Abstract

During growth of multilayers by pulsed laser deposition (PLD), often both intermixing and resputtering occur due to the high kinetic energy of the particles transferred from the target to the substrate surface. In order to obtain a fundamental understanding of the underlying processes, W/Si multilayers have been studied by the complementary methods of transmission electron microscopy (TEM), X-ray reflectivity (XRR) and in-situ rate monitoring. For the experiments, deposition conditions were chosen that result in high energetic Si ions and mainly low energetic W atoms for the multilayer growth. Under these conditions, interface mixing of up to 3 nm occurs at the W/Si interfaces, while the Si/W interfaces remain sharp. Furthermore, enhanced resputtering of Si leads to a Si thickness deficit of up to 2 nm at the W/Si interfaces. The presented results can be understood by a combination of theoretical calculations as well as SRIM and TRIDYN simulations, which match perfectly to the experimentally obtained intermixing and enhanced resputtering of Si at the W/Si interfaces.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Pulsed laser deposition (PLD) is a thin film growth technique, which allows the preparation of multilayers for a wide range of material classes [1, 2]. It is well known that the microstructure of laser deposited films often strongly differs from those of sputtered or evaporated films [3]. This is mainly caused by the occurrence of high energetic ions with energies of up to 100–150 eV besides atoms with energies of 5–10 eV [4, 5]. Thus, the mean energy of the deposited ions is higher than the Wigner energy which is in the range of 10–25 eV for most materials [6]. The fraction of ionized particles in the plasma plume strongly depends on the laser fluence used for material ablation from the target surface and can reach a value of more than 90 % for high laser fluences [5]. As a consequence, implantation into the already grown film, intermixing at multilayer interfaces and resputtering effects occur [3, 7].

During sputter deposition it is well known that sputtering yields of light elements from the target surface can be enhanced by alloying a small amount of heavy atoms (e.g. W) to the target material [8]. This effect originates in a reduction of the implantation depth of the light element due to an increased stopping power and is known as “sputter yield amplification” (SYA) [9]. Choosing conditions that allow depositing light particles energetically on a layer of a much heavier material, such a SYA-effect should also be observable at the interfaces of laser deposited multilayers. In order to control both resputtering and intermixing, a fundamental understanding of these effects is essential. Furthermore, for many thin film applications it is important to ensure both sharp interfaces and accurate layer thickness, for instance during preparation of X-ray multilayer mirrors or multilayer zone plates [10, 11].

Aim of this paper is to study resputtering and intermixing in W/Si multilayers grown under conditions, where the light Si particles with a mass of 28.1 atomic mass units (amu) are deposited with high kinetic energy, while the much heavier W atoms (m=183.9 amu) are deposited with low particle energy. Using these conditions, intermixing and resputtering should only occur at the W/Si interfaces (i.e. when Si is deposited on W) but not at the Si/W interfaces. As a consequence, multilayers with highly asymmetric interfaces should be achieved. By implanting Si particles into the W layers, the SYA-effect of Si might be observable as well. For these studies, the complementary methods of transmission electron microscopy (TEM), X-ray reflectivity (XRR) and in-situ rate monitoring are used, and the obtained results are compared to theoretical calculations as well as to SRIM and TRIDYN simulations.

2 Experimental

W and Si thin films as well as W/Si multilayers were deposited onto Si(111) substrates by pulsed laser deposition using a standard setup [12]. The films were grown at room temperature at a target-to-substrate distance of 7 cm. KrF excimer laser pulses (wavelength of 248 nm, pulse duration of 30 ns, repetition rate of 10 Hz) were focused onto the W and Si targets, respectively, in ultrahigh vacuum (<10−8 mbar). By both changing the distance of the focusing lens to the target and the laser energy used, the laser fluence could be controlled in a range of 1–5 J/cm2. Here, this variability of energy density is particularly important due to the strongly different melting points of W and Si leading to unequal deposition conditions for both materials.

