Abstract

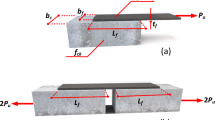

The application of fiber-reinforced polymer (FRP) strips or rods in the form of near-surface-mounted (NSM) reinforcement has become an attractive solution to strengthen the existing buildings and bridges. It is of interest to engineers to have an accurate estimate of the bond capacity of this technique. In this paper, fuzzy logic approach is utilized to propose an alternative method of determining the pullout strength of NSM FRP strips/rods which are bonded to the concrete block. Two types of fuzzy logic models, namely Mamdani and Takagi–Sugeno, are developed. With the aim of enhancing the interpretability of the fuzzy model, the rule base of Mamdani model is extracted from the classification decision tree, and the membership functions corresponding to the linguistic concepts are built by uniform partitioning the range of variables. On the other hand, in order to arrive at closed-form equations for pullout capacity, the subtractive clustering algorithm is employed to deduce the rule base and membership functions of Takagi–Sugeno model (first order), and its consequent part is tuned by the least square optimization using training dataset. Several fuzzy logic models of both types with different numbers of rules are developed and compared in terms of different error measures. To train and validate the fuzzy models, a large database of 384 direct pullout tests on NSM FRP bonded to concrete is assembled from the literature. The results reveal that both of the proposed Mamdani and Takagi–Sugeno models demonstrate good accuracy against the experimental data and outperform the published models. A parametric study indicates that the proposed fuzzy models can predict the maximum effective bond length, and thus, they are able to capture the underlying mechanics of the problem.

Similar content being viewed by others

References

Chen JF, Teng JG (2001) Anchorage strength models for FRP and steel plates bonded to concrete. J Struct Eng 127(7):784–791

Kara IF, Ashour AF, Köroğlu MA (2016) Flexural performance of reinforced concrete beams strengthened with prestressed near-surface-mounted FRP reinforcements. Compos Part B Eng 91:371–383

Kalupahana WKKG, Ibell TJ, Darby AP (2013) Bond characteristics of near surface mounted CFRP bars. Constr Build Mater 43:58–68

Sharaky IA, Torres L, Baena M, Vilanova I (2013) Effect of different material and construction details on the bond behaviour of NSM FRP bars in concrete. Constr Build Mater 38:890–902

Bilotta A, Ceroni F, Di Ludovico M, Nigro E, Pecce M, Manfredi G (2011) Bond efficiency of EBR and NSM FRP systems for strengthening concrete members. J Compos Constr 15(5):757–772

Seo SY, Feo L, Hui D (2013) Bond strength of near surface-mounted FRP plate for retrofit of concrete structures. Compos Struct 95:719–727

Seracino R, Raizal Saifulnaz MR, Oehlers DJ (2007) Generic debonding resistance of EB and NSM plate-to-concrete joints. J Compos Constr 11(1):62–70

Zhang SS, Teng JG, Yu T (2013) Bond strength model for CFRP strips near-surface mounted to concrete. J Compos Constr. https://doi.org/10.1061/(ASCE)CC.1943-5614.0000402

Guillaume S (2001) Designing fuzzy inference systems from data: an interpretability-oriented review. IEEE Trans Fuzzy Syst 9(3):426–443

Mikut R, Jäkel J, Gröll L (2005) Interpretability issues in data-based learning of fuzzy systems. Fuzzy Set Syst 150(2):179–197

Dilmaç H, Demir F (2013) Stress–strain modeling of high-strength concrete by the adaptive network-based fuzzy inference system (ANFIS) approach. Neural Comput Appl 23(1):385–390

Cevik A, Ozturk S (2009) Neuro-fuzzy model for shear strength of reinforced concrete beams without web reinforcement. Civ Eng Environ Syst 26(3):263–277

Cevik A (2011) Modeling strength enhancement of FRP confined concrete cylinders using soft computing. Expert Syst Appl 38(5):5662–5673

Nasrollahzadeh K, Basiri MM (2014) Prediction of shear strength of FRP reinforced concrete beams using fuzzy inference system. Expert Syst Appl 41(4):1006–1020

Nasrollahzadeh K, Nouhi E (2018) Fuzzy inference system to formulate compressive strength and ultimate strain of square concrete columns wrapped with fiber-reinforced polymer. Neural Comput Appl 30(1):69–86

Subaşı S, Beycioğlu A, Sancak E, Şahin İ (2013) Rule-based Mamdani type fuzzy logic model for the prediction of compressive strength of silica fume included concrete using non-destructive test results. Neural Comput Appl 22(6):1133–1139

Doran B, Yetilmezsoy K, Murtazaoglu S (2015) Application of fuzzy logic approach in predicting the lateral confinement coefficient for RC columns wrapped with CFRP. J Eng Struct 88(1):74–91

Hoque N, Jumaat MZ, Shukri AA (2017) Critical curtailment location of EBR FRP bonded RC beams using dimensional analysis and fuzzy logic expert system. Compos Struct 166:87–95

ud Darain KM, Jumaat MZ, Hossain MA, Hosen MA, Obaydullah M, Huda MN, Hossain I (2015) Automated serviceability prediction of NSM strengthened structure using a fuzzy logic expert system. Expert Syst Appl 42(1):376–389

ud Darain KM, Shamshirband S, Jumaat MZ, Obaydullah M (2015) Adaptive neuro fuzzy prediction of deflection and cracking behavior of NSM strengthened RC beams. Constr Build Mater 98:276–285

Sharaky IA, Torres L, Baena M, Miàs C (2013) An experimental study of different factors affecting the bond of NSM FRP bars in concrete. Compos Struct 99:350–365

De Lorenzis L, Rizzo A, La Tegola A (2002) A modified pull-out test for bond of near-surface mounted FRP rods in concrete. Compos Part B Eng 33(8):589–603

De Lorenzis L, Nanni A (2002) Bond between near-surface mounted fiber-reinforced polymer rods and concrete in structural strengthening. ACI Struct J 99(2):123–132

Lee D, Cheng L, Yan-Gee Hui J (2012) Bond characteristics of various NSM FRP reinforcements in concrete. J Compos Constr 17(1):117–129

Ceroni F, Pecce M, Bilotta A, Nigro E (2012) Bond behavior of FRP NSM systems in concrete elements. Compos Part B Eng 43(2):99–109

Bilotta A, Ceroni F, Nigro E, Pecce M (2014) Strain assessment for the design of NSM FRP systems for the strengthening of RC members. Constr Build Mater 69:143–158

Seracino R, Jones NM, Ali MS, Page MW, Oehlers DJ (2007) Bond strength of near-surface mounted FRP strip-to-concrete joints. J Compos Constr 11(4):401–409

Rashid R, Oehlers DJ, Seracino R (2008) IC debonding of FRP NSM and EB retrofitted concrete: plate and cover interaction tests. J Compos Constr 12(2):160–167

Oehlers DJ, Haskett M, Wu C, Seracino R (2008) Embedding NSM FRP plates for improved IC debonding resistance. J Compos Constr 12(6):635–642

Soliman SM, El-Salakawy E, Benmokrane B (2010) Bond performance of near-surface-mounted FRP bars. J Compos Constr 15(1):103–111

Novidis DG, Pantazopoulou SJ (2008) Bond tests of short NSM-FRP and steel bar anchorages. J Compos Constr 12(3):323–333

Shield C, French C, Milde E (2005) The effect of adhesive type on the bond of NSM tape to concrete. In: ACI SP230: 7th international symposium on fiber-reinforced polymer (FRP) reinforcement for concrete structures

Lee D, Hui J, Cheng L (2012) Bond characteristics of NSM reinforcement in concrete due to adhesive type and surface configuration. In: 6th International conference on FRP composites in civil engineering (CICE2012). Rome, Italy

Palmieri A, Matthys S, Taerwe L (2012) Double bond shear tests on NSM FRP strengthened members. In: 6th international conference on FRP composites in civil engineering (CICE2012)

Novidis D, Pantazopoulou SJ, Tentolouris E (2007) Experimental study of bond of NSM-FRP reinforcement. Constr Build Mater 21(8):1760–1770

Palmieri A, Matthys S, Barros JA, Costa I, Bilotta A, Nigro E, Ceroni F, Szambo Z, Balazs G (2012) Bond of NSM FRP strengthened concrete: round robin test initiative. In: 6th international conference on FRP composites in civil engineering (CICE2012)

De Lorenzis L, Lundgren K, Rizzo A (2004) Anchorage length of near-surface mounted fiber-reinforced polymer bars for concrete strengthening-experimental investigation and numerical modeling. ACI Struct J 101(2):269–278

El-Gamal S, Al-Salloum Y, Alsayed S, Aqel M (2012) Performance of near surface mounted glass fiber reinforced polymer bars in concrete. J Reinf Plast Compos 31(22):1501–1515

