Abstract

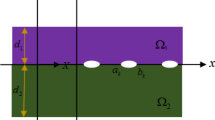

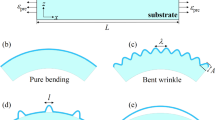

By employing the two-dimensional analysis, i.e., plane strain and plane stress, a semi-analytical method is developed to investigate the interfacial delamination in electrodes. The key parameters are obtained from the governing equations, and their effects on the evolution of the delamination are evaluated. The impact of constraint perpendicular to the plane is also investigated by comparing the plane strain and plane stress. It is found that the delamination in the plane strain condition occurs easier, indicating that the constraint is harmful to maintain the structure stability. According to the obtained governing equations, a formula of the dimensionless critical size for delamination is provided, which is a function of the maximum volumetric strain and the Poisson’s ratio of the active layer.

Similar content being viewed by others

Abbreviations

- x (and \(\eta )\), z (and \(\zeta )\) :

-

Cartesian coordinates (m)

- L and h :

-

Length and thickness of the active layer (m)

- \(L_{c} \) :

-

Critical size for delamination (m)

- c :

-

Molar concentration of lithium-ions \((\hbox {mol}\cdot \hbox {m}^{-3})\)

- \(c_{\mathrm{max}}\) :

-

Stoichiometric saturation concentration \((\hbox {mol}\cdot \hbox {m}^{-3})\)

- \(c_{\mathrm{ave}}\) :

-

Average concentration \((\hbox {mol}\cdot \hbox {m}^{-3})\)

- \(\varphi \) :

-

Inhomogeneity of concentration \((\hbox {mol}\cdot \hbox {m}^{-1})\)

- \(N_x\) and \(Q_{xz}\) :

-

Normal and shear force resultant \((\hbox {N}\cdot \hbox {m}^{-1})\)

- \(M_x \) :

-

Bending moment of active layer (N)

- \(M_{c} \) :

-

Diffusion-induced bending moment (N)

- \(i_{n}\) :

-

Surface current density \((\hbox {A}\cdot \hbox {m}^{-2})\)

- \(\bar{{i}}\) :

-

Electrochemical load factor

- D :

-

Diffusivity of lithium-ions \((\hbox {m}^{2}\cdot \hbox {s}^{-1})\)

- \(\varOmega \) :

-

Partial molar volume of active material \((\hbox {m}^{3}\cdot \hbox {mol}^{-1})\)

- p (and \(\sigma _{n})\) :

-

Interfacial normal stress \((\hbox {N}\cdot \hbox {m}^{-2})\)

- q (and \(\sigma _{t} )\) :

-

Interfacial shear stress \((\hbox {N}\cdot \hbox {m}^{-2})\)

- \(\sigma _{nc} \) and \(\sigma _{tc} \) :

-

Interfacial normal and shear strength \((\hbox {N}\cdot \hbox {m}^{-2})\)

- \(\sigma _x , \sigma _z , \tau _{xz} \) :

-

Stresses \((\hbox {N}\cdot \hbox {m}^{-2})\)

- \(\varepsilon _x , \varepsilon _z , \varepsilon _{xz}\) :

-

Strains

- \(\delta _{n} \) and \(\delta _{t} \) :

-

Interfacial opening and sliding displacement (m)

- \(\delta _{nc} \) and \(\delta _{tc} \) :

-

Critical opening and sliding displacement (m)

- \(\varGamma \) :

-

Interfacial fracture toughness \((\hbox {J}\cdot \hbox {m}^{-2})\)

- \(\upsilon _\mathrm{p} \) and \(\upsilon _\mathrm{s} \) :

-

Poisson’s ratio of active material and substrate

- \(E_\mathrm{p} \) and \(E_\mathrm{s} \) :

-

Young’s modulus of active material and substrate \((\hbox {N}\cdot \hbox {m}^{-2})\)

- \(\bar{{E}}\) :

-

Dimensionless Young’s modulus

- \(u_\mathrm{p}\) and \(w_\mathrm{p} \) :

-

Displacements of the active layer (m)

- \(u_0 \) :

-

Mid-plane displacement (m)

- \(u_\mathrm{s} \) and \(w_\mathrm{s} \) :

-

Displacements of substrate surface (m)

- \(L_1 \) and \(L_2 \) :

-

Rigid displacements of the active layer and substrate (m)

- \(\bar{{L}}_0\) :

-

Rigid displacement difference between active layer and substrate

- I :

-

Bending stiffness of active layer \((\hbox {N}\cdot \hbox {m}\))

- \(G_\mathrm{p}\) :

-

Shear modulus of the active layer \((\hbox {N}\cdot \hbox {m}^{-2})\)