In-situ rate measurements were realized by depositing the ablated material onto a microbalance quartz crystal (Inficon SQM 160). X-ray reflectivity (XRR) measurements were carried out using a Philips X’pert diffractometer with CoK α -radiation. Transmission electron microscopy (TEM) images were taken with a Philips CM30. Theoretical calculations were done using SRIM (Stopping and Range of Ions in Matter) [13] and TRIDYN software (dynamical Monte Carlo simulations) [14].

3 Results

In order to find the optimal deposition conditions, the fluence dependence of the deposition rates of Si and W were determined by changing the laser energy as well as the lens-to-target distance and hence modifying the spot size on the target. For these experiments, the thin films were grown on a microbalance quartz crystal using 1000 laser pulses at each different lens position. The resulting deposition rates vs. used laser fluence are given in Fig. 1. Above the deposition threshold of about 1.2 J/cm2, the deposition rate of Si increases almost linearly up to a rate of about 5×10−3 nm/pulse and then remains almost constant above a laser fluence of 1.6 J/cm2. As known, as soon as the deposition rate saturates, the emerged Knudsen layer in front of the target is dense enough to strongly absorb the incoming laser beam and no further material can be ablated from the target surface. Since the laser energy is then coupled mainly into the plasma, most of its particles are ionized obeying kinetic energies in the range of 100 eV. Thus, for the implantation and resputtering experiments, a laser fluence of 1.7 J/cm2 was chosen in order to maximize these effects, as a high amount of energetic Si ions is essential for these studies. In contrast, for the deposition of W a laser fluence close to the deposition threshold (determined to about 2.4 J/cm2) was taken in order to minimize the fraction of energetic ions (see Fig. 1). A laser fluence of about 2.9 J/cm2 was chosen as a compromise to obtain a sufficiently high growth rate and a deposition of mainly atoms and only a low amount of ions.

Using the parameters described above, W/Si multilayers of varying thicknesses were deposited and first analyzed by TEM in order to study, whether or not an asymmetric interface mixing becomes visible as expected from the different kinetic energies of the deposited W and Si particles. A cross section TEM micrograph of a multilayer can be seen in Fig. 2, which indeed reveals an intermixing at the W/Si-interface. The intermixing range of Si into W can be estimated to about 3 nm. In contrast, there are no signs for intermixing at the Si/W interface, which matches with the assumption of almost no implantation effects of W into Si due to their much lower particle energies.

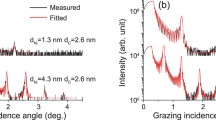

For more quantitative analysis of the interaction between Si and W, the multilayers were further analyzed by XRR measurements as shown in Figs. 3a and 3b. The resulting XRR spectra were fitted by IMD simulations [15] to obtain both the periods and individual layer thicknesses of the multilayers. The corresponding results of the Si and W layer thicknesses vs. the laser pulses used for deposition of the respective layers are presented in Fig. 3c. The increases of layer thicknesses represent the deposition rates of Si and W, respectively. Interestingly, the Si single layer thicknesses are always smaller by an amount of about 2.5 nm than expected from the deposition rates determined by growing Si single layers onto Si substrates, while the W layers mainly show the expected thicknesses. This deficit in the Si layer thickness can be seen in the graph by an extrapolation of the observed line towards a negative interception with the y-axis. Obviously, about 270 pulses of Si have to be deposited, before the Si layer starts to become visible in the X-ray measurements. Without using other knowledge, this can be interpreted in two ways, either as a deficit of the Si layer due to resputtering of Si by W at the Si/W interface, or due to implantation of Si particles into the W layer. (At this point one should note that the electron density of Si is about 5 times smaller than that of W, and thus an intermixed W-Si layer is mainly interpreted in our IMD calculations as a W layer.) As we will see later, the deficit in the Si layer thickness is in fact caused by an implantation of Si into the W layer combined with an enhanced resputtering of Si.

In order to study, at which interface resputtering occurs, in-situ rate measurements were performed (after each eight pulses) during deposition of a W/Si multilayer (see Fig. 4, and for more detail Fig. 5). In these measurements, intermixing effects are not detectable, but resputtering effects at interfaces can directly be measured as a lack of mass. During deposition of W onto Si, the deposition rate of W immediately starts with a straight line and thus no resputtering effect becomes visible. In contrast, at the Si/W interfaces first the mass on the quartz crystal stays almost constant and then slowly increases until a constant deposition rate of Si is reached after about 300 laser pulses. This is a strong indication of resputtering occurring only at the W/Si interfaces.