Peng H, Hao H, Zhang J, Liu Y, Cai CS (2015) Experimental investigation of the bond behavior of the interface between near-surface-mounted CFRP strips and concrete. Constr Build Mater 96:11–19

Zadeh LA (1965) Fuzzy sets. Inform Control 8(3):338–353

Takagi T, Sugeno M (1985) Fuzzy identification of systems and its applications to modeling and control. IEEE Trans Syst Man Cybern 1:116–132

Mamdani EH, Assilian S (1975) An experiment in linguistic synthesis with a fuzzy logic controller. Int J Man Mach Stud 7(1):1–13

Yuan Y, Shaw MJ (1995) Induction of fuzzy decision trees. Fuzzy Set Syst 69(2):125–139

Quinlan JR (1986) Induction of decision trees. Mach Learn 1(1):81–106

Brieman L, Friedman JH, Olshen R, Stone C (1984) Classification and regression trees. Wadsworth, Belmont

Chiu SL (1994) Fuzzy model identification based on cluster estimation. J Intell Fuzzy Syst 2(3):267–278

Funding

This research received no specific grant from any funding agency in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Appendices

Appendix 1: List of fuzzy rules in the proposed Mamdani model for the pullout capacity of NSM FRP

IF | THEN |

|---|---|

1. L = [VL] ⋀ fc′ = [VL] | Pf = [VL] |

2. L = [VL] ⋀ fc′ ≠ [VL] | Pf = [L] |

3. L ≠ [VL] ⋀ AfEf = [VL] ⋀ Dg/Wg ≠ [H] ⋀ Pnorm/Anorm = [VL] | Pf = [AL] |

4. L ≠ [VL] ⋀ AfEf = [VL] ⋀ Dg/Wg ≠ [H] ⋀ Pnorm/Anorm = [L] | Pf = [L] |

5. L ≠ [VL] ⋀ AfEf = [VL] ⋀ Dg/Wg ≠ [H] ⋀ Pnorm/Anorm = [M] | Pf = [AH] |

6. L ≠ [VL] ⋀ AfEf = [VL] ⋀ Dg/Wg ≠ [H] ⋀ Pnorm/Anorm = ([H] ν [VH]) | Pf = [L] |

7. L ≠ [VL] ⋀ AfEf = [VL] ⋀ Dg/Wg = [H] | Pf = [AH] |

8. L ≠ [VL] ⋀ AfEf = ([L] ν [M] ν [H]) ⋀ fc′ = ([VL] ν [L]) ⋀ fe = [VL] | Pf = [AL] |

9. L ≠ [VL] ⋀ AfEf = [VH] ⋀ fc′ = ([VL] ν [L]) ⋀ fe = [VL] | Pf = [L] |

10. L ≠ [VL] ⋀ AfEf ≠ [VL] ⋀ fc′ = [VL] ⋀ fe ≠ [VL] | Pf = [AL] |

11. L ≠ [VL] ⋀ AfEf = ([L] ν [M] ν [H]) ⋀ fc′ = [L] ⋀ fe ≠ [VL] | Pf = [AL] |

12. L ≠ [VL] ⋀ AfEf = [VH] ⋀ fc′ = [L] ⋀ fe ≠ [VL] | Pf = [AH] |

13. L = ([L] ν [M]) ⋀ AfEf ≠ [VL] ⋀ fc′ = ([M] ν [H] ν [VH]) ⋀ fe = ([VL] ν [L]) ⋀ Pnorm/Anorm = [VL] | Pf = [H] |

14. L = ([L] ν [M]) ⋀ AfEf ≠ [VL] ⋀ fc′ = ([M] ν [H] ν [VH]) ⋀ fe = ([M] ν [H] ν [VH]) ⋀ Pnorm/Anorm = [VL] | Pf = [AL] |

15. L = ([L] ν [M]) ⋀ AfEf ≠ [VL] ⋀ fc′ = ([M] ν [H] ν [VH]) ⋀ Pnorm/Anorm ≠ [VL] | Pf = [AL] |

16. L = ([H] ν [VH]) ⋀ AfEf ≠ [VL] ⋀ fc′ = [M] | Pf = [VH] |

17. L = ([H] ν [VH]) ⋀ AfEf ≠ [VL] ⋀ fc′ = ([H] ν [VH]) | Pf = [H] |

Appendix 2: Closed-form relations for the proposed Sugeno model (with three rules) for the pullout capacity of NSM FRP

Example

An experimental data point with L = 200 mm, AfEf = 2053 kN, fc′ = 52.8 MPa, fe = 16 MPa, Pnorm/Anorm = 5.28, and Dg/Wg = 3.77 is considered. The details of calculations are as follows: Pf1 = 59.5475 kN, Pf2 = 30.2443 kN, Pf3 = − 34.3894 kN, w1 = 0.0064, w2 = 0.8182, and w3 = 0.0003. Thereby, the proposed Sugeno fuzzy model yields Pf = 30.54 kN, which agrees with the experimental value of 30.45 kN (see Fig. 7).

Appendix 3: The detailed information on experimental data

This appendix includes a table listing the geometrical/mechanical properties of FRP bars/strips, groove, epoxy, and concrete as well as other testing conditions such as the experimental pullout capacity and bonded length. The table is as follows:

References | No. | L (mm) | FRP bar or strip | Groove | fe (MPa) | fc′ (MPa) | Pf (kN) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ef (GPa) | fu (MPa) | Db (mm) | tf (mm) | wf (mm) | Dg (mm) | Wg (mm) | ||||||

