Abstract

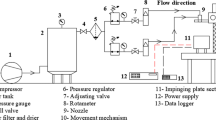

Herein, an experimental attempt is conducted to research thermal and flow behaviors of an impinging jet exiting from a coaxial type nozzle with a conical outer and a circular inner outlets. The experiments include four different values of the cone angle (Φ = 0°, 10°, 20° and 30°) and several values of the separation distance between the nozzle outlet and the target surface (0.5 ≤ H / D ≤ 6). Tests are performed for a single value of total flowrate (1.33 × 10−3 m3 s−1). It is revealed that the local Nusselt numbers on the target surface increase with decreasing separation distance. Especially, in the close-range impingement conditions (H / D ≤ 2), the cone angle of 20o performs the optimum thermal performance. Both the rate and spatial uniformity of convective heat transfer strongly depend on the coupling of the nozzle-to-plate distance and angle. From the flow dynamics aspect, wall pressure distributions are measured, and positive and negative (subatmospheric) peaks are observed depending on the combined influence of angle and distance.

Similar content being viewed by others

Abbreviations

- A r :

-

circular area on the plate [m2]

- D :

-

outer diameter of the outer flow passage [m]

- D i :

-

diameter of the inner circular passage [m]

- H :

-

distance between the target surface and the nozzle outlet [m]

- Nu :

-

local Nusselt number, Nu = h D/k

- Q :

-

volumetric flowrate [m3 s−1]

- P :

-

pressure [Pa]

- r∗:

-

dimensionless radial distance, r ∗ = r/D

- R :

-

Correlation coefficient

- r :

-

radial distance [m]

- Re:

-

Reynolds number, Re = um Di/v

- u m :

-

mean velocity [m s−1]

- Φ∗:

-

Modified cone angle, Φ ∗ = Φ (180/π)

- a :

-

(atmospheric)

- j :

-

(jet)

- o :

-

(outer)

- st :

-

(stagnation)

- tot :

-

(total)

References

Fenot M, Dorignac E (2016) Heat transfer and flow structure of an impinging jet with upstream flow. Int J Therm Sci 109:386–400. https://doi.org/10.1016/j.ijthermalsci.2016.06.010

Singh D, Premachandran B, Kohli S (2017) Double circular air jet impingement cooling of a heated circular cylinder. Int J Heat Mass Transf 109:619–646. https://doi.org/10.1016/j.ijheatmasstransfer.2017.02.035

Dua X, Yang Z, Jin Z, Xia C, Bao D (2018) A comparative study of passive control on flow structure evolution and convective heat transfer enhancement for impinging jet. Int J Heat Mass Transf 126:256–280. https://doi.org/10.1016/j.ijheatmasstransfer.2018.01.061

Trinh XT, Fenot M, Dorignac E (2017) Flow and heat transfer of hot impinging jets issuing from lobed nozzles. Int J Heat Fluid Flow 67:185–201. https://doi.org/10.1016/j.ijheatfluidflow.2017.08.010

Colucci DW, Viskanta R (1996) Effect of nozzle geometry on local convective heat transfer to a confined impinging air jet. Exp Therm Fluid Sci 13:71–80. https://doi.org/10.1016/0894-1777(96)00015-5

Lee J, Lee SJ (2000) The effect of nozzle configuration on stagnation region heat transfer enhancement of axisymmetric jet impingement. Int J heat mass Transf 43:3497–3509. https://doi.org/10.1016/S0017-9310(99)00349-X

Lee DH, Song J, Jo MC (2004) The effects of nozzle diameter on ımpinging jet heat transfer and fluid flow. J heat transfer 126:554–557. https://doi.org/10.1115/1.1777583

Meena HC, Reodikar SA, Vinze R, Prabhu SV (2016) Influence of the shape of the orifice on the local heat transfer distribution between smooth flat surface and impinging incompressible air jet. Exp Thermal Fluid Sci 70:292–306. https://doi.org/10.1016/j.expthermflusci.2015.09.018

Ahmed ZU, Al-Abdeli YM, Guzzomi FG (2016) Heat transfer characteristics of swirling and non-swirling impinging turbulent jets. Int J Heat Mass Transf 102:991–1003. https://doi.org/10.1016/j.ijheatmasstransfer.2016.06.037

Ahmed ZU, Al-Abdeli YM, Guzzomi FG (2017) Flow field and thermal behaviour in swirling and non-swirling turbulent impinging jets. Int J Therm Sci 114:241–256. https://doi.org/10.1016/j.ijthermalsci.2016.12.013

Crispo CM, Greco CS, Cardone G (2018) Convective heat transfer in circular and chevron impinging synthetic jets. Int J Heat Mass Transf 126:969–979. https://doi.org/10.1016/j.ijheatmasstransfer.2018.06.062

Terekhov VI, Kalinina SV, Sharov KA (2016) An experimental investigation of flow structure and heat transfer in an impinging annular jet. Int Commun Heat Mass Transf 79:89–97. https://doi.org/10.1016/j.icheatmasstransfer.2016.10.011

Markal B, Aydin O, Avci M (2012) Exergy analysis of a counter-flow Ranque-Hilsch vortex tube having different helical vortex generators. Int J Exergy 10(2):228–238. https://doi.org/10.1504/IJEX.2012.045867

Habib MA, Whitelaw JH (1980) Velocity characteristics of confined coaxial jets with and without swirl. J Fluids Eng 102:47–53. https://doi.org/10.1115/1.3240623

