Abstract

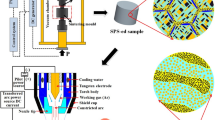

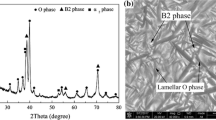

The paper demonstrates the prospects of spark plasma sintering (SPS) for the high-speed diffusion bonding of the high-strength ultrafine-grained (UFG) near-α Ti–5Al–2V alloy. The effect of increased diffusion bonding intensity in the UFG Ti alloys is discussed also. The bonding areas of the UFG near-α Ti–5Al–2V alloy obtained by SPS are featured by high density, strength, and corrosion resistance. The rate of bonding in the UFG alloys has been shown to depend on the heating rate non-monotonously (with a pronounced maximum). At the stage of continuous heating and isothermic holding, the bonding kinetics was found to be determined by the exponential creep rate, the intensity of which in the coarse-grained alloys is limited by the diffusion rate in the crystal lattice α-Ti. In the UFG alloy, the exponential creep processes associated with gliding and climb of dislocations, the activation energy of which corresponds to the diffusion activation energy in the lattice dislocation nuclei, may take place simultaneously with the grain boundary sliding and Coble creep, the activation energy of which corresponds to the grain boundary diffusion activation energy.

Similar content being viewed by others

Notes

In our opinion, the origin of the forming of the TiC nanoparticles is the presence of carbon in the titanium alloy (see Table 1), the concentration of which does not exceed the permissible value but appears to be enough for forming the TiC particles.

The differences in the initial shrinkage level result from the ≈ 0.02 mm difference in the specimen heights.

Since the average grain size in the weld in the UFG alloys was almost the same to the one of the metals outside the weld (Fig. 14), the origin of the reduced weld microhardness in the UFG alloys is still unclear. We think the reduced weld microhardness in the UFG alloys to be related most probably to the grain boundary recovery leading to the reduced density of defects in the UFG alloy grain boundaries. The second probable origin of the increased microhardness of the weld-affected zone in the CG alloys may be the creep (as discussed in more detail below), which is known to be accompanied by the formation of the dislocation substructures and low-angle boundaries [46, 47]. This hypothesis was confirmed by the results of EBSD analysis of the welds for the CG materials (Fig. 10a), in which the low-angle boundaries with the grain boundary angle of less than 2° were observed outside the weld predominantly (Fig. 10b).

The weld specimen was heated at the same rate (100 °С/min) up to 700 °С and then was held at this temperature for 10 min under different values of the uniaxial pressure σs = 50, 70, and 100 MPa (Fig. 21).

References

Lütjering G, Williams JC (2007) Titanium. Springer, Berlin, p 415. https://doi.org/10.1007/978-3-540-73036-1

Burte H (1973) Titanium science and technology. Springer, New York, p 341. https://doi.org/10.1007/978-1-4757-1346-6

Gorynin IV, Chechulin BB (1990) Titan in mechanical engineering. Mashinostroenie, Moscow, p 400 (in Russian)

Bilobrov I, Trachevsky V (2011) Approach to modify the properties of titanium alloys for use in nuclear industry. J Nucl Mater 415(2):222–225. https://doi.org/10.1016/j.jnucmat.2011.05.056

Oryshchenko AS, Gorynin IV, Leonov VP, Kudryavtsev AS, Mikhailov VI, Chudakov EV (2015) Marine titanium alloys: present and future. Inorg Mater Appl Res 6(6):571–579. https://doi.org/10.1134/S2075113315060106

Leonov VP, Gorynin IV, Kudryavtsev AS, Ivanova LA, Travin VV, Lysenko LV (2015) Titanium alloys in steam turbine construction. Inorg Mater Appl Res 6(1):580–590. https://doi.org/10.1134/S2075113315060076

Rodchenkov BS, Kozlov AV, Kuznetsov YuG, Kalinin GM, Strebkov YuS (2007) Irradiation behavior of Ti–4Al–2V (ПT-3B) alloy for ITER blanket modules flexible attachment. J Nucl Mater 367–370:1312–1315. https://doi.org/10.1016/j.jnucmat.2007.03.261