[6] | N150-1 | 150 | 160 | 2800 | – | 3.6 | 16 | 20 | 7.1 | 28 | 24 | 88.26 |

N200-1 | 200 | 160 | 2800 | – | 3.6 | 16 | 20 | 7.1 | 28 | 24 | 90.21 | |

N150-1-1S | 150 | 160 | 2800 | – | 3.6 | 16 | 20 | 7.1 | 28 | 24 | 90.22 | |

N150-1-2S | 150 | 160 | 2800 | – | 3.6 | 16 | 20 | 7.1 | 28 | 24 | 90.22 | |

[21] | L1612AC1-1 | 192 | 170 | 2350 | 8 | – | – | 16 | 12 | 18.85 | 23.5 | 36.8 |

L1612AC1-2 | 192 | 170 | 2350 | 8 | – | – | 16 | 12 | 18.85 | 23.5 | 36.65 | |

L1616AC1-1 | 192 | 170 | 2350 | 8 | – | – | 16 | 16 | 18.85 | 23.5 | 40.12 | |

L1616AC1-2 | 192 | 170 | 2350 | 8 | – | – | 16 | 16 | 18.85 | 23.5 | 39.82 | |

L1515AC2-1 | 192 | 134 | 2010 | 9 | – | – | 15 | 15 | 18.85 | 23.5 | 44.91 | |

L1515AC2-2 | 192 | 134 | 2010 | 9 | – | – | 15 | 15 | 18.85 | 23.5 | 44.65 | |

L1616BC1-1 | 192 | 170 | 2350 | 8 | – | – | 16 | 16 | 22.95 | 23.5 | 48.99 | |

L1616BC1-2 | 192 | 170 | 2350 | 8 | – | – | 16 | 16 | 22.95 | 23.5 | 47.31 | |

T1616BC1-1 | 240 | 170 | 2350 | 8 | – | – | 16 | 16 | 22.95 | 23.5 | 54.79 | |

T1616BC1-2 | 240 | 170 | 2350 | 8 | – | – | 16 | 16 | 22.95 | 23.5 | 58.09 | |

L1612AG1-1 | 192 | 64 | 1350 | 8 | – | – | 16 | 12 | 18.85 | 23.5 | 31.43 | |

L1612AG1-2 | 192 | 64 | 1350 | 8 | – | – | 16 | 12 | 18.85 | 23.5 | 35.63 | |

L1616AG1-1 | 192 | 64 | 1350 | 8 | – | – | 16 | 16 | 18.85 | 23.5 | 36.23 | |

L1616AG1-2 | 192 | 64 | 1350 | 8 | – | – | 16 | 16 | 18.85 | 23.5 | 38.92 | |

L1916AG1U-1 | 192 | 64 | 1350 | 8 | – | – | 16 | 16 | 18.85 | 23.5 | 35.8 | |

L1916AG1U-2 | 192 | 64 | 1350 | 8 | – | – | 16 | 16 | 18.85 | 23.5 | 36.33 | |

L1616AG1I-1 | 192 | 64 | 1350 | 8 | – | – | 19 | 16 | 18.85 | 23.5 | 35.28 | |

L1616AG1I-2 | 192 | 64 | 1350 | 8 | – | – | 16 | 16 | 18.85 | 23.5 | 33.33 | |

L1818AG2-1 | 192 | 64 | 1350 | 12 | – | – | 16 | 16 | 18.85 | 23.5 | 59.97 | |

L1818AG2-2 | 192 | 64 | 1350 | 12 | – | – | 18 | 18 | 18.85 | 23.5 | 57.53 | |

L1616BG1-1 | 192 | 64 | 1350 | 8 | – | – | 18 | 18 | 22.95 | 23.5 | 56.67 | |

L1616BG1-2 | 192 | 64 | 1350 | 8 | – | – | 16 | 16 | 22.95 | 23.5 | 44.56 | |

L1616BG1-3 | 192 | 64 | 1350 | 8 | – | – | 16 | 16 | 22.95 | 23.5 | 48.06 | |

L1616CG1-1 | 192 | 64 | 1350 | 8 | – | – | 16 | 16 | 22.34 | 23.5 | 56.34 | |

L1616CG1-2 | 192 | 64 | 1350 | 8 | – | – | 16 | 16 | 22.34 | 23.5 | 45.36 | |

L1616CG1-3 | 192 | 64 | 1350 | 8 | – | – | 16 | 16 | 22.34 | 23.5 | 52.34 | |

L1616DG1-1 | 192 | 64 | 1350 | 8 | – | – | 16 | 16 | 21 | 23.5 | 52.1 | |

L1616DG1-2 | 192 | 64 | 1350 | 8 | – | – | 16 | 16 | 21 | 23.5 | 57.79 | |

[22] | SW/k1.25/104 | 30 | 174.71 | 2214 | 8 | – | – | 16 | 16 | 28 | 22 | 9.46 |

SW/k1.50/104 | 30 | 174.71 | 2214 | 8 | – | – | 10 | 10 | 28 | 22 | 11.79 | |

SW/k2.00/104 | 30 | 174.71 | 2214 | 8 | – | – | 12 | 12 | 28 | 22 | 12.07 | |

SW/k2.50/104 | 30 | 174.71 | 2214 | 8 | – | – | 16 | 16 | 28 | 22 | 13.39 | |

SW/k1.25/112 | 90 | 174.71 | 2214 | 8 | – | – | 20 | 20 | 28 | 22 | 25.71 | |

SW/k1.50/112 | 90 | 174.71 | 2214 | 8 | – | – | 10 | 10 | 28 | 22 | 26.34 | |

SW/k2.00/112 | 90 | 174.71 | 2214 | 8 | – | – | 12 | 12 | 28 | 22 | 23.2 | |

SW/k2.50/112 | 90 | 174.71 | 2214 | 8 | – | – | 16 | 16 | 28 | 22 | 32.16 | |

SW/k1.25/124 | 180 | 174.71 | 2214 | 8 | – | – | 20 | 20 | 28 | 22 | 46.02 | |

SW/k1.50/124 | 180 | 174.71 | 2214 | 8 | – | – | 10 | 10 | 28 | 22 | 49.7 | |

SW/k2.00/124 | 180 | 174.71 | 2214 | 8 | – | – | 12 | 12 | 28 | 22 | 49.68 | |

SW/k2.50/124 | 180 | 174.71 | 2214 | 8 | – | – | 16 | 16 | 28 | 22 | 58.62 | |

CR3/k1.24/104 | 38 | 109.27 | 2014 | 11.3 | – | – | 20 | 20 | 28 | 22 | 12.64 | |

CR3/k1.59/104 | 38 | 109.27 | 2014 | 11.3 | – | – | 14 | 14 | 28 | 22 | 12.83 | |

CR3/k2.12/104 | 38 | 109.27 | 2014 | 11.3 | – | – | 18 | 18 | 28 | 22 | 16.63 | |

GR3/k1.27/104 | 38 | 37.17 | 873 | 11 | – | – | 24 | 24 | 28 | 22 | 11.22 | |

GR3/k1.64/104 | 38 | 37.17 | 873 | 11 | – | – | 14 | 14 | 28 | 22 | 11.41 | |

GR3/k2.18/104 | 38 | 37.17 | 873 | 11 | – | – | 18 | 18 | 28 | 22 | 13.07 | |

[23] | G4D6a | 78 | 41.3 | 799 | 13 | – | – | 24 | 24 | 13.8 | 27.6 | 24.69 |

G4D12a | 156 | 41.3 | 799 | 13 | – | – | 15.87 | 15.87 | 13.8 | 27.6 | 34.61 | |

G4D12b | 156 | 41.3 | 799 | 13 | – | – | 19.05 | 19.05 | 13.8 | 27.6 | 36.97 | |

G4D12c | 156 | 41.3 | 799 | 13 | – | – | 25.4 | 25.4 | 13.8 | 27.6 | 42.84 | |

G4D18a | 234 | 41.3 | 799 | 13 | – | – | 15.87 | 15.87 | 13.8 | 27.6 | 42.55 | |

G4D24c | 312 | 41.3 | 799 | 13 | – | – | 25.4 | 25.4 | 13.8 | 27.6 | 61.93 | |

C3D6a | 57 | 164.7 | 1550 | 9.5 | – | – | 12.7 | 12.7 | 13.8 | 27.6 | 15.68 | |

C3D12a | 114 | 164.7 | 1550 | 9.5 | – | – | 12.7 | 12.7 | 13.8 | 27.6 | 26.73 | |

C3D12b | 114 | 164.7 | 1550 | 9.5 | – | – | 19.05 | 19.05 | 13.8 | 27.6 | 30.62 | |

C3D12c | 114 | 164.7 | 1550 | 9.5 | – | – | 25.4 | 25.4 | 13.8 | 27.6 | 28.8 | |

C3D18a | 171 | 164.7 | 1550 | 9.5 | – | – | 12.7 | 12.7 | 13.8 | 27.6 | 42.06 | |

C3D24b | 228 | 164.7 | 1550 | 9.5 | – | – | 19.05 | 19.05 | 13.8 | 27.6 | 43.97 | |

C3S6a | 57 | 164.7 | 1550 | 9.5 | – | – | 12.7 | 12.7 | 13.8 | 27.6 | 13.19 | |

C3S12a | 114 | 164.7 | 1550 | 9.5 | – | – | 12.7 | 12.7 | 13.8 | 27.6 | 17.47 | |

C3S12b | 114 | 164.7 | 1550 | 9.5 | – | – | 19.05 | 19.05 | 13.8 | 27.6 | 15.4 | |

C3S12c | 114 | 164.7 | 1550 | 9.5 | – | – | 25.4 | 25.4 | 13.8 | 27.6 | 17.49 | |

C3S18a | 171 | 164.7 | 1550 | 9.5 | – | – | 12.7 | 12.7 | 13.8 | 27.6 | 24.92 | |

C3S24a | 228 | 164.7 | 1550 | 9.5 | – | – | 12.7 | 12.7 | 13.8 | 27.6 | 22.36 | |

C4S6 | 78 | 104.8 | 1875 | 13 | – | – | 15.87 | 15.87 | 13.8 | 27.6 | 22.61 | |

C4S12 | 156 | 104.8 | 1875 | 13 | – | – | 15.87 | 15.87 | 13.8 | 27.6 | 25.98 | |

C4S18 | 234 | 104.8 | 1875 | 13 | – | – | 15.87 | 15.87 | 13.8 | 27.6 | 29.52 | |

C4S24 | 312 | 104.8 | 1875 | 13 | – | – | 15.87 | 15.87 | 13.8 | 27.6 | 35.3 | |

[24] | C-r-S-1.5-A6 | 250 | 149 | 1650 | 9.5 | – | – | 14.25 | 14.25 | 48 | 28.5 | 8.72 |

C-r-S-2-A6 | 250 | 149 | 1650 | 9.5 | – | – | 19 | 19 | 48 | 28.5 | 9.44 | |

C-r-S-2.5-A6 | 250 | 149 | 1650 | 9.5 | – | – | 23.75 | 23.75 | 48 | 28.5 | 8.93 | |

C-r-SWSC-1.5-A6 | 250 | 130 | 2300 | 10 | – | – | 15 | 15 | 48 | 28.5 | 70.94 | |

C-r-SWSC-2-A6 | 250 | 130 | 2300 | 10 | – | – | 20 | 20 | 48 | 28.5 | 66.19 | |

C-r-SWSC-2.5-A6 | 250 | 130 | 2300 | 10 | – | – | 25 | 25 | 48 | 28.5 | 71.64 | |

C-r-SC-1.5-A6 | 250 | 130 | 2300 | 7.5 | – | – | 11.25 | 11.25 | 48 | 28.5 | 48.26 | |

C-r-SC-2-A6 | 250 | 130 | 2300 | 7.5 | – | – | 15 | 15 | 48 | 28.5 | 54.47 | |

C-r-SC-2.5-A6 | 250 | 130 | 2300 | 7.5 | – | – | 18.75 | 18.75 | 48 | 28.5 | 56.19 | |

