Abstract

UV-C irradiation critically effects the growth of micro-fungi and also deteriorate leather materials. In the present study vegetable tanned and chrome tanned leather were infected with pure cultures of Aspergillus niger and Aspergillus flavus, which were isolated from stored leather materials. UV-C light (λ = 254 nm) was applied on infected leather for 15 and 60 min. The changes in leather qualities were examined through weight, tensile strength, scanning electron microscope, energy dispersive X-ray and Fourier transform infrared spectroscopy study after 15 and 30 days of fungal inoculation. Vegetable tanned leather was more vulnerable in case of fungal attack than chrome tanned leather while A. flavus showed more influence on leather deterioration than A. niger. The results showed that weight loss after 30 days for 15 and 60 min irradiation exposure was 1.3% compared to A. flavus infected leather (3.93%). The tensile strength of vegetable and chrome tanned UV irradiated leather was increased by 44% and 7% respectively. The scanning electron microscopic images exhibit the limited presence of conidiophores in UV-C exposed leather which confirmed the potentiality of irradiation for controlling fungal growth. The infrared spectral analysis of UV-C exposed infected leather samples showed neither shifting of wavenumber nor displacement of any functional groups. Altogether the efficacy of UV-C irradiation against biodeterioration of leather was concluded to be effective. This method can be used to control fungal growth without compromising the leather quality.

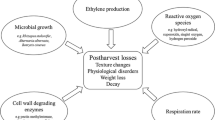

Graphical Abstract

Similar content being viewed by others

1 Introduction

Leather, an agricultural intermediate commodity, is used for leather goods, shoes, clothing and other items [1]. Worldwide production for leather was 586.9 thousand tons/year from 2012 to 2014 with an average which indicates that the leather industry is now one of the fastest-growing industries [2]. From South Asia, Afghanistan, Bangladesh, Bhutan, India, Indonesia, Maldives, Nepal, Pakistan, Sri Lanka contribute largely to the production and global exports of finished leather. The finished leather used for several commodities of daily use is highly susceptible to fungal attack [3]. During storage and transportation, the development of mold with white, gray, blue, yellow, and black colonies or strains has always been troublesome for leather manufacturers and sellers because mold development seriously affects aesthetic aspects, functional and other properties of leather and the products made from them and results in significant economic losses [4]. As the cost of raw materials and manufactures for leather production occupies significant portion, it is fundamental to maintain good infrastructure and good quality throughout the whole cycle of leather production including storage and transportation. By doing so, the quality of leather and the rising trend of global exports of leather from South Asia should be maintained.

Leather often needs to be stored for a substantial period after being tanned or even after being finished and also as leather products at leather warehouse facilities before it is transported to a local buyer or shipped to international destinations. In addition, shipping might also take up to months to reach the final destination. Fungal growth during the storage of leather is a serious cause of spoilage in leather materials. For several years, the mechanism of biodeterioration of microorganisms on leather has been a subject for investigation. Airborne fungi play an important role in the deterioration of leather and leather goods which cause a great threat and huge economical loss to the industries related to leather products. Leather, as a biological product, is made of protein fiber and is abundant with organic matter. Besides having high moisture, the hides and leather are rich in fats, proteins and carbohydrates that serve as substrates for the growth of microorganisms, especially bacteria and fungi [5]. Aspergillus sp., Penicillium sp., Mucor sp., Rhizopus nigricans and Paecilomyces variotii are mainly responsible for the biodeterioration of finished leather [2]. Microorganisms produce enzymes that can degrade macromolecules into smaller units [6]. These smaller units can be absorbed through the cell membranes and be used as nutrients and energy sources for microorganisms [7]. In the deterioration study, mass loss was considered as an important parameter [8]. Some species of fungi synthesize important substances of this substrate, which can lead to a variety of defects as a result of microbial activity [9]. Fungi can easily grow on various stage of processed leather from hides and skin such as wet blue, chrome tanned leather, vegetable leather and even on finished leather under favorable condition. In hot and humid environment fungi grow on leather creates colorful patches, decolorize the finished product which ultimately cause trouble in production, storage and transportation [4]. Fungal attack causes staining, cracking, wrinkling, disfigurement and displacement of leather material which is accompanied by the transformation of the chemical and mechanical properties of the material. This leads to the permanent loss of leather’s quality and visual look [10]. Therefore, the anti-fungal treatment of leather has been developed which include application of paranitrophenol, pentachlorophenol, 2-(thiocyanomethylthio) benzothiazole etc. during the time of manufacturing of leather to deal with this critical issue [7]. Besides, irradiation and anti-mildew treatment have been practiced to prevent the growth of fungi on finished and tanned leather as paying attention to cleanliness and sanitation to eradicate the source of fungi and also controlling environmental conditions [4]. Anti-fungal chemicals used in various steps of leather processing consist in many times and chemical-consuming steps [11]. This implies high costs and time-consuming processing of the leather materials and residues. These anti-fungal agents are not easily molded or fungal resistant due to incorrect use of leather in various external conditions [12]. In addition, most of the anti-fungal chemicals are hazardous and not environmentally friendly. Therefore, the fungal preventive process based on green technologies needs to be focused.

