Abstract

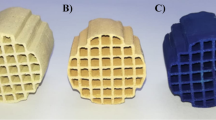

Due to the industrialization, it is urgent to reduce the carbon dioxide emissions. For that, diverse technologies can be applied. In adsorption processes, the development of new materials is an emerging challenge in order to increase the CO2 adsorption capacity of materials and the efficiency of the processes. In this work, a new hybrid honeycomb monolith composed by zeolite and activated carbon was produced by extrusion process. Single adsorption equilibrium isotherms of carbon dioxide and nitrogen were measured by a gravimetric method using a Rubotherm® magnetic suspension balance at three temperatures, 303, 333 and 373 K. The experimental points were well described by Dual-Site Langmuir model. The material presented a carbon dioxide adsorption capacity of 2.63 mol kg−1 at 1 bar and 303 K. Binary breakthrough curves were obtained at 298 K and 2.4 bar with different feed mixtures. The experimental results of adsorption equilibrium were validated with the Dual-Site Langmuir isotherm extended to multicomponent mixtures. A mathematical model was applied to predict the dynamic behaviour of the adsorption bed.

(Adapted from Moreira et al. 2017)

Similar content being viewed by others

Abbreviations

- \({a_m}\) :

-

Monolith channel specific area (m−1)

- \({a_p}\) :

-

Particle external specific area (m−1)

- \({b_{0i}}\) :

-

Affinity constant at infinite temperature (bar−1)

- \({b_i}\) :

-

Affinity constant (bar−1)

- \({C_{inlet}}\) :

-

Inlet gas phase concentration (mol m−3)

- \({C_i}\) :

-

Gas phase concentration of component \(i\) (mol m−3)

- \({C_p}\) :

-

Heat capacity of the mixture at constant pressure (J mol−1 K−1)

- \({\hat {C}_p}\) :

-

Heat capacity at constant pressure (per mass unit) (J kg−1 K−1)

- \({C_{p,i}}\) :

-

Heat capacity at constant pressure of component \(i\) (J mol−1 K−1)

- \({\tilde {C}_{p,s}}\) :

-

Solid specific heat (per mass unit) (J kg−1 K−1)

- \({\tilde {C}_{p,w}}\) :

-

Wall specific heat (per mass unit) (J kg−1 K−1)

- \({C_s}\) :

-

Concentration at the solid interface (mol m−3)

- \({C_t}\) :

-

Total gas phase concentration (mol m−3)

- \({\tilde {C}_{v,ads,i}}\) :

-

Molar specific heat of component \(i\) in the adsorbed phase at constant volume (J mol−1 K−1)

- \({C_{v,i}}\) :

-

Molar specific heat of component \(i\) at constant volume (J mol−1 K−1)

- \(D\) :

-

Total diameter of channels (m)

- \({D_{ax}}\) :

-

Mass axial dispersion coefficient (m2 s−1)

- \({D_{k,i}}\) :

-

Knudsen diffusivity of component \(i\) (m2 s−1)

- \({D_m}\) :

-

Molecular diffusivity (m2 s−1)

- \({D_{m,i}}\) :

-

Molecular diffusivity of component \(i\) (m2 s−1)

- \(e\) :

-

Column wall thickness (m)

- \({h_f}\) :

-

Heat transfer coefficient between the gas and the particle (W m−2 K−1)

- \({h_w}\) :

-

Heat transfer coefficient between the gas phase and the wall (W m−2 K−1)

- \({k_g}\) :

-

Thermal conductivity of the gas mixture (W m−2 K−1)

- \({k_{g,i}}\) :

-

Thermal conductivity of component \(i\) (W m−2 K−1)

- \({k_f}\) :

-

Film mass transfer coefficient (m s−1)

- \({k_{macro}}\) :

-

LDF coefficient for macropores (s−1)

- \({k_{micro}}\) :

-

LDF coefficient for micropores (s−1)

- \({L_c}\) :

-

Monolith length (m)

- \({l_w}\) :

-

Monolith wall thickness (m)

- \({m_S}\) :

-

Adsorbent mass (kg)

- \({M_w}\) :

-

Adsorbate molecular weight (kg mol−1)

- \(P\) :

-

Pressure (bar)

- \({P_i}\) :

