Abstract

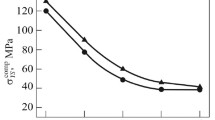

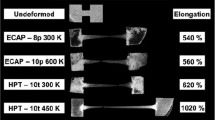

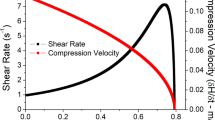

The mechanical properties of Al-(Mg)-0.5Sc alloys have been investigated. Room-temperature tensile and toughness properties were found to reflect a superposition of the properties of Al-Mg and Al-0.5Sc alloys and are quite competitive with high-performance Al alloys. A combination of substructure refinement by Mg and stabilization by Al3Sc precipitates produces exceptional superplasticity as exemplified by superplastic forming (SPF) elongations in excess of 1000 pct at a strain rate of 0.01 s-1. Overall, these alloys demonstrate an extremely attractive combination of strength, toughness, density, and SPF fabricability.

Similar content being viewed by others

References

Aluminum Lithium Alloys, T.H. Sanders, Jr. and E.A. Starke, Jr., eds., AIME, New York, NY, 1981.

Aluminum Lithium Alloys II, T.H. Sanders, Jr. and E.A. Starke, Jr., eds., AIME, New York, NY, 1983.

Aluminum Lithium Alloys III, C. Baker, P.J. Gregson, S.J. Harris, and C.J. Peel, eds., The Institute of Metals, London, 1986.

T.R. McNelley and A. Garg:Scripta Metall., vol. 18, pp. 917–20.

T.R. McNelley, E.-W. Lee, and M.E. Mills:Metall. Trans. A, 1986, vol. 17A, pp. 1035–41.

E.-W. Lee, T.R. McNelley, and A.F. Stengel:Metall. Trans. A, 1986, vol. 17A, pp. 1043–50.

L.A. Willey: United States Patent No. 3,619,181, 1971.

M.E. Drits, S.T. Pavlenko, L.S. Toropova, Yu.G. Bykov, and L.B. Ber:Sov. Phys. Dokl., 1981, vol. 26, pp. 344–46.

M.D. Drits, L.S. Toropova, and Yu.G. Bykov:Metalloved. Term. Obbrab. Met., 1983, vol. 7, pp. 60–63.

V.l. Elagin, V.V. Zakharov, and T.D. Rostova:Metalloved. Term. Obbrab. Met., 1983, vol. 7, pp. 57–60.

N. Blake and M.A. Hopkins:J. Mater. Sci., 1985, vol. 20, pp. 2861–67.

G.J. Hildeman and R.E. Sanders: United States Patent No. 4,379,719, 1983.

S.L. Langenbeck, J.M. Cox, G.J. Hildeman, D.K. Denzer, R.J. Rioja, C.W. Cho, and J.W. Simon:Elevated Temperature Al Alloy Development, AFWAL Contract No. F33615-81-C-5096, Mar. 1984.

J.G. Kaufman and A.H. Knoll:Mater. Res. Stand., 1964, pp. 1–7.

N.A. Kahn and E.A. Imbembo:Welding Res. Suppl., 1956, pp. 217S–20S.

L.A. Willey: ALCOA Laboratories Physical Metallurgy Division Report 13-62-EH3, 1962.

S.I. Fujikawa, M. Sugaya, H. Takei, and K.I. Hirano:J. Less-Common Met., 1979, vol. 63, pp. 87–97.

T.H. Sanders, E.A. Ludwiczak, and R.R. Sawtell:Mater. Sci. Eng., 1980, vol. 43, pp. 247–60.

P. Griffiths and C. Hammond:Acta Metall., 1972, vol. 20, pp. 935–45.

C.A. Henshall, T.G. Nieh, and J. Wadsworth:SAMPE Ad vancing Technology in Materials and Processes, 1985, vol. 30, pp. 994–1004.

D. Lee and W.A. Backofen:Trans. TMS-AIME, 1967, vol. 239, pp. 1034–40.

N.E. Paton and C.H. Hamilton:Metall. Trans. A, 1979, vol. 10A, pp. 241–50.

J.A. Wert, N.E. Paton, C.H. Hamilton, and M.W. Mahoney:Metall. Trans. A, 1981, vol. 12A, pp. 1267–76.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Sawtell, R.R., Jensen, C.L. Mechanical properties and microstructures of Al-Mg-Sc alloys. Metall Trans A 21, 421–430 (1990). https://doi.org/10.1007/BF02782422

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02782422