2016) Thermoplastic polyesters. In: Olabisi O, Adewale K (eds) Handbook of thermoplastics. CRC Press, pp 319–347

Lepoittevin B, Roger P (2011) Poly(ethylene terephthalate). In: Thomas S, Visakh PM (eds) Handbook of engineering and speciality thermoplastics. Wiley, Scrivener, pp 97–125

Awaja F, Daver F, Kosior E, Cser F (2004) The effect of chain extension on the thermal behaviour and crystallinity of reactive extruded r-PET. J Therm Anal Calorim 78:865–884

Galanty PG, Richardson JJ (1988) Polyethylene terephthalates (PET). In: Engineering plastics. Engineered materials handbook, vol 2. ASM International, Metals Park, pp 172-176

Al-Sabagh AM, Yehia FZ, Eshaq G, Rabie AM, ElMetwally AE (2016) Greener routes for recycling of polyethylene terephthalate. Egypt J Pet 25:53–64

Gourmelon G (2015) Global plastic production rises, recycling lags. New Worldwatch Institute analysis explores trends in global plastic consumption and recycling. Retrived from http://vitalsigns.worldwatch.org/sites/default/files/vital_signs_trend_plastic_full_pdf.pdf

Arena U, Mastellone ML, Perugini F (2003) Life cycle assessment of a plastic packaging recycling system. Int J Life Cycle Assess 8:92–98

Karsli NG (2015) A study on the fracture, mechanical and thermal properties of chain extended recycled poly (ethylene terephthalate). J Thermoplast Composite Mater 30(8):1157–1172

Nofar M, Salehiyan R, Ray SS (2019) Rheology of poly (lactic acid)-based systems. Polym Rev 3:3. https://doi.org/10.1080/15583724.2019.1572185

Nofar M, Park CB (2014) Poly (lactic acid) foaming. Prog Polym Sci 39(10):1721–1741

Rieckmann T, Völker S (2004) Poly (ethylene terephthalate) polymerization–mechanism, catalysis, kinetics, mass transfer and reactor design. In: Scheirs J, Long TE (eds) Modern polyesters: chemistry and technology of polyesters and copolyesters. Wiley, New York, pp 29–115

Awaja F, Daver F, Kosior E (2004) Recycled poly (ethylene terephthalate) chain extension by a reactive extrusion process. Polym Eng Sci 44:1579–1587

Incarnato L, Scarfato P, Di Maio L, Acierno D (2000) Structure and rheology of r-PET modified by reactive extrusion. Polymer 41:6825–6831

Daver F, Gupta R, Kosior E (2008) Rheological characterisation of recycled poly (ethylene terephthalate) modified by reactive extrusion. J Mater Process Technol 204:397–402

Japon S, Boogh L, Leterrier Y, Månson JA (2000) Reactive processing of poly (ethylene terephthalate) modified with multifunctional epoxy-based additives. Polymer 41:5809–5818

Bikiaris DN, Karayannidis GP (1996) Thermomechanical analysis of chain-extended PET and PBT. J Appl Polym Sci 60:55–61

Makkam S, Harnnarongchai W (2014) Rheological and mechanical properties of r-PET modified by reactive extrusion. Energy Procedia 56:547–553

Raffa P, Coltelli MB, Savi S, Bianchi S, Castelvetro V (2012) Chain extension and branching of poly (ethylene terephthalate) (PET) with di-and multifunctional epoxy or isocyanate additives: an experimental and modelling study. React Funct Polym 72:50–60

Rosu RF, Shanks RA, Bhattacharya SN (1999) Shear rheology and thermal properties of linear and branched poly (ethylene terephthalate) blends. Polymer 40:5891–5898

Li G, Yang SL, Jiang JM, Wu CX (2005) Crystallization characteristics of weakly branched poly (ethylene terephthalate). Polymer 46:11142–11148

Nofar M, Zhu W, Park CB, Randall J (2011) Crystallization kinetics of linear and long-chain-branched polylactide. Ind Eng Chem Res 50:13789–13798

Nofar M (2018) Synergistic effects of chain extender and nanoclay on the crystallization behavior of polylactide. Int J Mater Sci Res 1(1):1–8. https://doi.org/10.18689/ijmsr-1000101

Nofar M, Sacligil D, Carreau PJ, Kamal MR, Heuzey MC (2019) Poly (lactic acid) blends: processing, properties and applications. Int J Biol Macromol 125:307–360

