Abstract

Objective

The accuracies of three-dimensional (3D) printed dental models using various digital light processing (DLP) and stereolithography (SLA) printers at different thicknesses were compared.

Materials and methods

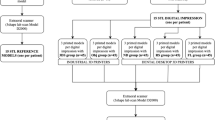

Based on digital dental models (originally digitized using R700; 3Shape, Copenhagen, Denmark), physical dental models were printed using three types of DLP printers: (1) EvoDent (UnionTec, Shanghai, China) with layer thicknesses of 50 μm and 100 μm; (2) EncaDent (Encashape, WuXi, China) with layer thicknesses of 20, 30, 50 and 100 μm; (3) Vida HD (Envisioned, Dearborn, MI, USA) with layer thicknesses of 50 and 100 μm. Models with the SLA printer Form 2 (Formlabs, Somerville, MA, USA) were printed with layer thicknesses of 25, 50 and 100 μm. All 22 printed models were converted to digital dental models using a D2000 model scanner (3 Shape, Copenhagen, Denmark) and compared three-dimensionally to the source files using Geomagic Qualify 12.0 (3D Systems, Rock Hill, SC, USA).

Results

The printing accuracy of all printers was higher at 50 μm. When the layer thickness was set at 100 μm, the printing speed and printing accuracy of DLP printer were both superior to those of the SLA printer. In all groups, the EvoDent 50 μm group had the highest consistency with the source files (mean absolute deviation of 0.0233 mm in the maxilla and 0.0301 mm in the mandible). While the accuracy of Form 2 100 μm group was the lowest (mean absolute deviation of 0.0511 mm in the maxilla and 0.0570 mm in the mandible).

Conclusion

For the 3D printers studied, 50 μm was the optimum layer thickness for DLP technology, and the printing accuracy using SLA technology increased with decreasing layer thickness. The DLP technology also had higher printing accuracy at a layer thickness of 100 μm. EvoDent 50 μm had the highest and Form 2 100 μm the lowest printing accuracy.

Zusammenfassung

Ziel

Ziel der vorliegenden Studie war es, die Genauigkeit von dreidimensional gedruckten Modellen, die mittels verschiedenen Digital Light Processing (DLP) und Stereolithographie Druckern (SLA) erstellt worden waren, zu untersuchen. Drüber hinaus wurde der Einfluss der Schichtstärken auf die Genauigkeit der gedruckten Modelle analysiert.

Material und Methode

Basierend auf digitalen Modellen, die ursprünglich mittels Scanner R700 (3Shape, Copenhagen, Denmark) erstellt worden waren, wurden analoge Modelle gedruckt. Dabei kamen drei DLP-Drucker zum Einsatz: (1) EvoDent (UnionTec, Shanghai, China), Schichtstärken von 50 und 100 μm; (2) EncaDent (Encashape, WuXi, China), Schichtstärken von 20, 30, 50 und 100 μm; (3) Vida HD (EnvisionTec, Dearborn, MI, USA) Schichtstärken von 50 und 100μm. Mit dem SLA-Drucker Form 2 (Formlabs, Somerville, MA, USA) wurden Modelle in drei Schickstärken geruckt: 25, 50 und 100 μm. Alle 22 gedruckten Modelle wurden mit dem D2000 Modellscanner (3Shape, Copenhagen, Denmark) gescannt und mit den ursprünglichen Scans dreidimensional verglichen. Zu diesem Zweck wurde das Programm Geomagic Qualify 12.0 (3D Systems, Rock Hill, SC, USA) eingesetzt.

Ergebnisse

Die Druckgenauigkeit aller Drucker wurde bei einer Schichtstärke von 50 μm gesteigert. Bei 100 μm waren Druckgeschwindigkeit und -genauigkeit bei den DLP Druckern den SLA Druckern überlegen. Die EvoDent 50 μm Gruppe zeigte die höchste Übereinstimmung mit den Ausgangsdatensätzen (mittlere absolute Abweichung von 0,0233 mm im Oberkiefer und 0,0301 mm im Unterkiefer). Die Genauigkeit in der Form 2 100 μm Gruppe fiel am niedrigsten aus (mittlere absolute Abweichung von 0,0511 mm im Oberkiefer und 0,0570 mm im Unterkiefer).

Schlussfolgerung

Für die ausgewählten DLP-Drucker lag die optimale Schichtstärke bei 50μm. Die Druckgenauigkeit der SLA-Drucker steigerte sich mit abnehmender Schichtstärke. Zusätzlich zur höheren Druckgeschwindigkeit wies die DLP Technologie bei einer Schichtstärke von 100μm eine höhere Druckgenauigkeit im Vergleich zur SLA-Technologie auf. EvoDent 50μm zeigte die höchste und Form 2 100μm die geringste Druckgenauigkeit.

