Abstract

Thermal treatment of the warm rock mass using liquid nitrogen (LN2) is a prospective rock fracturing technology in many geo-engineering applications. This paper presents an experimental and numerical work aimed at investigating the effect of thermal treatments (i.e., heating–LN2 cooling) on fracture failure characteristics. Mode I fracture toughness as a function of thermal treatment was determined using semi-circular bending tests. The roughness of the resultant fracture surfaces was quantitatively evaluated with a 3D laser scanner and fractal theory. Experimental results show that the thermal treatment has a significant influence on the fracture toughness and roughness. The fracture toughness of the thermally treated samples shows a negative correlation with the heating temperature, except in the range of 25–200 ºC where the fracture toughness shows a slight increase. However, the fracture roughness of thermally treated samples shows an opposite trend as it gradually increases with temperature. Scanning electron microscope analysis associates these phenomena to the development of thermal microcracks. Moreover, numerical simulations using the finite-discrete element method thermo-mechanical code (FDEM-TM) were conducted to reproduce the thermo/mechanical behavior of thermally treated rock, and to help explain the influence of the thermally induced microcracks on the failure mechanisms. The thermally induced microcracks contribute to the variation of the fracture toughness and roughness according to the laboratory experiment and numerical simulation. This work provides an improved understanding of the temperature effect on rock fracture characteristics in engineering applications.

Highlights

-

Fracture characteristics of the heating-cooling treated granite are investigated.

-

Fracture toughness first rises and then drops when heating temperature increases.

-

Fracture roughness shows a positive correlation with the heating temperature.

-

Numerical models reproduce the laboratory results and help to explain the failure mechanism.

-

Thermal microcracks contribute to the variation of fracture toughness and fracture roughness.

Similar content being viewed by others

Abbreviations

- R :

-

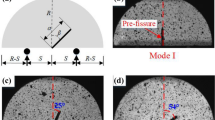

Radius of the semi-circular bend specimen

- B :

-

Thickness of the semi-circular bend specimen

- a :

-

Crack length in the semi-circular bend specimen

- S :

-

Span length in the semi-circular bend specimen

- K IC :

-

Fracture toughness

- P max :

-

Peak load

- Y I :

-

Dimensionless stress intensity factor

- F:

-

Fracture surface

- D :

-

Fractal dimension

- ε and N(ε):

-

Box size and the total number of the boxes

- h ij :

-

Height of points

- M :

-

Lumped mass matrix

- C :

-

Damping diagonal matrix

- x :

-

Vector of the nodal coordinates

- F I, F M, F T and F C :

-

Vectors of internal force, mechanical force, thermal force, and contact force

- σ t :

-

Thermal stress in element

- K :

-

Bulk modulus

- α :

-

Linear thermal expansion coefficient

- T :

-

Temperature

- δ ij :

-

Kronecker’s delta

- c:

-

Heat capacity

- ρ :

-

Mass density

- Q s :

-

Source term

- q :

-

Heat flux

- k :

-

Thermal conductivity

- J :

-

Temperature gradient

- A, b and l :

-

Equivalent area, width and length of the thermal element

- q + c and q − c :

-

Heat flux across the discontinuity

- k c :

-

Interfacial heat conductivity

- T + c and T − c :

-

Temperature at opposite discontinuity surfaces

- o and s :

-

Opening and shear displacement

- o p and s p :

-

Opening and sliding displacement of damage initiation

- o r and s r :

-

Opening and sliding displacement of critical damage

- d :

-

Dimensionless damage factor

- G I and G II :

-

Mode I and mode II fracture energy

References

Ahrens TJ (1995) Mineral physics and crystallography. American Geophysical Union, Washington

Ai T, Zhang R, Zhou HW, Pei JL (2014) Box-counting methods to directly estimate the fractal dimension of a rock surface. Appl Surf Sci 314:610–621. https://doi.org/10.1016/j.apsusc.2014.06.152

Balme MR, Rocchi V, Jones C, Sammonds PR, Meredith PG, Boon S (2004) Fracture toughness measurements on igneous rocks using a high-pressure, high-temperature rock fracture mechanics cell. J Volcanol Geoth Res 132:159–172. https://doi.org/10.1016/S0377-0273(03)00343-3

Blanpied ML, Marone CJ, Lockner DA, Byerlee JD, King DP (1998) Quantitative measure of the variation in fault rheology due to fluid-rock interactions. J Geophys Res 103:9691–9712. https://doi.org/10.1029/98JB00162

Breede K, Dzebisashvili K, Liu X, Falcone G (2013) A systematic review of enhanced (or engineered) geothermal systems: past, present and future. Geotherm Energy 1:163. https://doi.org/10.1186/2195-9706-1-4