C-r-Ri-1.5-A6 | 250 | 143 | 2328 | 9 | – | – | 13.5 | 13.5 | 48 | 28.5 | 57.53 | |

C-r-Ri-2-A6 | 250 | 143 | 2328 | 9 | – | – | 18 | 18 | 48 | 28.5 | 62.2 | |

C-r-Ri-2.5-A6 | 250 | 143 | 2328 | 9 | – | – | 22.5 | 22.5 | 48 | 28.5 | 72.95 | |

C-r-Ro-1.5-A6 | 250 | 117 | 1617 | 9 | – | – | 13.5 | 13.5 | 48 | 28.5 | 59.63 | |

C-r-Ro-2-A6 | 250 | 117 | 1617 | 9 | – | – | 18 | 18 | 48 | 28.5 | 52.28 | |

C-r-Ro-2.5-A6 | 250 | 117 | 1617 | 9 | – | – | 22.5 | 22.5 | 48 | 28.5 | 59.51 | |

C-st-Ro-1.5-A6 | 250 | 125 | 1676 | – | 4.5 | 16 | 24 | 13.5 | 48 | 28.5 | 72.06 | |

C-st-Ro-2-A6 | 250 | 125 | 1676 | – | 4.5 | 16 | 32 | 15.75 | 48 | 28.5 | 74.11 | |

C-st-Ro-2.5-A6 | 250 | 125 | 1676 | – | 4.5 | 16 | 40 | 18 | 48 | 28.5 | 73.54 | |

C-sq-Ro-1.5-A6 | 250 | 150 | 1506 | – | 10 | 10 | 15 | 15 | 48 | 28.5 | 71.19 | |

C-sq-Ro-2-A6 | 250 | 150 | 1506 | – | 10 | 10 | 20 | 20 | 48 | 28.5 | 75.02 | |

C-sq-Ro-2.5-A6 | 250 | 150 | 1506 | – | 10 | 10 | 25 | 25 | 48 | 28.5 | 71.91 | |

G-r-SWSCI-1.5-A6 | 250 | 41 | 760 | 10 | – | – | 15 | 15 | 48 | 28.5 | 70.74 | |

G-r-SWSCI-2-A6 | 250 | 41 | 760 | 10 | – | – | 20 | 20 | 48 | 28.5 | 74.58 | |

G-r-SWSCI-2.5-A6 | 250 | 41 | 760 | 10 | – | – | 25 | 25 | 48 | 28.5 | 71.46 | |

G-r-Gr-1.5-A6 | 250 | 55 | 1150 | 10 | – | – | 15 | 15 | 48 | 28.5 | 80.51 | |

G-r-Gr-2-A6 | 250 | 55 | 1150 | 10 | – | – | 20 | 20 | 48 | 28.5 | 85.26 | |

G-r-Gr-2.5-A6 | 250 | 55 | 1150 | 10 | – | – | 25 | 25 | 48 | 28.5 | 92.69 | |

G-r-Ri-1.5-A6 | 250 | 47 | 1080 | 9 | – | – | 13.5 | 13.5 | 48 | 28.5 | 49.88 | |

G-r-Ri-2-A6 | 250 | 47 | 1080 | 9 | – | – | 18 | 18 | 48 | 28.5 | 54.95 | |

G-r-Ri-2.5-A6 | 250 | 47 | 1080 | 9 | – | – | 22.5 | 22.5 | 48 | 28.5 | 63.32 | |

C-r-Ro-1.5-A6 | 250 | 117 | 1617 | 9 | – | – | 13.5 | 13.5 | 48 | 28.5 | 60.08 | |

C-r-Ro-1.5-A7 | 250 | 117 | 1617 | 9 | – | – | 13.5 | 13.5 | 61.4 | 28.5 | 47.38 | |

