Abstract

During soldering and service, intermetallic compounds (IMCs) have an important impact on the performance and reliability of electronic products. A thin and continuous intermetallic layer facilitates the formation of reliable solder joints and improves the creep and fatigue resistance of solder joints. However, if the IMCs overgrow, the coarse IMC becomes brittle and tends to crack under stress, leading to a decrease in solder joint reliability. Based on the latest developments in the field of lead-free solders at home and abroad, this paper comprehensively reviews the interfacial reaction between SnAgCu Pb-free solders and different substrates and the growth behavior of IMCs and clarifies the growth mechanism of interfacial IMCs. The effects of the modification measures of lead-free solder on the IMCs and reliability of SnAgCu/substrate interface are analyzed, which provide a theoretical basis for the development and application of new lead-free solder.

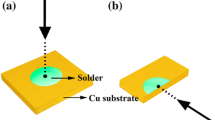

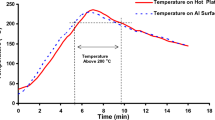

Adapted from Ref. [18] with permission from Elsevier

Adapted from Ref. [26] with permission from Springer

Adapted from Ref. [38] with permission from Elsevier

Adapted from Ref. [39] with permission from Elsevier

Adapted from Ref. [45] with permission from Elsevier

Adapted from Ref. [54] with permission from Elsevier

Adapted from Ref. [60] with permission from Elsevier

Adapted from Ref. [73] with permission from Elsevier

Adapted from Ref. [85] with permission from Elsevier

Adapted from Ref. [91] with permission from Elsevier

Adapted from Ref. [101] with permission from Elsevier

Adapted from Ref. [101] with permission from Elsevier

Adapted from Ref. [103] with permission from Elsevier

Adapted from Ref. [107] with permission from Elsevier

Adapted from Ref. [120] with permission from Springer

Adapted from Ref. [124] with permission from Elsevier

Adapted from Ref. [132] with permission from Elsevier

Adapted from Ref. [133] with permission from Elsevier

Adapted from Ref. [138] with permission from Elsevier

Similar content being viewed by others

References

Tan AT, Tan AW, Yusof F (2015) Influence of nanoparticle addition on the formation and growth of intermetallic compounds (IMCs) in Cu/Sn–Ag–Cu/Cu solder joint during different thermal conditions. Sci Technol Adv Mater 16(3):033505

Xu T, Hu X, Li Y et al (2017) The growth behavior of interfacial intermetallic compound between Sn–3.5 Ag–0.5 Cu solder and Cu substrate under different thermal-aged conditions. J Mater Sci: Mater Electron 28(24):18515–18528

Yang M, Li M, Kim J (2012) Texture evolution and its effects on growth of intermetallic compounds formed at eutectic Sn37Pb/Cu interface during solid-state aging. Intermetallics 31:177–185

Xue P, Xue S, Shen Y et al (2012) Study on properties of Sn–9Zn–Ga solder bearing Nd. J Mater Sci: Mater Electron 23(6):1272–1278

Zhang L, Cui J, Han J et al (2014) Finite element analysis of SnAgCu (Zn Co, Fe) lead-free solder joints for electronic packaging. Int J Nonlinear Sci Numer Simul 15(3–4):197–206

Wang H, Xue S, Zhao F et al (2010) Effects of Ga, Al, Ag, and Ce multi-additions on the properties of Sn–9Zn lead-free solder. J Mater Sci: Mater Electron 21(2):111–119

Xue P, Xue S, Shen Y et al (2014) Inhibiting the growth of Sn whisker in Sn-9Zn lead-free solder by Nd and Ga. J Mater Sci: Mater Electron 25(6):2671–2675

Haseeb A, Arafat MM, Johan MR (2012) Stability of molybdenum nanoparticles in Sn–3.8 Ag–0.7 Cu solder during multiple reflow and their influence on interfacial intermetallic compounds. Mater Charact 64:27–35

Li JF, Agyakwa PA, Johnson CM (2012) Effect of trace Al on growth rates of intermetallic compound layers between Sn-based solders and Cu substrate. J Alloy Compd 545:70–79