Comparison of a part of in-situ thickness measurements of Fig. 4 with TRIDYN simulations for (a) Si deposition on W and (b) W deposition on Si. The number of laser pulses is set to zero at the W and Si surfaces, respectively

As a consequence, reducing the kinetic energy of the deposited Si particles should allow avoiding resputtering and hence mass loss at the W/Si interfaces. To prove this, in a further investigation the laser fluence of Si was reduced to a value of about 1.3 J/cm2 close to the deposition threshold, where mainly low energetic Si atoms are deposited. As expected, now the Si thickness deficit observed at higher laser fluence at the W/Si interface is completely vanished (see Fig. 6). This is a clear indication that the effect of resputtering can be controlled directly by the used Si laser fluence and is completely avoidable by using a laser fluence close to the deposition threshold. This is particularly important for the deposition of highly precise W/Si multilayers with layer thicknesses of only a few nanometers and sharp interfaces [11].

Also, it should be mentioned that the amount of Si layer deficit at the W/Si interface can slightly be increased by raising the laser fluence of W as well. At first view, this might be surprising, but can be understood in the following way. The higher the kinetic energy of W particles when reaching the film surface, the denser the W layer becomes. This effect is typical for PLD and is known as densification of the deposited material by “shot peening” [16]. As a consequence, due to the dense W layer incoming energetic Si particles are deposited closer to the surface and thus resputtering is enhanced.

In order to understand the implantation and resputtering mechanisms at both interfaces in more detail, different theoretical calculations and simulations were done. First, the threshold energy E th of the incoming ions needed for resputtering was calculated based on the equations of Yamamura and Tawara [17]. For two materials A and B with masses M A and M B , respectively, and the surface energy U S , the threshold energy E th can be calculated using

Here γ is the coefficient of energy transfer, given by γ=4M A M B /(M A +M B )2. Using the surface energies U S of 4.7 eV and 8.7 eV for Si and W, respectively, the threshold values E th for resputtering are calculated to E th (Si)=100 eV and E th (W)=130 eV for Si and W, respectively. This indicates that a kinetic energy of the Si ions of 100 eV is sufficient for resputtering. In contrast, Si can hardly be resputtered by W particles as only a small fraction of the W particles is ionized and the average kinetic energy of the W ions is about 30 eV smaller than needed for resputtering. Based on these calculations it can be concluded that sputtering of Si by W particles at the Si/W interfaces can be neglected and the Si deficit seen in the XRR measurements originates from resputtering at the W/Si interfaces, which is in agreement with the rate measurements.

In addition, detailed SRIM simulations were done to determine the implantation depth profile, when hitting a W or Si surface by 100000 energetic ions with energies of 50–150 eV. Exemplary, the penetration depths of the incident ions (100 eV) and the distribution of the recoil target atoms are shown in Fig. 7, for the implantation of Si into W and vice versa (please note that the periodic distribution of implanted W ions is an artifact of the SRIM simulation due to a smallest depth interval of about one atomic layer). Under these conditions, the mean penetration depth of Si ions into W is about 0.6 nm and W is partially moved towards the film surface. Again, this is an indication that implantation of Si into W occurs near the surface, which can induce resputtering of already deposited material. In contrast, at the Si/W interfaces high energetic W ions are implanted much deeper below the surface (about 2.5 nm) and mostly induce forward scattering of the lighter Si atoms, but no resputtering of Si. But, at this interface, intermixing due to implantation of W in Si can hardly be noticed in our experiments due to the small amount of energetic W ions. The partial sputter yields were determined to Y Si→W=0.157, Y Si→Si=0.144, Y W→Si=0 and Y W→W=0.09 for 100 eV incident particles. Thus, these simulations reinforce the indication that the Si deficit seen in the XRR measurements is located at the W/Si interfaces.