[25] | B-8-SC-2 | 300 | 46 | 1272 | 8 | – | – | 14 | 14 | 28 | 19 | 33.1 |

B-8-SC-3 | 300 | 46 | 1272 | 8 | – | – | 14 | 14 | 28 | 19 | 30.2 | |

B-6-SC-1 | 300 | 46 | 1282 | 6 | – | – | 10.02 | 10.02 | 28 | 19 | 33.9 | |

B-6-SC-2 | 300 | 46 | 1282 | 6 | – | – | 10.02 | 10.02 | 28 | 19 | 28.8 | |

C-8-S-1 | 300 | 155 | 2495 | 8 | – | – | 14 | 14 | 28 | 19 | 48.5 | |

C-8-S-2 | 300 | 155 | 2495 | 8 | – | – | 14 | 14 | 28 | 19 | 55.3 | |

C-8-S-3 | 300 | 155 | 2495 | 8 | – | – | 14 | 14 | 28 | 19 | 45.2 | |

G-8-RB-2 | 300 | 59 | 1333 | 8 | – | – | 14 | 14 | 28 | 19 | 45.3 | |

G-8-RB-3 | 300 | 59 | 1333 | 8 | – | – | 14 | 14 | 28 | 19 | 50.9 | |

C-2.5*15-S-1 | 300 | 182 | 2863 | – | 2.5 | 15 | 25.02 | 8 | 28 | 19 | 53 | |

C-2.5*15-S-2 | 300 | 182 | 2863 | – | 2.5 | 15 | 25.02 | 8 | 28 | 19 | 56 | |

C-2.5*15-S-3 | 300 | 182 | 2863 | – | 2.5 | 15 | 25.02 | 8 | 28 | 19 | 46.3 | |

[3] | C12/60/S/1.6P | 60.39 | 141 | 2300 | 12 | – | – | 16 | 16 | 90 | 60 | 27.7 |

C12/60/S/3.2P | 120.58 | 141 | 2300 | 12 | – | – | 16 | 16 | 90 | 60 | 39.7 | |

C12/60/S/6.4P | 241.15 | 141 | 2300 | 12 | – | – | 16 | 16 | 90 | 60 | 51.5 | |

C12/60/S/12.7P | 478.54 | 141 | 2300 | 12 | – | – | 16 | 16 | 90 | 60 | 73.1 | |

A9/60/L/1.6P | 45.22 | 120 | 2070 | 9 | – | – | 18 | 18 | 90 | 60 | 19.1 | |

A9/60/L/3.2P | 90.34 | 120 | 2070 | 9 | – | – | 18 | 18 | 90 | 60 | 34.9 | |

A9/60/L/6.4P | 180.86 | 120 | 2070 | 9 | – | – | 18 | 18 | 90 | 60 | 58.2 | |

A9/60/L/12.7P | 358.9 | 120 | 2070 | 9 | – | – | 18 | 18 | 90 | 60 | 79 | |

A12/60/S/1.6P | 60.39 | 127 | 2070 | 12 | – | – | 16 | 16 | 90 | 60 | 26.1 | |

A12/60/S/3.2P | 120.58 | 127 | 2070 | 12 | – | – | 16 | 16 | 90 | 60 | 46.9 | |

A12/60/S/6.4P | 241.15 | 127 | 2070 | 12 | – | – | 16 | 16 | 90 | 60 | 70.5 | |

A12/60/S/12.7P | 478.54 | 127 | 2070 | 12 | – | – | 16 | 16 | 90 | 60 | 76 | |

A9/60/S/1.6P | 45.22 | 120 | 2070 | 9 | – | – | 13 | 13 | 90 | 60 | 21.6 | |

A9/60/S/3.2P | 90.43 | 120 | 2070 | 9 | – | – | 13 | 13 | 90 | 60 | 33.1 | |

A9/60/S/6.4P | 180.86 | 120 | 2070 | 9 | – | – | 13 | 13 | 90 | 60 | 52.9 | |

A9/60/S/12.7P | 358.9 | 120 | 2070 | 9 | – | – | 13 | 13 | 90 | 60 | 68.4 | |

C12/30/S/1.6P | 60.39 | 141 | 2300 | 12 | – | – | 16 | 16 | 90 | 30 | 28.6 | |

C12/30/S/3.2P | 120.58 | 141 | 2300 | 12 | – | – | 16 | 16 | 90 | 30 | 37.3 | |

C12/30/S/6.4P | 241.15 | 141 | 2300 | 12 | – | – | 16 | 16 | 90 | 30 | 66.2 | |

C12/30/S/12.7P | 478.54 | 141 | 2300 | 12 | – | – | 16 | 16 | 90 | 30 | 69 | |

A9/30/S/1.6P | 45.22 | 120 | 2070 | 9 | – | – | 13 | 13 | 90 | 30 | 20.1 | |

A9/30/S/3.2P | 90.43 | 120 | 2070 | 9 | – | – | 13 | 13 | 90 | 30 | 27.6 | |

A9/30/S/6.4P | 180.86 | 120 | 2070 | 9 | – | – | 13 | 13 | 90 | 30 | 44.8 | |

A9/30/S/12.7P | 358.9 | 120 | 2070 | 9 | – | – | 13 | 13 | 90 | 30 | 50.7 | |

R/60/S/1.6P | 57.6 | 123 | 2040 | – | 2 | 16 | 20 | 6 | 90 | 60 | 28.1 | |

R/60/S/3.2P | 115.2 | 123 | 2040 | – | 2 | 16 | 20 | 6 | 90 | 60 | 34.3 | |

R/60/S/6.4P | 230.4 | 123 | 2040 | – | 2 | 16 | 20 | 6 | 90 | 60 | 50.8 | |

R/60/S/12.7P | 457.2 | 123 | 2040 | – | 2 | 16 | 20 | 6 | 90 | 60 | 57.1 | |

R/60/L/1.6P | 57.6 | 123 | 2040 | – | 2 | 16 | 24 | 10 | 90 | 60 | 26.2 | |

R/60/L/3.2P | 115.2 | 123 | 2040 | – | 2 | 16 | 24 | 10 | 90 | 60 | 43.4 | |

R/60/L/6.4P | 230.4 | 123 | 2040 | – | 2 | 16 | 24 | 10 | 90 | 60 | 61.6 | |

S/60/S/Sika/1.6P | 64 | 137 | 2720 | – | 10 | 10 | 14 | 14 | 90 | 60 | 31.8 | |

S/60/S/Sika/3.2P | 128 | 137 | 2720 | – | 10 | 10 | 14 | 14 | 90 | 60 | 50.1 | |

S/60/S/Sika/6.4P | 256 | 137 | 2720 | – | 10 | 10 | 14 | 14 | 90 | 60 | 73.4 | |

S/60/S/Sika/12.7P | 508 | 137 | 2720 | – | 10 | 10 | 14 | 14 | 90 | 60 | 94.2 | |

S/60/L/Sika/1.6P | 64 | 137 | 2720 | – | 10 | 10 | 18 | 18 | 90 | 60 | 33.7 | |

S/60/L/Sika/3.2P | 128 | 137 | 2720 | – | 10 | 10 | 18 | 18 | 90 | 60 | 56.2 | |

S/60/L/Sika/6.4P | 256 | 137 | 2720 | – | 10 | 10 | 18 | 18 | 90 | 60 | 40.7 | |

S/60/L/Sto/1.6P | 64 | 137 | 2720 | – | 10 | 10 | 18 | 18 | 90.7 | 60 | 28.8 | |

S/60/L/Sto/3.2P | 128 | 137 | 2720 | – | 10 | 10 | 18 | 18 | 90.7 | 60 | 50.5 | |

S/60/L/Sto/6.4P | 256 | 137 | 2720 | – | 10 | 10 | 18 | 18 | 90.7 | 60 | 87.1 | |

S/60/L/Sto/12.7P | 508 | 137 | 2720 | – | 10 | 10 | 18 | 18 | 90.7 | 60 | 77.4 | |

S/60L/Sto/12.7P-re | 508 | 137 | 2720 | – | 10 | 10 | 18 | 18 | 90.7 | 60 | 64.4 | |

