Abstract

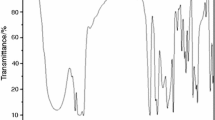

A bio-based epoxy resin, triglycidyl ether of resveratrol (TGER), was synthesized based on the renewable resveratrol deriving from tannins. The structure and properties of TGER have been characterized by 1H NMR, 13C NMR, FTIR, GPC and viscosity measurement. Besides, systematical investigation was carried out on the curing reaction of TGER and diaminodiphenylmethane (DDM), assisted by the characterization of mechanical properties and thermal properties of cured TGER/DDM by means of differential scanning calorimetry, thermogravimetric analysis, dynamic mechanical analysis (DMA), flexural and impact measurement. Non-isothermal and isothermal curing analysis showed that TGER/DDM system, deriving from autocatalytic curing reaction, possessed 40 °C lower curing temperature (84 °C) than bisphenol A diglycidyl ether (DGEBA) (124 °C) and much lower activation energy than DGEBA/DDM system calculated by Kissinger equation. DMA revealed that TGER possessed high glass transition temperature (T g = 148 °C) and glassy storage modulus (2.391 GPa@23 °C). Meanwhile, TGER/DDM thermosets also exhibited good mechanical properties and heat resistance, illustrating that multi-phenol group and stilbene group of resveratrol endowed polymer with high cross-linking density and rigidness. Therefore, TGER could be a promising alternative to petroleum-based epoxy resin.

Similar content being viewed by others

References

Moore CJ (2008) Synthetic polymers in the marine environment: a rapidly increasing, long-term threat. Environ Res 108:131–139. https://doi.org/10.1016/j.envres.2008.07.025

Auvergne R, Caillol S, David G, Boutevin B, Pascault JP (2014) Biobased thermosetting epoxy: present and future. Chem Rev 114:1082–1115. https://doi.org/10.1021/cr3001274

Baroncini EA, Yadav SK, Palmese GR, Iii JFS (2016) Recent advances in bio-based epoxy resins and bio-based epoxy curing agents. J Appl Polym Sci 133:44103. https://doi.org/10.1002/app.44103

Sasaki S, Ooya T, Takeuchi T (2010) Highly selective bisphenol A—imprinted polymers prepared by atom transfer radical polymerization†. Polym Chem 1:1684–1688. https://doi.org/10.1039/c0py00140f

vom Saal FS, Hughes C (2005) Bisphenol A and risk assessment. Environ Health Perspect 113:926–933. https://doi.org/10.1289/ehp.7713

Mathers RT (2012) How well can renewable resources mimic commodity monomers and polymers? J Polym Sci Part A Polym Chem 50:1–15. https://doi.org/10.1002/pola.24939

Kumar S, Samal SK, Mohanty S, Nayak SK (2016) Recent development of bio-based epoxy resins: a review. Polym Plast Technol Eng. https://doi.org/10.1080/03602559.2016.1253742

Bell BM, Briggs JR, Campbell RM (2008) Glycerin as a renewable feedstock for epichlorohydrin production. The GTE process. CLEAN Soil Air Water 36:657–661. https://doi.org/10.1002/clen.200800067

Lacerda TM, Gandini A (2014) Marriage of furans and vegetable oils through click chemistry for the preparation of macromolecular materials: a succinct review. J Renew Mater 2:2–12. https://doi.org/10.7569/jrm.2013.634127

Santacesaria E, Tesser R, Di Serio M, Turco R, Russo V, Verde D (2011) A biphasic model describing soybean oil epoxidation with H2O2 in a fed-batch reactor. Chem Eng J 173:198–209. https://doi.org/10.1016/j.cej.2011.05.018

Campanella A, Fontanini C, Baltanás MA (2008) High yield epoxidation of fatty acid methyl esters with performic acid generated in situ. Chem Eng J 144:466–475. https://doi.org/10.1016/j.cej.2008.07.016

Fourcade D, Ritter BS, Walter P, Schönfeld R, Mülhaupt R (2013) Renewable resource-based epoxy resins derived from multifunctional poly(4-hydroxybenzoates). Green Chem 15:910–918. https://doi.org/10.1039/c3gc37088g

Elchinger P-H, Montplaisir D, Zerrouki R (2012) Starch–cellulose crosslinking—towards a new material. Carbohyd Polym 87:1886–1890. https://doi.org/10.1016/j.carbpol.2011.09.027

Aron PM, Kennedy JA (2008) Flavan-3-ols: nature, occurrence and biological activity. Mol Nutr Food Res 52:79–104. https://doi.org/10.1002/mnfr.200700137

