Abstract

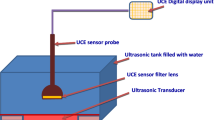

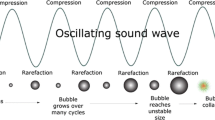

The application of ultrasound to leather processing has a significant role for more efficient and advanced manufacturing techniques for leather production. The effect of important process parameters for scale-up such as mechanical agitation, float, and concentration of dye bath has been experimentally examined. The results indicate that float level and dye bath concentration has significant effect on exhaustion of dye. There is no appreciable improvement due to mechanical agitation over the effect of ultrasound in leather dyeing. Dyeing of chrome-tanned wet-blue leather has been carried out directly in the ultrasonic tank with larger area of sample for scale-up possibility. The results indicate notable improvement (1.6-fold) in dye exhaustion as compared to dyeing in process vessel immersed in the ultrasound tank. This is also equivalent to 4.3-fold increase due to ultrasound as compared to control process without ultrasound at static condition. Ultrasound-aided dyeing of vegetable-tanned (EI) leather shows sixfold improvement as compared to control process. Acoustic cavitation energy in the ultrasonic tank, another important parameter for the scale-up, has been measured and the results indicate that ~60% acoustic energy is absorbed by leather in the process. Influence of ultrasound on dye aggregate size, an important parameter for diffusion, was also studied and found to be beneficial. Different ultrasonic equipments such as ultrasonic tank or ultrasonic probe have been tested and compared for their efficacy. Mass balance for ultrasonic leather dyeing process was performed and compared with control processes. Preliminary techno economic cost benefit analysis indicates positive trend for ultrasonic dyeing as compared to conventional drumming process. Savings in dye due to the use of ultrasound yield significant profit taking into account of ultrasonic energy cost, with a payback period for ultrasonic equipment cost. Therefore, the use of ultrasound in leather processing is a potential viable option for tanners in near future as advanced technology.

Similar content being viewed by others

References

Mason TJ (1990) The uses of ultrasound in chemistry. Royal Society of Chemistry, Cambridge

Contamine F, Faid F, Wilhelm AM, Berlan J, Delmas H (1994) Chemical reactions under ultrasound. Chem Eng Sci 49(24B):5865–5873. doi:10.1016/0009-2509(94) 00297-5

Sivakumar V (2001) Studies on the application power ultrasound in leather processing, Ph.D. Thesis, Anna University, India

Sivakumar V, Rao PG (2001) Application of power ultrasound in leather processing: an eco-friendly approach. J Cleaner Prod 9(1):25–33

Ding JF, Xie JP, Attenburrow GE (1999) Power ultrasound in leather technology. In: Mason TJ (ed) Advances in Sonochemistry, vol 5. JAI press, London

Sivakumar V, Swaminathan G, Rao PG (2004) Use of ultrasound in soaking for improved efficiency. J Soc Leather Technol Chem Soc 88(6):249–251

Herfeld H (1978) Acceleration of wet processing by ultrasonics, Gerbereiniss. Pranis 30:163–166

Alpa, Spa, Italy (1995) Reducing the load: ultrasound in liming and unhairing. World Leather 8(7):89–91

Herfeld H (1978) About the use of ultrasonics in chemicals cleaning of leather and for the acceleration of wet processing in leather production. Leder und Haute Markt 30:232–237 & 271–274

Sivakumar V, Chandrasekaran F, Swaminathan G, Rao PG (2009) Towards cleaner degreasing method in Industries: ultrasound assisted aqueous degreasing process in leather making. J Clean Prod 17(1):101–104. doi:10.1016/j.jclepro.2008.02.012

Mantysalo E, Marjoniemi M, Kilpelainen M (1997) Chrome tannage using high-intensity ultrasonic field. Ultrason Sonochem 4(2):141–144. doi:10.1016/S1350-4177(97) 00030-8

Ernst RL, Gutmann F (1950) Ultrasonically assisted tanning. J Soc Leather Technol Soc 34:454–459

Cujan Z, Kolomaznik K, Mladek M (1984) Accelerating tanning process by use of ultrasonication. Leder Waren 19(4):180–182

Xie JP, Ding JF, Mason TJ, Attenburrow GE, Mason TJ (1999) Influence of power ultrasound on leather processing. Part I: dyeing. J Am Leather Chem Assoc 94:146–157

Sivakumar V, Rao PG (2003) Studies on the use of power ultrasound in leather dyeing. Ultrason Sonochem 10(2):85–94. doi:10.1016/S1350-4177(02) 00148-7

Sivakumar V, Rao PG (2003) Diffusion rate enhancement in leather dyeing with power ultrasound. J Am Leather Chem Assoc 98(6):230–237