-

Partial pressure of component \(i\) (bar)

- \({q_i}\) :

-

Adsorbed amount of component \(i\) (mol kg−1)

- \({\bar {q}_i}\) :

-

Particle average adsorbed concentration (mol kg−1)

- \(q_{i}^{*}\) :

-

Adsorbed concentration in equilibrium of component \(i\) (mol kg−1)

- \({q_{sat,i}}\) :

-

Adsorbent saturation capacity of component \(i\) (mol kg−1)

- Re:

-

Reynolds number

- \({R_g}\) :

-

Universal gas constant (J mol−1 K−1)

- \({R_c}\) :

-

Equivalent monolith radius (approximation of cylindrical monolith) (m)

- \({R_{ch,e}}\) :

-

Equivalent channel radius (approximation of cylindrical channel) (m)

- \(T\) :

-

Temperature (K)

- \({T_g}\) :

-

Temperature of the gas phase (K)

- \({T_{inlet}}\) :

-

Inlet temperature (K)

- \({T_s}\) :

-

Temperature of the solid phase (K)

- \({T_w}\) :

-

Wall temperature (K)

- \({T_\infty }\) :

-

External temperature (K)

- \(Sc\) :

-

Schmidt number

- \(Sh\) :

-

Sherwood number

- \({u_0}\) :

-

Superficial gas velocity (m s−1)

- \({u_m}\) :

-

Intersticial gas velocity (m s−1)

- \(U\) :

-

Overall heat transfer coefficient (W m−2 K−1)

- \({V_C}\) :

-

Volume of the permanent magnet, of the sample basket and of the glass wool used to hold the sample (m3 mol−1)

- \({V_S}\) :

-

Volume of the solid adsorbent (m3 mol−1)

- \({y_i}\) :

-

Molar faction of component \(i\)

- \(z\) :

-

Axial position (m)

- \({{{\upalpha}}}\) :

-

Adsorption separation factor

- \({{{{\upalpha}}}_{\text{w}}}\) :

-

Ratio of the internal surface area to the volume of the column wall (m−1)

- \({{{{\upalpha}}}_{{\text{wl}}}}\) :

-

Ratio of the log mean surface area to the volume of the column wall (m−1)

- \(\Delta {\text{H}}\) :

-

Heat of adsorption (kJ mol−1)

- \(\Delta {{\text{H}}_{\text{i}}}\) :

-

Isosteric heat of adsorption of component \(i\) (kJ mol−1)

- \(\Delta {\text{m}}\) :

-

Difference in weight between two measurements (kg)

- \({{{{\upvarepsilon}}}_{\text{i}}}\) :

-

Energy parameter for interaction between molecules

- \({{{{\upvarepsilon}}}_m}\) :

-

Monolith porosity

- \({{{{\upvarepsilon}}}_w}\) :

-

Monolith wall porosity

- λ:

-

Axial heat dispersion coefficient (W m−1 K−1)

- \({{{{\upmu}}}_{\text{g}}}\) :

-

Gas viscosity (Pa s)

- \({{{\uprho}}}\) :

-

Gas density (kg m−3)

- \({{{{\uprho}}}_{{\text{ap}}}}\) :

-

Apparent density (kg m−3)

- \({{{{\uprho}}}_{\text{b}}}\) :

-

Bulk density (kg m−3)

- \({{{{\uprho}}}_{\text{G}}}\) :

-

Density of the gas phase at the measuring conditions (T,P) (kg m−3)

- \({{{{\uprho}}}_{\text{L}}}\) :

-

Density of the adsorbed phase (kg m−3)

- \({{{{\uprho}}}_{\text{w}}}\) :

-

Wall density (kg m−3)

- \({{{{\uptau}}}_{\text{p}}}\) :

-

Particle tortuosity

- BPR:

-

Back-pressure regulator

- EDS:

-

Energy dispersive X-ray spectroscopy

- GA:

-

Gas analyser

- LDF:

-

Linear driving force model

- MFC:

-

Mass flow controller

- MFM:

-

Mass flow meter

- RH:

-

Humidity sensor

- SEM:

-

Scanning electron microscopy

References

Akbar, S., Shah, T.H., Shanaz, R., Sarwar, G.: Thermal studies of synthetic zeolite and its zinc exchange forms. J. Chem. Soc. Pak. 29, 5–11 (2007)