Zeng G, Xue S, Zhang L et al (2010) A review on the interfacial intermetallic compounds between Sn–Ag–Cu based solders and substrates. J Mater Sci: Mater Electron 21(5):421–440

Sun L, Zhang L, Zhong S et al (2015) Reliability study of industry Sn3.0Ag0.5Cu/Cu lead-free soldered joints in electronic packaging. J Mater Sci: Mater Electron 26(11):9164–9170

Chuang CM, Lin KL (2003) Effect of microelements addition on the interfacial reaction between Sn-Ag-Cu solders and the Cu substrate. J Electron Mater 32(12):1426–1431

Ma X, Qian Y, Yoshida F (2002) Effect of La on the Cu–Sn intermetallic compound (IMC) growth and solder joint reliability. J Alloy Compd 334(1–2):224–227

Wang YW, Chang CC, Kao CR (2009) Minimum effective Ni addition to SnAgCu solders for retarding Cu3Sn growth. J Alloy Compd 478(1–2):L1–L4

Wu CML, Yu DQ, Law CMT et al (2004) Properties of lead-free solder alloys with rare earth element additions. Mater Sci Eng: R: Rep 44(1):1–44

Zhang L, Xue S, Gao L et al (2009) Effects of rare earths on properties and microstructures of lead-free solder alloys. J Mater Sci: Mater Electron 20(8):685–694

Law CMT, Wu CML, Yu DQ et al (2006) Microstructure, solderability, and growth of intermetallic compounds of Sn–Ag–Cu–RE lead-free solder alloys. J Electron Mater 35(1):89–93

Zhang L, Xue SB, Zeng G et al (2012) Interface reaction between SnAgCu/SnAgCuCe solders and Cu substrate subjected to thermal cycling and isothermal aging. J Alloy Compd 510(1):38–45

Lee TY, Choi WJ, Tu KN et al (2002) Morphology, kinetics, and thermodynamics of solid-state aging of eutectic SnPb and Pb-free solders (Sn–3.5 Ag, Sn–3.8 Ag–0.7 Cu and Sn–0.7 Cu) on Cu. J Mater Res 17(2):291–301

Tu X, Yi D, Wu J et al (2017) Influence of Ce addition on Sn-3.0 Ag-0.5 Cu solder joints: thermal behavior, microstructure and mechanical properties. J Alloy Compd 698:317–328

Chriaštel’ová J, Trnková LR, Dimová KP et al (2011) Reaction of liquid Sn–Ag–Cu–Ce solders with solid copper. J Electron Mater 40(9):1956–1961

Xujing N, Songbai X, Peizhuo Z et al (2016) Effect of Pr addition on properties of Sn-0.5Ag-0.7 Cu-0.5 Ga lead-free solder. J Electron Mater 45(10):5443–5448

Zeng G, Xue S, Zhang L et al (2011) Properties and microstructure of Sn–0.7 Cu–0.05 Ni solder bearing rare earth element Pr. J Mater Sci: Mater Electron 22(8):1101–1108

Xiao Z, Xue S, Hu Y et al (2011) Properties and microstructure of Sn-9Zn lead-free solder alloy bearing Pr. J Mater Sci: Mater Electron 22(6):659–665

Wang H, Xue S, Wang JX (2017) Study on the microstructure and properties of low-Ag Sn–0.3 Ag–0.7 Cu–0.5 Ga solder alloys bearing Pr. J Mater Sci: Mater Electron 28(11):8246–8254

Gao L, Xue S, Zhang L et al (2010) Effect of praseodymium on the microstructure and properties of Sn3. 8Ag0. 7Cu solder. J Mater Sci: Mater Electron 21(9):910–916

Li B et al (2005) Effect of rare earth element addition on the microstructure of Sn–Ag–Cu solder joint. J Electron Mater 34(3):217–224

Gao L, Xue S, Zhang L et al (2010) Effects of trace rare earth Nd addition on microstructure and properties of SnAgCu solder. J Mater Sci: Mater Electron 21(7):643–648

