Abstract

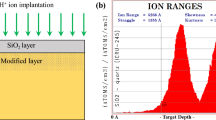

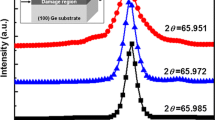

It was reported that non-amorphizing implantation by hydrogen has a potential in improving silicon machining. Post-implantation high-temperature treatment will affect implantation-induced damage, which can have impact on silicon machining. In this article, a relation of a thermal annealing of hydrogen implanted in silicon to micro-cutting experiment is investigated. Hydrogen ions were implanted into 4″ silicon wafers with 175 keV, 150 keV, 125 keV and doses of 2 × 1016 cm−2, 2 × 1016 cm−2 and 3 × 1016 cm−2, respectively. In this way, low hydrogen atom–low defect concentration was created in the region less than ~0.8 μm deep and high hydrogen atom–high defect concentration was obtained at silicon depth of ~0.8–1.5 μm. The post-implantation annealing was carried out at 300 and 400 °C in nitrogen for 1 h. Physical and electrical properties of implanted and annealed samples were characterized by secondary ion mass spectroscopy (SIMS), X-ray diffraction (XRD), Rutherford backscattering (RBS) and nanoindentation. Plunge cutting experiment was carried out in <110> and <100> silicon crystal direction. The critical depth of cut and cutting force were monitored and found to be influenced by the annealing. The limits of hydrogen implantation annealing contribution to the cutting characteristics of silicon are discussed in light of implantation process and redistribution of hydrogen and defects generation during annealing process.

Similar content being viewed by others

References

J. Yan, T. Asami, H. Harada, T. Kuriyagawa, CRIP Ann. Manuf. Technol. 61, 131 (2012)

F. Fang, Y. Chen, H. Zhang, X. Hu, G. Zhang, C.I.R.P. Ann, Manuf. Technol. 60, 527 (2011)

R.G. Jasinevicius, P.S. Pizani, Int. J. Adv. Manuf. Technol. 34, 680 (2007)

M. Arif, M. Rahman, W.Y. San, Int. J. Adv. Manuf. Technol. 63, 481 (2012)

S. To, H. Wang, E.V. Jelenković, Int. J. Mach. Tools Manuf. 74, 50 (2013)

H. Tanaka, S. Shimada, CIRP Annals-Manuf. Technol. 62, 55 (2013)

J. Wang, F. Fang, H. Zhang, Precos. Eng. 31, 220 (2015)

G.B. Xiao, S. To, E.V. Jelenković, J. Mater. Proc. Technol. 225, 439 (2015)

T. Höchauber, A. Misra, M. Nastasi, J. Appl. Phys. 92, 2335 (2002)

B. Aspar, H. Moriceau, E. Jalaguier, C. Lagahe, A. Soubie, B. Biasse, A.M. Papon, A. Claverie, J. Grisolia, G. Benassayag, F. Letertre, O. Rayssac, T. Barge, C. Maleville, B. Ghyselen, J. Electr. Mater. 30, 834 (2001)

J. F. Ziegler, SRIM—The stopping and range of ions in matter, http://www.srim.org/

C. Miclaus, M.S. Goorsky, J. Phys. D Appl. Phys. 36, 60633 (2003)

L. Chang, L.C. Xhang, Acta Mater. 57, 214 (2009)

M. Wang, W. Wang, Z. Lu, Int. J. Adv. Manuf. Technol. 65, 843 (2013)

M. Arif, X. Zhang, M. Rahman, S. Kumar, Int. J. Mach. Tools Manuf. 64, 114 (2013)

G.F. Cerofolini, L. Meda, C. Vopones, G. Ottavini, J. DeFayette, R. Dierck, D. Donelli, M. Oralndini, M. Anderle, R. Canteri, C. Clayes, J. Vanhellemont, Phys. Rev. B 41, 12608 (1990)

A.J. Pitera, E.A. Fitzgerald, J. Appl. Phys. 97, 104511 (2005)

X. Duo, W. Liu, S. Xing, M. Zhang, X. Fu, C. Lin, P. Hu, S.X. Wang, L.M. Wang, J. Phys. D: Appl. Phys. 34, 5 (2001)

N.M. Johnson, F.A. Pone, R.A. Street, R.J. Nemenich, Phys. Rev. B 35, 4166 (1987)

M.K. Weldon, V.E. Marsico, Y.J. Chabal, A. Agarwal, D.J. Eaglesham, J. Sapjeta, W.L. Brown, D.C. Jacobson, Y. Caudano, S.B. Christman, E.E. Chaban, J. Vac. Sci. Technol. B 15, 1065 (1997)

Z.F. Di, M.Q. Huang, Y.Q. Wang, M. Nastasi, J. Appl. Phys. Letter. 97, 194101 (2010)

D. Gu, H. Baumgart, K.K. Bourdelle, G.K. Celler, A.A. Elmustafa, Jap. J. Appl. Phys. 48, 101202 (2009)

S. Reboh, F. Rieutord, L. Vignoud, F. Mazen, N. Cherkashin, M. Zussy, D. Landru, C. Deguet, Appl. Phys. Lett. 103, 181811 (2013)

F. Rieutord, F. Mazen, S. Reboh, J.D. Penot, L. Bilteanu, J.P. Crocombette, V. Vales, V. Holy, L. Capello, J. Appl. Phys. 113, 153511 (2013)

Acknowledgments

The work described in this paper was supported by a Grant from the Guangdong Provincial Key Laboratory of Micro/Nano Manufacturing Technology and Equipment, School of Electromechanical Engineering, Guangdong University of Technology, the People’s Republic of China (Project no.: GDMNML2013-06), a Grant from the Scheme of Guangdong Innovation Team (Project no.:201001G0104781202) and a Grant from Innovation Technology Commission (ITC) of the Hong Kong Special Administrative Region, China (Project Ref. ITCPD/17-9).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jelenković, E.V., To, S., Sundaravel, B. et al. Micro-cutting of silicon implanted with hydrogen and post-implantation thermal treatment. Appl. Phys. A 122, 708 (2016). https://doi.org/10.1007/s00339-016-0227-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-016-0227-0