Abstract

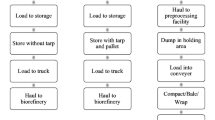

The paddy straw was collected in the form of bales with three mechanical process CI (stubble shaver + rectangular baler), CII (stubble shaver + rake + rectangular baler), and CIII (stubble shaver + round baler) and straw yield prediction modelling and sensitivity analysis based on input and output energy is investigated using the Cobb–Douglas production function and marginal physical productivity (MPP) method. For each process, model I is divided into direct and indirect energies and model II consisted of renewable and non-renewable energies sources. The MPP value of direct, indirect, renewable and non-renewable energy sources was found to be 1.79, 1.38, − 10.57, and 1.36; 1.77, 3.32, 6.03, and 1.87; 5.86, 2.31, − 4.69, and 6.01 for CI, CII and CIII, respectively. Model I was more sensitive towards direct energy, whereas model II was sensitive towards non-renewable energy sources in each process. For CIII, the return to scale was increasing, but for CI and CII, it was declining. The contribution of direct and non-renewable energy sources was fairly dominating over indirect and renewable energy sources for each selected process. The maximum energy productivity and minimum specific energy were observed in CI whereas maximum net energy gain was observed in CII. The GHG emission was minimum in CII for the baler machine as compared to CI and CIII. The results of the study will aid academics and policymakers in optimising energy inputs to increase output energy while reducing pollution by avoiding the burning of paddy straw.

Similar content being viewed by others

References

Cbalabi ZS, Bailey BJ (1991) Sensitivity analysis of a non-steady state model of the greenhouse microclimate. Agric for Meteorol 56:111–127

Dyer JA, Desjardins RL (2006) Carbon dioxide emissions associated with the manufacturing of tractors and farm machinery in Canada. Biosyst Eng 93(1):107–118

Guerrieri AS, Alexandros Sotirios Anifantis AS, Santoro F, Pascuzzi S (2019) Study of a large square Baler with innovative technological systems that optimize the baling effectiveness. Agric MDPI Open Access J 9(5):1–8

Hatirli SA, Ozkan B, Fert C (2005) An econometric analysis of energy input–output in Turkish agriculture. Renew Sust Energy Rev 9:608–623

Heidari MD, Omid M (2011) Energy use patterns and econometric models of major greenhouse vegetable productions in Iran. Energy 36:220–225

Kepner RA, Bainer R, Barger EL (1972) Principles of farm machinery management, chapter 2. The AVI publishing Co. Inc., Westport, p 17

Lemos SV, Denadai MS, Guerra SPS, Esperancini MST, Bueno OC, Takitane IC (2014) Economic efficiency of two baling systems for sugarcane straw. Ind Crops Prod 55:97–101

Lianga QM, Fana Y, Wei YM (2007) Multi-regional input–output model for regional energy requirements and CO2 emissions in China. Energy Policy 35:1685–1700

Malik A, Kumar V, Sharma A, Kumar A (2017) Performance evaluation of strip till seed drill for wheat crop. Int J Sci Eng Res 8:81–100

Mandal KG, Saha KP, Gosh PL, Hati KM, Bandyopadhyay KK (2002) Bioenergy and economic analyses of soybean-based crop production systems in central India. Biomass Bioenergy 23:337–345

Manes GS, Singh S (2005) Sustainability of cotton cultivation through optimal use of energy inputs in Punjab. IE (i) J AG 86:61–64

Mani I, Patel SK (2012) Energy consumption pattern in production of paddy crop in Haryana State in India. Agric Mech Asia Africa Latin Am 43(2):39–42

McLaughlin O, Mawhood B, Jamieson C, Slade R (2016) Rice straw for bioenergy: the effectiveness of policymaking and implementation in Asia. Proceedings of the 24th European Biomass Conference and Exhibition at Amsterdam, Netherlands, 6–9 June, 2016, pp 1–16. https://doi.org/10.5071/24thEUBCE2016-4AV.3.20