Utracki LA, Mukhopadhyay P, Gupta RK (2014) Polymer blends: introduction. Polymer blends handbook. Springer, Berlin, pp 3–170

Barlow JW, Paul DR (1981) Polymer blends and alloys—a review of selected considerations. Polym Eng Sci 21:985–996

Escala A, Stein RS (1979) Crystallization studies of blends of polyethylene terephthalate and polybutylene terephthalate. Polym Eng Sci 37:91–95

Avramova N (1995) Amorphous poly (ethylene terephthalate)/poly (butylene terephthalate) blends: miscibility and properties. Polymer 36:801–808

Ito K, Haraguchi Y, Hayakawa S, Toda A (2008) Enhanced crystallization of blended poly (ethylene terephthalate) and poly (butylene terephthalate). Polym J 40:992

Zhang Z, Feng L, Li Y, Wang Y, Yan C (2015) Nonisothermal crystallization kinetics of poly (butylene terephthalate)/poly (ethylene terephthalate)/glass fiber composites. Polym Compos 36:510–516

Szostak M (2004) Mechanical and thermal properties of PET/PBT blends. Mol Cryst Liq Cryst 416:209–215

Rajakumar PR, Nanthini R (2011) Thermal and morphological behaviours of polybutylene terephthalate/polyethylene terephthalate blend nanocomposites. Rasayan J Chem 4:567–579

Akkapeddi MK (2003) Commercial polymer blends. Polymer blends handbook. Springer, Dordrecht, pp 1023–1115

Aravinthan G, Kale DD (2005) Blends of poly (ethylene terephthalate) and poly (butylene terephthalate). J Appl Polym Sci 98:75–82

Tao J, Jin HF, Sun T (1991) A study on compatibility of PBT/PET binary blended fibre. Plast Rubber Composites Process Appl UK 16:49–53

Lang X, Dong X, Jiyong M, Jing L, Lijuan W (2015) CN Patent No. 102911486 (B). Retrived 13 April 2017

Matthias B, Ulrich P (2014) U.S. Patent No. 2014163156 (A1). Retrieved 13 April 2017

Jin JH, Dae CG, Chul CH, Hyun KS (2013) KR Patent No. 20130021502 (A). Retrieved 13 April 2017

Baxi RN, Pathak SU, Peshwe DR (2010) Mechanical, thermal, and structural characterization of poly(ethylene terephthalate) and poly(butylene terephthalate) blend systems by the addition of postconsumer poly(ethylene terephthalate). J Appl Polym Sci 115:928–934

Rahmat AR, Lim PS, Sin LT, Bee ST, Tee TT (2012) The effects of CE on viscosity and mechanical properties of poly (buthylene terephthalate) blending with recycled poly (ethylene terephthalate)-glass fiber composite. J Appl Sci 12:296–300

Villalobos M, Awojulu A, Greeley T, Turco G, Deeter G (2006) Oligomeric CEs for economic reprocessing and recycling of condensation plastics. Energy 31:3227–3234

Cheng SZD, Pan R, Wunderlich B (1988) Thermal analysis of poly(butylene terephthalate) for heat capacity, rigid amorphous content, and transition behavior. Macromol Chem Phys 189:2443–2458

Wunderlich B (1980) Macromolecular physics, vol 3. Crystal melting. Academic Press, New York

Pospiech D, Häußler L, Korwitz A, Fischer O, Starke S, Jehnichen D, Koppl T, Altstadt V (2012) The miscibility of poly(butyleneterephthalate) (PBT) with phosphorus polyester flame retardants. High Perform Polym 24(1):64–73

Acknowledgment

The authors would like to thank to Arcelik A.S. and Central Research and Development Director Cem Kural, Materials Technologies Research and Development Department Manager Dr. Mustafa Sezer, Polymer & Chemistry Team Leader Dr. Yusuf Yusufoğlu, Research and Development Specialist Ceren Kovanci, Research and Development Technicians Metehan Cihangir and Sefa Yasin Uzen for supporting the research activities conducted in this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nofar, M., Oğuz, H. Development of PBT/Recycled-PET Blends and the Influence of Using Chain Extender. J Polym Environ 27, 1404–1417 (2019). https://doi.org/10.1007/s10924-019-01435-w

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-019-01435-w