Introducing short wave radiation as an antifungal treatment method in the leather industry can be a potential and green approach. Disinfestation and decontamination by UV irradiation alternative to fumigation and antifungal chemical have emerged as a successful replacement. It is well known that ultraviolet radiation is a good method to prevent fungal activity. The fungicidal effects of various wavelengths of ultraviolet exposure, i.e., UV-A (315–400 nm), UV-B (280–315 nm) and UV-C (100–280 nm) on Aspergillus spore, reduce the germination rate uniformly [13]. UV-A and UV-B can delay conidial germination in Aspergillus flavus and Penicillium notatum [14]. UV-disinfection reduces the Ochratoxin A mycotoxin by Aspergillus on grapes [15]. UV irradiation helps inactivate fungal spores of Aspergillus niger from cornmeal [16]. UV-C irradiation on fungal spores has a significant impact on their enzyme activity as well. Studies show that UV-C was able to reduce the production of α-amylase in Aspergillus niger [17]. Some other studies show that UV mutagenesis improved the production of CMCase and FPase on Aspergillus niger [18]. UV-irradiated leather fibers lost a significant degree of orientation in their molecular chains and the UV radiation caused disorientation in the collagen molecular chains which caused a lower birefringence [19]. It was also revealed that the tensile strength of leather decreases with the increase of radiation doses. Chrome tanned leather treated with α-tocopherol exhibited improvement in strength, softness against UV radiation [20]. UV intensity and exposure time are the most important factors, which increase or decrease the degradation rate of leather. UV-C is more effective and requires much less time compared to UV-A and UV-B to sterilize artifacts so that the overall UV-C exposure time is decreased and the risk of damage is also reduced. For over 10 years, the use of UV-C in laboratory conditions for developing a safe workplace procedure and the evaluation of mould remediation with minimal impact on artifacts is a significant beginning.

Therefore, our study aimed at suggesting the influence of UV-C irradiation on naturally occurring fungi growing on leather materials. To fulfill this, we examined physical, chemical and aesthetic properties of both fungal infected vegetable and chrome tanned leather exposed under ultraviolet radiation. The measuring parameters were weight loss, tensile strength, presence or absence of functional groups and composition of trace elements in leather for 15 and 30 days intervals after infecting of fungi and administration of UV-C irradiation.

2 Materials and methods

2.1 Isolation and identification

Several infected leather samples were collected from the stored warehouse of a local leather factory in Kolkata, India. Infected areas of leather were rubbed and scrapped by a sterile tweezer to obtain samples. The scrapped part was taken into sterile petri plates until laboratory inoculation. Then, the collected samples were inoculated onto freshly prepared Czapek Dox Agar plates. The inoculated plates were incubated at 27 °C and 90 ± 5% relative humidity for 7 days. Two exclusive fungal strains Aspergillus niger and Aspergillus flavus were identified from the infected leather materials after microscopic observations. Later, these fungal strains had been confirmed from Agharkar Research Institute, Pune, India.

2.2 Biodeterioration study on leather

2.2.1 Preparation of fungal culture

Czapek Dox medium was prepared in conical flasks and the pH was maintained at 7.3 ± 0.2 (CyberScan pH 510). Next, the sterilization was done with the agar in the conical flasks using autoclave at 121 °C temperature and 103,421 N m−2 pressure for 15 min. In the laminar airflow chamber, the Czapek Dox medium was poured from the conical flask to each sterile test tube (1/3 volume). All test tubes were inclined (45°) slightly and left for being solidified. After 24 h, one loopful culture from each fungal species (Aspergillus niger and Aspergillus flavus) was stricken over the slants separately. All the slants were kept in an incubator at growth temperature (27 °C) for 7 days.

2.2.2 Preparation of leather sample

Vegetable tanned and chrome tanned cowhide finished leather (15 cm × 15 cm × 0.05 cm) was selected for the biodeterioration study. The vegetable tanning content of the vegetable tanned leather are tannic acid derived from oak and bark of black wattle whereas chromium salts are used for tanning of chromium tanned leather. Both types of leather were collected from the storehouse of Centre of Leather Research Institute (CLRI), Kolkata and they were kept in a desiccator for 4 h before the further experiment.

2.2.3 Experimental setup

Collected leather samples were artificially infected with storage fungi of Aspergillus niger and Aspergillus flavus. Surface sterilized airtight plastic containers (22 cm × 17 cm × 8 cm) were used for each experimental setup. Fungal spores from the early prepared fungal slants were smeared over the surface of each leather sample with the help of a sterile inoculating loop. After inoculation, the leather samples were placed and sealed in the containers which contained a thin film of sterilized Czapek Dox medium. The fungal cultures (Aspergillus niger and Aspergillus flavus) were inoculated separately on vegetable tanned and chrome tanned leather and kept in plastic containers. The setup was incubated for 15 and 30 days at 27 °C. Simultaneously a controlled study was also performed using the same quality of leather. The boxes were monitored regularly to maintain relative humidity about 90–100% to provide ideal growth conditions [21]. Finally, the samples were washed and dried for further testing and data were recorded after 15 and 30 days separately.

