Abstract

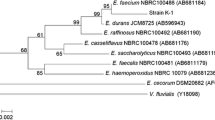

The costs of amylase represent ca. 24 % of the expenditures in the starch industry and an increase in amylase production and/or activity will greatly cut down on production costs. In the present study, we obtained a high amylase-producing strain of bacteria, WangLB, and identified it as a member of the Bacillus genus based on 16S rDNA analysis. The fermentation conditions for amylase production in the strain were optimized, and the maximum amylase activity we obtained was 26,670 ± 1390 U/mL, under the optimized conditions of 48-h incubation in liquid starch medium, 35 °C, pH 10, 1 % v/v inoculum concentration, 20 g/L starch concentration, and 0.1 % w/v peptone. The influences of 16 small organic inducers on amylase production were tested, and the results showed that 20 mmol/L alanine greatly enhanced amylase production to 290 % of the baseline level. We also conducted an amylase enzymology analysis. The molecular weight of the amylase was 55 kD, determined by SDS-PAGE. The optimum temperature and pH for the amylase were 55 °C and pH 9, respectively. The enzyme also showed high activity over a wide range of temperatures (50–85 °C) and pH values (3–10), and the activity of the amylase was Ca2+ independent. The kinetic parameters K m and V max were 0.37 ± 0.02 mg/mL and 233 U/mg, respectively. Finally, the amylase was applied to the hydrolysis of five different brands of starch. It was found that the hydrolyzability of the substrate by amylase increased along with starch solubility.

Similar content being viewed by others

References

Roy, J. K., & Mukherjee, A. K. (2013). Applications of a high maltose forming, thermo-stable α-amylase from an extremely alkalophilic Bacillus licheniformis strain AS08E in food and laundry detergent industries. Biochemical Engineering Journal, 77, 220–230.

Reddy, N., Nimmagadda, A., & Rao, K. S. (2004). An overview of the microbial α-amylase family. The African Journal of Biotechnology, 2, 645–648.

Deb, P., Talukdar, S. A., Mohsina, K., Sarker, P. K., & Sayem, S. (2013). Production and partial characterization of extracellular amylase enzyme from Bacillus amyloliquefaciens P-001. Springer Plus, 2, 154.

Gupta, R., Gigras, P., Mohapatra, H., Goswami, V. K., & Chauhan, B. (2003). Microbial α-amylases: a biotechnological perspective. Process Biochemistry, 38, 1599–1616.

Fossi, B. T., Tavea, F., Jiwoua, C., & Ndjouenkeu, R. (2009). Screening and phenotypic characterization of thermostable amylases producing yeasts and bacteria strains from some Cameroonian soils. African Journal of Microbiology Research, 3, 504–514.

Maity, C., Samanta, S., Halder, S. K., Mohapatra, P. K. D., Pati, B. R., Jana, M., & Mondal, K. C. (2011). Isozymes of α-amylases from newly isolated Bacillus thuringiensis CKB19: production from immobilized cells. Biotech Bioproc Engin, 16, 312–319.

Morgan, F., & Priest, F. (1981). Characterization of a thermostable α-amylase from Bacillus licheniformis NCIB 6346. The Journal of Applied Bacteriology, 50, 107–114.

Samanta, S., Das, A., Halder, S. K., Jana, A., Kar, S., Mohapatra, P. K. D., Pati, B. R., & Mondal, K. C. (2014). Thermodynamic and kinetic characteristics of an α-amylase from Bacillus licheniformis SKB4. Acta Biologica Szegediensis, 58, 147–156.

Hashemi, M., Mousavi, S. M., Razavi, S. H., & Shojaosadati, S. A. (2013). Comparison of submerged and solid state fermentation systems effects on the catalytic activity of Bacillus sp. KR-8104 α-amylase at different pH and temperatures. Industrial Crops and Products, 43, 661–667.

Sivaramakrishnan, S., Gangadharan, D., Nampoothiri, K. M., Soccol, C. R., & Pandey, A. (2006). a-amylases from microbial sources—an overview on recent developments. Food Technology and Biotechnology, 44, 173–184.

Xie, F., Quan, S., Liu, D., Ma, H., Li, F., Zhou, F., & Chen, G. (2014). Purification and characterization of a novel α-amylase from a newly isolated Bacillus methylotrophicus strain p 11–2. Process Biochemistry, 49, 47–53.

Kikani, B. A., & Singh, S. P. (2011). Single step purification and characterization of a thermostable and calcium independent alpha-amylase from Bacillus amyloliquifaciens TSWK1-1 isolated from Tulsi Shyam hot spring reservoir, Gujarat (India). International Journal of Biological Macromolecules, 48, 676–681.

Burhan, A., Nisa, U., Gökhan, C., Ömer, C., Ashabil, A., & Osman, G. (2003). Enzymatic properties of a novel thermostable, thermophilic, alkaline and chelator resistant amylase from an alkaliphilic Bacillus sp. isolate ANT-6. Process Biochemistry, 38, 1397–1403.