Similar content being viewed by others

References

Camardella LT, de Vasconcellos Vilella O, Breuning H (2017) Accuracy of printed dental models made with 2 prototype technologies and different designs of model bases. Am J Orthod Dentofacial Orthop 151(6):1178–1187

Casko JS, Vaden JL, Kokich VG et al (1998) Objective grading system for dental casts and panoramic radiographs. Am J Orthod Dentofacial Orthop 114(5):589–599

Czarnota J, Hey J, Fuhrmann R (2016) Measurements using orthodontic analysis software on digital models obtained by 3D scans of plaster casts : Intrarater reliability and validity. J Orofac Orthop 77(1):22–30

Ender A, Mehl A (2011) Full arch scans: conventional versus digital impressions—an in-vitro study. Int J Comput Dent 14(1):11–21

Favero CS, English JD, Cozad BE, Wirthlin JO, Short MM, Kasper FK (2017) Effect of print layer height and printer type on the accuracy of 3‑dimensional printed orthodontic models. Am J Orthod Dentofacial Orthop 152(4):557–565

Fleming PS, Marinho V, Johal A (2011) Orthodontic measurements on digital study models compared with plaster models: a systematic review. Orthod Craniofac Res 14(1):1–16

Groth C, Kravitz ND, Jones PE, Graham JW, Redmond WR (2014) Three-dimensional printing technology. J Clin Orthod 48(8):475–485

Grunheid T, Patel N, De Felippe NL, Wey A, Gaillard PR, Larson BE (2014) Accuracy, reproducibility, and time efficiency of dental measurements using different technologies. Am J Orthod Dentofacial Orthop 145(2):157–164

Hazeveld A, Huddleston Slater JJ, Ren Y (2014) Accuracy and reproducibility of dental replica models reconstructed by different rapid prototyping techniques. Am J Orthod Dentofacial Orthop 145(1):108–115

Kasparova M, Grafova L, Dvorak P et al (2013) Possibility of reconstruction of dental plaster cast from 3D digital study models. Biomed Eng Online 12(1):49–60

Keating AP, Knox J, Bibb R, Zhurov AI (2008) A comparison of plaster, digital and reconstructed study model accuracy. J Orthod 35(3):191–201 (discussion 175)

Kim J, Chun YS, Kim M (2018) Accuracy of bracket positions with a CAD/CAM indirect bonding system in posterior teeth with different cusp heights. Am J Orthod Dentofacial Orthop 153(2):298–307

Kim SY, Shin YS, Jung HD, Hwang CJ, Baik HS, Cha JY (2018) Precision and trueness of dental models manufactured with different 3‑dimensional printing techniques. Am J Orthod Dentofacial Orthop 153(1):144–153

Murugesan K, Anandapandian PA, Sharma SK, Vasantha Kumar M (2012) Comparative evaluation of dimension and surface detail accuracy of models produced by three different rapid prototype techniques. J Indian Prosthodont Soc 12(1):16–20

Rebong RE, Stewart KT, Utreja A, Ghoneima AA (2018) Accuracy of three-dimensional dental resin models created by fused deposition modeling, stereolithography, and Polyjet prototype technologies: a comparative study. Angle Orthod 88(3):363–369

Rossini G, Parrini S, Castroflorio T, Deregibus A, Debernardi CL (2016) Diagnostic accuracy and measurement sensitivity of digital models for orthodontic purposes: a systematic review. Am J Orthod Dentofacial Orthop 149(2):161–170

Schaefer O, Schmidt M, Goebel R, Kuepper H (2012) Qualitative and quantitative three-dimensional accuracy of a single tooth captured by elastomeric impression materials: an in vitro study. J Prosthet Dent 108(3):165–172

Shahbazian M, Jacobs R, Wyatt J et al (2010) Accuracy and surgical feasibility of a CBCT-based stereolithographic surgical guide aiding autotransplantation of teeth: in vitro validation. J Oral Rehabil 37(11):854–859

Sousa MV, Vasconcelos EC, Janson G, Garib D, Pinzan A (2012) Accuracy and reproducibility of 3‑dimensional digital model measurements. Am J Orthod Dentofacial Orthop 142(2):269–273

Standardization IOf (1994) ISO 5725-1: 1994: accuracy (trueness and precision) of measurement methods and results-part 1: general principles and definitions. International Organization for Standardization, Geneva, Switzerland

Hassan WWN, Othman SA, Chan CS, Ahmad R, Ali SN, Abd Rohim A (2016) Assessing agreement in measurements of orthodontic study models: digital caliper on plaster models vs 3‑dimensional software on models scanned by structured-light scanner. Am J Orthod Dentofacial Orthop 150(5):886–895

Hassan WWN, Yusoff Y, Mardi NA (2017) Comparison of reconstructed rapid prototyping models produced by 3‑dimensional printing and conventional stone models with different degrees of crowding. Am J Orthod Dentofacial Orthop 151(1):209–218

Acknowledgements

The authors would like to thank Wei Wei, Jia-jun Zhou and Ye Zhang for their excellent technical assistance.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Z.-c. Zhang, P.-l. Li, F.-t. Chu and G. Shen declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Zhang, Zc., Li, Pl., Chu, Ft. et al. Influence of the three-dimensional printing technique and printing layer thickness on model accuracy. J Orofac Orthop 80, 194–204 (2019). https://doi.org/10.1007/s00056-019-00180-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00056-019-00180-y

Keywords

- Orthodontic models

- Digital light processing

- Stereolithography

- Three-dimensional superimposition

- Geomagic software