- \(\mu \) :

-

Friction coefficient

- Q :

-

State of charge (SOC)

- t :

-

Time (s)

- \(\bar{{t}}_{c}\) :

-

Time to delamination onset

- F :

-

Faraday constant \((\hbox {s}\cdot \hbox {A}\cdot \hbox {mol}^{-1})\)

- \(H_1 \) :

-

Sliding displacement related to the interfacial stresses

- \(\bar{{F}}_{p} , \bar{{F}}_{q} , \bar{{G}}_{p} , \bar{{G}}_{q} \) :

-

Kernel functions for integral equations

The others which have “\(^{-}\)” on top stand for the corresponding dimensionless symbols. For example, \(\overline{c}\) stands for the dimensionless version of c

References

Chen, J.: Recent progress in advanced materials for lithium ion batteries. Materials 6, 156–183 (2013)

Dahn, J.R., Zheng, T., Liu, Y., et al.: Mechanisms for lithium insertion in carbonaceous materials. Science 270, 590 (1995)

Boukamp, B.A., Lesh, G.C., Huggins, R.A.: All-solid lithium electrodes with mixed-conductor matrix. J. Electrochem. Soc. 128, 725–729 (1981)

Baggetto, L., Niessen, R.A., Roozeboom, F., et al.: High energy density all-solid-state batteries: a challenging concept towards 3D integration. Adv. Funct. Mater. 18, 1057–1066 (2008)

Chan, C.K., Peng, H., Liu, G., et al.: High-performance lithium battery anodes using silicon nanowires. Nat. Nanotechnol. 3, 31–35 (2008)

Maranchi, J.P., Hepp, A.F., Evans, A.G., et al.: Interfacial properties of the a-Si/Cu: active-inactive thin-film anode system for lithium-ion batteries. J. Electrochem. Soc. 153, A1246–A1253 (2006)

Kasavajjula, U., Wang, C., Appleby, A.J.: Nano- and bulk-silicon-based insertion anodes for lithium-ion secondary cells. J. Power Sources 163, 1003–1039 (2007)

Howe, J.Y., Burton, D.J., Qi, Y., et al.: Improving microstructure of silicon/carbon nanofiber composites as a Li battery anode. J. Power Sources 221, 455–461 (2013)

Li, H., Huang, X., Chen, L., et al.: A high capacity nano Si composite anode material for lithium rechargeable batteries. Electrochem. Solid State 2, 547–549 (1999)

Kim, H., Han, B., Choo, J., et al.: Three-dimensional porous silicon particles for use in high-performance lithium secondary batteries. Angew. Chem. Ind. Ed. 120, 10305–10308 (2008)

Souquet, J.L., Duclot, M.: Thin film lithium batteries. Solid State Ion. 148, 375–379 (2002)

Xiao, X., Liu, P., Verbrugge, M.W., et al.: Improved cycling stability of silicon thin film electrodes through patterning for high energy density lithium batteries. J. Power Sources 196, 1409–1416 (2011)

Maranchi, J.P., Hepp, A.F., Kumta, P.N.: High capacity, reversible silicon thin-film anodes for lithium-ion batteries. Electrochem. Solid State 6, A198–A201 (2003)

Haftbaradaran, H., Xiao, X., Verbrugge, M.W., et al.: Method to deduce the critical size for interfacial delamination of patterned electrode structures and application to lithiation of thin-film silicon islands. J. Power Sources 206, 357–366 (2012)

Pal, S., Damle, S.S., Patel, S.H., et al.: Modeling the delamination of amorphous-silicon thin film anode for lithium-ion battery. J. Power Sources 246, 149–159 (2014)

Liu, M.: Finite element analysis of lithiation-induced decohesion of a silicon thin film adhesively bonded to a rigid substrate under potentiostatic operation. Int. J. Solids Struct. 67, 263–271 (2015)

Prezas, P.D., Somerville, L., Jennings, P., et al.: Effect of fast charging of lithium-ion cells: Performance and post-test results. SAE Technical Paper, 2016-01-1194 (2016)

Lu, B., Song, Y., Guo, Z., et al.: Modeling of progressive delamination in a thin film driven by diffusion-induced stresses. Int. J. Solids Struct. 50, 2495–2507 (2013)

Lu, B., Song, Y.C., Guo, Z.S., et al.: Analysis of delamination in thin film electrodes under galvanostatic and potentiostatic operations with Li-ion diffusion from edge. Acta Mech. Sin. 29, 348–356 (2013)

Cheng, Y.-T., Verbrugge, M.W.: Evolution of stress within a spherical insertion electrode particle under potentiostatic and galvanostatic operation. J. Power Sources 190, 453–460 (2009)