Akhtar, F., Andersson, L., Ogunwumi, S., Hedin, N., Bergström, L.: Structuring adsorbents and catalysts by processing of porous powders. J. Eur. Ceram. Soc. 34, 1643–1666 (2014). https://doi.org/10.1016/j.jeurceramsoc.2014.01.008

Al-Baghli, N.A., Loughlin, K.F.: Adsorption of methane, ethane, and ethylene on titanosilicate ETS-10 zeolite. J. Chem. Eng. Data. 50, 843–848 (2005). https://doi.org/10.1021/je0496793

An, H., Feng, B., Su, S.: CO2 capture by electrothermal swing adsorption with activated carbon fibre materials. Int. J. Greenh. Gas Control. 5, 16–25 (2011). https://doi.org/10.1016/j.ijggc.2010.03.007

Balahmar, N., Lowbridge, A.M., Mokaya, R.: Templating of carbon in zeolites under pressure: synthesis of pelletized zeolite templated carbons with improved porosity and packing density for superior gas (CO2 and H2) uptake properties. R. Soc. Chem. 4, 14254–14266 (2016)

Blomen, E., Hendriks, C., Neele, F.: Capture technologies: improvements and promising developments. Energy Procedia. 1, 1505–1512 (2009). https://doi.org/10.1016/j.egypro.2009.01.197

Brandani, F., Rouse, A., Brandani, S., Ruthven, D.M.: Adsorption kinetics and dynamic behavior of a carbon monolith. Adsorption. 10, 99–109 (2004). https://doi.org/10.1023/B:ADSO.0000039866.37214.6a

Cavenati, S., Grande, C.A., Rodrigues, A.E.: Adsorption equilibrium of methane, carbon dioxide, and nitrogen on zeolite 13X at high pressures. J. Chem. Eng. Data. 49, 1095–1101 (2004). https://doi.org/10.1021/je0498917

D’Alessandro, D.M., Smit, B., Long, J.R.: Carbon dioxide capture: prospects for new materials. Angew. Chem. Int. Ed. 49, 6058–6082 (2010). https://doi.org/10.1002/anie.201000431

da Silva, A.: Cyclic Adsorption Processes: Application to Propane/Propylene Separation. FEUP (1999)

Do, D.D.: Adsorption Analysis: Equilibria and Kinetics. Chemical Engineering. Imperial College Press, London (1998)

Domínguez, G., Hernández-Huesca, R., Aguilar-Armenta, G.: Isosteric heats of adsorption of N2O and NO on natural zeolites. J. Mex. Chem. Soc. 54, 111–116 (2010)

Esteves, I.A.A.C., Lopes, M.S.S., Nunes, P.M.C., Mota, J.P.B.: Adsorption of natural gas and biogas components on activated carbon. Sep. Purif. Technol. 62, 281–296 (2008). doi.https://doi.org/10.1016/j.seppur.2008.01.027

Ferreira, A.F.P., Santos, J.C., Plaza, M.G., Lamia, N., Loureiro, J.M., Rodrigues, A.E.: Suitability of Cu-BTC extrudates for propane–propylene separation by adsorption processes. Chem. Eng. J. 167, 1–12 (2011). https://doi.org/10.1016/j.cej.2010.07.041

Fleker, O., Borenstein, A., Lavi, R., Benisvy, L., Ruthstein, S., Aurbach, D.: Preparation and properties of metal organic framework/activated carbon composite materials. Langmuir. 32, 4935–4944 (2016). https://doi.org/10.1021/acs.langmuir.6b00528

Folger, P.: Carbon capture: a technology assessment. Congr Res Serv 10–20 (2010). https://digitalcommons.unl.edu/cgi/viewcontent.cgi?article=1018&context=crsdocs

Folger, P.: Carbon Capture: A Technology Assessment. Congressional Research Service, Washington, DC (2013). https://fas.org/sgp/crs/misc/R41325.pdf

García-Martínez, J., Cazorla-Amorós, D., Linares-Solano, A., Lin, Y.S.: Synthesis and characterisation of MFI-type zeolites supported on carbon materials. Microporous Mesoporous Mater. 42, 255–268 (2001). https://doi.org/10.1016/S1387-1811(00)00328-0