Ye H, Xue S, Luo J et al (2013) Properties and interfacial microstructure of Sn–Zn–Ga solder joint with rare earth Pr addition. Mater Des 46:816–823

Zhang L, Yang F, Zhong S (2016) Whisker growth on SnAgCu–xPr solders in electronic packaging. J Mater Sci: Mater Electron 27(6):5618–5621

Wu J, Xue S, Wang J et al (2017) Effect of Pr addition on properties and Sn whisker growth of Sn–0.3 Ag–0.7 Cu low-Ag solder for electronic packaging. J Mater Sci: Mater Electron 28(14):10230–10244

Choi H, Kaplan WD, Choe H (2016) Effect of yttrium on the fracture strength of the Sn-1.0 Ag-0.5 Cu solder joints. J Electron Mater 45(7):3259–3262

Hao H, Tian J, Shi YW et al (2007) Properties of Sn3. 8Ag0. 7Cu solder alloy with trace rare earth element Y additions. J Electron Mater 36(7):766–774

Wu CML, Yu DQ, Law CMT et al (2002) Microstructure and mechanical properties of new lead-free Sn-Cu-RE solder alloys. J Electron Mater 31(9):928–932

Xia Z, Chen Z, Shi Y et al (2002) Effect of rare earth element additions on the microstructure and mechanical properties of tin-silver-bismuth solder. J Electron Mater 31(6):564–567

Chen Q, Li G (2010) Effects of dopants on wettability and microstructure evolution of lead-free solder joints. In: Electronic packaging technology and high density packaging (ICEPT-HDP), 2010 11th international conference on. IEEE, 2010, 314–318

Zhang L, Fan X, Guo Y et al (2014) Properties enhancement of SnAgCu solders containing rare earth Yb. Mater Des 57:646–651

Shi Y, Tian J, Hao H et al (2008) Effects of small amount addition of rare earth Er on microstructure and property of SnAgCu solder. J Alloy Compd 453(1–2):180–184

Liu Ping, Yao Pei, Liu Jim (2009) Evolutions of the interface and shear strength between SnAgCu–xNi solder and Cu substrate during isothermal aging at 150 C. J Alloy Compd 486(1-2):474–479

Tu KN, Thompson RD (1982) Kinetics of interfacial reaction in bimetallic CuSn thin films. Acta Metall 30(5):947–952

Gao F, Takemoto T, Nishikawa H (2006) Effects of Co and Ni addition on reactive diffusion between Sn–3.5 Ag solder and Cu during soldering and annealing. Mater Sci Eng, A 420(1–2):39–46

Laurila T, Vuorinen V, Kivilahti JK (2005) Interfacial reactions between lead-free solders and common base materials. Mater Sci Eng R: Rep 49(1–2):1–60

Cheng HK, Huang CW, Lee H et al (2015) Interfacial reactions between Cu and SnAgCu solder doped with minor Ni. J Alloy Compd 622:529–534

Tay SL, Haseeb A, Johan MR et al (2013) Influence of Ni nanoparticle on the morphology and growth of interfacial intermetallic compounds between Sn-3.8Ag-0.7Cu lead-free solder and copper substrate. Intermetallics 33:8–15

El-Daly AA, Hammad AE, Al-Ganainy GS et al (2014) Influence of Zn addition on the microstructure, melt properties and creep behavior of low Ag-content Sn–Ag–Cu lead-free solders. Mater Sci Eng, A 608:130–138

El-Daly AA, Hammad AE, Al-Ganainy GS et al (2014) Properties enhancement of low Ag-content Sn–Ag–Cu lead-free solders containing small amount of Zn. J Alloy Compd 614:20–28

Cho MG, Kang SK, Shih DY et al (2007) Effects of minor additions of Zn on interfacial reactions of Sn–Ag–Cu and Sn–Cu solders with various Cu substrates during thermal aging. J Electron Mater 36(11):1501–1509

Mayappan R, Yahya I, Ab Ghani NA et al (2014) The effect of adding Zn into the Sn–Ag–Cu solder on the intermetallic growth rate. J Mater Sci: Mater Electron 25(7):2913–2922