Crank, J.: The Mathematics of Diffusion. Oxford University Press, Oxford (1979)

Camacho, G.T., Ortiz, M.: Computational modelling of impact damage in brittle materials. Int. J. Solids Struct. 33, 2899–2938 (1996)

Woelke, P.B., Shields, M.D., Hutchinson, J.W.: Cohesive zone modeling and calibration for mode I tearing of large ductile plates. Eng. Fract. Mech. 147, 293–305 (2015)

Tvergaard, V., Hutchinson, J.W.: The relation between crack growth resistance and fracture process parameters in elastic–plastic solids. J. Mech. Phys. Solids 40, 1377–1397 (1992)

Li, J., Dozier, A.K., Li, Y., et al.: Crack pattern formation in thin film lithium-ion battery electrodes. J. Electrochem. Soc. 158, A689–A694 (2011)

Lei, G.H., Sun, H.S., Ng, C.W.W.: Relative displacements in semi-infinite plane. Rock Soil Mech. 35, 1224 (2014)

Lu, B., Song, Y., Zhang, J.: Time to delamination onset and critical size of patterned thin film electrodes of lithium ion batteries. J. Power Sources 289, 168–183 (2015)

Szczech, J.R., Jin, S.: Nanostructured silicon for high capacity lithium battery anodes. Energy Environ. Sci. 4, 56–72 (2011)

Acknowledgements

The project was supported by the National Natural Science Foundation of China (Grants 11332005 and 11172159) and the Shanghai Municipal Education Commission of China (Grant 13ZZ070).

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix A: Coefficient functions in the governing equations

The explicit expressions for the kernel functions \(\bar{{F}}_p \), \(\bar{{F}}_q \), \(\bar{{G}}_p \), \(\bar{{G}}_q \), \(\bar{{f}}_{c},\) and \(\bar{{g}}_c \) can be described as

Appendix B: Numerical method for solving the derived integral equations

In order to numerically solve the integral Eqs. (15a)–(17d) and Eq. (20), the length of the active layer L is divided into \(\psi \) segments. \(\bar{{x}}_i =\bar{{\eta }}_i =x_i /L=(2i-1)/2\psi \) denotes the mid-point of the ith line segment. Hence, the interface can be partitioned into three zones: damage-free zone (\(1\leqslant i\leqslant \varsigma )\), cohesive zone (\(\varsigma +1\leqslant i\leqslant \xi ),\) and debonding zone (\(\xi +1\leqslant i\leqslant \psi )\). Numerical integration of the integrals in Eqs. (15a)–(17d) and Eq. (20) can be made by the first integral mean value theorem. Take \(\int _0^1 {\bar{{G}}_p } \bar{{p}}\hbox {d}\bar{{\eta }}\) as an example

where \(\alpha _j \!=\!\left( {j-1} \right) /\psi \) and \(\bar{{\bar{{G}}}}_p \left( {\bar{{x}},\bar{{\eta }}_j } \right) \!=\!\int _{\alpha _j }^{\alpha _{j+1} } {\bar{{G}}_p \left( {\bar{{x}},\bar{{\eta }}} \right) } \hbox {d}\bar{{\eta }}\). By using the same numerical integration for all integrals involved, the dimensionless governing Eqs. (15a)–(17d) and Eq. (20) can be discretized into a system of linear equations of \(\bar{{p}}\) and \(\bar{{q}}\).

Consequently, there are \(2\psi +1\) unknowns including \(\bar{{p}}\left( {\bar{{\eta }}_j } \right) \), \(\bar{{q}}\left( {\bar{{\eta }}_j } \right) \!,\) and \(\bar{{L}}_0 \) in \(2\psi +1\) linear algebraic equations. For a given time, the stresses and the lengths of the cohesive zone and debonding zone can be obtained by solving the system of linear equations repeatedly. In the first iteration, initial trial values of segment numbers \(\varsigma \) and \(\xi \) are assumed and the corresponding interfacial stresses can be obtained by solving the equations. Accordingly, \(\varsigma \) and \(\xi \) can be adjusted by comparing the interfacial stresses with cohesive strengths, as well as comparing the open/sliding displacements with critical values. Then the second iteration begins. The iteration will not stop until \(\varsigma \) and \(\xi \) no longer change.

Rights and permissions

About this article

Cite this article

Liu, M., Lu, B., Shi, DL. et al. Two-dimensional analysis of progressive delamination in thin film electrodes. Acta Mech. Sin. 34, 359–370 (2018). https://doi.org/10.1007/s10409-017-0692-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10409-017-0692-5