[5] | B-6-SC-1 | 300 | 46 | 1282 | 6 | – | – | 10 | 10 | 27.5 | 19 | 33.87 |

B-6-SC-2 | 300 | 46 | 1282 | 6 | – | – | 10 | 10 | 27.5 | 19 | 28.84 | |

B-6-SC-3 | 300 | 46 | 1282 | 6 | – | – | 10 | 10 | 27.5 | 19 | 36.32 | |

B-8-SC-1 | 300 | 46 | 1272 | 8 | – | – | 14 | 14 | 27.5 | 19 | 31.57 | |

B-8-SC-2 | 300 | 46 | 1272 | 8 | – | – | 14 | 14 | 27.5 | 19 | 33.1 | |

B-8-SC-3 | 300 | 46 | 1272 | 8 | – | – | 14 | 14 | 27.5 | 19 | 30.24 | |

G-8-SW-1 | 300 | 51 | 1250 | 8 | – | – | 14 | 14 | 27.5 | 19 | 17.72 | |

G-8-SW-2 | 300 | 51 | 1250 | 8 | – | – | 14 | 14 | 27.5 | 19 | 40.8 | |

G-8-SW-3 | 300 | 51 | 1250 | 8 | – | – | 14 | 14 | 27.5 | 19 | 38.04 | |

G-8-RB-1 | 300 | 59 | 1333 | 8 | – | – | 14 | 14 | 27.5 | 19 | 46.71 | |

G-8-RB-2 | 300 | 59 | 1333 | 8 | – | – | 14 | 14 | 27.5 | 19 | 45.25 | |

G-8-RB-3 | 300 | 59 | 1333 | 8 | – | – | 14 | 14 | 27.5 | 19 | 50.86 | |

C-8-S-1 | 300 | 155 | 2495 | 8 | – | – | 14 | 14 | 27.5 | 19 | 48.52 | |

C-8-S-2 | 300 | 155 | 2495 | 8 | – | – | 14 | 14 | 27.5 | 19 | 55.3 | |

C-8-S-3 | 300 | 155 | 2495 | 8 | – | – | 14 | 14 | 27.5 | 19 | 45.23 | |

C-10X10-S-1 | 300 | 159 | 1397 | – | 10 | 10 | 15 | 15 | 27.5 | 19 | 51.72 | |

C-10X10-S-2 | 300 | 159 | 1397 | – | 10 | 10 | 15 | 15 | 27.5 | 19 | 47.89 | |

C-10X10-S-3 | 300 | 159 | 1397 | – | 10 | 10 | 15 | 15 | 27.5 | 19 | 51.56 | |

C-1.4X10-S-1 | 300 | 177 | 2221 | – | 1.4 | 10 | 15 | 5 | 27.5 | 19 | 31.16 | |

C-1.4X10-S-2 | 300 | 177 | 2221 | – | 1.4 | 10 | 15 | 5 | 27.5 | 19 | 32.93 | |

C-1.4X10-S-3 | 300 | 177 | 2221 | – | 1.4 | 10 | 15 | 5 | 27.5 | 19 | 34.73 | |

C-2.5X15-S-1 | 300 | 182 | 2863 | – | 2.5 | 15 | 25 | 8 | 27.5 | 19 | 52.97 | |

C-2.5X15-S-1 | 300 | 182 | 2863 | – | 2.5 | 15 | 25 | 8 | 27.5 | 19 | 56.03 | |

C-2.5X15-S-1 | 300 | 182 | 2863 | – | 2.5 | 15 | 25 | 8 | 27.5 | 19 | 46.26 | |

[26] | C-8-SW-14X14-1 | 300 | 100 | 1040 | 8 | – | – | 14 | 14 | 27.5 | 19 | 47.48 |

C-8-SW-14X14-2 | 300 | 100 | 1040 | 8 | – | – | 14 | 14 | 27.5 | 19 | 48.22 | |

C-8-SW-14X14-3 | 300 | 100 | 1040 | 8 | – | – | 14 | 14 | 27.5 | 19 | 46.02 | |

B-8-SC-20X20-1 | 300 | 46 | 1272 | 8 | – | – | 20 | 20 | 27.5 | 19 | 44.84 | |

B-8-SC-20X20-2 | 300 | 46 | 1272 | 8 | – | – | 20 | 20 | 27.5 | 19 | 39.02 | |

B-8-SC-20X20-3 | 300 | 46 | 1272 | 8 | – | – | 20 | 20 | 27.5 | 19 | 42.8 | |

B-10-SC-15X15-1 | 300 | 42 | 1204 | 10 | – | – | 15 | 15 | 27.5 | 19 | 38.02 | |

B-10-SC-15X15-2 | 300 | 42 | 1204 | 10 | – | – | 15 | 15 | 27.5 | 19 | 40 | |

B-10-SC-15X15-3 | 300 | 42 | 1204 | 10 | – | – | 15 | 15 | 27.5 | 19 | 39 | |

B-10-SC-20X20-1 | 300 | 42 | 1204 | 10 | – | – | 20 | 20 | 27.5 | 19 | 43.46 | |

B-10-SC-20X20-2 | 300 | 42 | 1204 | 10 | – | – | 20 | 20 | 27.5 | 19 | 41.12 | |

B-10-SC-20X20-3 | 300 | 42 | 1204 | 10 | – | – | 20 | 20 | 27.5 | 19 | 38.96 | |

[36] | Gent-C-SC-6 | 300 | 124 | 2068 | 6 | – | – | 12 | 12 | 50 | 30 | 33 |

Gent-B-SC-6 | 300 | 52.5 | 1470 | 6 | – | – | 12 | 12 | 30 | 30 | 38.4 | |

Gent-B-SC-8 | 300 | 51 | 1324 | 8 | – | – | 14 | 14 | 30 | 30 | 39.8 | |

Gent-C-S-1.4X10 | 300 | 165 | 1850 | – | 1.4 | 10 | 15 | 5 | 50 | 30 | 24.6 | |

Gent-G-RB-8 | 300 | 60 | 1500 | 8 | – | – | 14 | 14 | 30 | 30 | 51.7 | |

Gent-C-STR-2X16 | 300 | 165 | 3100 | – | 2 | 16 | 25 | 8 | 50 | 30 | 59.9 | |

Gent-C-SM-8 | 300 | 155 | 2800 | 8 | – | – | 14 | 14 | 50 | 30 | 56.9 | |

Gent-C-STR-10X10 | 300 | 155 | 2000 | – | 10 | 10 | 15 | 15 | 50 | 30 | 61 | |

Gent-G-SpW-8 | 300 | 55 | 1290 | 8 | – | – | 14 | 14 | 30 | 30 | 43.7 | |

Minho-C-SC-6 | 300 | 124 | 2068 | 6 | – | – | 12 | 12 | 50 | 32 | 36.7 | |

Minho-B-SC-6 | 300 | 52.5 | 1470 | 6 | – | – | 12 | 12 | 30 | 32 | 26.5 | |

Minho-B-SC-8 | 300 | 51 | 1324 | 8 | – | – | 14 | 14 | 30 | 32 | 33.5 | |

Minho-C-S-1.4X10 | 300 | 165 | 1850 | – | 1.4 | 10 | 15 | 5 | 50 | 32 | 39.1 | |

Minho-G-RB-8 | 300 | 60 | 1500 | 8 | – | – | 14 | 14 | 30 | 32 | 40.3 | |

Minho-C-STR-2X16 | 300 | 165 | 3100 | – | 2 | 16 | 25 | 8 | 50 | 32 | 48 | |

Minho-C-SM-8 | 300 | 155 | 2800 | 8 | – | – | 14 | 14 | 50 | 32 | 47.4 | |

Minho-C-STR-10X10 | 300 | 155 | 2000 | – | 10 | 10 | 15 | 15 | 50 | 32 | 58.9 | |

Naples-B-SC-6 | 300 | 52.5 | 1470 | 6 | – | – | 12 | 12 | 30 | 23 | 33 | |

Naples-B-SC-8 | 300 | 51 | 1324 | 8 | – | – | 12 | 12 | 30 | 23 | 31.6 | |

Naples-G-RB-8 | 300 | 60 | 1500 | 8 | – | – | 14 | 14 | 30 | 23 | 47.6 | |

Naples-C-STR-2X16 | 300 | 165 | 3100 | – | 2 | 16 | 25 | 8 | 50 | 23 | 51.7 | |

Naples-C-SM-8 | 300 | 155 | 2800 | 8 | – | – | 14 | 14 | 50 | 23 | 49.6 | |

Naples-C-STR-10X10 | 300 | 155 | 2000 | – | 10 | 10 | 15 | 15 | 50 | 23 | 50.3 | |

Naples-G-RB-8′ | 300 | 55 | 1290 | 8 | – | – | 14 | 14 | 30 | 23 | 32.2 | |

Buda-C-SC-6 | 300 | 124 | 2068 | 6 | – | – | 12 | 12 | 50 | 42 | 33.9 | |

Buda-B-SC-6 | 300 | 52.5 | 1470 | 6 | – | – | 12 | 12 | 30 | 42 | 30.6 | |

Buda-C-S-1.4X10 | 300 | 165 | 1850 | – | 1.4 | 10 | 15 | 5 | 50 | 42 | 25.1 | |

Buda-G-RB-8 | 300 | 60 | 1500 | 8 | – | – | 14 | 14 | 30 | 42 | 44.7 | |

Buda-C-STR-2X16-1 | 300 | 165 | 3100 | – | 2 | 16 | 25 | 8 | 50 | 42 | 39.7 | |

Buda-C-STR-2X16-2 | 300 | 165 | 3100 | – | 2 | 16 | 25 | 8 | 50 | 42 | 40 | |

Buda-C-STR-2X16-3 | 300 | 165 | 3100 | – | 2 | 16 | 25 | 8 | 50 | 42 | 40.6 | |

Buda-C-SM-8-1 | 300 | 155 | 2800 | 8 | – | – | 14 | 14 | 50 | 42 | 41.1 | |

Buda-C-SM-8-2 | 300 | 155 | 2800 | 8 | – | – | 14 | 14 | 50 | 42 | 42.7 | |

Buda-C-STR-10X10 | 300 | 155 | 2000 | – | 10 | 10 | 15 | 15 | 50 | 42 | 58.3 | |

[27] | 30MPa-100-10 | 100 | 161.8 | 2643 | – | 1.2 | 10 | 12 | 3.2 | 16 | 30 | 13 |

30MPa-100-10 | 100 | 161.8 | 2643 | – | 1.2 | 10 | 12 | 3.2 | 16 | 30 | 22.6 | |

30MPa-100-10 | 100 | 161.8 | 2643 | – | 1.22 | 10.02 | 12.02 | 3.22 | 16 | 30 | 20.4 | |

30MPa-150-10 | 150 | 161.8 | 2643 | – | 1.23 | 10.33 | 12.33 | 3.23 | 16 | 30 | 23.2 | |

30MPa-200-10 | 200 | 161.8 | 2643 | – | 1.22 | 10.48 | 12.48 | 3.22 | 16 | 30 | 27.9 | |

30MPa-250-10 | 250 | 161.8 | 2643 | – | 1.22 | 10.29 | 12.29 | 3.22 | 16 | 30 | 26.6 | |

30MPa-300-10 | 300 | 161.8 | 2643 | – | 1.22 | 10.38 | 12.38 | 3.22 | 16 | 30 | 26 | |

30MPa-350-10 | 350 | 161.8 | 2643 | – | 1.22 | 10.35 | 12.35 | 3.22 | 16 | 30 | 23 | |

42MPa-200-10 | 200 | 161.8 | 2643 | – | 1.27 | 10.29 | 12.29 | 3.27 | 16 | 41.8 | 30.6 | |

48MPa-200-10 | 200 | 161.8 | 2643 | – | 1.28 | 10.1 | 12.1 | 3.28 | 16 | 48.2 | 33.7 | |

49MPa-200-10 | 200 | 161.8 | 2643 | – | 1.26 | 10.56 | 12.56 | 3.26 | 16 | 49.2 | 33.3 | |

49MPa-200-20 | 200 | 162.3 | 2796 | – | 1.28 | 20.43 | 22.43 | 3.28 | 16 | 49.2 | 68.6 | |

49MPa-100-20 | 100 | 162.3 | 2796 | – | 1.27 | 20.37 | 22.37 | 3.27 | 16 | 49.2 | 64.1 | |

49MPa-200-20 | 200 | 162.3 | 2796 | – | 1.28 | 20.22 | 22.22 | 3.28 | 16 | 49.2 | 75 | |

49MPa-300-20 | 300 | 162.3 | 2796 | – | 1.24 | 19.79 | 21.79 | 3.24 | 16 | 49.2 | 68.1 | |

30MPa-100-20 | 100 | 162.3 | 2796 | – | 1.2 | 20 | 22 | 3.2 | 16 | 30 | 51.4 | |

30MPa-200-20 | 200 | 162.3 | 2796 | – | 1.2 | 20 | 22 | 3.2 | 16 | 30 | 57.8 | |

30MPa-300-20 | 300 | 162.3 | 2796 | – | 1.2 | 20 | 22 | 3.2 | 16 | 30 | 66.7 | |

65MPa-200-10 | 200 | 144.6 | 2634 | – | 2.88 | 10.08 | 12.08 | 4.88 | 16 | 64.8 | 45 | |

53MPa-200-10 | 200 | 161.8 | 2643 | – | 1.24 | 10.23 | 12.23 | 3.24 | 16 | 52.8 | 31.9 | |

53MPa-200-20 | 200 | 162.3 | 2796 | – | 1.26 | 20.47 | 22.47 | 3.26 | 16 | 52.8 | 77.9 | |

53MPa-200-10 | 200 | 161.8 | 2643 | – | 1.3 | 10.43 | 12.43 | 3.3 | 16 | 53 | 34 | |

53MPa-200-20 | 200 | 162.3 | 2796 | – | 1.27 | 20.1 | 22.1 | 3.27 | 16 | 53 | 72.5 | |

53MPa-100-10 | 100 | 161.8 | 2643 | – | 1.26 | 10.37 | 12.37 | 3.26 | 16 | 53 | 29.5 | |

53MPa-300-10 | 300 | 161.8 | 2643 | – | 1.27 | 10.3 | 12.3 | 3.27 | 16 | 53 | 37.9 | |

53MPa-100-20 | 100 | 162.3 | 2796 | – | 1.25 | 20.23 | 22.23 | 3.25 | 16 | 53 | 63.8 | |