Mobtaker HG, Akram A, Keyhani A (2011) Energy use and sensitivity analysis of energy inputs for alfalfa production in Iran. Energy Sustain Dev 16(10):84–89

Mohammadi A, Omid M (2010) Economic analysis and relation between energy inputs and yield of greenhouse cucumber production in Iran. Appl Energy 87:191–196

Nguyen TLT, Gheewala SH, Garivait S (2007) Energy balance and GHG–abatement cost of cassava utilization for fuel ethanol in Thailand. Energy Policy 35:4585–4596

Nguyena HV, Nguyenb CD, Tranb TV, Haub HD, Nguyenb NT, Martin Gummert M (2016) Energy efficiency, greenhouse gas emissions, and cost of rice straw collection in the Mekong river delta of Vietnam. Field Crop Res 198:16–22

Ozkan B, Akcaoz H, Fert C (2004a) Energy input–output analysis in Turkish agriculture. Renew Energy 29:39–51

Ozkan B, Akcaoz H, Karadeniz F (2004b) Energy requirement and economic analysis of citrus production in Turkey. Energy Convers Manag 45:18211830

Pimentel D (1992) Energy inputs in production agriculture. Energy World Agric 6:13–29

Rafiee S, Mousavi Avval SH, Mohammadi A (2010) Modeling and sensitivity analysis of energy inputs for apple production in Iran. Energy 35:3301–3306

Sarkar N, Aikat K (2013) Kinetic study of acid hydrolysis of rice straw. ISRN Biotechnol. https://doi.org/10.5402/2013/170615

Sidhu HS, Singh M, Singh Y, Blackwellc J, Lohan SK, Humphreys E, Jat ML, Singh V, Singh S (2015) Development and evaluation of the Turbo Happy Seeder for sowing wheat into heavy rice residues in NW India. Field Crops Res 184:201–212

Siemens JC, Bowers W (1999) Machinery management, 5th edn. Deere and Company, Litho

Singh S, Mittal JP (1992) Energy in production agriculture, 1st edn. Mittal Publications, New Delhi

Singh G, Singh S, Singh J (2004) Optimization of energy inputs for wheat crop in Punjab. Energy Convers Manag 45:453–465

Singh H, Singh AK, Kushwaha HL, Singh A (2007) Energy consumption pattern of wheat production in India. Energy 32:1848–1854

Sharma A, Chandel R (2016) Comparative field and economic evaluation of baler. Agric Eng 3:69–76

Tabil L, Adapa P, Kashaninejad M (2011) Biomass feedstock preprocessing—part 2: densification. In: Bernardes MADS (ed) Biofuel’s engineering process technology. McGraw-Hill Education, pp 439–464

Ullah A (2009) A comparative analysis of energy use patterns in small and large scale irrigated rice farming systems: a case study in Ayutthaya Province in the Central Region of Thailand. M.Sc. Thesis, Asian Institute of Technology, School of Environment, Resources and Development, Thailand

Acknowledgements

Authors gratefully acknowledged cooperative farmers of Moga district, Punjab, India in recognition of their honest and sincere help in conducting the presented work.

Funding

No funding was received for conducting this study.

Author information

Authors and Affiliations

Contributions

Conceptualization: AS, Methodology: AS, Formal analysis: AS, Investigation: AS, Resources: AS and ASB, Data curation: AS, Writing original draft preparation: AS, Writing, review, and editing: AS and ASB, Visualization: AS, Supervision: AS and ASB, Funding acquisition: ASB.

Corresponding author

Ethics declarations

Conflict of interest

The author has no conflicts of interest to declare that are relevant to the content of this article.

Rights and permissions

About this article

Cite this article

Sharma, A., Brar, A.S. Energy input–output modeling and sensitivity analysis for on-farm mechanically paddy straw bales formation. Paddy Water Environ 20, 255–264 (2022). https://doi.org/10.1007/s10333-021-00888-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10333-021-00888-x