Kotadia HR, Mokhtari O, Clode MP et al (2012) Intermetallic compound growth suppression at high temperature in SAC solders with Zn addition on Cu and Ni–P substrates. J Alloy Compd 511(1):176–188

Kotadia HR, Mokhtari O, Bottrill M et al (2010) Reactions of Sn-3.5Ag-based solders containing Zn and Al additions on Cu and Ni (P) substrates. J Electron Mater 39(12):2720–2731

Yang SC, Ho CE, Chang CW et al (2007) Massive spalling of intermetallic compounds in solder-substrate reactions due to limited supply of the active element. J Appl Phys 101(8):084911

El-Daly AA, El-Hosainy H, Elmosalami TA et al (2015) Microstructural modifications and properties of low-Ag-content Sn–Ag–Cu solder joints induced by Zn alloying. J Alloy Compd 653:402–410

Chen BL, Li GY (2004) Influence of Sb on IMC growth in Sn–Ag–Cu–Sb Pb-free solder joints in reflow process. Thin Solid Films 462:395–401

Tang Y, Pang Y C, Zhan J X, et al. Effects of Sb addition on grain ripening growth at interface of Sn–Ag–Cu–xSb/Cu in wetting reactions. In: Electronic packaging technology and high density packaging (ICEPT-HDP), 2012 13th international conference on. IEEE, 2012: 219–223

Yang M, Ji H, Wang S et al (2016) Effects of Ag content on the interfacial reactions between liquid Sn–Ag–Cu solders and Cu substrates during soldering. J Alloy Compd 679:18–25

Yang M, Ko YH, Bang J et al (2017) Effects of Ag addition on solid–state interfacial reactions between Sn–Ag–Cu solder and Cu substrate. Mater Charact 124:250–259

Ma X, Wang F, Qian Y et al (2003) Development of Cu-Sn intermetallic compound at Pb-free solder/Cu joint interface. Mater Lett 57(22–23):3361–3365

El-Daly AA, El-Taher AM, Gouda S (2015) Development of new multicomponent Sn–Ag–Cu–Bi lead-free solders for low-cost commercial electronic assembly. J Alloy Compd 627:268–275

Zhao J, Cheng C, Qi L et al (2009) Kinetics of intermetallic compound layers and shear strength in Bi-bearing SnAgCu/Cu soldering couples. J Alloy Compd 473(1–2):382–388

Perkins LS, DePristo AE (1995) The influence of lattice distortion on atomic self-diffusion on fcc (001) surfaces: Ni, Cu, Pd, Ag. Surf Sci 325(1–2):169–176

Van Loo FJJ (1990) Multiphase diffusion in binary and ternary solid-state systems. Prog Solid State Chem 20(1):47–99

Qi L, Zhao J, Wang X, et al. The effect of Bi on the IMC growth in Sn-3Ag-0.5 Cu solder interface during aging process. In: Business of electronic product reliability and liability, 2004 international conference on. IEEE, 2004, 42–46

Li G, Shi X (2006) Effects of bismuth on growth of intermetallic compounds in Sn–Ag–Cu Pb-free solder joints. Trans Nonferr Met Soc China 16:s739–s743

Choi WK, Lee HM (2000) Effect of soldering and aging time on interfacial microstructure and growth of intermetallic compounds between Sn-3.5 Ag solder alloy and Cu substrate. J Electron Mater 29(10):1207–1213

Hodúlová E, Palcut M, Lechovič E et al (2011) Kinetics of intermetallic phase formation at the interface of Sn–Ag–Cu–X (X = Bi, In) solders with Cu substrate. J Alloy Compd 509(25):7052–7059

Liu X, Huang M, Zhao N et al (2014) Liquid-state and solid-state interfacial reactions between Sn–Ag–Cu–Fe composite solders and Cu substrate. J Mater Sci: Mater Electron 25(1):328–337