Guigo N, Mija A, Vincent L, Sbirrazzuoli N (2010) Eco-friendly composite resins based on renewable biomass resources: polyfurfuryl alcohol/lignin thermosets. Eur Polym J 46:1016. https://doi.org/10.1016/j.eurpolymj.2010.02.010

Hernandez ED, Bassett AW, Sadler JM, La Scala JJ, Stanzione JF (2016) Synthesis and characterization of bio-based epoxy resins derived from vanillyl alcohol. ACS Sustain Chem Eng 4:4328–4339. https://doi.org/10.1021/acssuschemeng.6b00835

Hu F, La Scala JJ, Sadler JM, Palmese GR (2014) Synthesis and characterization of thermosetting furan-based epoxy systems. Macromolecules 47:3332–3342. https://doi.org/10.1021/ma500687t

Maiorana A, Reano FA, Centore R et al (2016) Structure property relationships of biobased n-alkyl bisferulate epoxy resins. Green Chem 18:4961–4973. https://doi.org/10.1039/C6GC01308B

Wan J, Gan B, Li C et al (2016) A sustainable, eugenol-derived epoxy resin with high biobased content, modulus, hardness and low flammability: Synthesis, curing kinetics and structure–property relationship. Chem Eng J 284:1080–1093. https://doi.org/10.1016/j.cej.2015.09.031

Tüzün A, Lligadas G, Ronda JC, Galià M, Cádiz V (2015) Integrating plant oils into thermally curable main-chain benzoxazine polymers via ADMET polymerization. Eur Polym J 67:503–512. https://doi.org/10.1016/j.eurpolymj.2014.12.023

Chrysanthos M, Galy J, Pascault J-P (2011) Preparation and properties of bio-based epoxy networks derived from isosorbide diglycidyl ether. Polymer 52:3611–3620. https://doi.org/10.1016/j.polymer.2011.06.001

Lukaszczyk J, Janicki B, Frick A (2012) Investigation on synthesis and properties of isosorbide based bis-GMA analogue. J Mater Sci Mater Med 23:1149–1155. https://doi.org/10.1007/s10856-012-4594-6

Łukaszczyk J, Janicki B, Kaczmarek M (2011) Synthesis and properties of isosorbide based epoxy resin. Eur Polym J 47:1601–1606. https://doi.org/10.1016/j.eurpolymj.2011.05.009

Wan J, Gan B, Li C et al (2015) A novel biobased epoxy resin with high mechanical stiffness and low flammability: synthesis, characterization and properties. J Mater Chem A 3:21907–21921. https://doi.org/10.1039/c5ta02939b

Liu X, Xin W, Zhang J (2009) Rosin-based acid anhydrides as alternatives to petrochemical curing agents. Green Chem 11:1018. https://doi.org/10.1039/b903955d

Liu X, Xin W, Zhang J (2010) Rosin-derived imide-diacids as epoxy curing agents for enhanced performance. Biores Technol 101:2520–2524. https://doi.org/10.1016/j.biortech.2009.11.028

Wang H, Liu X, Liu B, Zhang J, Xian M (2009) Synthesis of rosin-based flexible anhydride-type curing agents and properties of the cured epoxy. Polym Int 58:1435–1441. https://doi.org/10.1002/pi.2680

Qin J, Liu H, Zhang P, Wolcott M, Zhang J (2014) Use of eugenol and rosin as feedstocks for biobased epoxy resins and study of curing and performance properties. Polym Int 63:760–765. https://doi.org/10.1002/pi.4588

Erdogan CS, Vang O (2016) Challenges in analyzing the biological effects of resveratrol. Nutrients. https://doi.org/10.3390/nu8060353

Burns J, Yokota T, Ashihara H, Lean ME, Crozier A (2002) Plant foods and herbal sources of resveratrol. J Agric Food Chem 50:3337–3340. https://doi.org/10.1021/jf0112973

Cash JJ, Davis MC, Ford MD et al (2013) High Tg thermosetting resins from resveratrol. Polym Chem 4:3859–3865. https://doi.org/10.1039/c3py00438d

McAninch IM, Palmese GR, Lenhart JL, La Scala JJ (2015) DMA testing of epoxy resins: The importance of dimensions. Polym Eng Sci 55:2761–2774. https://doi.org/10.1002/pen.24167

Mc Aninch IM, Palmese GR, Lenhart JL, La Scala JJ (2015) Epoxy–amine networks with varying epoxy polydispersity. J Appl Polym Sci. https://doi.org/10.1002/app.41503