2.3 UV exposure study on fungal infected leather

2.3.1 Preparation of fungal medium

Czapek Dox medium was prepared in conical flasks for this non-destructive controlling method. The composition of the Czapek Dox medium was comprised of dipotassium hydrogen phosphate (1 g L−1), magnesium sulfate (0.5 g L−1), potassium chloride (0.3 g L−1), ferrous sulfate (0.01 g L−1) and sucrose (15 g L−1). The pH of the medium was adjusted to 7.3 ± 0.2. The carbon source of the Czapek Dox medium was taken half of its composition and nitrogen source was absent from the media composition.

2.3.2 Experimental setup of UV exposure study

All leather samples were taken into an airtight sterile polyethylene box separately. After that, 25 mL of sterile Czapek Dox medium was added in the box. Then the spore suspensions of Aspergillus niger and Aspergillus flavus were spread over the surface of each sample separately by a sterile brush. Then all the samples in the boxes were incubated at 27 °C for 7 days to grow the fungi on the test samples. After 7 days of incubation, the infected leather samples were placed under UVC light (Philips TUV 11 W) of the irradiation chamber for 15 and 60 min. The distance between sample and UV light was 20 cm. The temperature was maintained at 20 ± 2 °C. The intensity of UVC light (total 5 UV lamps, 1 lamp was top-side attached and other 4 lamps were attached to sidewall of the UV chamber) was 1200 µw cm−2 and peak at 254 nm was used in this study. After necessary exposure time period, these samples were kept in fresh plastic box which contained sterile Czapek Dox medium.

2.4 Analysis

After 15 and 30 days of incubation, samples were taken from the plastic box and these samples were used for different measurements.

2.4.1 Weight loss

All leather samples were properly washed followed by dried in a hot air oven (60 °C) for 2 h and finally kept in desiccator for 24 h before taking initial and final weight according to the gravimetric method. Each sample was weighed three times and averaged. The weight loss percentage of every test sample was determined by the following equation [8, 22]:

Here W = Weight loss percentage of leather sample, W1 = Initial dry weight of the leather sample, W2 = Final dry weight of the leather sample.

2.4.2 Tensile strength

All samples after 15 and 30 days of incubation, including controlled samples, were taken for this test. IUP-6 was followed as a norm for this method. The apparatus used for this test were the tensile testing machine and press knife. Each test sample was cut into dumbbell shape where length was 110 mm and thickness was nearest 0.1 mm. The cross-sectional area was calculated by multiplying the width with the thickness of each testing specimen. Then, the leather specimen was inserted into the two jaws of the tensile testing machine. After that, the machine was run till the sample broke and the reached highest load was taken as the breaking load. Thus, tensile strength was resulted by dividing of breaking load by cross-section area of the test sample.

2.4.3 Fourier-transform infrared spectroscopy (FTIR)

IR spectroscopy is a useful technique for the unknown spectra identification of leather samples. In the present study, FTIR (PerkinElmer Spectrum 100) was used to detect the deterioration of leather. The leather samples were cut into 2 mm × 2 mm in size after 30 days of incubation. To observe the presence or absence of absorption bands, the mid-infrared region (4000 to 400 cm−1) with a resolution of 4 cm−1 is used to analyze the sample. The spectra at each data point were recorded as transmission percentages.

2.4.4 SEM (scanning electronic microscope) and EDX (energy dispersive X-ray)

The leather surfaces, internal features as well as elemental composition were studied using SEM equipped with an EDX system. After 30 days of incubation, each leather sample was cut into 4 mm × 4 mm pieces for SEM analysis. Leather pieces were fixed on aluminum support using carbon tape. The magnification of SEM photographs was 200 × to 2500 ×. The percentage of trace elements like carbon, chlorine, chromium etc. was also measured in triplicates by EDX.

3 Result and discussion

3.1 Weight loss measurement

Weight loss measurement of fungal infected and control samples were observed after 15 and 30 days incubation. The comparisons of percentage of weight loss between non-irradiated and UV irradiated samples are illustrated in Figs. 1 and 2. All the fungal infected samples showed significant weight loss compared to the control samples, whereas UV-C irradiated fungal infected samples showed less weight loss in comparison to the fungal infected samples.