Schaefer M, Fournelle RA, Liang J (1998) Theory for intermetallic phase growth between Cu and liquid Sn–Pb solder based on grain boundary diffusion control. J Electron Mater 27(11):1167–1176

Yu DQ, Wang L (2008) The growth and roughness evolution of intermetallic compounds of Sn–Ag–Cu/Cu interface during soldering reaction. J Alloy Compd 458(1–2):542–547

Wang YW, Lin YW, Tu CT et al (2009) Effects of minor Fe Co, and Ni additions on the reaction between SnAgCu solder and Cu. J Alloy Compd 478(1–2):121–127

Sun L, Zhang L, Xu L et al (2016) Effect of nano-Al addition on properties and microstructure of low-Ag content Sn-1Ag-0.5 Cu solders. J Mater Sci: Mater Electron 27(7):7665–7673

Sun L, Chen M, Wei C et al (2018) Effect of thermal cycles on interface and mechanical property of low-Ag Sn1. 0Ag0. 5Cu (nano-Al)/Cu solder joints. J Mater Sci: Mater Electron 29(12):9757–9763

Zhang QK, Long WM, Yu XQ et al (2015) Effects of Ga addition on microstructure and properties of Sn–Ag–Cu/Cu solder joints. J Alloy Compd 622:973–978

Luo D, Xue S, Li Z (2014) Effects of Ga addition on microstructure and properties of Sn–0.5 Ag–0.7 Cu solder. J Mater Sci: Mater Electron 25(8):3566–3571

Sisamouth L, Hamdi M, Ariga T (2010) Investigation of gap filling ability of Ag–Cu–In brazing filler metals. J Alloy Compd 504(2):325–329

Yu AM, Lee CW, Kim MS et al (2007) The effect of the addition of in on the reaction and mechanical properties of Sn − 1.0 Ag − 0.5 Cu solder alloy. Met Mater Int 13(6):517

Tian S, Li S, Zhou J et al (2017) Effect of indium addition on interfacial IMC growth and bending properties of eutectic Sn–0.7 Cu solder joints. J Mater Sci: Mater Electron 28(21):16120–16132

Li LF, Cheng YK, Xu GL et al (2014) Effects of indium addition on properties and wettability of Sn–0.7 Cu–0.2 Ni lead-free solders. Mater Des 64:15–20

Šebo P, Moser Z, Švec P et al (2009) Effect of indium on the microstructure of the interface between Sn3. 13Ag0. 74CuIn solder and Cu substrate. J Alloy Compd 480(2):409–415

Sharif A, Chan YC (2005) Effect of indium addition in Sn-rich solder on the dissolution of Cu metallization. J Alloy Compd 390(1–2):67–73

Henderson DW, Gosselin T, Sarkhel A et al (2002) Ag 3 Sn plate formation in the solidification of near ternary eutectic Sn–Ag–Cu alloys. J Mater Res 17(11):2775–2778

Lucas JP, Rhee H, Guo F et al (2003) Mechanical properties of intermetallic compounds associated with Pb-free solder joints using nanoindentation. J Electron Mater 32(12):1375–1383

Wu RW, Tsao LC, Chen RS (2015) Effect of 0.5 wt% nano-TiO2 addition into low-Ag Sn0.3Ag0.7Cu solder on the intermetallic growth with Cu substrate during isothermal aging. J Mater Sci: Mater Electron 26(3):1858–1865

Leong JC, Tsao LC, Fang CJ et al (2011) Effect of nano-TiO2 addition on the microstructure and bonding strengths of Sn3. 5Ag0. 5Cu composite solder BGA packages with immersion Sn surface finish. J Mater Sci: Mater Electron 22(9):1443–1449

Tang Y, Li GY, Pan YC (2013) Influence of TiO2 nanoparticles on IMC growth in Sn-3.0Ag-0.5 Cu-xTiO2 solder joints in reflow process. J Alloy Compd 554:195–203

Tsao LC (2011) Suppressing effect of 0.5 wt% nano-TiO2 addition into Sn-3.5Ag-0.5 Cu solder alloy on the intermetallic growth with Cu substrate during isothermal aging. J Alloy Compd 509(33):8441–8448

