Abstract

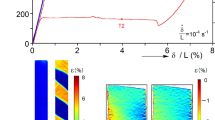

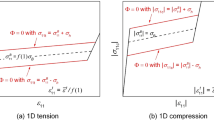

The superelastic response of NiTi shape memory alloys under various loading conditions is experimentally investigated using thin-walled tube specimens. The isotropic relation between the elastic and shear moduli of austenite and martensite as well as the von Mises stress and strain equivalency are also studied in uniaxial tension and pure torsion. In addition to proportional loading, several non-proportional loading experiments based on both force and displacement control modes are conducted. Axial and shear stress–strain behaviors as well as effective stress–strain curves during proportional and non-proportional loadings are investigated. Experimental results in proportional loading based on displacement (strain) control indicate that a smooth hardening in transformation regions occurs, while a relatively sharp hardening takes place in force (stress) control. This phenomenon shows that in the stress control, a small stress increment causes a large strain increment while, in the strain control, a small strain increment corresponds to a small stress increment during the transformation. Experimental results in multi-axial loading show that the loading path and the loading control mode affect the mechanical response of NiTi tube. Furthermore, several combined tension-torsion experiments are conducted, and the mechanical coupling between tension and torsion in thin-walled tubes is investigated.

Similar content being viewed by others

References

Duerig T Present and future applications of shape memory and superelastic materials. In: Materials Research Society Symposium Proceedings, 1995. Cambridge Univ Press, p 497–497

Duerig T, Pelton A, Stöckel D (1999) An overview of nitinol medical applications. Mater Sci Eng A 273:149–160

Van Humbeeck J (1999) Non-medical applications of shape memory alloys. Mater Sci Eng A 273:134–148

Kuribayashi K, Tsuchiya K, You Z, Tomus D, Umemoto M, Ito T, Sasaki M (2006) Self-deployable < i > origami</i > stent grafts as a biomedical application of Ni-rich TiNi shape memory alloy foil. Mater Sci Eng A 419(1):131–137

Khalili S, Shokuhfar A, Malekzadeh K, Ashenai Ghasemi F (2007) Low-velocity impact response of active thin-walled hybrid composite structures embedded with SMA wires. Thin-Walled Struct 45(9):799–808

Lexcellent C, Vivet A, Bouvet C, Calloch S, Blanc P (2002) Experimental and numerical determinations of the initial surface of phase transformation under biaxial loading in some polycrystalline shape-memory alloys. J Mech Phys Solids 50(12):2717–2735

Lavernhe-Taillard K, Calloch S, Arbab-Chirani S, Lexcellent C (2009) Multiaxial shape memory effect and superelasticity. Strain 45(1):77–84

Sittner P, Hara Y, Tokuda M (1995) Experimental-study on the thermoelastic martensitic-transformation in shape-memory alloy polycrystal induced by combined external forces. Metall Mater Trans A 26(11):2923–2935

Tokuda M, Sittner P, Takakura M, Haze M (2002) Multi-axial constitutive equations of polycrystalline shape memory alloy—(Experimental background). JSME Int J Ser A-Solid M 45(2):276–281

Sun Q-P, Li Z-Q (2002) Phase transformation in superelastic NiTi polycrystalline micro-tubes under tension and torsion—from localization to homogeneous deformation. Int J Solids Struct 39(13):3797–3809

Nemat-Nasser S, Choi JY, Guo W-G, Isaacs JB, Taya M (2005) High strain-rate, small strain response of a NiTi shape-memory alloy. J Eng Mater Technol 127(1):83–89

Andani MT, Elahinia M (2014) A rate dependent tension–torsion constitutive model for superelastic nitinol under non-proportional loading; a departure from von Mises equivalency. Smart Mater Struct 23(1):015012

Bruhns OT, Grabe C (2008) On the viscous and strain rate dependent behavior of polycrystalline NiTi. Int J Solids Struct 45(7–8):1876–1895

Bruhns OT, Grabe C (2009) Path dependence and multiaxial behavior of a polycrystalline NiTi alloy within the pseudoelastic and pseudoplastic temperature regimes. Int J Plast 25(3):513–545

McNaney JM, Imbeni V, Jung Y, Papadopoulos P, Ritchie RO (2003) An experimental study of the superelastic effect in a shape-memory Nitinol alloy under biaxial loading. Mech Mater 35(10):969–986

Mehrabi R, Kadkhodaei M (2013) 3D phenomenological constitutive modeling of shape memory alloys based on microplane theory. Smart Mater Struct 22(2):025017

Mehrabi R, Kadkhodaei M, Elahinia M (2014) A thermodynamically-consistent microplane model for shape memory alloys. Int J Solids Struct 51(14):2666–2675

Wang X, Wang Y, Lu Z, Deng C, Yue Z (2010) An experimental study of the superelastic behavior in NiTi shape memory alloys under biaxial proportional and non-proportional cyclic loadings. Mech Mater 42(3):365–373

Benafan O (2012) Deformation and phase transformation processes in polycrystalline NiTi and NiTiHf high temperature shape memory alloys. University of Central Florida Orlando, Florida

Wang Y, Yue Z, Wang J (2007) Experimental and numerical study of the superelastic behaviour on NiTi thin-walled tube under biaxial loading. Comput Mater Sci 40(2):246–254

Stebner A, Brown D, Brinson L (2013) Young’s modulus evolution and texture-based elastic–inelastic strain partitioning during large uniaxial deformations of monoclinic nickel–titanium. Acta Mater 61(6):1944–1956

Mehrabi R, Kadkhodaei M, Andani MT, Elahinia M (2014) Microplane modeling of shape memory alloy tubes under tension, torsion, and proportional tension–torsion loading. J Intel Mat Syst Str:1045389X14522532

Sittner P, Takakura M, Hara Y, Tokuda M (1996) On transformation pathways of general stress controlled thermoelastic martensitic transformation in shape memory alloys. J Phys IV 6(C1):357–366

Peng X, Yang Y, Huang S (2001) A comprehensive description for shape memory alloys with a two-phase constitutive model. Int J Solids Struct 38(38–39):6925–6940

Mehrabi R, Kadkhodaei M, Elahinia M (2014) Constitutive modeling of tension-torsion coupling and tension-compression asymmetry in NiTi shape memory alloys. Smart Mater Struct 23(7):75021–75035

Poynting J (1909) On pressure perpendicular to the shear planes in finite pure shears, and on the lengthening of loaded wires when twisted. Proc R Soc London, Ser A, Containing Papers of a Mathematical and Physical Character 82(557):546–559

Mehrabi R, Andani MT, Elahinia M, Kadkhodaei M (2014) Anisotropic behavior of superelastic NiTi shape memory alloys; an experimental investigation and constitutive modeling. Mech Mater 77:110–124

Lim TJ, McDowell DL (1999) Mechanical behavior of an Ni-Ti shape memory alloy under axial-torsional proportional and nonproportional loading. J Eng Mater Technol ASME 121(1):9–18

Conflict of Interests

The authors declare that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mehrabi, R., Andani, M.T., Kadkhodaei, M. et al. Experimental Study of NiTi Thin-Walled Tubes Under Uniaxial Tension, Torsion, Proportional and Non-Proportional Loadings. Exp Mech 55, 1151–1164 (2015). https://doi.org/10.1007/s11340-015-0016-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-015-0016-2