Leonov VP, Chudakov EV, Malinkina YY (2017) The influence of microadditives of ruthenium on the structure, corrosive-mechanical strength, and Fractography of destruction of pseudo-alpha-titanium alloys. Inorg Mater Appl Res 8(4):556–565. https://doi.org/10.1134/S2075113317040165

Kozhevnikov OA, Nesterova EV, Rybin VV, Yarmolovich II (1999) Influence of neutron irradiation of deformability and fracture micromechanisms of titanium α-alloys. J Nucl Mater 271–272:472–477. https://doi.org/10.1016/S0022-3115(98)00803-4

Malinkina YY, Chudakov EV, Leonov VP (2017) The influence of ruthenium on structure, corrosion and mechanical properties, and fatigue characteristics of titanium α-alloys in corrosive environment. Inorg Mater Appl Res 8(6):906–913. https://doi.org/10.1134/S2075113317060090

Semenova IP, Polyakov AV, Raab GI, Lowe TC, Valiev RZ (2012) Enhanced fatigue properties of ultrafine-grained Ti rods processed by ECAP-conform. J Mater Sci 47(22):7777–7781. https://doi.org/10.1007/s10853-012-6675-9

Medvedev A, Ng HP, Lapovok R, Estrin Y, Lowe TC, Anumalasetty VN (2015) Comparison of laboratory-scale and industrial-scale equal channel angular pressing of commercial purity titanium. Mater Lett 145:308–311. https://doi.org/10.1016/j.matlet.2015.01.051

Segal VM (2018) Review: Modes and processes of severe plastic deformation (SPD). Materials 11(7):1175. https://doi.org/10.3390/ma11071175

Chuvil’deev VN, Kopylov VI, Nokhrin AV, Tryaev PV, Kozlova NA, Tabachkova NYu, Lopatin YuG, Ershova AV, Mikhaylov AS, Gryaznov MYu, Chegurov MK (2017) Study of mechanical properties and corrosive resistance of ultrafine-grained α-titanium alloy Ti–5Al–2V. J Alloys Compd 723:354–367. https://doi.org/10.1016/j.jallcom.2017.06.220

Afonso CRM, Amigó A, Stolyarov V, Gunderov D, Amigó V (2017) From porous to dense nanostructured β-Ti alloys through high-pressure torsion. Sci Rep 7(1):13618. https://doi.org/10.1038/s41598-017-13074-z

Zhilyaev AP, Langdon TG (2008) Using high-pressure torsion for metal processing: fundamentals and applications. Prog Mater Sci 53(6):893–979. https://doi.org/10.1016/j.pmatsci.2008.03.002

Straumal BB, Kilmametov AR, Ivanisenko Y, Mazilkin AA, Valiev RZ, Afonikova NS, Gornakova AS, Hahn H (2018) Diffusive and displacive phase transitions in Ti–Fe and Ti–Co alloys under high pressure torsion. J Alloys Compd 735:2281–2286. https://doi.org/10.1016/j.jallcom.2017.11.317

Kilmametov AR, Ivanisenko Y, Mazilkin AA, Straumal BB, Gornakova AS, Fabrichnaya OB, Kriegel MJ, Rafaja D, Hahn H (2018) The α → ω and β → ω phase transformations in Ti–Fe under high-pressure torsion. Acta Mater 144:337–351. https://doi.org/10.1016/j.actamat.2017.10.051

Zherebtsov S, Murzinova M, Salishev G, Semiatin SL (2011) Spheroidization of the lamellar microstructure in Ti–6Al–4V alloy during warm deformation and annealing. Acta Mater 59(10):4138–4150. https://doi.org/10.1016/j.actamat.2011.03.037

Zherebtsov S, Kudryavtsev E, Kostjuchenko S, Malysheva S, Salishchev GA (2012) Strength and ductility-related properties of ultrafine-grained two-phase titanium alloy produced by warm multiaxial forging. Mater Sci Eng A 536:190–196. https://doi.org/10.1016/j.msea.2011.12.102