Tsao LC, Chu CP, Peng SF (2011) Study of interfacial reactions between Sn3. 5Ag0.5Cu composite alloys and Cu substrate. Microelectron Eng 88(9):2964–2969

Li ZL, Li GY, Cheng LX et al (2016) Effect of nano-TiO2 addition on microstructural evolution of small solder joints. J Mater Sci: Mater Electron 27(6):6076–6087

Li Y, Zhao XC, Liu Y et al (2014) Effect of TiO2 addition concentration on the wettability and intermetallic compounds growth of Sn3.0Ag0.5Cu-xTiO2 nano-composite solders. J Mater Sci: Mater Electron 25(9):3816–3827

Wen Y, Zhao X, Chen Z et al (2017) Reliability enhancement of Sn-1.0Ag-0.5Cu nano-composite solders by adding multiple sizes of TiO2 nanoparticles. J Alloy Compd 696:799–807

Gain AK, Chan YC (2014) Growth mechanism of intermetallic compounds and damping properties of Sn-Ag-Cu-1 wt% nano-ZrO2 composite solders. Microelectron Reliab 54(5):945–955

Gain AK, Fouzder T, Chan YC et al (2011) Microstructure, kinetic analysis and hardness of Sn-Ag-Cu-1 wt% nano-ZrO2 composite solder on OSP-Cu pads. J Alloy Compd 509(7):3319–3325

Tsao LC (2011) Evolution of nano-Ag3Sn particle formation on Cu-Sn intermetallic compounds of Sn3. 5Ag0.5Cu composite solder/Cu during soldering. J Alloy Compd 509(5):2326–2333

Chang SY, Tsao LC, Wu MW et al (2012) The morphology and kinetic evolution of intermetallic compounds at Sn–Ag–Cu solder/Cu and Sn–Ag–Cu-0.5Al2O3 composite solder/Cu interface during soldering reaction. J Mater Sci: Mater Electron 23(1):100–107

Tsao LC, Wu MW, Chang SY (2012) Effect of TiO2 nanoparticles on the microstructure and bonding strengths of Sn0. 7Cu composite solder BGA packages with immersion Sn surface finish. J Mater Sci: Mater Electron 23(3):681–687

Tsao LC, Chang SY, Lee CI et al (2010) Effects of nano-Al2O3 additions on microstructure development and hardness of Sn3.5Ag0.5Cu solder. Mater Des 31(10):4831–4835

Chuang TH, Wu MW, Chang SY et al (2011) Strengthening mechanism of nano-Al2O3 particles reinforced Sn3.5Ag0.5Cu lead-free solder. J Mater Sci: Mater Electron 22(8):1021–1027

Zhao Z et al (2016) Effect of nano-Al2O3 reinforcement on the microstructure and reliability of Sn-3.0 Ag-0.5 Cu solder joints. Microelectron Reliab 60:126–134

Mehrabi K, Khodabakhshi F, Zareh E et al (2016) Effect of alumina nanoparticles on the microstructure and mechanical durability of meltspun lead-free solders based on tin alloys. J Alloy Compd 688:143–155

Sharma A, Baek BG, Jung JP (2015) Influence of La2O3 nanoparticle additions on microstructure, wetting, and tensile characteristics of Sn–Ag–Cu alloy. Mater Des 87:370–379

Zhang L, Gao L (2015) Interfacial compounds growth of SnAgCu (nano La2O3)/Cu solder joints based on experiments and FEM. J Alloy Compd 635:55–60

Gu Y, Zhao X, Li Y et al (2015) Effect of nano-Fe2O3 additions on wettability and interfacial intermetallic growth of low-Ag content Sn–Ag–Cu solders on Cu substrates. J Alloy Compd 627:39–47

Chellvarajoo S, Abdullah MZ, Samsudin Z (2015) Effects of Fe2NiO4 nanoparticles addition into lead free Sn-3.0Ag-0.5Cu solder pastes on microstructure and mechanical properties after reflow soldering process. Mater Des 67:197–208