Forshaw S, Matthews AJ, Brown TJ, Diorazio LJ, Williams L, Wills M (2017) Asymmetric transfer hydrogenation of 1,3-alkoxy/aryloxy propanones using tethered Arene/Ru (II)/TsDPEN complexes. Org Lett 19:2789–2792. https://doi.org/10.1021/acs.orglett.7b00756

Tian N, Gong J, Wen X, Yao K, Tang T (2014) Synthesis and characterization of a novel organophosphorus oligomer and its application in improving flame retardancy of epoxy resin. RSC Advances 4:17607–17614. https://doi.org/10.1039/c4ra01525h

Francis B, Thomas S, Jose J, Ramaswamy R, Lakshmana Rao V (2005) Hydroxyl terminated poly(ether ether ketone) with pendent methyl group toughened epoxy resin: miscibility, morphology and mechanical properties. Polymer 46:12372–12385. https://doi.org/10.1016/j.polymer.2005.10.103

Liu J, Tang J, Wang X, Wu D (2012) Synthesis, characterization and curing properties of a novel cyclolinear phosphazene-based epoxy resin for halogen-free flame retardancy and high performance. RSC Adv 2:5789–5799. https://doi.org/10.1039/c2ra20739g

Afzal A, Siddiqi HM (2011) A comprehensive study of the bicontinuous epoxy–silica hybrid polymers: I. Synthesis, characterization and glass transition. Polymer 52:1345–1355. https://doi.org/10.1016/j.polymer.2011.01.046

Wang X, Gillham JK (1992) Analysis of crosslinking in amine-cured epoxy systems: the one-to-one relationship between Tg and conversion. J Appl Polym Sci 45:2127–2143. https://doi.org/10.1002/app.1992.070451209

Wang H, Zhang Y, Zhu L, Du Z, Zhang B, Zhang Y (2011) Curing behaviors and kinetics of epoxy resins with a series of biphenyl curing agents having different methylene units. Thermochim Acta 521:18–25. https://doi.org/10.1016/j.tca.2011.03.036

Vyazovkin S, Burnham AK, Criado JM, Pérez-Maqueda LA, Popescu C, Sbirrazzuoli N (2011) ICTAC Kinetics Committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta 520:1–19. https://doi.org/10.1016/j.tca.2011.03.034

Vyazovkin S, Wight CA (1999) Model-free and model-fitting approaches to kinetic analysis of isothermal and nonisothermal data. Thermochim Acta 340–341:53–68. https://doi.org/10.1016/S0040-6031(99)00253-1

Kamal MR (1974) Thermoset characterization for moldability analysis. Polym Eng Sci 14:231–239. https://doi.org/10.1002/pen.760140312

Wan J, Bu Z-Y, Xu C-J, Li B-G, Fan H (2011) Preparation, curing kinetics, and properties of a novel low-volatile starlike aliphatic–polyamine curing agent for epoxy resins. Chem Eng J 171:357–367. https://doi.org/10.1016/j.cej.2011.04.004

Wan J, Li C, Bu Z-Y, Xu C-J, Li B-G, Fan H (2012) A comparative study of epoxy resin cured with a linear diamine and a branched polyamine. Chem Eng J 188:160–172. https://doi.org/10.1016/j.cej.2012.01.134

Liu YL, Wang YH (2004) Preparation and properties of novel benzoxazine and polybenzoxazine with maleimide groups. J Polym Sci Part A Polym Chem 42:5954–5963. https://doi.org/10.1002/pola.20162

Ma S, Liu X, Jiang Y, Tang Z, Zhang C, Zhu J (2013) Bio-based epoxy resin from itaconic acid and its thermosets cured with anhydride and comonomers. Green Chem 15:245–254. https://doi.org/10.1039/c2gc36715g

Acknowledgements

The authors acknowledge financial support from The Jilin Province Science and Technology Innovation and Achievements Transformation Project of China (20140306011GX), the National Natural Science Foundation of China (Grant No. 21644003), the National Natural Science Foundation of China (Grant No. 51603020).

Author information

Authors and Affiliations

Contributions

LS and YA conceived and designed the experiments. YA contributed to reagents, materials and analysis tools. LS, XZ, MZ, LJ and LL performed the experiments. LS, LX and ML contributed significantly to analysis and manuscript preparation. LS performed the data analyses and wrote the manuscript. LS and YA helped perform the analysis with constructive discussions.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Shang, L., Zhang, X., Zhang, M. et al. A highly active bio-based epoxy resin with multi-functional group: synthesis, characterization, curing and properties. J Mater Sci 53, 5402–5417 (2018). https://doi.org/10.1007/s10853-017-1797-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1797-8