Abstract

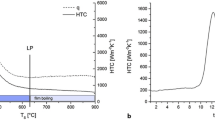

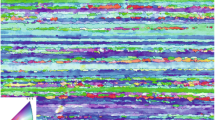

Quenching profiles during their extrusion with subsequent ageing can increase their strength by a factor of 1.5–2 compared to the as-extruded state. Water-air spray cooling is a quenching technology which allows the desired profile temperature to be reached with high accuracy and which is characterised by low energy demand. To apply this cooling technique correctly, the heat transfer coefficient’s dependence on the surface temperature and properties of the extruded profile, made from EN AW-6082 alloy, and on the spray cooling parameters was determined using the lumped heat capacitance method. The absence of a significant impact of the spraying distance and inclination angle on the average heat transfer coefficient within the investigated range was noted. Dependencies of the relative heat transfer coefficient on the temperature and the distance to the spray axis were derived. It was shown that these dependencies, which can be used for modelling such processes, are practically identical for all considered spraying parameters.

Zusammenfassung

Das Abschrecken von Profilen beim Strangpressen mit anschließendem Auslagern kann im Vergleich zum stranggepressten Zustand zu einer Festigkeitssteigerung um den Faktor 1,5 bis 2 führen. Eine der einsetzbaren Abschrecktechnologien ist die Wasser-Luft-Spraykühlung, die eine gezielte Einstellung der Profiltemperatur erlaubt und durch einen geringen Energieverbrauch charakterisiert ist. Zur Anwendung dieser Abkühltechnologie wurde an stranggepressten Profilen der Aluminiumlegierung EN AW-6082 die Abhängigkeit des Wärmeübergangskoeffizienten von der Oberflächentemperatur, den entsprechenden Profileigenschaften und den Sprayparametern mit der Methode der konzentrierten Wärmekapazitäten ermittelt. Ein signifikanter Einfluss des Sprühabstands und –winkels auf die gemittelten Wärmeübergangskoeffizienten im untersuchten Bereich wurde nicht festgestellt. Abhängigkeiten des relativen Wärmeübergangskoeffizienten von der Temperatur und dem Abstand zur Sprühachse wurden hergeleitet. Für die hergeleiteten Abhängigkeiten, die für eine Modellierung solcher Prozesse herangezogen werden können, wurde gezeigt, dass diese für alle untersuchten Sprühparameter anwendbar sind.

Similar content being viewed by others

Abbreviations

- A :

-

cooling surface area (mm2)

- Bi :

-

Biot number (–)

- c p :

-

specific heat (J/(kg·K))

- L :

-

distance from the nozzle exit to the plate surface (mm)

- p A :

-

air pressure (MPa)

- p W :

-

water pressure (MPa)

- q :

-

water consumption (g/s)

- r :

-

radial component (mm)

- R :

-

specimen radius (mm)

- s :

-

plate thickness (mm)

- t :

-

time (s)

- T :

-

surface temperature (°C)

- T 0 :

-

initial temperature (°C)

- T ∞ :

-

temperature of the cooling medium (°C)

- V :

-

volume (mm3)

- α :

-

heat transfer coefficient (W/(m2·K))

- α A :

-

temperature-dependent averaged heat transfer coefficient per impinged area (W/(m2·K))

- α maxA :

-

maximum temperature-dependent averaged heat transfer coefficient per impinged area (W/(m2·K))

- α T :

-

spatial-dependent heat transfer coefficient (W/(m2·K))

- \(\bar{\alpha }\) :

-

mean heat transfer coefficient averaged over both the total specified impingement area and the surface temperature range (W/(m2·K))

- β :

-

jet aperture angle (°)

- γ :

-

angle between the nozzle and perpendicular to the plate (°)

- ρ :

-

density (kg/m3)

- λ :

-

thermal conductivity (J/(K·m·s))

References

Ščerba VN (2001) Pressovanie aljuminievych splavov. Moskva, Intermet inžiniring pp 213–217

Kramer C (2000) Intensive cooling of light metal alloy extrusions by air and water. Proc. 7th International Aluminum Extrusion Technology Seminar Shaping the Future Vol. I Extrusion Process—Extrusion Equipment, Chicago, Illinois, pp 397–407