In order to understand both the implantation and the resputtering characteristics more detailed, TRIDYN simulations were performed. In contrast to SRIM, where only the very early stages of deposition can be studied, in TRIDYN simulations the dynamical changes at and below the surface are taken into account and hence actual concentration profiles can be calculated for different deposition states (see Fig. 8). Based on these simulations, also the mass changes during film growth can be calculated and directly be compared with those obtained in-situ by the rate monitor. In order to obtain best agreement between simulation and experiment, the energy of the deposited energetic Si ions was varied between 50 and 150 eV. Additionally the amount of ions was modified between 30 % and 100 %, while the remaining Si particles were assumed to be atoms with average energy of 5–10 eV and thus are deposited always on top of the film surface. Only when setting the kinetic energy of the Si ions to 100 eV and assuming that 100 % of the particles are ionized, the results of the rate measurements match with the simulation (see Fig. 5a). This validates the assumption already made above that at the laser fluence of 1.7 J/cm2 the plasma in front of the Si target is completely ionized resulting in high energetic Si particles of typically 100 eV. (In the SRIM and TRIDYN calculations, only fixed particle energies could be chosen, while in reality broader energy distributions around these average particle energies occur, which should slightly smear out the results.) Similarly, the changes in deposition rate during growth of W onto Si could only be reconstructed by the simulation by assuming that most of the deposited particles are neutral atoms with energies of 5–10 eV, while less than 5 % of the W particles are ionized with a kinetic energy of 100 eV (see Fig. 5b). As argued above, these results were expected by the chosen laser fluence for W close to the deposition threshold.

In Fig. 8, the concentration profiles resulting from TRIDYN simulations for a deposition of energetic Si ions (100 eV) onto a W layer, which gave best agreement with the rate monitor experiments, are depicted for different growth states. The dashed line at x=0 nm marks the initial W surface before Si deposition. When depositing energetic Si particles they are implanted about 0.6 nm deep into the W layer and start to change the composition. This mechanism below the actual surface is known for PLD as “subsurface growth mode” [18]. Thus, the W concentration below the surface decreases, while a maximum in W content remains at the film surface (on the right hand side). As already seen in the SRIM simulations, W is partially transported to the current surface and a maximum in W concentration is formed there. With ongoing Si deposition, this peak is decreasing as Si also partially remains at the film surface (see the implantation profile of Si in Fig. 7). Experimentally, the resulting concentration profile due to implantation of Si into W could be seen as an intermixing layer in the TEM measurements (of about 3 nm). There is only little resputtering of W taking place mainly at the beginning of the Si deposition onto W and finally vanishes. In contrast strongly enhanced resputtering of Si occurs during deposition of the first few nanometers of Si (see the normalized sputter yields of Fig. 9) in comparison to the final equilibrium value, when only Si is resputtered by Si. This enhanced resputtering of Si can also be followed in Fig. 8 by comparing the actual surface position with the equivalent layer thickness of Si grown onto Si. For instance, when 6.6 nm of Si are deposited onto W, the actual surface position is located at 5.1 nm, about 1.5 nm smaller than the initially expected one. Finally, for larger Si thicknesses, the actual and expected deposition rate is equal. Both can be understood by an enhanced resputtering of Si during Si implantation into W and later into the intermixed W–Si layer (the so-called “sputter yield amplification”, mentioned in the introduction). As long as there are heavy W-atoms close to the actual film surface, the implantation depth of Si is reduced due to an increased stopping power leading to the enhanced resputtering of Si. As a consequence, this explains the Si deficit observed in the XRR measurements on W/Si multilayers as well as the mass loss seen in the rate measurements close to the W/Si interfaces.

4 Conclusion

In summary it has been shown that both implantation and enhanced resputtering occur in W/Si multilayers due to energetic deposition of Si particles and can be studied in detail by the complementary methods of ex-situ TEM, XRR and in-situ rate monitoring. While implantation of Si into the W layers leads to an intermixing range of about 3 nm, a Si deficit of up to 2.5 nm is observed at the W/Si interface due to enhanced resputtering of Si. Both effects can be clearly understood by a combination of theoretical calculations, SRIM and TRIDYN simulations, which further allow determining the implantation depths and concentration profiles during film growth. The deficit in Si layer thickness is mainly caused by a sputter yield amplification of Si, when the light Si particles are implanted more closely below the film surface due to the occurrence of much heavier W atoms. Also it was demonstrated that using laser fluences close to the corresponding deposition thresholds, multilayers with sharp interfaces can be realized as then the kinetic energy of most deposited particles is lower than the energy threshold necessary for implantation.