Huang Y, Xiu Z, Wu G et al (2016) Sn-3.0Ag-0.5Cu nanocomposite solders reinforced by graphene nanosheets. J Mater Sci: Mater Electron 27(7):6809–6815

Liu XD, Han YD, Jing HY et al (2013) Effect of graphene nanosheets reinforcement on the performance of SnAgCu lead-free solder. Mater Sci Eng, A 562:25–32

Huang Y, Xiu Z, Wu G et al (2016) Improving shear strength of Sn-3.0 Ag-0.5 Cu/Cu joints and suppressing intermetallic compounds layer growth by adding graphene nanosheets. Mater Lett 169:262–264

Xu L, Wang L, Jing H et al (2015) Effects of graphene nanosheets on interfacial reaction of Sn–Ag–Cu solder joints. J Alloy Compd 650:475–481

Kong K, Choi Y, Ryu BH et al (2006) Investigation of metal/carbon-related materials for fuel cell applications by electronic structure calculations. Mater Sci Eng, C 26(5–7):1207–1210

Gan Y, Sun L, Banhart F (2008) One-and two-dimensional diffusion of metal atoms in graphene. Small 4(5):587–591

Xu L et al (2016) Design and performance of Ag nanoparticle-modified graphene/SnAgCu lead-free solders. Mater Sci Eng, A 667:87–96

Chen G, Wu F, Liu C et al (2016) Microstructures and properties of new Sn-Ag-Cu lead-free solder reinforced with Ni-coated graphene nanosheets. J Alloy Compd 656:500–509

Khodabakhshi F, Sayyadi R, Javid NS (2017) Lead free Sn-Ag-Cu solders reinforced by Ni-coated graphene nanosheets prepared by mechanical alloying: microstructural evolution and mechanical durability. Mater Sci Eng, A 702:371–385

Telang AU, Bieler TR, Zamiri A et al (2007) Incremental recrystallization/grain growth driven by elastic strain energy release in a thermomechanically fatigued lead-free solder joint. Acta Mater 55(7):2265–2277

Yu DQ, Wu CML, He DP et al (2005) Effects of Cu contents in Sn-Cu solder on the composition and morphology of intermetallic compounds at a solder/Ni interface. J Mater Res 20(8):2205–2212

Jang JW, Liu CY, Kim PG et al (2000) Interfacial morphology and shear deformation of flip chip solder joints. J Mater Res 15(8):1679–1687

Hu X, Xu T, Jiang X et al (2016) Interfacial reaction and IMCs growth behavior of Sn3Ag0.5Cu/Ni solder bump during aging at various temperatures. J Mater Sci: Mater Electron 27(5):4245–4252

Ho CE, Lin YL, Kao CR (2002) Strong effect of Cu concentration on the reaction between lead-free microelectronic solders and Ni. Chem Mater 14(3):949–951

Ho CE, Tsai RY, Lin YL et al (2002) Effect of Cu concentration on the reactions between Sn–Ag–Cu solders and Ni. J Electron Mater 31(6):584–590

Zribi A, Clark A, Zavalij L et al (2001) The growth of intermetallic compounds at Sn–Ag–Cu solder/Cu and Sn–Ag–Cu solder/Ni interfaces and the associated evolution of the solder microstructure. J Electron Mater 30(9):1157–1164

Dariavach N, Callahan P, Liang J et al (2006) Intermetallic growth kinetics for Sn–Ag, Sn–Cu, and Sn–Ag–Cu lead-free solders on Cu, Ni, and Fe-42Ni substrates. J Electron Mater 35(7):1581–1592

Ho CE, Lin YW, Yang SC et al (2006) Effects of limited Cu supply on soldering reactions between SnAgCu and Ni. J Electron Mater 35(5):1017–1024

Yang SC, Chang CC, Tsai MH et al (2010) Effect of Cu concentration, solder volume, and temperature on the reaction between SnAgCu solders and Ni. J Alloy Compd 499(2):149–153