Ajayi, A. O. and Fagade, O. E. (2007) Heat activation and stability of amylases from Bacillus species. African Journal of Biotechnology, 6.

Emtenani, S., Asoodeh, A., & Emtenani, S. (2015). Gene cloning and characterization of a thermostable organic-tolerant alpha-amylase from Bacillus subtilis DR8806. International Journal of Biological Macromolecules, 72, 290–298.

Sankaralingam, S., Shankar, T., Ramasubburayan, R., Prakash, S., & Kumar, C. (2012). Optimization of culture conditions for the production of amylase from Bacillus licheniformis on submerged fermentation. American–Eurasian J. Agric and environmental science, 12, 1507–1513.

Abdel-Fattah, Y. R., Soliman, N. A., El-Toukhy, N. M., El-Gendi, H., & Ahmed, R. S. (2013). Production, purification, and characterization of thermostable α-amylase produced by Bacillus licheniformis Isolate AI20. J Chem, 2013, 1–11.

Roy, J. K., Rai, S. K., & Mukherjee, A. K. (2012). Characterization and application of a detergent-stable alkaline alpha-amylase from Bacillus subtilis strain AS-S01a. International Journal of Biological Macromolecules, 50, 219–229.

Satyanarayana, T., Sharma, A., Mehta, D., Puri, A. K., Kumar, V., Nisha, M. and Joshi, S. (2012). Biotechnological applications of biocatalysts from the firmicutes Bacillus and Geobacillus species. Springer, 343–379.

Lévêque, E., Janeček, Š., Haye, B., & Belarbi, A. (2000). Thermophilic archaeal amylolytic enzymes. Enzyme and Microbial Technology, 26, 3–14.

Shafique, S., Bajwa, R., & Shafique, S. (2010). Mutagenesis and genetic characterisation of amylolytic Aspergillus niger. Natural Product Research, 24, 1104–1114.

Halder, D., Paswan, K., Chowdhury, A., Biswas, E., & Basu, M. (2014). Characterization and cell immobilization of a potent amylase producing mesophilic soil bacteria Bacillus cereus strain BRSC-S-A26MB. Journal of Mycopathological Research, 52, 11–19.

Zeni, J., Cence, K., Grando, C. E., Tiggermann, L., Colet, R., Lerin, L. A., Cansian, R. L., Toniazzo, G., de Oliveira, D., & Valduga, E. (2011). Screening of pectinase-producing microorganisms with polygalacturonase activity. Applied Biochemistry and Biotechnology, 163, 383–392.

Wang, S., Lian, Z., Wang, L., Yang, X., & Liu, Y. (2015). Preliminary investigations on a polygalacturonase from Aspergillus fumigatus in Chinese Pu’er tea fermentation. Bioresources and Bioprocessing, 2, 1–13.

Laemmli, U. K. (1970). Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature, 227, 680–685.

Wang, S., Sun, Z., Dong, S., Liu, Y., & Liu, Y. (2014). Molecular interactions between (−)-epigallocatechin gallate analogs and pancreatic lipase. PloS One, 9, e111143.

Weisburg, W. G., Barns, S. M., Pelletier, D. A., & Lane, D. J. (1991). 16S ribosomal DNA amplification for phylogenetic study. Journal of Bacteriology, 173, 697–703.

Yoon, J.-H., Lee, S. T., & Park, Y.-H. (1998). Inter-and intraspecific phylogenetic analysis of the genus Nocardioides and related taxa based on 16S rDNA sequences. International Journal of Systematic Bacteriology, 48, 187–194.

Shafique, S., Bajwa, R., & Shafique, S. (2009). Screening of Aspergillus niger and A. flavus strains for extra cellular alpha-amylase activity. Pakistan Journal of Botany, 41, 897–905.

Abdullah, R., Ikram-Ul-Haq, & Javid, M. (2011). Optimization of cultural conditions for the production of alpha amylase by wild and mutant strain of Aspergillus oryzae in stirred fermenter. Pakistan Journal of Botany, 43, 715–723.

Jana, M., Maity, C., Samanta, S., Pati, B. R., Islam, S. S., Mohapatra, P. K. D., & Mondal, K. C. (2013). Salt-independent thermophilic α-amylase from Bacillus megaterium VUMB109: an efficacy testing for preparation of maltooligosaccharides. Industrial Crops and Products, 41, 386–391.

Acknowledgments

This work was financially supported by the Natural Sciences and Engineering Research Council of Canada (NSERC)—Research Development Fund (RDF) to W. Q. The authors would like to thank Dr. Md. Shafiqur Rahman for his assistance and advice with the experiment in the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, S., Jeyaseelan, J., Liu, Y. et al. Characterization and Optimization of Amylase Production in WangLB, a High Amylase-Producing Strain of Bacillus . Appl Biochem Biotechnol 180, 136–151 (2016). https://doi.org/10.1007/s12010-016-2089-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-016-2089-5