Mahmud T, Truelove JS, Wall TF (1987) Flow characteristics of swirling coaxial jets from divergent nozzles. J Fluids Eng 109:275–282. https://doi.org/10.1115/1.3242661

Singh P, Chander S (2018) Heat transfer and fluid flow characteristics of a pair of interacting dual swirling flame jets impinging on a flat surface. Int J Heat Mass Transf 124:90–108. https://doi.org/10.1016/j.ijheatmasstransfer.2018.03.034

Celik N, Eren H (2009) Heat transfer due to impinging co-axial jets and the jets’ fluid flow characteristics. Exp Thermal Fluid Sci 33:715–727. https://doi.org/10.1016/j.expthermflusci.2009.01.007

Celik N (2011) Effects of the surface roughness on heat transfer of perpendicularly impinging co-axial jet. Heat Mass Transf 47:1209–1217. https://doi.org/10.1007/s00231011-0785-9

Markal B (2018) Experimental investigation of heat transfer characteristics and wall pressure distribution of swirling coaxial confined impinging air jets. Int J Heat Mass Transf 124:517–532. https://doi.org/10.1016/j.ijheatmasstransfer.2018.03.101

Markal B (2019) The effect of Total flowrate on the cooling performance of swirling coaxial impinging jets. Heat Mass Transf 55:3275–3288. https://doi.org/10.1007/s00231-019-02653-7

Markal B, Aydin O (2018) Experimental investigation of coaxial impinging air jets. Appl Therm Eng 141:1120–1130. https://doi.org/10.1016/j.applthermaleng.2018.06.066

Dinesh KKJR, Kirkpatrick MP, Jenkins KW (2010) Investigation of the influence of swirl on a confined coannular swirl jet. Comput Fluids 39:756–767. https://doi.org/10.1016/j.compfluid.2009.12.004

Chouaieb S, Kriaa W, Mhiri H, Bournot P (2017) Swirl generator effect on a confined coaxial jet characteristics. Int J Hydrog Energy 42:29014–29025. https://doi.org/10.1016/j.ijhydene.2017.08.061

Ko NWM, Kwan ASH (1976) The initial region of subsonic coaxial jets. J Fluids Mech 73(2):305–332. https://doi.org/10.1017/S0022112076001389

Kline SJ, McClintock FA (1953) Describing uncertainties in single-sample experiments. Mech Eng 75(1):3–8

Ianiro A, Cardone G (2012) Heat transfer rate and uniformity in multichannel swirling impinging jets. Appl Therm Eng 49:89–98. https://doi.org/10.1016/j.applthermaleng.2011.10.018

Öztekin E, Aydin O, Avcı M (2013) Heat transfer in a turbulent slot jet flow impinging on concave surfaces. Int Commun Heat Mass Transf 44:77–82. https://doi.org/10.1016/j.icheatmasstransfer.2013.03.006

Lytle D, Webb BW (1994) Air jet impingement heat transfer at low nozzle-plate spacings. Int J Heat Mass Transf 37:1687–1697. https://doi.org/10.1016/0017-9310(94)90059-0

Eiamsa-ard S, Wongcharee K, Eiamsa-ard P, Thianpong C (2010) Heat transfer enhancement in a tube using delta-winglet twisted tape inserts. Appl Therm Eng 30:310–318. https://doi.org/10.1016/j.applthermaleng.2009.09.006

Eiamsa-ard S, Nanan K, Wongcharee K (2015) Heat transfer visualization of co/counter-dual swirling impinging jets by thermochromic liquid crystal method. Int J Heat Mass Transf 86:600–621. https://doi.org/10.1016/j.ijheatmasstransfer.2015.03.031

Abdel-Fattah A (2007) Numerical and experimental study of turbulent impinging twin jet flow. Exp Thermal Fluid Sci 31:1061–1072. https://doi.org/10.1016/j.expthermflusci.2006.11.006

Ozmen Y (2011) Confined impinging twin air jets at high Reynolds numbers. Exp Thermal Fluid Sci 35:355–363. https://doi.org/10.1016/j.expthermflusci.2010.10.006

Walker JDA, Smith CR, Cerra AW, Doligalski TL (1987) The impact of a vortex ring on a wall. J Fluid Mech 181:99–140. https://doi.org/10.1017/S0022112087002027

Benhacine A, Kharouna N, Khezzar L, Nemouchi Z (2012) Large eddy simulation of a slot jet impinging on a convex surface. Heat Mass Transf 48:1–15. https://doi.org/10.1007/s00231-011-0835-3

Huang L, EL-Genk MS (1998) Heat transfer and flow visualization experiments of swirling, multi-channel, and conventional impinging jets. Int J Heat Mass Transf 41:583–600. https://doi.org/10.1016/S0017-9310(97)00123-3

Schafer DM, Ramadhyani S, Incropera FP (1992) Numerical simulation of laminar convection heat transfer from an in-line array of discrete sources to a confined rectangular jet. Num Heat Transf Part A: Appl: Int J Comput Methodol Transf 22:121–141. https://doi.org/10.1080/10407789208944762

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Markal, B., Avci, M. & Aydin, O. Conical coaxial impinging air jets: angle effect on the heat transfer performance. Heat Mass Transfer 56, 3135–3146 (2020). https://doi.org/10.1007/s00231-020-02925-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-020-02925-7