53MPa-300-20 | 300 | 162.3 | 2796 | – | 1.25 | 20.15 | 22.15 | 3.25 | 16 | 53 | 66.3 | |

33MPa-100-15 | 100 | 161.8 | 2643 | – | 1.26 | 14.93 | 16.93 | 3.26 | 16 | 33.4 | 31.9 | |

33MPa-200-15 | 200 | 161.8 | 2643 | – | 1.26 | 15.65 | 17.65 | 3.26 | 16 | 33.4 | 47.5 | |

33MPa-300-15 | 300 | 161.8 | 2643 | – | 1.26 | 15.31 | 17.31 | 3.26 | 16 | 33.4 | 51.6 | |

65MPa-200-10 | 200 | 161.8 | 2643 | – | 2.9 | 9.95 | 11.95 | 4.9 | 16 | 64.8 | 45.1 | |

33MPa-300-20 | 300 | 162.3 | 2796 | – | 1.24 | 19.85 | 21.85 | 3.24 | 16 | 33.4 | 67.8 | |

33MPa-200-20 | 200 | 162.3 | 2796 | – | 1.2 | 20 | 22 | 3.2 | 16 | 33.4 | 60.7 | |

[30] | N/C-10-E-1.5-6 | 57 | 128 | 1546 | 9.5 | – | – | 14.25 | 14.25 | 43.5 | 41 | 28.68 |

N/C-10-E-1.5-12 | 114 | 128 | 1546 | 9.5 | – | – | 14.25 | 14.25 | 43.5 | 41 | 52.45 | |

N/C-10-E-1.5-18 | 171 | 128 | 1546 | 9.5 | – | – | 14.25 | 14.25 | 43.5 | 41 | 74.85 | |

N/C-10-E-1.5-24 | 228 | 128 | 1546 | 9.5 | – | – | 14.25 | 14.25 | 43.5 | 41 | 84.77 | |

N/C-10-E-2.0-6 | 57 | 128 | 1546 | 9.5 | – | – | 19 | 19 | 43.5 | 41 | 35.56 | |

N/C-10-E-2.0-12 | 114 | 128 | 1546 | 9.5 | – | – | 19 | 19 | 43.5 | 41 | 59.35 | |

N/C-10-E-2.0-18 | 171 | 128 | 1546 | 9.5 | – | – | 19 | 19 | 43.5 | 41 | 64.57 | |

N/C-10-E-2.0-24 | 228 | 128 | 1546 | 9.5 | – | – | 19 | 19 | 43.5 | 41 | 75.62 | |

N/C-10-E-2.0-36 | 324 | 128 | 1546 | 9.5 | – | – | 19 | 19 | 43.5 | 41 | 96.29 | |

N/C-10-E-2.0-48 | 456 | 128 | 1546 | 9.5 | – | – | 19 | 19 | 43.5 | 41 | 96.23 | |

N/C-13-E-1.5-18 | 228.6 | 134 | 1250 | 12.7 | – | – | 19.05 | 19.05 | 43.5 | 41 | 48.83 | |

N/C-13-E-2.0-18 | 228.6 | 134 | 1250 | 12.7 | – | – | 25.4 | 25.4 | 43.5 | 41 | 49.05 | |

N/G-13-E-2.0-12 | 152.4 | 42 | 749 | 12.7 | – | – | 25.4 | 25.4 | 43.5 | 41 | 52.19 | |

N/G-13-E-2.0-18 | 228.6 | 42 | 749 | 12.7 | – | – | 25.4 | 25.4 | 43.5 | 41 | 66.93 | |

N/G-13-E-2.0-24 | 304.8 | 42 | 749 | 12.7 | – | – | 25.4 | 25.4 | 43.5 | 41 | 77.74 | |

N/G-13-E-2.0-36 | 457.2 | 42 | 749 | 12.7 | – | – | 25.4 | 25.4 | 43.5 | 41 | 79.8 | |

[31] | 7-2/2-3D-CF | 36 | 124 | 2068 | 12 | – | – | 20 | 20 | 30 | 30.8 | 10.3 |

7-2/2-5D-CF | 60 | 124 | 2068 | 12 | – | – | 20 | 20 | 30 | 30.8 | 17.3 | |

7-2/2-10D-CF | 120 | 124 | 2068 | 12 | – | – | 20 | 20 | 30 | 30.8 | 32.5 | |

8-2/4-3D-CF | 36 | 124 | 2068 | 12 | – | – | 40 | 20 | 30 | 30.8 | 15.3 | |

8-2/4-5D-CF | 60 | 124 | 2068 | 12 | – | – | 40 | 20 | 30 | 30.8 | 20.2 | |

8-2/4-10D-CF | 120 | 124 | 2068 | 12 | – | – | 40 | 20 | 30 | 30.8 | 38.5 | |

[32] | Anchorfix-3-t1 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 32.4 | 60.1 | 29.8 |

Anchorfix-3-t2 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 32.4 | 60.1 | 34.2 | |

Anchorfix-3-t3 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 32.4 | 60.1 | 30.2 | |

Anchorfix-3-t4 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 32.4 | 60.1 | 26.7 | |

Anchorfix-3-t5 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 32.4 | 60.1 | 29.4 | |

Anchorfix-3-t6 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 32.4 | 60.1 | 30.2 | |

Concresive1420-t1 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 27.6 | 60.1 | 42.3 | |

Concresive1420-t2 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 27.6 | 60.1 | 37.8 | |

Concresive1420-t3 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 27.6 | 60.1 | 50.3 | |

Concresive1420-t4 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 27.6 | 60.1 | 42.7 | |

Concresive1420-t5 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 27.6 | 60.1 | 34.2 | |

Concresive1420-t6 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 27.6 | 60.1 | 37.8 | |

Epofil-t1 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 50.3 | 60.1 | 58.7 | |

Epofil-t3 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 50.3 | 60.1 | 52.9 | |

Epofil-t4 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 50.3 | 60.1 | 53.8 | |

Epofil-t5 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 50.3 | 60.1 | 59.2 | |

Epofil-t6 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 50.3 | 60.1 | 59.2 | |

Sikadure35-t3 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 61.4 | 60.1 | 52.5 | |

Sikadure35-t4 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 61.4 | 60.1 | 53.8 | |

Sikadure35-t5 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 61.4 | 60.1 | 49.8 | |

Sikadure35-t6 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 61.4 | 60.1 | 53.4 | |

Sikadure32-t1 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 35.2 | 60.1 | 53.4 | |

Sikadure32-t2 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 35.2 | 60.1 | 53.4 | |

Sikadure32-t3 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 35.2 | 60.1 | 55.2 | |

Sikadure32-t5 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 35.2 | 60.1 | 60.5 | |

Sikadure32-t6 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 35.2 | 60.1 | 56.5 | |

DP460NS-t1 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 35.2 | 60.1 | 76.1 | |

DP460NS-t2 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 35.2 | 60.1 | 62.7 | |

DP460NS-t3 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 35.2 | 60.1 | 81.4 | |

DP460NS-t4 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 35.2 | 60.1 | 76.1 | |

DP460NS-t5 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 35.2 | 60.1 | 79.6 | |

DP460NS-t6 | 152 | 130 | 2100 | – | 2 | 16 | 19 | 6.4 | 35.2 | 60.1 | 65.4 | |

[33] | C-r-Ro-1.5-A6 | 250 | 124 | 2068 | 9 | – | – | 13.5 | 13.5 | 35.2 | 28.5 | 60.08 |

C-r-Ro-1.5-A7 | 250 | 124 | 2068 | 9 | – | – | 13.5 | 13.5 | 61.4 | 28.5 | 47.38 | |

C-r-SC-2.0-A6 | 250 | 130 | 2300 | 7.5 | – | – | 15 | 15 | 35.2 | 28.5 | 56.19 | |

