Abstract

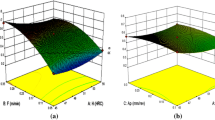

In this study, the effects of cutting edge geometry, workpiece hardness, feed rate and cutting speed on surface roughness and resultant forces in the finish hard turning of AISI H13 steel were experimentally investigated. Cubic boron nitrite inserts with two distinct edge preparations and through-hardened AISI H13 steel bars were used. Four-factor (hardness, edge geometry, feed rate and cutting speed) two-level fractional experiments were conducted and statistical analysis of variance was performed. During hard turning experiments, three components of tool forces and roughness of the machined surface were measured. This study shows that the effects of workpiece hardness, cutting edge geometry, feed rate and cutting speed on surface roughness are statistically significant. The effects of two-factor interactions of the edge geometry and the workpiece hardness, the edge geometry and the feed rate, and the cutting speed and feed rate also appeared to be important. Especially honed edge geometry and lower workpiece surface hardness resulted in better surface roughness. Cutting-edge geometry, workpiece hardness and cutting speed are found to be affecting force components. The lower workpiece surface hardness and honed edge geometry resulted in lower tangential and radial forces.

Similar content being viewed by others

References

Narutaki N, Yamane Y (1979) Tool wear and cutting temperature of CBN tools in machining of hardened steels. Ann CIRP 28(1):23–28

Hodgson T, Trendler PHH, Michelletti GF (1981) Turning hardened tool steels with cubic boron nitride inserts. Ann CIRP 30(1):63–66

Koenig W, Komanduri R, Toenshoff HK, Ackeshott G (1984) Machining of hard metals. Ann CIRP 33(2):417–427

Koenig W, Klinger M (1990) Machining hard materials with geometrically defined cutting edges–field of applications and limitations. Ann CIRP 39(1):61–64

Koenig W, Berktold A, Koch F (1993) Turning versus grinding – a comparison of surface integrity aspects and attainable accuracies. Ann CIRP 42(1):39–43

Klocke F, Eisenblatter G(1997) Dry cutting. Ann CIRP 46(2):519–526

Toenshoff HK, Arendt C, Ben Amor R (2000) Cutting hardened steel. Ann CIRP 49(2):1–19

Chou YS, Barash MM (1995) Review on hard turning and CBN cutting tools. SME Technical Paper, Proceedings of 1st International Machining and Conference, MR95-214, pp 951–962

Matsumoto Y, Barash MM, Liu CR (1987) Cutting mechanism during machining of hardened steel. Mater Sci Technol 3:299–305

Shaw MC, Vyas A (1993) Chip formation in the machining of hardened steel. Ann CIRP 42(1):29–33

Davies MA, Chou Y, Evans CJ (1996) On chip morphology, tool wear and cutting mechanics in finish hard turning. Ann CIRP 45(1):77–82

Elbestawi MA, Srivastava AK, El-Wardany TI (1996) A model for chip formation during machining of hardened steel. Ann CIRP 45(1):71–76

Astakhov VP, Shvets SV, Osman MOM (1997) Chip structure classification based on mechanism of its formation. J Mater Process Technol 71:247–257

Davies MA, Burns TJ, Evans CJ (1997) On the dynamics of chip formation in machining hard metals. Ann CIRP 46(1):25–30

Shaw MC, Vyas A (1998) The mechanisms of chip formation with hard turning steel. Ann CIRP 47(1):77–82

Poulachon G, Moisan AL (1998) A contribution to the study of the cutting mechanisms during high speed machining of hardened steel. Ann CIRP 47(1):73

Poulachen G, Moison AL (2000) Hard turning: chip formation mechanisms and metallurgical aspects. J Manuf Sci Eng 122:406–412

Poulachen G, Moison AL, Jawahir IS (2001) On modelling of the influence of thermo-mechanical behavior in chip formation during hard turning of 100Cr6 bearing steel. Ann CIRP 50(1):31–36

Barry J, Byrne G (2002) The mechanisms of chip formations in machining of hardened steels. J Manuf Sci Eng 124:528–535

Ueda T, Al Huda M, Yamada K, Nakayama K (1999) Temperature measurement of CBN tool in turning high hardness steel. Ann CIRP 48(1):63–66

Chou YK, Evans CJ (1997) Tool wear mechanism in continuous cutting of hardened tool steels. Wear 212:59–65

Barry J, Byrne G (2001) Cutting tool wear in the machining of hardened steels. Part II: CBN cutting tool wear. Wear 247:152–160

Matsumoto Y, Hashimoto F, Lahoti G (1999) Surface integrity generated by precision hard turning. Ann CIRP 48(1):59–62

Thiele JD, Melkote SN (1999) Effect of cutting edge geometry and workpiece hardness on surface generation in the finish hard turning of AISI 52100 steel. J Mater Process Technol 94:216–226

Thiele JD, Melkote SN, Peascoe RA, Watkins TR (2000) Effect of cutting-edge geometry and workpiece hardness on surface residual stresses in finish hard turning of AISI 52100 steel. ASME J Manuf Sci Eng 122:642–649

Özel T (2003) Modeling of hard part machining: effect of insert edge geometry in CBN tools. J Mater Process Technol 141:284–293

Guo YB, Liu CR (2002) Mechanical properties of hardened AISI 52100 steel in hard machining processes. ASME J Manuf Sci Eng 124:1–9

Chou YK, Evans CJ, Barash MM (2003) Experimental investigation on CBN turning of AISI 52100 steel. J Mater Process Technol 134:1–9

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Özel, T., Hsu, TK. & Zeren, E. Effects of cutting edge geometry, workpiece hardness, feed rate and cutting speed on surface roughness and forces in finish turning of hardened AISI H13 steel. Int J Adv Manuf Technol 25, 262–269 (2005). https://doi.org/10.1007/s00170-003-1878-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-003-1878-5