Abstract

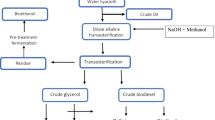

Biodiesels obtained from aquatic biomass such as Water Hyacinth and Salvinia Molesta are discussed as potential blending substance in pure diesel. Biodiesel not only supports the economy of fuel but also saves the environment by decreasing the pollution levels. Aquatic weeds create various kinds of problems in ecosystem. One of the main issues is their fast growth which clogs the waterways. But this problem also offers a great opportunity to build a biofuel economy based on biomass of aquatic weeds. There is no need of investment of money for production of this biomass as it is considered as a waste till date. Government has to spend money to clean the water body from these aquatic weeds. Use of this waste in production of biodiesel confirms two objectives simultaneously, firstly it supports the Atmanirbhar Bharat by building our own fuel and secondly it generates wealth from waste. This paper highlights the potential of Water Hyacinth biodiesel (WHB) and Salvinia Molesta biodiesel as alternative fuels for diesel engines.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Abbreviations

- B0:

-

0% Biodiesel in fuel + 100% Diesel

- B10:

-

10% Biodiesel in fuel + 90% Diesel

- B20:

-

20% Biodiesel in fuel + 80% Diesel

- B30:

-

30% Biodiesel in fuel + 70% Diesel

- B40:

-

40% Biodiesel in fuel + 60% Diesel

- B100:

-

100% Biodiesel in fuel + 0% Diesel

- CI:

-

Compression ignition

- CO:

-

Carbon monoxide

- CO2:

-

Carbon dioxide

- HRR:

-

Heat release rate

- PM:

-

Particulate matter

- O2:

-

Oxygen

References

Konwar LJ, Boro J, Deka D (2014) Review on latest developments in biodiesel production using carbon-based catalysts. Renew Sustain Energy Rev 29:546–564. https://doi.org/10.1016/j.rser.2013.09.003

Yusuf NNAN, Kamarudin SK, Yaakub Z (2011) Overview on the current trends in biodiesel production. Energy Convers Manage 52:2741–2751. https://doi.org/10.1016/j.enconman.2010.12.004

Demirbas A (2009) Progress and recent trends in biodiesel fuels. Energy Convers Manage 50:14–34. https://doi.org/10.1016/j.enconman.2008.09.001

Issariyakul T, Dalai AK, Desai P (2011) Evaluating esters derived from mustard oil (Sinapis alba) as potential diesel additives. JAOCS, J Am Oil Chem Soc 88:391–402. https://doi.org/10.1007/s11746-010-1679-6

Saladini F, Patrizi N, Pulselli FM, Marchettini N, Bastianoni S (2016) Guidelines for emergy evaluation of first, second and third generation biofuels. Renew Sustain Energy Rev 66:221–227. https://doi.org/10.1016/j.rser.2016.07.073

Bhuiya MMK, Rasul MG, Khan MMK, Ashwath N, Azad AK, Hazrat MA (2014) Second generation biodiesel: potential alternative to-edible oil-derived biodiesel. Energy Procedia 61:1969–1972. https://doi.org/10.1016/j.egypro.2014.12.054

Atadashi IM, Aroua MK, Aziz AA (2010) High quality biodiesel and its diesel engine application: a review. Renew Sustain Energy Rev 14:1999–2008. https://doi.org/10.1016/j.rser.2010.03.020

Umdu ES, Tuncer M, Seker E (2009) Transesterification of Nannochloropsis oculata microalga’s lipid to biodiesel on Al2O3 supported CaO and MgO catalysts. Biores Technol 100:2828–2831. https://doi.org/10.1016/j.biortech.2008.12.027

Huang GH, Chen F, Wei D, Zhang XW, Chen G (2010) Biodiesel production by microalgal biotechnology. Appl Energy 87:38–46. https://doi.org/10.1016/j.apenergy.2009.06.016