Cometalʼs BICS (1998) No banana, full quench on hard difficulty, fast profiles. Alum Extrusion 2:18–20

Rodman D, Kerber K, Yu Z, Mozgova I, Nürnberger F, Bach FW (2011) Spatial- and temperature-dependent heat transfer coefficients during spray-cooling of cast AlSi10Mg discs. Forsch Ingenieurwes 71:25–34

Krause C, Wulf E, Nürnberger F, Bach FW (2008) Heat transfer and drop charakteristik during spray cooling in a temperature range from 900 °C to 100 °C. Forsch Ingenieurwes 72:163–173

Nowak M, Golovko O, Nürnberger F, Frolov I, Schaper M (2013) Water-air spray cooling of extruded profiles: process integrated heat treatment of the alloy EN AW-6082. J Mater Eng Perform 22:2580–2587

Jeschar R, Reiners U, Scholz R (1984) Wärmeübergang bei der zweiphasigen Spritzwasserkühlung. Gas Wärme Int 33:299–308

Krause C, Gretzki T, Nürnberger F, Schaper M, Bach FW (2006) Determination of heat transfer coefficients during spray cooling by measuring spray characteristics. Forsch Ingenieurwes 70:237–242

Bratland DH, Grong Ð, Shercliff H, Myhr OR, Tjotta S (1997) Modelling of precipitation reactions in industrial processing. Acta Mater 45:1–22

Hall DD, Mudawar I, Morgan RE, Ehlers SL (1997) Validation of a system approach to modelling spray quenching of aluminium alloy extrusions, composites, and continuous castings. J Mater Eng Perform 6:77–92

Mudawar I, Valentine WS (1989) Determination of the local quench curve for spray-cooled metallic surfaces. J Heat Treat 7:107–121

Mudawar I, Deiters TA (1994) A universal approach to predicting temperature response of metallic parts to spray quenching. Int J Heat Mass Transf 37:347–362

Vorster WJJ, Schwindt SA, Schupp J, Korsunsky AM (2009) Analysis of spray field development on a vertical surface during water spray-quenching using a flat spray nozzle. Appl Therm Eng 29:1406–1416

Puschmann F (2003) Experimentelle Untersuchung der Spraykühlung zur Qualitätsverbesserung durch definierte Einstellung des Wärmeübergangs. Dissertation, Otto-von-Guericke-Universität Magdeburg

Krause C (2008) Randschichtvergüten verzahnter Bauteile mittels einer Wasser-Luft-Spraykühlung. Dissertation, Gottfried Wilhelm Leibniz Universität Hannover

Hamed MS (2000) Evaluation of the heat transfer coefficients in water spray quenching systems. 20th ASM Heat Treating Society Conference Proceedings, St. Louis, pp 785–790

Merker GP, Eiglmeier C (1999) Fluid- und Wärmetransport Wämeübertragung. B. G. Teubner, Stuttgart

Holman PD (2002) Heat transfer. McGraw-Hill, New York

Frolov YV, Gretzki T, Yu Z, Nuernberger F, Hassel Th, Bach FW (2009) Surface hardening spline geometries of heat-treatable steel Cf53 using water-air spray cooling. Conf. Proc. Achievements and prospects of development of processes and equipment of working by pressure in metallurgy and mechanical engineering, 21st–24th of April, Kramatorsk, Ukraine, 2009, pp 270–275

Golovko AN, Rodman D, Nürnberger F, Schaper M, Frolov YV, BÑelÑaiev SM (2012) Investigation of the water-air cooling process of the thick-walled extruded profile made of alloy EN AW-6060 on the output table. Metall Min Ind 4:66–74

Menzler D, Repgen B (1994) Wärmeübergang bei der Wasserkühlung von Aluminium-Strangpressprofilen. Aluminium 70:360–364

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Golovko, O., Frolov, I., Rodman, D. et al. Spray cooling of extruded EN AW-6082 aluminium alloy sheets: spatial heat transfer coefficients. Forsch Ingenieurwes 78, 131–137 (2014). https://doi.org/10.1007/s10010-014-0181-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10010-014-0181-y