Sivakumar V, Rao PG (2004) Power ultrasound assisted cleaner leather dyeing technique: influence of process parameters. Environ Sci Technol 38(5):1616–1621. doi:10.1021/es034853d

Xie JP, Ding JF, Mason TJ, Attenburrow GE, Mason TJ (2000) Influence of power ultrasound on leather processing. Part II: fatliquoring. J Am Leather Chem Assoc 95:85–91

Sivakumar V, Swaminathan G, Rao PG (2005) Studies on the application of power ultrasound in fatliquoring process. J Am Leather Chem Assoc 100(5):187–195

Thakore KA (1988) Application of ultrasonics in dyeing of cotton fabrics with direct dyes—Part 1—Kinetics of dyeing & diffusion Kinetics—Part II. Indian J Text Res 13:133–139 & 208–212

Saligram AM, Shukla SR (1993) Low temperature dyeing of silk in the presence of ultrasound and ultraviolet radiation. J Soc Dyers Col 109:41–43

Sivakumar V, Swaminathan G, Rao PG (2005) Studies on the influence of power ultrasound on dye penetration in leather dyeing using photomicrographic analysis. J Microsc 220:31–35. doi:10.1111/j.1365-2818.2005.01509.x

Sivakumar V, Poorna Prakash R, Rao PG, Ramabrahmam BV, Swaminathan G (2008) Power ultrasound in fatliquor preparation based on vegetable oil for leather application. J Clean Prod 16(4):549–553. doi:10.1016/j.jclepro.2007.01.006

Sivakumar V, Ravi Verma V, Rao PG, Swaminathan G (2007) Studies on the use of power ultrasound in solid–liquid myrobalan extraction process. J Clean Prod 15(18):1815–1820. doi:10.1016/j.jclepro.2006.06.006

Sivakumar V, Swaminathan G, Rao PG, Ramasami T (2008) Influence of ultrasound on diffusion through skin/leather matrix. Chem Eng Process Process Intensif 47(12):2076–2083. doi:10.1016/j.cep. 2007.10.020

Mortimer AJ, Trollope BJ, Villeneuve EJ, Roy OZ (1988) Ultrasound-enhanced diffusion through isolated frog skin. Ultrasonics 26:348–351. doi:10.1016/0041-624X(88) 90034-0

Lenart I, Auslander D (1980) The effect of ultrasound on diffusion through membranes. Ultrasonics 18:216–218. doi:10.1016/0041-624X(80) 90123-7

Kumar R (1994) Can sound help chemical engineers? Indian Chem Eng J 36(1–2):3–18

Prasad Naidu DV, Rajan R, Kumar R, Gandhi KS, Arakeri VH, Chanrasekaran S (1994) Modelling of a batch sonochemical reactor. Chem Eng Sci 49:877–888. doi:10.1016/0009-2509(94) 80024-3

Rajan R, Kumar R, Gandhi KS (1998) Modelling of sonochemical oxidation of the water-KI-CCl4 system. Chem Eng Sci 53(2):255–271. doi:10.1016/S0009-2509(97) 00211-X

Keil FJ, Dähnke S (1997) Numerical calculation of scale-up effects of pressure fields in sonochemical reactors—homogeneous phase. Hung J Ind Chem 25:71–80

Dähnke S, Swamy KM, Keil FJ (1999) A comparative study on the modeling of sound pressure field distributions in a sonoreactor with experimental investigation. Ultrason Sonochem 6(4):221–226. doi:10.1016/S1350-4177(99) 00011-5

SLTC (1958) International union of leather chemists societies physical testing commission—recommended physical test methods—IUP/1. J Soc Leather Technol Chem Soc 42:382–393

Ramesh S, Koltypin Y, Gedanken A (1997) Ultrasound driven aggregation and surface silanol modification in amorphous silica microspheres. J Mater Res 12:3271–3277. doi:10.1557/JMR.1997.0430

Samal AB, Adzerikho ID, Mrochek AG, Loiko EN (2000) Platelet aggregation and change in intracellular Ca2+ induced by low frequency ultrasound in vitro. Eur J Ultrasound 11:53–59. doi:10.1016/S0929-8266(99) 00077-4

Otto C, Baumann M, Schreiner T, Bartsch G, Borberg H, Schwandt P, Schmid-SchÖnbein H (2001) Standardized ultrasound as a new method to induce platelet aggregation, evaluation, influence of lipoproteins and of glycoprotein IIb/IIIa antagonist tirofiban. Eur J Ultrasound 14:157–166. doi:10.1016/S0929-8266(01) 00157-4

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sivakumar, V., Swaminathan, G., Gangadhar Rao, P. et al. Ultrasound-aided leather dyeing: a preliminary investigation on process parameters influencing ultrasonic technology for large-scale production. Int J Adv Manuf Technol 45, 41–54 (2009). https://doi.org/10.1007/s00170-009-1956-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-009-1956-4