The control samples with and without UV-C also showed a negligible or no weight loss after 15 and 30 days incubation. Both vegetable and chrome tanned finished leather with fungal infection (A. niger and A. flavus) and without UV-irradiation lost 5.75%, 3.93%, 1.70% 1.26% of their initial weight respectively after 30 days of incubation. The less weight loss by A. niger in case of chrome leather because during chromium sulphate tanning procedure, the chromium (III) salts stabilize collagen bonds directly between carboxyl groups on adjacent triple helices. This chrome-tanning mechanism converts animal hide into ‘leather’. The chemical bonding enhances the strength of the leather as stitching strengthens a torn material [23]. This strength helps the chrome tanned leather to withstand against external factors. Vegetable extract in case of vegetable tanning, react with collagen primarily via hydrogen bonding, fix to amino side-chains by electrostatic salt links with carboxylate or hydrogen bonding with carboxylic acid groups. This reaction is very much depends on pH [24]. Therefore more biodeterioration has taken place in more in vegetable tanned leather in the present study. Also A. flavus showed more impacts on weight loss than A. niger except 15 days deterioration of vegetable tanned leather (Fig. 1). As the presence of nutrients of the plant extracts and oils during the tanning process of vegetable tanned leather, may serve as food for fungi [9]. This study indicates that vegetable tanned leather was much susceptible to microbial attack when kept in the warehouse for further processing. The weight-loss monitoring of this study indicates that fungi cause the change of the leather tissue density which is apparently associated with the fact that molecular weight of collagen decreases and denser packing of structural elements becomes easier. This leads to leather overall weight loss reduction [25]. Thus, fungal contamination leads the mass loss of leathers by deterioration. This study has revealed that the percentage of the weight loss of the vegetable tanned infected leather sample was more for non-irradiated samples and less for irradiated samples compared to infected chrome tanned leather (Figs. 1, 2). However, the UVC irradiation has also some significant influencing factor regarding mass loss which might be the reason of more weight loss of chrome tanned sample initially infected with A. niger (around 0.39% more weight loss) than that of the vegetable tanned sample. The presence of chromium complexes in the collagen matrix increases the absorption of UV irradiation [26]. Increased absorption causes a significant photodecomposition and scission in the main chains and hence causes weak stability that leads to decreased dynamic viscosity for irradiated samples as well as causes weight loss [27]. However, the stability of the main chain is not much disturbed as the exposure duration was only for 15 min. Unlike the weight loss ratio of non-irradiated fungal deteriorated leather sample, the weight loss of UV-C irradiated fungal infected sample was much less which was around 0.5 to 1.3%. It has been observed that samples were exposed to long time UV-C irradiation has lost their weight less comparatively than the samples of short time UV exposure. Therefore, this finding indicates that leather samples exposed in short time UV-C ray was more prone to weight loss because of fungal attack than long time UV-C exposed samples. This finding indicates that short time UV-C exposure might not properly stop fungal activity in the deteriorated samples and the enzyme activity of fungi again availed after the short time UV exposure where long time UV exposure properly inhibited the fungal activity. Besides, A. flavus had more influence in leather deterioration than A. niger. It is found from previous study that continuous UV irradiation for long time such as 48 h. causes mass losses of leather [28]. Since, the duration of UV exposure used this experiment was 15 and 60 min, therefore a minimum period (15 min) of UV-C exposure is generally recommended, as it does not significantly alter mass or weight, rather it helps to resist fungal development.

3.2 Physical strength analysis

Tables 1 and 2 show the observation of physical strength assessment; tensile strength test and percentage of elongation at break of fungal infected and control (without fungi) leather samples after 15 and 30 days of incubation. These samples include both non-irradiated and UVC-irradiated samples. The analysis of tensile strength and percentage of elongation at break of fungal deteriorated leather samples without UV-irradiation has shown a considerable change in comparison to control samples. After 30 days incubation, the ultimate percentage losses of tensile strength of A. niger and A. flavus infected vegetable tanned samples were about 42.80% and 61.61% respectively while in the case of chrome tanned leather the losses were 36.3% and 45% respectively in comparison to control samples. The same pattern was observed for the percentage of elongation for both types of leather (Tables 1, 2).

Though there are several factors such as the direction of force applied, type of hides or skin, methods of tanning and finishing, the location of the specimen to cut for testing, etc. which are involved to determine the physical strength of leather [29]. However, the observation of this study has indicated that the change in physical strength and damage of leather has been occurred to the leather samples due to consequences of fungal deterioration which actually modify the structure of leather with loss of its protein material, subsequently lead to hydrolysis of the leather and finally breaking of fibers of the leather, the leather sample become disintegrated [9, 30]. Thus, fungal deterioration causes the decrease of the physical strength of leather and compromises its quality. On the other hand, on average, tensile strength and percentage of elongation at break have been fallen almost insubstantially after 15 and 30 days storage in the case of UV induced sample except some cases has (A. flavus infected short time and longtime UV induced sample) showed significant fall in physical strength (Tables 1, 2). Comparing to fungal-infected non-irradiated samples, it was found that, UV-C exposure around 15 to 60 min worked as a positive effective factor of the physical strength of both types of the finished leather. It has been also found that UV-C irradiated samples followed by A. niger infection showed a small loss of physical strength comparing those of UV-C induced leather samples infecting with A. flavus. This finding indicates that 7 days growth of fungi before UV-C exposure might influence change of tensile strength and elongation at break of UV-C treated samples. However, long time UV-C affects a bit of tensile strength and elongation at break of leather than control sample without UV. From a previous study it was found that UV exposure on collagen-based samples for a long time such as 48 h, 150 h etc., may rupture collagen peptide chains which lead to the destruction of collagen fibers and the reduction of cross-linking degree which resulted in the reduction of physio-mechanical properties of leather samples [31]. By combining the observation of this study and previous literature studies, it is suggested that constant long time UV exposure may change the internal structure of leather samples as well as affects the physical strength [31,32,33]. Small-time exposure of UV irradiation in the present study, however, can resist the fungal damage to the leather samples. Thereby, 15 to 60 min UV-C exposure can be applied as it helps to resist the fungal growth of leather as well as it may have less influence on the physical strength of leather samples (Tables 1, 2).