Pachla W, Kulczyk M, Prybysz S, Skiba J, Wojciechowski K, Przybysz M, Topolski K, Sobolewski A, Charkiewicz M (2015) Effect of severe plastic deformation realized by hydrostatic extrusion and rotary swaging on the properties of CP Ti grade 2. J Mater Process Technol 221:255–268. https://doi.org/10.1016/j.jmatprotec.2015.02.027

Seixas MR, Bortolini C, Pereira A, Nakazato RZ, Popat KC, Alves Claro APR (2018) Development of new quaternary alloy Ti–25Ta–25Nb–3Sn for biomedical applications. Mater Res Exp 5(2):025402. https://doi.org/10.1088/2053-1591/aa87c8

Topol’s’kyi VP, Petrychenko IK, Akhonin SV, Mishchenko RM (2008) Weldability of T110 high-strength titanium alloy. Mater Sci 44(3):413–417. https://doi.org/10.1007/s11003-008-9098-7

Lukoyanov AV (2014) Formation of pores in the weld metal in automatic argon-shielded arc welding of titanium alloys. Weld Int 28(4):301–303. https://doi.org/10.1080/09507116.2013.796682

Gao F, Li P, Jiang P, Liao Z (2018) The effect of constraint conditions on microstructure and properties of titanium alloy electron beam welding. Mater Sci Eng A 721:117–124. https://doi.org/10.1016/j.msea.2018.02.069

Su M-L, Li J-N, Liu K-G, Qi W-J, Weng F, Zhang Y-B, Li J-S (2019) Mechanical property and characterization of TA1 titanium alloy sheets welded by vacuum electron beam welding. Vacuum 159:315–318. https://doi.org/10.1016/j.vacuum.2018.10.027

Sanders DG, Ramulu M (2004) Examination of superplastic forming combined with diffusion bonding for titanium: perspective from experience. J Mater Eng Perform 13(6):744–752. https://doi.org/10.1361/10599490421574

Aydin K, Kaya Y, Kahraman N (2012) Experimental study of diffusion welding/bonding of titanium to copper. Mater Des 37:356–368. https://doi.org/10.1016/j.matdes.2012.01.026

Mironov S, Sato YS, Kokawa H (2018) Friction-stir welding and processing of Ti–6Al–4V titanium alloy: a review. J Mater Sci Technol 34(1):58–72. https://doi.org/10.1016/j.jmst.2017.10.018

Shaysultanov D, Stepanov N, Malopheyev S, Vysotskiy I, Sanin V, Mironov S, Kaibyshev R, Salishchev G, Zherebtsov SV (2018) Friction stir welding of a carbon-doped CoCrFeNiMn high-entropy alloy. Mater Charact 145:353–361. https://doi.org/10.1016/j.matchar.2018.08.063

Rai R, De A, Bhadeshia HKDH, BebRoy T (2011) Review: friction stir welding tools. Sci Technol Weld Joing 16(4):325–342. https://doi.org/10.1179/1362171811Y.0000000023

Ermachenko AG, Lutfullin R Ya, Mulyukov RR (2011) Advanced technologies of processing titanium alloys and their applications in industry. Rev Adv Mater Sci 29(1):68–82

Kaibyshev OA, Lutfullin RA, Berdin VK (1994) The effect of superplasticity on the solid state weldability of the titanium alloy Ti4.5Al3Mo–1V. Acta Metall Mater 42(8):2609–2615. https://doi.org/10.1016/0956-7151(94)90202-X

Olevsky E, Dudina D (2018) Field-assisted sintering. Springer, Berlin. https://doi.org/10.1007/978-3-319-76032-2

Hulbert DM, Anders A, Dudina DV, Anderson J, Jiang D, Unuvar C, Anselmi-Tamburini U, Lavernia EJ (2008) The absence of plasma in “spark plasma sintering”. J Appl Phys 104(3):033305. https://doi.org/10.1063/1.2963701