Raju V, Kishore PS, Nanthagopal K, Ashok B (2018) An experimental study on the effect of nanoparticles with novel tamarind seed methyl ester for diesel engine applications. Energy Convers Manage 164:655–666. https://doi.org/10.1016/j.enconman.2018.03.032

Atabani AE, Mahlia TMI, Anjum Badruddin I, Masjuki HH, Chong WT, Lee KT (2013) Investigation of physical and chemical properties of potential edible and non-edible feedstocks for biodiesel production, a comparative analysis. Renew Sustain Energy Rev 21:749–755. https://doi.org/10.1016/j.rser.2013.01.027

Zhong W, Xuan T, He Z, Wang Q, Li D, Zhang X et al (2016) Experimental study of combustion and emission characteristics of diesel engine with diesel/second-generation biodiesel blending fuels. Energy Convers Manage 121:241–250. https://doi.org/10.1016/j.enconman.2016.05.033

Srinophakun P, Thanapimmetha A, Rattanaphanyapan K, Sahaya T, Saisriyoot M (2017) Feedstock production for third generation biofuels through cultivation of Arthrobacter AK19 under stress conditions. J Clean Prod 142:1259–1266. https://doi.org/10.1016/j.jclepro.2016.08.068

Venu H, Venkataraman D, Purushothaman P, Vallapudi DR (2019) Eichhornia crassipes biodiesel as a renewable green fuel for diesel engine applications: performance , combustion , and emission characteristics. Environ Sci Pollut Res 26:18084–18097. https://doi.org/10.1007/s11356-019-04939-z

Alagu K, Venu H, Jayaraman J, Raju VD, Subramani L, Appavu P et al (2019) Novel Water Hyacinth biodiesel as a potential alternative fuel for existing unmodified diesel engine: performance , combustion and emission characteristics. Energy 179:295–305. https://doi.org/10.1016/j.energy.2019.04.207

Ganguly A, Chatterjee PK, Dey A (2012) Studies on ethanol production from Water Hyacinth—A review. Renew Sustain Energy Rev 16:966–972. https://doi.org/10.1016/j.rser.2011.09.018

Bote MA, Naik VR, Jagadeeshgouda KB (2020) Materials science for energy technologies review on Water Hyacinth weed as a potential bio fuel crop to meet collective energy needs. Mater Sci Energy Technol 3:397–406. https://doi.org/10.1016/j.mset.2020.02.003

Awasthi M, Kaur J, Rana S (2013) Bioethanol production through Water Hyacinth, Eichhornia crassipes via optimization of the pretreatment conditions. Int J Emerg Technol Adv Eng 3:42–46

Gielen D, Boshell F, Saygin D, Bazilian MD, Wagner N, Gorini R (2019) The role of renewable energy in the global energy transformation. Energy Strateg Rev 24:38–50. https://doi.org/10.1016/j.esr.2019.01.006

Mubarak M, Shaija A (2016) Ultrasonication: An effective pre-treatment method for extracting lipid from Salvinia Molesta for biodiesel production. Resour Technol 2:126–132. https://doi.org/10.1016/j.reffit.2016.07.005

Mubarak M, Shaija A, Suchithra TV (2016) Ultrasonication: An effective pre-treatment method for extracting lipid from Salvinia molesta for biodiesel production. Resour Efficient Technol 2(3): 126–132. https://doi.org/10.1016/j.reffit.2016.07.005

Mubarak M, Shaija A, Suchithra TV (2020) Experimental evaluation of Salvinia Molesta oil biodiesel/diesel blends fuel on combustion, performance and emission analysis of diesel engine. Fuel 287: 119526. https://doi.org/10.1016/j.fuel.2020.119526

Shanab SMM, Hanafy EA, Shalaby EA (2016) Water Hyacinth as non-edible source for biofuel production. Waste Biomass Valor. https://doi.org/10.1007/s12649-016-9816-6

Rahman MA, Aziz MA (2021) Biodiesel from Water Hyacinth biomass and its influence on CI engine performance , emission , combustion and heat loss characteristics with the induction of hydroxy. Energy 24:120151. https://doi.org/10.1016/j.energy.2021.120151