3.3 FT-IR analysis

Figures 3 and 4 illustrate the FTIR spectra of both vegetable and chrome tanned finished leather after 30 days incubation. It represents the spectra of non-irradiated, UV-C irradiated and control sample. All of eight spectra of Fig. 3 show broad transmittance bands at between 3600 and 3100 cm−1 which correspond N–H or O–H group. The (b) and (c) spectra (Fig. 3) show a peak at 2921 cm−1 which are because of C-H stretching whereas (a) spectrum doesn’t show a considerable peak at this wavenumber. Though control sample’s (spectra (a)) shows less transmittance than biodeteriorated samples. This indicates that deteriorated samples functional groups were strongly fluctuated than control sample. It is also proved from FTIR study that fungal deterioration alters the structural stability of collagen in both UV-C exposed and control leather samples. The FT-IR spectra of chrome tanned leather (Fig. 4) show a broad signal in the range between 3600 and 3000 cm−1 with the highest peak located at around 3300 cm−1 which corresponds N–H stretching vibrations from peptide linkage and O–H groups of water molecules in collagen structure [26, 28]. It is observed from Fig. 4 that there is no dramatic change between control sample’s spectrum and other seven deteriorated samples’ spectra.

FT-IR spectra of vegetable tanned leather samples after 30 days’ incubation a control sample without fungi and UV exposure, b A. niger infected leather, c A. flavus infected sample, d control sample with only UV-C exposure for 60 min, e sample exposed for 60 min of UV-C and initially infected by A. niger, f sample exposed for 15 min of UV-C and initially infected by A. niger, g 60 min of UV-C exposure and initially infected by A. flavus sample and h sample exposed for 15 min of UV-C exposure and initially infected by A. flavus

FT-IR spectra of chrome tanned leather samples after 30 days’ incubation a control sample without fungi and UV exposure, b A. niger infected leather, c A. flavus infected sample, d control sample with only UV-C exposure for 60 min, e sample exposed for 60 min of UV-C and initially infected by A. niger, f sample exposed for 15 min of UV-C and initially infected by A. niger, g 60 min of UV-C exposure and initially infected by A. flavus sample and h sample exposed for 15 min of UV-C exposure and initially infected by A. flavus

However, the disappearance of the peak at 1746 cm−1 (C=O stretching bond) at (b) and (c) spectra while control sample’s spectrum shows very intensified peak at the same wavenumber and this peak was again appeared at UV-C induced samples’ spectra. Moreover, (b) & (c) spectra show the decreasing of relative intensity at almost every peak comparing to control (a) sample’s spectrums which indicate the deterioration role of fungi [30, 34]. The spectra (Figs. 3, 4) also depict the changes of the structural and functional groups of both short and long time UV-C induced leather samples after 30 days incubation.

From both figures, it has been observed that control samples’ spectra (a), only UV-C irradiated samples of control (d) and UV-C irradiated, fungal infected leather samples (e, f, g, h) have given almost same signature at same wavelength range and their intensity is almost same even after 30 days. It is also clear that each spectrum of UV-C samples shows very intensified peaks which are due to the functional groups showed strong vibration. It might be because of initially biodegradation by fungi and also effect of UV-C irradiation which affected the collagen structure of the leather. As more amino acids were released from the collagen macromolecular chain, resulting free amino acids and increasing content of coil (from close examining of amide I & amide II bands). Therefore we get more intensified spectrum of leather sample due to fungal attacks as well as UV-C exposure [35]. As, this study indicates that neither shifting of wavenumber nor any significant displacement of any functional group of UV-C exposure sample in comparison to control sample, rather amide I band and amide II band have showed intensified peak along with control sample. This feature supports that UV-C exposure on fungal deteriorated leather from 15 to 60 min have not shown considerably functional change of both leather samples, rather it helps to resist further fungal growth at least for 30 days storage.

3.4 SEM and SEM–EDX analysis

The scanning electron microscopy (SEM) study (Figs. 5, 6) and SEM–EDX analysis (Tables 3, 4) of this experiment have revealed a significant finding after 30 days of incubation where fungal deteriorated samples were compared with the observation of control sample as well as with UV-C exposed fungal infected samples. From the SEM images (Fig. 5) it is observed that the control samples represent smooth surfaces with compactness, well-defined pores and also there is no observable fiber damage. On the other hand, fungal infected samples exhibit deteriorated surfaces and irreparable damages structure like rough surfaces and damaged fibers.