Tokita M (2013) Spark plasma sintering (SPS) method, systems, and applications, chapter 11.2.3. In: Somiya S (ed) Handbook of advanced ceramics, 2nd edn. Academic Press, pp 1149–1177. https://dx.doi.org/10.1016/B978-0-12-385469-8.00060-5

Munir ZA, Anselmi-Tamburini U, Ohyanagi M (2006) The effect of electric field and pressure on the synthesis and consolidation materials: a review of the spark plasma sintering method. J Mater Sci 41(3):763–777. https://doi.org/10.1007/s10853-006-6555-2

Chuvil’deev VN, Panov DV, Boldin MS et al (2015) Structure and properties of advanced materials obtained by spark plasma sintering. Acta Astronaut 109:172–176. https://doi.org/10.1016/j.actaastro.2014.11.008

Long Y, Zhang H, Wang T, Huang X, Li Y, Wu J, Chen H (2013) High-strength Ti–6Al–4V with ultrafine-grained structure fabricated by high energy ball milling and spark plasma sintering. Mater Sci Eng A 585:408–414. https://doi.org/10.1016/j.msea.2013.07.078

Karakozov BK, Skakov MK, Kurbanbekov SR, Baklanov VV, Sintnikov AA, Dudina DV, Maly VI, Yakovlev VI (2018) Structural and phase transformations in alloys during spark plasma sintering of Ti + 23.5at.%Al + 21at.%Nb powder mixtures. Inorg Mater 54(1):37–41. https://doi.org/10.1134/S0020168518010053

Weston NS, Derguti F, Tudball A, Jackson M (2015) Spark plasma sintering of commercial and development titanium alloys powders. J Mater Sci 50(14):4860–4878. https://doi.org/10.1007/s10853-015-9029-6

Chuvil’deev VN, Boldin MS, Dyatlova YaG et al (2015) A comparative study of the hot pressing and spark plasma sintering of Al2O3–ZrO2–Ti(C, N) powders. Inorg Mater 51(10):1047–1053. https://doi.org/10.1134/S0020168515090034

Chuvil’deev VN, Nokhrin AV, Boldin MS, Baranov GV, Sakharov NV, Belov VYu, Lantsev EA, Popov AA, Melekhin NV, Lopatin YuG, Blagoveshchenskiy YuV, Isaeva NV (2019) Impact of mechanical activation on sintering kinetics and mechanical properties of ultrafine-grained 95W–Ni–Fe tungsten heavy alloys. J Alloys Compd 773:666–688. https://doi.org/10.1016/j.jallcom.2018.09.176

Chuvil’deev VN, Blagoveshchenskiy YuV, Nokhrin AV et al (2017) Spark plasma sintering of tungsten carbide nanopowders obtained through DC arc plasma synthesis. J Alloys Compd 708:547–561. https://doi.org/10.1016/j.jallcom.2017.03.035

Rahaman MN (2003) Ceramic processing and sintering, 2nd edn. Marcel Dekker Inc., New York, p 876

Derby B, Ashby MF (1987) A microstructural model for primary creep. Acta Metall 35:1349–1353. https://doi.org/10.1016/0001-6160(87)90017-4

Ashby MF (1983) Mechanisms of deformation and fracture. Adv Appl Mech 23:117–177. https://doi.org/10.1016/S0065-2156(08)70243-6

Frost HJ, Ashby MF (1982) Deformation-mechanism maps. Pergamon Press, London, p 328

Kral P, Dvorak J, Zherebtsov S, Salishchev G, Kvapilova M, Sklenicka V (2013) Effect of severe plastic deformation of creep behaviour of a Ti–6Al–4V alloy. J Mater Sci 48:4789–4795. https://doi.org/10.1007/s10853-013-7160-9

Stepanova E, Grabovetskaya G, Zabudchenko O (2018) Hydrogen effect on the creep of titanium alloy of the Ti–Al–V system. Defect Diffus Forum 385:212–217. https://doi.org/10.4028/www.scientific.net/DDF.385.212

