Abstract

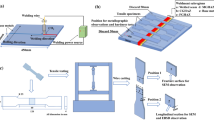

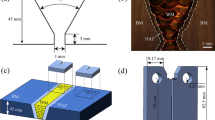

Martensite–austenite (M–A) constituent formed during welding is generally recognized as an important factor to decrease the toughness of welded joint. In this article, the morphology and chemical composition of M–A constituent in the low carbon bainitic steel welded joint was analysed in detail by means of optical microscope, transmission electron microscope and scanning electron microscope with electron probe microanalysis. The experimental results show that the M–A constituent formed in the different sub-zones presents different morphologies and different amounts. The maximum amount of M–A constituent occurs in the coarse grained heat affected zone (HAZ). It is evident that the carbon atoms segregate on the M–A constituent and carbon concentration on the slender M–A constituent is higher than that on the massive M–A constituent. Meanwhile, the distribution profile of silicon on the M–A constituent shows an obvious inhomogeneity. Most of M–A constituents have a twinned structure and/or a high dislocation density. According to impact testing results, the crack initiation energy in the HAZ specimens deteriorates significantly because the large M–A constituent can assist the formation of cleavage crack. On the other hand, the coarse prior austenite grain in the HAZ lowers the crack propagation energy.

Similar content being viewed by others

References

Viano DM, Ahmed NU, Schumann GO (2000) Sci Technol Weld Join 5(1):26

Kojima A, Yoshii K, Hada T, Saeki O, Ichikawa K, Yoshida Y, Shimura Y, Azuma K (2004) Nippon Steel Tech Report 90:39

Koseki T, Thewlis G (2005) Mater Sci Technol 21:867

Ricks RA, Howell PR, Barritte GS (1982) J Mater Sci 17:730. doi:10.1007/BF00540369

Davis CL, King JE (1994) Metall Mater Trans A 25:563

Li C, Wang Y, Chen Y (2011) J Mater Sci 46:6424. doi:10.1007/s10853-011-5592-7

Li Y, Crowther DN, Green MJW, Mitchell PS, Baker TN (2001) ISIJ Int 41:46

Moeinifar S, Kokabi AH, Hosseini HRM (2011) Mater Des 32:869

Harrrison PL, Farrar RA (1989) Int Mater Rev 34:35

Biss V, Cryderman RL (1970) Metall Trans 2:2267

De Meester B (1997) ISIJ Int 37:537

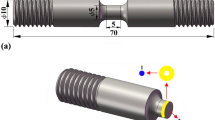

EN ISO 9692-2 (1998) Welding and allied processes-joint preparation: Part 2: submergered arc welding of steels

GB/T 12470 (2003) Low-alloy steel electrodes and fluxes for submerged arc welding (Chinese Standard)

ISO 9016 (2001) Destructive tests on welds in metallic materials-impact tests-test specimen location, notch orientation and examination

Wiesner CS (1996) Int J Pres Ves Pip 69:185

Cvetkovski S, Adziev T, Adziev G, Sedmak A (2002) Eur Struct Integr Soc 30:95

Avazkonandeh-Gharavol MH, Haddad-Sabzevar M, Haerian A (2009) J Mater Sci 44:1902. doi:10.1007/s10853-009-4141-0

Thewlis G, Chao WT, Harrison PL, Rose AJ (2008) Mater Sci Technol 24:771

Bhadeshia HKDH, Christian JW (1990) Metall Trans A 21A:767

Bonnevie E, Ferriere G, Ikhlef A, Kaplan D, Orain JM (2004) Mater Sci Eng A 385:352

Santofimia MJ, Kwakernaak C, Sloof WG, Zhao L, Sietsma J (2010) Mater Charact 61:937

Taillard R, Verrier P, Maurickx T, Foct J (1995) Metall Mater Trans A 26A:447

Pereloma EV, Timokhina IB, Miller MK, Hodgson PD (2007) Acta Mater 55:2587

Lambert A, Drillet J, Gourgues AF, Sturel T, Pineau A (2000) Sci Technol Weld Join 5:168

Poorhaydari K, Patchett BM, Ivey DG (2006) Mater Sci Eng A 435–436:371

Lan L, Qiu C, Zhao W, Gao X, Du L (2011) Mater Sci Eng A 529:192

Tweed JH, Knott JF (1987) Acta Metall 35:1401

Matsuda F, Ikeuchi K, Fukada Y, Horii Y, Okada H, Shiwaku T, Shiga C, Suzuki S (1995) Trans JWRI 24:1

Li Y, Baker TN (2010) Mater Sci Technol 26:1029

Moeinifar S, Kokabi AH, Madaah Hosseini HR (2011) J Mater Process Technol 211:368

Acknowledgements

The present study is supported by the National Natural Science Foundation of China (No. 51074052) and the Fundamental Research Funds for the Central Universities (N100607001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lan, L., Qiu, C., Zhao, D. et al. Analysis of martensite–austenite constituent and its effect on toughness in submerged arc welded joint of low carbon bainitic steel. J Mater Sci 47, 4732–4742 (2012). https://doi.org/10.1007/s10853-012-6346-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6346-x