Grande, C.A., Ribeiro, R.P.P.L., Rodrigues, A.E.: CO2 capture from NGCC power stations using electric swing adsorption (ESA). Energy Fuels. 23, 2797–2803 (2009). https://doi.org/10.1021/ef8010756

Gumma, S., Talu, O.: Gibbs dividing surface and helium adsorption. Adsorption. 9, 17–28 (2003). https://doi.org/10.1023/a:1023859112985

Harlick, P.J.E., Tezel, F.H.: An experimental adsorbent screening study for CO2 removal from N2. Microporous Mesoporous Mater. 76, 71–79 (2004). https://doi.org/10.1016/j.micromeso.2004.07.035

Keller, J.U., Staudt, R., Tomalla, M.: Volume-gravimetric measurements of binary gas adsorption equilibria. Ber. Bunsenges. Phys. Chem. 96, 28–32 (1992). https://doi.org/10.1002/bbpc.19920960105

Kelut, P., Kulkarni, K., Kulkarni, A.: CO2 adsorption by various catalysts. Chem. Process Eng. Res. 18, 7–15 (2014)

Konwar, R.J., De, M.: Effects of synthesis parameters on zeolite templated carbon for hydrogen storage application. Microporous Mesoporous Mater. 175, 16–24 (2013). https://doi.org/10.1016/j.micromeso.2013.03.014

Lakhera, S.K., Harsha, S., Suman, A.S.: Synthesis and characterization of 13X zeolite/activated carbon composite. Int. J. ChemTech Res. 7, 1364–1368 (2015)

Lee, S.-Y., Park, S.-J.: A review on solid adsorbents for carbon dioxide capture. J. Ind. Eng. Chem. 23, 1–11 (2015). https://doi.org/10.1016/j.jiec.2014.09.001

Leung, D.Y.C., Caramanna, G., Maroto-Valer, M.M.: An overview of current status of carbon dioxide capture and storage technologies. Renew. Sustain. Energy Rev. 39, 426–443 (2014). https://doi.org/10.1016/j.rser.2014.07.093

Li, Y.Y., Perera, S.P., Crittenden, B.D.: Zeolite monoliths for air separation: part 1: manufacture and characterization. Chem. Eng. Res. Des. 76, 921–930 (1998a). https://doi.org/10.1205/026387698525720

Li, Y.Y., Perera, S.P., Crittenden, B.D.: Zeolite monoliths for air separation: part 2: oxygen enrichment, pressure drop and pressurization. Chem. Eng. Res. Des. 76, 931–941 (1998b). https://doi.org/10.1205/026387698525739

Lopes, F.V.S., Grande, C.A., Ribeiro, A.M., Loureiro, J.M., Evaggelos, O., Nikolakis, V., Rodrigues, A.E.: Adsorption of H2, CO2, CH4, CO, N2 and H2O in activated carbon and zeolite for hydrogen production. Sep. Sci. Technol. 44, 1045–1073 (2009). https://doi.org/10.1080/01496390902729130

Lowell, S., Shields, J.E., Thomas, M.A., Thommes, M.: Characterization of Porous Solids and Powders: Surface Area, Pore Size and Density. Springer Science*Business Media, LLC, Boston (2004)

Marx, D., Joss, L., Hefti, M., Mazzotti, M.: Temperature swing adsorption for postcombustion CO2 capture: single- and multicolumn experiments and simulations. Ind. Eng. Chem. Res. 55, 1401–1412 (2016). https://doi.org/10.1021/acs.iecr.5b03727

Masala, A., Vitillo, J.G., Mondino, G., Martra, G., Blom, R., Grande, C.A., Bordiga, S.: Conductive ZSM-5-based adsorbent for CO2 capture: active phase vs monolith. Ind. Eng. Chem. Res. 56, 8485–8498 (2017). https://doi.org/10.1021/acs.iecr.7b01058

Masika, E., Mokaya, R.: Preparation of ultrahigh surface area porous carbons templated using zeolite 13X for enhanced hydrogen storage. Prog. Nat. Sci.: Mater. Int. 23, 308–316 (2013). https://doi.org/10.1016/j.pnsc.2013.04.007