Kolobov YuR, Grabovetskaya GP, Ivanov KV, Valiev RZ, Zhu YT (2004) Grain boundary diffusion and creep of UFG Ti and Ti–6Al–4V alloy processed by severe plastic deformation. In: YT Zhu, TG Langdon, RZ Valiev, S Semiatin et al (eds) Proceedings of “ultrafine grained materials III”, pp 621–628

Dudarev EF, Grabovetskaya GP, Kolobov YuR, Bakach GP, Kashin OA, Zhu TYu (2004) Deformation behavior and mechanical properties of ultrafine-grained titanium produced by equal-channel angular pressing. Russ Metall (Metally) 2004(1):45–82 (in Russian)

Luo L, Zhao X, Liu X, Yang X (2017) Creep behavior of UFG CP Ti at room temperature. IOP Conf Ser Mater Sci Eng 250(1):012062. https://doi.org/10.1088/1757-899X/250/1/012062

Liu X, Zhang Q, Zhao X, Yang X, Luo L (2016) Ambient-temperature nanoindentation creep in ultrafine-grained titanium processed by ECAP. Mater Sci Eng A 676:73–79. https://doi.org/10.1016/j.msea.2016.08.111

Coble RL (1963) A model for boundary diffusion controlled creep in polycrystalline materials. J Appl Phys 34:1679–1682. https://doi.org/10.1063/1.1702656

Nieh TG, Wadsworth D, Sherby OD (1997) Superplasticity in metals and ceramics. Cambridge University Press, Cambridge

Perevezentsev VN, Rybin VV, Chuvil’deev VN (1992) The theory of structural superplasticity: I. The physical nature of the superplasticity phenomenon. Acta Metall Mater 40(5):887–894. https://doi.org/10.1016/0956-7151(92)90065-M

Young WS, Culter IB (1970) Initial sintering with constant rates of heating. J Am Ceram Soc 53(12):659–663. https://doi.org/10.1111/j.1151-2916.1970.tb12036.x

Nanda Kumar AK, Watabe M, Kurokawa K (2011) The sintering kinetics of ultrafine tungsten carbide powders. Ceram Int 37:2643–2654. https://doi.org/10.1016/j.ceramint.2011.04.011

Nanda Kumar AK, Watabe M, Kurokawa K (2012) The influence of Si on the microstructure and sintering behavior of ultrafine WC. Philos Mag 92(32):3950–3967. https://doi.org/10.1080/14786435.2012.700127

Chuvil’deev VN, Kopylov VI, Nokhrin AV, Lopatin YuG, Kozlova NA, Tabachkova NYu, Semenycheva AV, Smirnova ES, Gryaznov MYu, Pirozhnikova OE (2015) The effect of the state of grain boundaries on the thermal stability of the structure of a submicrocrystalline titanium alloy. Tech Phys Lett 41(6):515–518. https://doi.org/10.1134/S1063785015060024

Acknowledgements

This study was performed with the support of the Russian Science Foundation (Grant No. 16-13-00066). The authors thank A.V. Piskunov and N.V. Sakharov (Lobachevsky Univ.) for developing the methods of EBSD analysis of the titanium alloy joints. The authors thank E.A. Lantsev (Lobachevsky Univ.) for conducting the tests in order to measure the temperature–shrinkage dependencies L0(T) without a specimen using Dr. Sinter® SPS-625 setup in different heating modes. The authors thank Afrikantov OKB Mechanical Engineering JSC for performing the argon-arc and electron-beam welding of the UFG alloy specimens.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also form a part of an ongoing study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chuvil’deev, V.N., Nokhrin, A.V., Kopylov, V.I. et al. Spark plasma sintering for high-speed diffusion bonding of the ultrafine-grained near-α Ti–5Al–2V alloy with high strength and corrosion resistance for nuclear engineering. J Mater Sci 54, 14926–14949 (2019). https://doi.org/10.1007/s10853-019-03926-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-03926-6