C-r-Ri-2.0-A6 | 250 | 150 | 2185 | 9 | – | – | 18 | 18 | 35.2 | 28.5 | 62.2 | |

C-r-Ro-2.0-A6 | 250 | 124 | 2068 | 9 | – | – | 18 | 18 | 35.2 | 28.5 | 52.28 | |

[34] | C-SC-9 | 300 | 124 | 1896 | 9.5 | – | – | 15 | 15 | 50 | 37.4 | 57.8 |

B-SC-6 | 300 | 55 | 1413 | 6 | – | – | 12 | 12 | 30 | 37.4 | 28.4 | |

B-SC-8 | 300 | 50 | 1285 | 8 | – | – | 15 | 15 | 30 | 36.2 | 39.8 | |

G-RB-10 | 300 | 40.8 | 760 | 10 | – | – | 15 | 15 | 30 | 36.2 | 50.6 | |

C-STR-2x16 | 300 | 124 | 2068 | – | 2 | 16 | 25 | 8 | 50 | 35 | 46.5 | |

C-SM-8 | 300 | 155 | 2800 | 8 | – | – | 15 | 15 | 50 | 35 | 56.9 | |

[35] | A-5G25 | 60 | 124 | 2108 | 12 | – | – | 25 | 25 | 30 | 30 | 15.2 |

B-5G25-J | 60 | 124 | 2108 | 12 | – | – | 25 | 25 | 30 | 30 | 16.92 | |

C-5G20 | 60 | 124 | 2108 | 12 | – | – | 20 | 20 | 30 | 30 | 12.05 | |

D-3G25 | 36 | 124 | 2108 | 12 | – | – | 25 | 25 | 30 | 30 | 7.96 | |

E-3G20 | 36 | 124 | 2108 | 12 | – | – | 20 | 20 | 30 | 30 | 7.17 | |

F-7.5G25 | 90 | 124 | 2108 | 12 | – | – | 25 | 25 | 30 | 30 | 18.2 | |

G-10G25 | 120 | 124 | 2108 | 12 | – | – | 25 | 25 | 30 | 30 | 21.6 | |

H-10G20 | 120 | 124 | 2108 | 12 | – | – | 20 | 20 | 30 | 30 | 19.4 | |

[37] | CR3/k1.33/104-e | 38 | 109.27 | 2014 | 9.5 | – | – | 15 | 15 | 28 | 22 | 13.12 |

CR3/k1.59/104-e | 38 | 109.27 | 2014 | 9.5 | – | – | 18 | 18 | 28 | 22 | 17.91 | |

CR3/k2.12/104-e | 38 | 109.27 | 2014 | 9.5 | – | – | 24 | 24 | 28 | 22 | 19.33 | |

CR3/k1.24/124-e | 228 | 109.27 | 2014 | 9.5 | – | – | 14 | 14 | 28 | 22 | 52.16 | |

CR3/k1.59/124-e | 228 | 109.27 | 2014 | 9.5 | – | – | 18 | 18 | 28 | 22 | 50.8 | |

CR3/k2.12/124-e | 228 | 109.27 | 2014 | 9.5 | – | – | 24 | 24 | 28 | 22 | 66.47 | |

GR3/k1.36/104-e | 38 | 37.17 | 873 | 9.5 | – | – | 15 | 15 | 28 | 22 | 10.67 | |

GR3/k1.64/104-e | 38 | 37.17 | 873 | 9.5 | – | – | 18 | 18 | 28 | 22 | 14.68 | |

GR3/k2.18/104-e | 38 | 37.17 | 873 | 9.5 | – | – | 24 | 24 | 28 | 22 | 14.57 | |

GR3/k1.27/124-e | 228 | 37.17 | 873 | 9.5 | – | – | 14 | 14 | 28 | 22 | 26.45 | |

GR3/k1.64/124-e | 228 | 37.17 | 873 | 9.5 | – | – | 18 | 18 | 28 | 22 | 39.55 | |

GR3/k2.18/124-e | 228 | 37.17 | 873 | 9.5 | – | – | 24 | 24 | 28 | 22 | 32.04 | |

SW/k1.50/104-e | 30 | 174.71 | 2214 | 7.5 | – | – | 12 | 12 | 28 | 22 | 12.75 | |

SW/k2.00/104-e | 30 | 174.71 | 2214 | 7.5 | – | – | 16 | 16 | 28 | 22 | 14.67 | |

SW/k2.50/104-e | 30 | 174.71 | 2214 | 7.5 | – | – | 20 | 20 | 28 | 22 | 15.5 | |

SW/k1.50/112-e | 90 | 174.71 | 2214 | 7.5 | – | – | 12 | 12 | 28 | 22 | 28.86 | |

SW/k2.00/112-e | 90 | 174.71 | 2214 | 7.5 | – | – | 16 | 16 | 28 | 22 | 25.62 | |

SW/k2.50/112-e | 90 | 174.71 | 2214 | 7.5 | – | – | 20 | 20 | 28 | 22 | 37.27 | |

SW/k1.50/124-e | 180 | 174.71 | 2214 | 7.5 | – | – | 12 | 12 | 28 | 22 | 41.32 | |

SW/k2.00/124-e | 180 | 174.71 | 2214 | 7.5 | – | – | 16 | 16 | 28 | 22 | 60 | |

SW/k2.50/124-e | 180 | 174.71 | 2214 | 7.5 | – | – | 20 | 20 | 28 | 22 | 67.43 | |

[38] | SD30-1.5D | 304.8 | 60.4 | 1478 | 12.7 | – | – | 19.05 | 19.05 | 14 | 37.2 | 64.9 |

SD30-2.0D | 304.8 | 60.4 | 1478 | 12.7 | – | – | 25.4 | 25.4 | 14 | 37.2 | 77 | |

SD42-1.5D | 304.8 | 60.4 | 1478 | 12.7 | – | – | 19.05 | 19.05 | 6 | 37.2 | 60.8 | |

SD42-2.0D | 304.8 | 60.4 | 1478 | 12.7 | – | – | 25.4 | 25.4 | 6 | 37.2 | 86.2 | |

SD-42.16D | 203.2 | 60.4 | 1478 | 12.7 | – | – | 25.4 | 25.4 | 6 | 64.8 | 85.7 | |

SD-31.16D | 203.2 | 60.4 | 1478 | 12.7 | – | – | 25.4 | 25.4 | 14 | 64.8 | 85 | |

[39] | T2.0-C15 | 250 | 131 | 2068 | – | 2 | 16 | 30 | 10 | 31.9 | 15 | 59 |

T2.0-C40 | 250 | 131 | 2068 | – | 2 | 16 | 30 | 10 | 31.9 | 40 | 63 | |

T2.0-C60 | 250 | 131 | 2068 | – | 2 | 16 | 30 | 10 | 31.9 | 60 | 56 | |

T4.5-C15 | 250 | 131 | 2068 | – | 4.5 | 16 | 30 | 10 | 31.9 | 15 | 68 | |

T4.5-C40 | 250 | 131 | 2068 | – | 4.5 | 16 | 30 | 10 | 31.9 | 40 | 74 | |

T4.5-C60 | 250 | 131 | 2068 | – | 4.5 | 16 | 30 | 10 | 31.9 | 60 | 88 | |

T2.0-BL80 | 80 | 131 | 2068 | – | 2 | 16 | 30 | 10 | 31.9 | 40 | 31 | |

T2.0-BL120 | 120 | 131 | 2068 | – | 2 | 16 | 30 | 10 | 31.9 | 40 | 41 | |

T2.0-BL160 | 160 | 131 | 2068 | – | 2 | 16 | 30 | 10 | 31.9 | 40 | 57 | |

T2.0-BL200 | 200 | 131 | 2068 | – | 2 | 16 | 30 | 10 | 31.9 | 40 | 55 | |

T2.0-BL250 | 250 | 131 | 2068 | – | 2 | 16 | 30 | 10 | 31.9 | 40 | 63 | |

T2.0-BL320 | 320 | 131 | 2068 | – | 2 | 16 | 30 | 10 | 31.9 | 40 | 63 | |

T2.0-BL400 | 400 | 131 | 2068 | – | 2 | 16 | 30 | 10 | 31.9 | 40 | 56 | |

T4.5-BL80 | 80 | 131 | 2068 | – | 4.5 | 16 | 30 | 10 | 31.9 | 40 | 37 | |

T4.5-BL80 | 120 | 131 | 2068 | – | 4.5 | 16 | 30 | 10 | 31.9 | 40 | 54 | |

T4.5-BL80 | 160 | 131 | 2068 | – | 4.5 | 16 | 30 | 10 | 31.9 | 40 | 60 | |

T4.5-BL80 | 200 | 131 | 2068 | – | 4.5 | 16 | 30 | 10 | 31.9 | 40 | 59 | |

T4.5-BL80 | 240 | 131 | 2068 | – | 4.5 | 16 | 30 | 10 | 31.9 | 40 | 84 | |

T4.5-BL80 | 250 | 131 | 2068 | – | 4.5 | 16 | 30 | 10 | 31.9 | 40 | 76 | |

T4.5-BL80 | 320 | 131 | 2068 | – | 4.5 | 16 | 30 | 10 | 31.9 | 40 | 100 | |

T2.0-GE60 | 250 | 131 | 2068 | – | 2 | 16 | 30 | 10 | 31.9 | 40 | 62 | |

T4.5-GE60 | 250 | 131 | 2068 | – | 4.5 | 16 | 30 | 10 | 31.9 | 40 | 73 | |

Rights and permissions

About this article

Cite this article

Nasrollahzadeh, K., Afzali, S. Fuzzy logic model for pullout capacity of near-surface-mounted FRP reinforcement bonded to concrete. Neural Comput & Applic 31, 7837–7865 (2019). https://doi.org/10.1007/s00521-018-3590-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-018-3590-2