References

D.B. Chrisey, G.K. Hubler, Pulsed Laser Deposition of Thin Films (Wiley, New York, 1994)

R. Eason, Pulsed Laser Deposition of Thin Films (Wiley, New York, 2007)

H.U. Krebs, Characteristic properties of laser deposited metallic systems. Int. J. Non-Equilib. Process. 10, 3–24 (1997)

J.G. Lunney, Pulsed laser deposition of metal and metal multilayer films. Appl. Surf. Sci. 86, 79–85 (1995)

S. Fähler, H.U. Krebs, Calculations and experiments of material removal and kinetic energy during pulsed laser ablation of metals. Appl. Surf. Sci. 96–98, 61–65 (1996)

H. Frey, G. Kienel, Dünnschichttechnologie (VDI, Düsseldorf, 1987), p. 103

S. Fähler, K. Sturm, H.U. Krebs, Resputtering during the growth of pulsed-laser-deposited metallic films in vacuum and in an ambient gas. Appl. Phys. Lett. 75, 3766–3768 (1999)

M. Austgen, D. Koehl, P. Zalden, T. Kubart, T. Nyberg, A. Pflug, M. Siemers, S. Berg, M. Wuttig, Sputter yield amplification by tungsten doping of Al2O3 employing reactive serial co-sputtering: process characteristics and resulting film properties. J. Phys. D 44, 345501 (2011)

S. Berg, A.M. Barklund, B. Gelin, C. Nender, I. Katardjiev, Atom assisted sputtering yield amplification. J. Vac. Sci. Technol. A 10, 1592–1596 (1992)

E. Spiller, Soft X-ray Optics (SPIE Optical Engineering Press, Bellingham, 1994)

A. Ruhlandt, T. Liese, V. Radisch, S. Krüger, M. Osterhoff, K. Giewekemeyer, H.U. Krebs, T. Salditt, A combined Kirkpatrick–Baez mirror and multilayer lens for sub-10 nm X-ray focusing. AIP Adv. 2, 012175 (2012)

H.U. Krebs, O. Bremert, Pulsed laser deposition of thin metallic alloys. Appl. Phys. Lett. 62, 2341–2343 (1993)

J.F. Ziegler, J.P. Biersack, M.D. Ziegler, SRIM—the Stopping and Range of Ions in Matter (SRIM Co., Chester, 2008)

W. Möller, W. Eckstein, Tridyn—a TRIM simulation code including dynamic composition changes. Nucl. Instrum. Methods Phys. Res., Sect. B, Beam Interact. Mater. Atoms 2, 814–818 (1984)

D.L. Windt, IMD—software for modeling the optical properties of multilayer films. Comput. Phys. 12, 360–370 (1998)

H. Windischmann, An intrinsic stress scaling law for polycrystalline thin films prepared by ion beam sputtering. J. Appl. Phys. 62, 1800–1807 (1987)

Y. Yamamura, H. Tawara, Energy dependence of ion-induced sputtering yields from monatomic solids at normal incidence. At. Data Nucl. Data Tables 62, 149–253 (1996)

S. Fähler, S. Kahl, M. Weisheit, K. Sturm, H.U. Krebs, The interface of laser deposited Cu/Ag multilayers: evidence for the ‘subsurface growth mode’ during pulsed laser deposition. Appl. Surf. Sci. 154–155, 419–423 (2000)

Acknowledgements

This work was supported by the Deutsche Forschungsgemeinschaft (SFB 755 and SFB 602).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Eberl, C., Liese, T., Schlenkrich, F. et al. Enhanced resputtering and asymmetric interface mixing in W/Si multilayers. Appl. Phys. A 111, 431–437 (2013). https://doi.org/10.1007/s00339-013-7587-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-013-7587-5