Alam NS, Singh B, Guldhe A (2021) Aquatic weed as a biorefinery for biofuels and value-added products: challenges and recent advancements. Cleaner Eng Technol. https://doi.org/10.1016/j.clet.2021.100235

Mishima D, Kuniki M, Sei K, Soda S, Ile M, Fujita M (2008) Ethanol production from candidate energy crops: Water hyacinth (Eichhornia crassipes) and water lettuce (Pistiaatratiotes L.). Bioresour Technol 99:2495–2500. https://doi.org/10.1016/j.biortech.2005.09.029

Xu J, Cui W, Cheng JJ, Stomp AM (2011) Production of high-starch duckweed and its conversion to bioethanol. Biosyst Eng 110:67–72. https://doi.org/10.1016/j.biosystemseng.2011.06.007

Abbasi SA, Naseema A, Nipaney PC (1995) Productivity (net primary production) of salvinia (Salvinia molesta, Mitchell) in nature environments. Int J Resour Conserv, pp 215–220

Jayus L, Nurhayati N, Mayzhuroh A, Arindhani S, Caroenchai C (2016) Studies on bioethanol production of commercial baker’s and alcohol yeast under aerated culture using sugarcane molasses as the media. Agric Agric Sci procedia 9:493–499. https://doi.org/10.1016/j.aaspro.2016.02.168

McAloon A, Taylorr F, Yee W, Ibsen K, Wooley R (2000) Determining the cost of producing ethanol from corn starch and lignocellulosic feedstock. National Renewable Energy Lab. Golden CO(US). https://doi.org/10.2172/766198

Williams J, Brammer J, Llewelyn R, Bergtold J (2016) An economic analysis of harvesting biomass from sorghums and corn. J AASFMRA, pp 89–101. https://doi.org/10.22004/ag.econ.236656

Satputaley SS, Zodpe DB, Deshpande NV (2018) ScienceDirect performance, combustion and exhaust emissions analysis of a diesel engine fuelled with algae oil and algae biodiesel. Mater Today Process 5:23022–23032. https://doi.org/10.1016/j.matpr.2018.11.031

Nautiyal P, Subramanian KA, Dastidar MG, Kumar A (2020) Experimental assessment of performance , combustion and emissions of a compression ignition engine fuelled with Spirulina platensis biodiesel. Energy 193. https://doi.org/10.1016/j.energy.2019.116861

Meng X, Chen G, Wang Y (2008) Biodiesel production from waste cooking oil via alkali catalyst and its engine test. Fuel Process Technol 9:5–11. https://doi.org/10.1016/j.fuproc.2008.02.006

Mani M, Subash C, Nagarajan G (2009) Performance, emission and combustion characteristics of a DI diesel engine using waste plastic oil. Appl Therm Eng 29:2738–2744. https://doi.org/10.1016/j.applthermaleng.2009.01.007

Arefin MA, Rashid F, Islam A (2021) A review of biofuel production from floating aquatic plants : an emerging source of bio-renewable energy. Biofuels, Bioprod Biorefin 15:574–591. https://doi.org/10.1002/bbb.2180

Thiruvenkatachari S, Saravanan CG, Geo VE, Vikneswaran M, Udayakumar R (2022) Experimental investigations on the production and testing of azolla methyl esters from Azolla microphylla in a compression ignition engine. Fuel 119448. https://doi.org/10.1016/j.fuel.2020.119448

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Jain, A., Bora, B.J., Kumar, R., Buradi, A. (2023). Comparative Study of Performance and Emission of Biodiesel Produced from Water Hyacinth and Salvinia Molesta: A Critical Review. In: Revankar, S., Muduli, K., Sahu, D. (eds) Recent Advances in Thermofluids and Manufacturing Engineering. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-4388-1_33

Download citation

DOI: https://doi.org/10.1007/978-981-19-4388-1_33

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-4387-4

Online ISBN: 978-981-19-4388-1

eBook Packages: EngineeringEngineering (R0)