Metz, B., Davidson, O., Coninck Hd, Loos, M., Meyer, L.: Carbon Dioxide Capture and Storage. Cambridge Volume University Press, UK. Intergovernmental Panel on Climate Change (Special Report) (2005)

Moreira, M.A., Ribeiro, A.M., Ferreira, A.F.P., Rodrigues, A.E.: Cryogenic pressure temperature swing adsorption process for natural gas upgrade. Sep. Purif. Technol. 173, 339–356 (2017). https://doi.org/10.1016/j.seppur.2016.09.044

Myers, A.L.: Thermodynamics of adsorption in porous materials. AIChE J. 48, 145–160 (2002). https://doi.org/10.1002/aic.690480115

Na, B.-K., Koo, K.-K., Eum, H.-M., Lee, H., Song, H.K.: CO2 recovery from flue gas by PSA process using activated carbon. Korean J. Chem. Eng. 18, 220–227 (2001). https://doi.org/10.1007/bf02698463

Nguyen, C., Do, D.D.: Dual Langmuir kinetic model for adsorption in carbon molecular sieve materials. Langmuir. 16, 1868–1873 (2000). https://doi.org/10.1021/la990584m

Park, Y., Ju, Y., Park, D., Lee, C.-H.: Adsorption equilibria and kinetics of six pure gases on pelletized zeolite 13X up to 1.0 MPa: CO2, CO, N2, CH4, Ar and H2. Chem. Eng. J. 292, 348–365 (2016). https://doi.org/10.1016/j.cej.2016.02.046

Poling, B.E., Prausnitz, J.M., O’Connell, J.P.: The Properties of Gases and Liquids. McGraw-Hill, New York (2001)

PSEnterprise. https://www.psenterprise.com/ (2017). Accessed 2 May 2017

Quintella, C.M., Hatimondi, S.A., Musse, A.P.S., Miyazaki, S.F., Cerqueira, G.S.: Moreira AdA: CO2 capture technologies: an overview with technology assessment based on patents and articles. Energy Procedia. 4, 2050–2057 (2011). https://doi.org/10.1016/j.egypro.2011.02.087

Rege, S.U., Yang, R.T., Buzanowski, M.A.: Sorbents for air prepurification in air separation. Chem. Eng. Sci. 55, 4827–4838 (2000). https://doi.org/10.1016/S0009-2509(00)00122-6

Rezaei, F., Grahn, M.: Thermal management of structured adsorbents in CO2 capture processes. Ind. Eng. Chem. Res. 51, 4025–4034 (2012). https://doi.org/10.1021/ie201057p

Ribeiro, R.P.P.L.: Electric Swing Adsorption for Gas Separation and Purification. phD Thesis, University of Porto (2013)

Ribeiro, A.M., Santos, J.C., Rodrigues, A.E.: Pressure swing adsorption for CO2 capture in Fischer-Tropsch fuels production from biomass. Adsorption. 17, 443–452 (2011). https://doi.org/10.1007/s10450-010-9280-8

Ribeiro, R.P.P.L., Grande, C.A., Rodrigues, A.E.: Electric swing adsorption for gas separation and purification: a review. Sep. Sci. Technol. 49, 1985–2002 (2014). https://doi.org/10.1080/01496395.2014.915854

Rios, R., da Silva Correia, L., Bastos-Neto, M., Torres, A., Hatimondi, S.A., Ribeiro, A., Rodrigues, A., Cavalcante, C., Jr., Azevedo, D.: Evaluation of carbon dioxide–nitrogen separation through fixed bed measurements and simulations. Adsorption. (2014). https://doi.org/10.1007/s10450-014-9639-3

Rostami, M., Mofarahi, M., Karimzadeh, R., Abedi, D.: Preparation and characterization of activated carbon–zeolite composite for gas adsorption separation of CO2/N2 system. J. Chem. Eng. Data. 61, 2638–2646 (2016). https://doi.org/10.1021/acs.jced.6b00374

Rouquerol, F., Rouquerol, J., Sing, K.: Adsorption by Powders and Porous Solids: Principles, Methodology and Applications, 1st edn. Elsevier Ltd., Amsterdam (1999)

Saini, V.K., Pinto, M., Pires, J.: Natural clay binder based extrudates of mesoporous materials: improved materials for selective adsorption of natural and biogas components. Green Chem. 13, 1251–1259 (2011). https://doi.org/10.1039/C0GC00940G