The SEM images (Fig. 5c, 6c) of UV-C induced leathers show the evidence of less fiber damage as well as less surface roughness. Because UV-C exposure might control fungal growth on leather samples, less damage has been found. Moreover the leather samples kept into the desiccator after laboratory experiment. As a result it became air-hydrated and dehydrated conidiophores containing leather samples were used for SEM analysis (Fig. 5b, 6b). A distinguished pattern of salts on the blemished and unblemished areas of the leather has been visible which might be evidence of an active role playing by fungi modifying the leathers chemical composition. The appearance of the blemished samples indicate that the microbial attack was involved which helped to leach the mineral components of the leather surface (Fig. 5b, 6b). Fungi utilize the components in leather for nutritional purposes. It has been comprehended from EDX analysis (Tables 3, 4), that there is significant difference of chemical composition among the leather samples of non-irradiated fungal infected sample, control samples and UV-C irradiated fungal infected sample. The carbon content in control sample with and without UV exposure are 72.25%, 71.54%, 71.88% respectively for vegetable tanned leather and 55.63% for chrome tanned leather. There is a remarkable decrease of carbon in fungal infected sample in both types of leather (Tables 3, 4). Same pattern is also found for other elements. The most reduction is found in case of C, Cl and Ca. This can be explained that the utilization of carbon by fungi for their energy and metabolism is the prime cause of carbon reduction. Another interesting finding is that Ca is present only in all control samples and non-infected UV exposed samples of both chrome and vegetable tanned leather but absent from all deteriorated samples (Tables 3, 4). It is known that a considerable amount of chemicals of both inorganic and organic compound are used during the process of making leather from hides and skins [36].

The decrease of the particular chemical elements found from SEM–EDX analysis indicates the up taking of these chemicals by fungi during incubation. Chromium sulfates are worked as weak fungicide, which also play some role and risk of microorganism infection is not primarily eliminated by the action of this fungicide [37]. In this study the chrome element was not used in tanning process (Additional file 1: Fig. S1) of vegetable tanned leather but the presence of Cr in EDX analysis indicates that the use of water in the tanning process might contain a small proportion of chromium element. In addition to that, both short and long time UV-C exposed deteriorated samples show almost same elemental composition as their respective fungal infected sample without UV-C exposure. These findings indicate that before UV exposure fungi might utilize the elements for their growth on leather samples and after 7 days as the whole infected leathers were exposed to UV-C irradiation. The growth of fungi became restricted and the loss of elements might be the result of initial 7 days of fungal development. The EDX analysis of UV-C exposed samples shows overall improvement in quality comparing to other infected leather samples. Leather itself contains fat and protein, which were degraded by Aspergillus and other fungal species. Therefore it can be utilized by fungal enzymes and converted into macromolecules to smaller units. These smaller units can be absorbed through the fungal cell membranes and can be used as nutrients and energy source for fungi [7, 37]. Thus supporting previous study, this study refers that the chemical differences observed in the undamaged and damaged leather surfaces might be as a result of the microbial deterioration of the upper strata of layer with a consequent loss of surface salts and the exposure of the underlying strata, which are of a different chemical composition [30, 38]. Therefore, SEM image and elemental analysis of this study suggest that fungal deterioration caused significant internal and chemical change in leather materials but not so much significant when it was exposed to UV-C radiation.

Chrome complexes in chrome tanned leather have high UV light absorption quality compared to vegetable tanned leather. Because vegetable tannin also absorbs energy from UV light but it might be not as active as of chrome tanned leather which has chromophore groups possessing high affinity to UV light absorption [39]. In addition, shrinkage temperature as well as hydrothermal stability of vegetable tanned leather started to decrease slowly after 30 h of continuous exposure of UV irradiation [31] which indicates that the condensed tannin used in the vegetable tanned leather inhibits the UV radiation to penetrate into the collagen for a certain period of time. Therefore, vegetable tanned leather started to react slowly under UV exposure. This indicates that the resistance of biodeterioration of chrome tanned leather will be more effective than vegetable tanned leather while irradiated with UVC light.

3.5 Conceptual model for UV-C irradiation

Based on this study, a conceptual model is proposed in view of further developments (Fig. 7). As per this model, the infected samples will be placed into a UV-C illumination chamber consisting of 5 UV-C lights (4 sidewall lights and 1 upper wall light) after leather processing and during the storage period. UV exposure will last between 15 and 60 min, depending on the degree of deterioration. Thus, the leather samples will be better and fungal-free, which will be more time- and cost-effective, as well as eco-friendly and non-destructive.