Brown SR (1987) A note on the description of surface roughness using fractal dimension. Geophys Res Lett 14:1095–1098. https://doi.org/10.1029/GL014i011p01095

Cai C, Huang Z, Li G, Gao F, Wei J, Li R (2016) Feasibility of reservoir fracturing stimulation with liquid nitrogen jet. J Pet Sci Eng 144:59–65. https://doi.org/10.1016/j.petrol.2016.02.033

Cha M, Yin X, Kneafsey T, Johanson B, Alqahtani N, Miskimins J, Patterson T, Wu Y-S (2014) Cryogenic fracturing for reservoir stimulation. Laboratory studies. J Pet Sci Eng 124:436–450. https://doi.org/10.1016/j.petrol.2014.09.003

Chen Y, Kobayashi T, Kuriki Y, Kusuda H, Mabuchi M (2008) Observation of microstructures in granite samples subjected to one cycle of heating and cooling. J Jpn Soc Eng Geol 49:217–226. https://doi.org/10.5110/jjseg.49.217

Dimadis G, Dimadi A, Bacasis I (2014) Influence of fracture roughness on aperture fracture surface and in fluid flow on coarse-grained marble, experimental results. J Geosci Environ Prot 02:59–67. https://doi.org/10.4236/gep.2014.25009

Edelsbrunner H (2003) Surface reconstruction by wrapping finite sets in space. In: Aronov B, Basu S, Pach J, Sharir M (eds) Discrete and computational geometry, 25th edn. Springer, Berlin, pp 379–404

Fan LF, Wu ZJ, Wan Z, Gao JW (2017) Experimental investigation of thermal effects on dynamic behavior of granite. Appl Therm Eng 125:94–103. https://doi.org/10.1016/j.applthermaleng.2017.07.007

Funatsu T, Seto M, Shimada H, Matsui K, Kuruppu M (2004) Combined effects of increasing temperature and confining pressure on the fracture toughness of clay bearing rocks. Int J Rock Mech Min Sci 41:927–938. https://doi.org/10.1016/j.ijrmms.2004.02.008

Geomechanica Inc (2020) Irazu 2D verification manual. Geomechanica Inc, Toronto

Grundmann SR, Rodvelt GD, Dials GA, Allen RE (1998) Cryogenic nitrogen as a hydraulic fracturing fluid in the Devonian Shale. All Days. SPE, London

Guo Q, Su H, Liu J, Yin Q, Jing H, Yu L (2020) An experimental study on the fracture behaviors of marble specimens subjected to high temperature treatment. Eng Fract Mech 225:106862. https://doi.org/10.1016/j.engfracmech.2019.106862

Guo TY, Wong LNY, Wu Z (2021) Microcracking behavior transition in thermally treated granite under mode I loading. Eng Geol 282:105992. https://doi.org/10.1016/j.enggeo.2021.105992

Ha J, Lisjak A, Grasselli G (2022) FDEM modelling of thermo-mechanical wellbore instabilities within shale formations., In: 49th U.S. Rock mechanics/geomechanics symposium, San Francisco, USA

Heuze FE (1983) High-temperature mechanical, physical and Thermal properties of granitic rocks: a review. Int J Rock Mech Min Sci Geomech Abstr 20:3–10. https://doi.org/10.1016/0148-9062(83)91609-1

Ichikawa Y, Kawamura K, Uesugi K, Seo Y-S, Fujii N (2001) Micro- and macrobehavior of granitic rock: observations and viscoelastic homogenization analysis. Comput Methods Appl Mech Eng 191:47–72. https://doi.org/10.1016/S0045-7825(01)00244-4

ISRM (1978) Suggested methods for determining tensile strength of rock materials. Int J Rock Mech Min Sci Geomech Abstr 15:99–103. https://doi.org/10.1016/0148-9062(78)90003-7

Ji P, Zhang X, Zhang Q (2018) A new method to model the non-linear crack closure behavior of rocks under uniaxial compression. Int J Rock Mech Min Sci 112:171–183. https://doi.org/10.1016/j.ijrmms.2018.10.015

Kant M, Rossi E, Madonna C, Höser D, von Rohr PR (2017) A theory on thermal spalling of rocks with a focus on thermal spallation drilling. J Geophys Res. https://doi.org/10.1002/2016JB013800

Kuruppu MD, Obara Y, Ayatollahi MR, Chong KP, Funatsu T (2014) ISRM-suggested method for determining the mode I static fracture toughness using semi-circular bend specimen. Rock Mech Rock Eng 47:267–274. https://doi.org/10.1007/s00603-013-0422-7