Siqueira, R.M., Freitas, G.R., Peixoto, H.R., Nascimento JFd, Musse, A.P.S., Torres, A.E.B., Azevedo, D.C.S., Bastos-Neto, M.: Carbon dioxide capture by pressure swing adsorption. Energy Procedia. 114, 2182–2192 (2017). https://doi.org/10.1016/j.egypro.2017.03.1355

Songolzadeh, M., Ravanchi, M.T., Soleimani, M.: Carbon dioxide capture and storage: a general review on adsorbents. World Acad. Sci. Eng. Technol. 6, 213–220 (2012)

Thiruvenkatachari, R., Su, S., An, H., Yu, X.X.: Post combustion CO2 capture by carbon fibre monolithic adsorbents. Prog. Energy Combust. Sci. 35, 438–455 (2009). https://doi.org/10.1016/j.pecs.2009.05.003

Thommes, M., Kaneko, K., Neimark Alexander, V., Olivier James, P., Rodriguez-Reinoso, F., Rouquerol, J., Sing Kenneth, S.W.: Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). pac. 87, 1051 (2015). https://doi.org/10.1515/pac-2014-1117

Wakao, N., Funazkri, T.: Effect of fluid dispersion coefficients on particle-to-fluid mass transfer coefficients in packed beds: correlation of sherwood numbers. Chem. Eng. Sci. 33, 1375–1384 (1978). https://doi.org/10.1016/0009-2509(78)85120-3

Wang, L., Yang, R.T.: Significantly increased CO2 adsorption performance of nanostructured templated carbon by tuning surface area and nitrogen doping. J Phys Chem C. 116, 1099–1106 (2012). https://doi.org/10.1021/jp2100446

Wang, M., Lawal, A., Stephenson, P., Sidders, J., Ramshaw, C.: Post-combustion CO2 capture with chemical absorption: a state-of-the-art review. Chem. Eng. Res. Des. 89, 1609–1624 (2011). https://doi.org/10.1016/j.cherd.2010.11.005

Webley, P.A.: Adsorption technology for CO2 separation and capture: a perspective. Adsorption. 20, 225–231 (2014). https://doi.org/10.1007/s10450-014-9603-2

Williams, J.L.: Monolith structures, materials, properties and uses. Catal. Today. 69, 3–9 (2001). https://doi.org/10.1016/S0920-5861(01)00348-0

Yang, R.T.: Gas Separation by Adsorption Processes. Imperial College Press, London (1997)

Young, L.C., Finlayson, B.A.: Mathematical models of the monolith catalytic converter: part I. Development of model and application of orthogonal collocation. AIChE J. 22, 331–343 (1976). https://doi.org/10.1002/aic.690220216

Zhang, Z., Zhang, W., Chen, X., Xia, Q., Li, Z.: Adsorption of CO2 on zeolite 13X and activated carbon with higher surface area. Sep. Sci. Technol. 45, 710–719 (2010). https://doi.org/10.1080/01496390903571192

Zhang, Z., Zhao, Y., Gong, Q., Li, Z., Li, J.: MOFs for CO2 capture and separation from flue gas mixtures: the effect of multifunctional sites on their adsorption capacity and selectivity. Chem. Commun. 49, 653–661 (2013). https://doi.org/10.1039/C2CC35561B

Acknowledgements

This work was financed by scholarship programme with reference PD/BD/105981/2014 by FCT – Fundação para a Ciência e Tecnologia. This work was financially supported by: Project POCI-01-0145-FEDER-006984 – Associate Laboratory LSRE-LCM funded by FEDER through COMPETE2020 Programa Operacional Competitividade e Internacionalização (POCI) – and by national funds through FCT – Fundação para a Ciência e Tecnologia. The support from Mr. Dabo Chen in Jingdezhen Jiayi advanced material Co. Ltd is highly appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Regufe, M.J., Ferreira, A.F.P., Loureiro, J.M. et al. New hybrid composite honeycomb monolith with 13X zeolite and activated carbon for CO2 capture. Adsorption 24, 249–265 (2018). https://doi.org/10.1007/s10450-018-9938-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10450-018-9938-1