4 Conclusions

The present experimental investigation demonstrated that A. flavas was more vulnerable for both types of leathers and also showed that vegetable tanned finished leather was deteriorated more than chrome tanned finished leather. Then the effect of UV-C treatment on the prevention of fungal biodeterioration of leather was investigated, and the results suggested that after UV-C treatment the deterioration was minimum based on physical, chemical and visual changes of leather. UV-C exposed infected leather shows neither shifting of wavenumber nor displacement of any functional groups, improvement in composition of trace elements, presence of conidiophores, increase of weight and tensile strength compared to infected leather samples. The results presented in this paper has been considered the hypothesis that 15 to 60 min UV-C irradiation exposure may be a potential method to restrict successfully the growth of fungi on vegetable tanned and chrome tanned finished leather.

Availability of data and materials

All data generated or analyzed during this study are included within this article.

References

Joseph K, Nithya N. Material flows in the life cycle of leather. J Clean Prod. 2009;17(7):676–82. https://doi.org/10.1016/j.jclepro.2008.11.018.

Masciana P. World statistical compendium for raw hides and skins, leather and leather footwear. Intergovernmental group on meat and dairy products sub-group on hides and skins. Rome: Food and Agricultural Organization of the United Nations; 2015.

Rathore DS, Sharma N, Chauhan S. Isolation, screening and relative capacity of fungi which causes infestation of finished leather. Int J Curr Microbiol Appl Sci. 2013;2(4):74–83.

Haibin G, Zhiyuan W, Yangxin L, Xianghua W, Wuyong C. Methods for inhibiting moulds growth on leather goods during transportation and storage. China Leather. 2010. https://doi.org/10.13536/j.cnki.issn1001-6813.2010.21.010.

Strzelczyk AB, Kuroczkin J, Krumbein WE. Studies on the microbial degradation of ancient leather bookbindings: part I. Int Biodeterior. 1987;23(1):3–27. https://doi.org/10.1016/0265-3036(87)90039-X.

Orlita A. The occurrence of moulds on shoe making materials. Kozarstvi. 1975;25:791–6.

Orlita A. Microbial biodeterioration of leather and its control: a review. Int Biodeterior Biodegrad. 2004;53(3):157–63. https://doi.org/10.1016/S0964-8305(03)00089-1.

Chaudhuri A, Bhattacharyya S, Chaudhuri P, Sudarshan M, Mukherjee S. In vitro deterioration study of concrete and marble by Aspergillus tamarii. J Build Eng. 2020;32:101774. https://doi.org/10.1016/j.jobe.2020.101774.

Fontoura J, Gutterres M. Damage of pickled hides, wet-blue leather and vegetable tanned leather due to biodeteriation. J Am Leather Chem Assoc. 2015;110(05):138–44.

Gumargalieva KZ, Zaikov GE. Biodegradation and biodeterioration of polymers: kinetical aspects. Nova Science Publishers; 1998.

Kanagaraj J, Panda RC, Kumar V. Trends and advancements in sustainable leather processing: Future directions and challenges—a review. J Environ Chem Eng. 2020;8(5):104379.

Haibin G, Chen W. Mould proof for the leather and the development of fungicides used in leather industry. China Leather. 2005;34(1):12–5.

Koller LR. Bactericidal effects of ultraviolet radiation produced by low pressure mercury vapor lamps. J Appl Phys. 1939;10(9):624–30. https://doi.org/10.1063/1.1707353.

Osman M, Elsayed MA, Mohamed YAH, Abo-Zeid AM. Effect of ultraviolet irradiation on germination and growth in Aspergillus flavus and Penicillium notatum. Mycol Res. 1989;92(3):293–6. https://doi.org/10.1016/S0953-7562(89)80068-1.

Selma MV, Freitas PM, Almela L, González-Barrio R, Espín JC, Suslow T, Tomás-Barberán F, Gil MI. Ultraviolet-c and induced stilbenes control ochratoxigenic Aspergillus in grapes. J Agric Food Chem. 2008;56(21):9990–6. https://doi.org/10.1021/jf8018062.

Jun S, Irudayaraj J, Demirci A, Geiser D. Pulsed UV-light treatment of corn meal for inactivation of Aspergillus niger spores. Int J Food Sci Technol. 2003;38(8):883–8. https://doi.org/10.1046/j.0950-5423.2003.00752x.

Varalakshmi KN, Kumudini BS, Nandini BN, Solomon J, Suhas R, Mahesh B, Kavitha AP. Production and characterization of alpha-amylase from Aspergillus niger JGI 24 isolated in Bangalore. Pol J Microbiol. 2009;58(1):29–36.

Irfan M, Javed J, Syed Q. UV mutagenesis of Aspergillus niger for enzyme production in submerged fermentation. Pak J Biochem Mol Biol. 2011;44(4):137–40.

Liu CK, Latona NP, Ashby R, Ding K. Environmental effects on chrome-free leather. Am Leather Chem Assoc. 2006;101(10):368–75.

Liu CK, Latona NP. Physical property studies for a collagen material: leather treated with tocopherol. Polym Mater Sci Eng Am Chem Soc Div Polym Mater Sci Eng. 2003;89:226–7.

Dersarkissian M, Goodberry M. Experiments with non-toxic anti-fungal agents. Stud Conserv. 1980;25(1):28. https://doi.org/10.2307/1505913.