Li J, Du Q, Sun C (2009) An improved box-counting method for image fractal dimension estimation. Pattern Recogn 42:2460–2469. https://doi.org/10.1016/j.patcog.2009.03.001

Lisjak A, Grasselli G, Vietor T (2014) Continuum–discontinuum analysis of failure mechanisms around unsupported circular excavations in anisotropic clay shales. Int J Rock Mech Min Sci 65:96–115. https://doi.org/10.1016/j.ijrmms.2013.10.006

Liu Q, Sun L (2019) Simulation of coupled hydro-mechanical interactions during grouting process in fractured media based on the combined finite-discrete element method. Tunn Undergr Space Technol 84:472–486. https://doi.org/10.1016/j.tust.2018.11.018

Mahanta B, Singh TN, Ranjith PG (2016) Influence of thermal treatment on mode I fracture toughness of certain Indian rocks. Eng Geol 210:103–114. https://doi.org/10.1016/j.enggeo.2016.06.008

Mavko G, Mukerji T, Dvorkin J (2009) The rock physics handbook. Cambridge University Press, Cambridge

Meredith PG, Atkinson BK (1985) Fracture toughness and subcritical crack growth during high-temperature tensile deformation of Westerly granite and Black gabbro. Phys Earth Planet Inter 39:33–51. https://doi.org/10.1016/0031-9201(85)90113-X

Munjiza A, Andrews KRF, White JK (1999) Combined single and smeared crack model in combined finite-discrete element analysis. Int J Numer Meth Eng 44:41–57. https://doi.org/10.1002/(SICI)1097-0207(19990110)44:1%3c41:AID-NME487%3e3.0.CO;2-A

Nasseri MHB, Schubnel A, Young RP (2007) Coupled evolutions of fracture toughness and elastic wave velocities at high crack density in thermally treated Westerly granite. Int J Rock Mech Min Sci 44:601–616. https://doi.org/10.1016/j.ijrmms.2006.09.008

Nasseri MHB, Tatone BSA, Grasselli G, Young RP (2009) Fracture toughness and fracture roughness interrelationship in thermally treated westerly granite. Pure Appl Geophys 166:801–822. https://doi.org/10.1007/s00024-009-0476-3

Neuville A, Toussaint R, Schmittbuhl J (2010) Hydrothermal coupling in a self-affine rough fracture. Phys Rev E 82:36317. https://doi.org/10.1103/PhysRevE.82.036317

Ozguven A, Ozcelik Y (2014) Effects of high temperature on physico-mechanical properties of Turkish natural building stones. Eng Geol 183:127–136. https://doi.org/10.1016/j.enggeo.2014.10.006

Panigrahy C, Seal A, Mahato NK, Bhattacharjee D (2019) Differential box counting methods for estimating fractal dimension of gray-scale images: a survey. Chaos, Solitons Fractals 126:178–202. https://doi.org/10.1016/j.chaos.2019.06.007

Peng K, Lv H, Fan F, Zou Q, Song X, Liu Z (2020) Effects of temperature on mechanical properties of granite under different fracture modes. Eng Fract Mech 226:106838. https://doi.org/10.1016/j.engfracmech.2019.106838

Ritchie RO (2011) The conflicts between strength and toughness. Nat Mater 10:817–822. https://doi.org/10.1038/nmat3115

Salimzadeh S, Paluszny A, Nick HM, Zimmerman RW (2018) A three-dimensional coupled thermo-hydro-mechanical model for deformable fractured geothermal systems. Geothermics 71:212–224. https://doi.org/10.1016/j.geothermics.2017.09.012

Scott S, Driesner T, Weis P (2015) Geologic controls on supercritical geothermal resources above magmatic intrusions. Nat Commun 6:7837. https://doi.org/10.1038/ncomms8837

Shao Z, Wang Y, Tang X (2020) The influences of heating and uniaxial loading on granite subjected to liquid nitrogen cooling. Eng Geol 271:105614. https://doi.org/10.1016/j.enggeo.2020.105614

Sun L, Liu Q, Grasselli G, Tang X (2020a) Simulation of thermal cracking in anisotropic shale formations using the combined finite-discrete element method. Comput Geotech 117:103237. https://doi.org/10.1016/j.compgeo.2019.103237

Sun L, Grasselli G, Liu Q, Tang X (2020b) Thermal cracking simulation of functionally graded materials using the combined finite–discrete element method. Comput Part Mech 7:903–917. https://doi.org/10.1007/s40571-019-00290-9