Qi L, Huang J, Zhang H et al (2010) Growth behavior of intermetallic compounds at SnAgCu/Ni and Cu interfaces. J Mater Eng Perform 19(1):129–134

Yoon JW, Kim SW, Jung SB (2005) IMC morphology, interfacial reaction and joint reliability of Pb-free Sn–Ag–Cu solder on electrolytic Ni BGA substrate. J Alloy Compd 392(1–2):247–252

Tu KN, Zeng K (2001) Tin-lead (SnPb) solder reaction in flip chip technology. Mater Sci Eng: R: Rep 34(1):1–58

Ho CE, Yang SC, Kao CR (2007) Interfacial reaction issues for lead-free electronic solders. J Mater Sci: Mater Electron 18(1–3):155–174

Lee YH, Lee HT (2007) Shear strength and interfacial microstructure of Sn–Ag–xNi/Cu single shear lap solder joints. Mater Sci Eng, A 444(1–2):75–83

Jang JW, Kim PG, Tu KN et al (1999) Solder reaction-assisted crystallization of electroless Ni–P under bump metallization in low cost flip chip technology. J Appl Phys 85(12):8456–8463

Ho CE, Lu MK, Lee PT et al (2017) TEM investigation of interfacial microstructure and fracture mode of the Sn–Ag–Cu/Ni joint system. Mater Sci Eng, A 706:269–278

Wang IT, Duh JG, Cheng CY et al (2012) Interfacial reaction and elemental redistribution in Sn3.0Ag0.5Cu–xPd/immersion Au/electroless Ni solder joints after aging. Mater Sci Eng, B 177(2):278–282

Yao P, Liu P, Liu J (2008) Effects of multiple reflows on intermetallic morphology and shear strength of SnAgCu–xNi composite solder joints on electrolytic Ni/Au metallized substrate. J Alloy Compd 462(1–2):73–79

Gain AK, Chan YC, Yung WKC (2011) Microstructure, thermal analysis and hardness of a Sn–Ag–Cu–1wt% nano-TiO2 composite solder on flexible ball grid array substrates. Microelectron Reliab 51(5):975–984

Gain AK, Zhang L, Chan YC (2015) Microstructure, elastic modulus and shear strength of alumina (Al2O3) nanoparticles-doped tin-silver-copper (Sn–Ag–Cu) solders on copper (Cu) and gold/nickel (Au/Ni)-plated Cu substrates. J Mater Sci: Mater Electron 26(9):7039–7048

Gain AK, Chan YC, Yung WKC (2011) Effect of additions of ZrO2 nano-particles on the microstructure and shear strength of Sn-Ag-Cu solder on Au/Ni metallized Cu pads. Microelectron Reliab 51(12):2306–2313

Fouzder T, Shafiq I, Chan YC et al (2011) Influence of SrTiO3 nano-particles on the microstructure and shear strength of Sn-Ag-Cu solder on Au/Ni metallized Cu pads. J Alloy Compd 509(5):1885–1892

Yoon JW, Kim SW, Jung SB (2005) IMC morphology, interfacial reaction and joint reliability of Pb-free Sn–Ag–Cu solder on electrolytic Ni BGA substrate. J Alloy Compd 392(1–2):247–252

Jing HY et al (2017) Influence of Ag-modified graphene nanosheets addition into Sn–Ag–Cu solders on the formation and growth of intermetallic compound layers. J Alloy Compd 702:669–678

Acknowledgements

This study was funded by the Postgraduate Research & Practice Innovation Program of Jiangsu Province (KYCX18-2149), the Natural Science Foundation of China (51475220), State Key Lab of Advanced Welding and Joining, Harbin Institute of Technology (AWJ-19Z04), the Qing Lan Project, the China Postdoctoral Science Foundation funded project (2016M591464), Six talent peaks project in Jiangsu Province (XCL-022).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xiong, My., Zhang, L. Interface reaction and intermetallic compound growth behavior of Sn-Ag-Cu lead-free solder joints on different substrates in electronic packaging. J Mater Sci 54, 1741–1768 (2019). https://doi.org/10.1007/s10853-018-2907-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2907-y