Gu JD, Ford TE, Berke NS, Mitchell R. Biodeterioration of concrete by the fungus Fusarium. Int Biodeterior Biodegrad. 1998;41(2):101–9.

Covington AD. The mechanism of chrome tanning. Glob J Inorg Chem. 2010;1(2):119–31.

Covington AD. Modern tanning chemistry. Chem Soc Rev. 1997;26(2):111–26.

Popov AA, Blinov NN, Krisyuk BE, Zaikov GE. Oxidative destruction of polymers under stress. Polym Degrad Stab. 1984;7(1):33–9. https://doi.org/10.1016/0141-3910(84)90028-4.

Sionkowska A. The influence of UV light on collagen/poly (ethylene glycol) blends. Polym Degrad Stab. 2006;91(2):305–12. https://doi.org/10.1016/j.polymdegradstab.2005.05.012.

Nalyanya KM, Migunde OP, Ngumbu RG, Onyuka A, Rop RK. Influence of UV radiation on the viscoelastic properties and dynamic viscosity of bovine hide using dynamic mechanical analysis. J Therm Anal Calorim. 2016;123(1):363–70.

Rosu L, Varganici C, Crudu A, Rosu D, Bele A. Ecofriendly wet-white leather vs. conventional tanned wet-blue leather. A photochemical approach. J Clean Prod. 2018;177:708–20. https://doi.org/10.1016/j.jclepro.2017.12.237.

Bureau of Indian Standards. Indian standard methods of physical testing of leather (IS: 591-1970); 1988.

Mansour M, Hassan R, Salem M. Characterization of historical bookbinding leather by FTIR, SEM-EDX and investigation of fungal species isolated from the leather. Egypt J Archaeol Restor Stud. 2017;7(1):1–10. https://doi.org/10.21608/ejars.2017.6823.

Gao Y, Yang S, Jian X, Miu L, Gaidau C, Chen W. Effect of UV irradiation on vegetable tanned leather. Leather Footwear J. 2015;15(4):219–28. https://doi.org/10.24264/lfj.15.4.1.

Fujimori E. Ultraviolet light-induced change in collagen macromolecules. Biopolymers. 1965;3(2):115–9. https://doi.org/10.1002/bip.360030202.

Dalmases AB, Jorba M, Vallès JF, Shendrik A, Otero LO. Biodegradation of leather tanned with inorganic salts. J Soc Leather Technol Chem. 2011;95(2):63–7.

Derrick MR, Stulik D, Landry JM. Infrared spectroscopy in conservation science. Getty Conservation Institute; 1999.

Hu Y, Tziamourani E, Boyatzis SC, Wang J, Wang L, Tang K. Degradation of artificially aged vegetable-tanned leather using RP-HPLC and FTIR-ATR. In: The 11th Asian international conference on leather science and technology, Xi’an, China; 2018.

Sharma KD, Sharma OP. Susceptibility of Indian leather for fungal attack. Def Sci J. 1976;27:81–2.

Pekhtasheva E, Neverov A, Zaikov G. Biodamages and protection of leather and fur. Chem Chem Technol. 2012;6(3):327–37. https://doi.org/10.23939/chcht06.03.327.

Pinzari F, Cialei V, Piñar G. A case study of ancient parchment biodeterioration using variable pressure and high vacuum scanning electron microscopy. Hist Technol Mater Conserv SEM Microanal. 2012; 93–9.

Bacardit A, Jorba M, Font J, Olle L. Study of the effect of temperature, relative humidity, and UV radiation on chrome-tanned leather ageing. J Am Leather Chem Assoc. 2012;107(06):179–85.

Funding

This work was supported by RUSA 2.0 (Rashtriya Uchchattar Shiksha Abhiyan) scheme availed by the Government of India. Also, this work was performed under the collaborative research scheme no (UGC-DAE-CSR-KC/CRS/19/RB-06/1049) of University Grants Commission Department of Atomic Energy Consortium for Scientific Research Kolkata Centre.

Author information

Authors and Affiliations

Contributions

Here, EJ performed the whole experiment with the help of SB, AC, NS and SA. EJ analyzed and interpreted the data of weight loss, physical strength analysis, FT-IR and SEM analysis and wrote the final manuscript. SB and AC supervised and revised the analysis and designed the whole experiments. SB and AC was a major contributor in writing the manuscript. AC, NS and SA help to perform chemical and biological experiment such as media preparation for the experiment, inoculation of samples, preparation of samples for SEM and FT-IR analysis. Finally, PC supported to design the experiment and proofed the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Additional file 1.

Tanning process of vegetable and chrome tanned leather.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Jhahan, E., Bhattacharyya, S., Chaudhuri, A. et al. Optimization and application of UVC irradiation for prevention of fungal biodeterioration of vegetable tanned and chrome tanned leather. J Leather Sci Eng 4, 28 (2022). https://doi.org/10.1186/s42825-022-00104-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1186/s42825-022-00104-4