Vilarrasa V, Rutqvist J (2017) Thermal effects on geologic carbon storage. Earth Sci Rev 165:245–256. https://doi.org/10.1016/j.earscirev.2016.12.011

Wang F, Konietzky H, Frühwirt T, Dai Y (2020) Laboratory testing and numerical simulation of properties and thermal-induced cracking of Eibenstock granite at elevated temperatures. Acta Geotech 15:2259–2275. https://doi.org/10.1007/s11440-020-00926-8

Wu X, Huang Z, Li R, Zhang S, Wen H, Huang P, Dai X, Zhang C (2018) Investigation on the damage of high-temperature shale subjected to liquid nitrogen cooling. J Natl Gas Sci Eng 57:284–294. https://doi.org/10.1016/j.jngse.2018.07.005

Wu X, Huang Z, Cheng Z, Zhang S, Song H, Zhao X (2019a) Effects of cyclic heating and LN2-cooling on the physical and mechanical properties of granite. Appl Therm Eng 156:99–110. https://doi.org/10.1016/j.applthermaleng.2019.04.046

Wu Q, Weng L, Zhao Y, Guo B, Luo T (2019b) On the tensile mechanical characteristics of fine-grained granite after heating/cooling treatments with different cooling rates. Eng Geol 253:94–110. https://doi.org/10.1016/j.enggeo.2019.03.014

Yan C, Fan H, Zheng Y, Zhao Y, Ning F (2020) Simulation of the thermal shock of brittle materials using the finite-discrete element method. Eng Anal Bound Elem 115:142–155. https://doi.org/10.1016/j.enganabound.2020.03.013

Yang S, Hu B (2018) Creep and Long-Term Permeability of a Red Sandstone Subjected to Cyclic Loading After Thermal Treatments. Rock Mech Rock Eng 51:2981–3004. https://doi.org/10.1007/s00603-018-1528-8

Yin T, Li X, Xia K, Huang S (2012) Effect of thermal treatment on the dynamic fracture toughness of laurentian granite. Rock Mech Rock Eng 45:1087–1094. https://doi.org/10.1007/s00603-012-0240-3

Yin W, Zhao Y, Feng Z (2020) Experimental research on the permeability of fractured-subsequently-filled granite under high temperature-high pressure and the application to HDR geothermal mining. Renew Energy 153:499–508. https://doi.org/10.1016/j.renene.2020.02.009

Yvonnet J, He Q-C, Zhu Q-Z, Shao J-F (2011) A general and efficient computational procedure for modelling the Kapitza thermal resistance based on XFEM. Comput Mater Sci 50:1220–1224. https://doi.org/10.1016/j.commatsci.2010.02.040

Zhang Q (2004) A boundary element method for thermoporoelasticity with application in rock mechanics. Master thesis. Master thesis, University of North Dakota

Zhang S, Huang Z, Wang H, Li G, Sepehrnoori K, Wu X, Hong C (2019) Experimental study on the rock-breaking characteristics of abrasive liquid nitrogen jet for hot dry rock. J Pet Sci Eng 181:106166. https://doi.org/10.1016/j.petrol.2019.06.030

Zhao Z (2016) Thermal influence on mechanical properties of granite: a microcracking perspective. Rock Mech Rock Eng 49:747–762. https://doi.org/10.1007/s00603-015-0767-1

Zhao Y, Feng Z, Zhao Y, Wan Z (2017) Experimental investigation on thermal cracking, permeability under HTHP and application for geothermal mining of HDR. Energy 132:305–314. https://doi.org/10.1016/j.energy.2017.05.093

Zhao Z, Dou Z, Xu H, Liu Z (2019) Shear behavior of Beishan granite fractures after thermal treatment. Eng Fract Mech 213:223–240. https://doi.org/10.1016/j.engfracmech.2019.04.012

Acknowledgements

This work was supported by the Natural Sciences and Engineering Research Council of Canada (NSERC) Discovery Grants 341275 and National Key Research and Development Program of China 2017YFC1501300.

Author information

Authors and Affiliations

Contributions

ZS: conceptualization, methodology, and writing—original draft; LS: conceptualization, methodology, software, and writing—review and editing; KRA: writing—review and editing, and visualization; QL: supervision, writing—review and editing, and funding acquisition; GG: supervision, writing—review and editing, and funding acquisition.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shao, Z., Sun, L., Aboayanah, K.R. et al. Investigate the Mode I Fracture Characteristics of Granite After Heating/-LN2 Cooling Treatments. Rock Mech Rock Eng 55, 4477–4496 (2022). https://doi.org/10.1007/s00603-022-02893-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-022-02893-w