Abstract

Background

Biodentine™ is currently and regularly used as a direct/indirect capping material and dentine substitute under a resin composite direct restoration. The present study investigated the influence of Biodentine™ maturation time on its shear bond strength to a resin-based composite restorative material.

Materials and methods

One hundred fifty PTFE tubes were divided into 2 groups (n = 75), and each group of tubes was filled with a different substrate material (Biodentine™ or GC Fuji IX glass ionomer cement). The tubes were subsequently divided into subgroups (n = 25) that were used to test different substrate maturation times (early, 12 min; medium, 72 h; and delayed, 2 weeks). A resin-based composite restorative material was bonded to the substrates using a 3-step etch and rinse adhesive system (Optibond FL, Kerr), and the bond was tested for shear bond strength.

Results

The Biodentine™/12-min group showed a very low shear bond strength of 2.796 ± 2.704 MPa. The values for the Biodentine™/72-h and Biodentine™/2-weeks groups increased as the maturation time interval increased and were 7.986 ± 2.100 MPa and 10.553 ± 3.281 MPa, respectively. The differences between the Biodentine™/12-min group and the Biodentine™/72-h and Biodentine™/2-weeks groups are statistically highly significant (p < .001). The difference between the Biodentine™/72-h group and the Biodentine™/2-weeks group is statistically significant (p < .05).

Conclusions

Bonding with Biodentine™ that has matured for 72 h results in a statistically significant increase in shear bond strength and yields a more clinically acceptable bond between the two materials.

Similar content being viewed by others

Introduction

As a direct/indirect capping material and a dentine replacement material, tricalcium silicate- based endodontic materials such as Biodentine™ can be used as a lining or as a base material under a final restoration [1]. The use of these materials results in a final structure consisting of multiple layers of different materials. One side of the lining/base material should have the ability to effectively bond (chemically or by microretention) to the overlaid material, and the other side of the lining should adhere properly to the tooth structure (dentine). The physico-mechanical properties of the base material should be able to resist the forces that are applied. The potential benefits of using tricalcium silicate-based endodontic materials as a lining/base material under resin-based composite are well known; they include, for example, reduction of polymerization shrinkage, which can lead to cracks and ultimately to cuspal fractures [2, 3]. Adequate adherence between all layers of the materials used is an important issue with a high clinical impact. If adhesive failure occurs at the restoration margin, the internal gap created by inadequate adherence of the materials will allow penetration of bacteria and fluids between the liner and the dentine and toward the pulp, leading to complications such as sensitivity, secondary decay, pulp inflammation, and ultimately failure of the restoration [2, 4].

Calcium hydroxide (CH) has been intensively used as a liner in the treatment of deep carious lesions with or without pulp exposure, mainly for its antibacterial properties. CH is subject to dissolution over time due to the inward and outward movement of fluid inside the dentinal tubules, and this movement leads to the formation of a dead space [5,6,7,8]. Moreover, CH is unable to adhere on one side to the tooth structure and on the other side to the restoration. These major drawbacks often lead to a loss of seal and to bacterial contamination [9, 10].

In the ‘90s, mineral trioxide aggregate (MTA) began to replace calcium hydroxide [11, 12]. MTA consists primarily of dicalcium silicate (Ca2SiO4), tricalcium silicate (Ca3SiO5) and bismuth oxide (Bi2O3) [13,14,15]. It offers many advantages, including biocompatibility and bioactivity, ability to set under wet conditions, dimensional stability, and formation of an efficient seal that limits bacterial contamination [13, 16, 17]. However, MTA also has many major drawbacks, including an extremely long setting time (the initial setting requires up to 2 h and 45 min), difficult handling characteristics, high price, poor mechanical properties, the presence of some toxic elements (e.g., arsenic), difficulty of removal after setting, and the potential for discoloration [11, 18].

To overcome MTA’s major drawbacks, a large range of bioactive materials have been developed [18]; among them is a calcium silicate-based cement (Biodentine™, Septodont, Saint-Maur-des-Fossés, France) [19]. It consists of tri- and dicalcium silicate (Ca3SiO5, Ca2SiO4), calcium carbonate (CaCO3) and zirconium oxide (ZrO2) and is mixed with a solution of calcium chloride in a triturator for 30 s prior to use [20]. Biodentine™ (BD) presents many advantages, such as a reduced (initial) setting time of 12 min, improved mechanical properties, user-friendly properties, and ease of handling [19, 21]. The short setting time gives the clinician the opportunity to bond a final restoration on BD immediately after the 12-min initial setting time and thus to perform the procedure in a 1-session appointment. A previous study that tested similar material (MTA) reported higher values for immediate bonding after placement [22]. In Hashem et al. [23], the authors recommended a 2-week delay before bonding on Biodentine™. According to the manufacturer’s recommendations, it can be bonded either after initial setting (12-min) or placed in bulk restoration and veneered with a definitive restoration within 6 months. A 1-session procedure is always preferable because it does not rely on the compliance of the patient to return for a second appointment. However, this should not take precedence over achieving more reliable bonding by performing the bonding in a second session. Therefore, it is important to evaluate the bond strength of a resin composite bonded to Biodentine™ at different Biodentine™ maturation times. Moreover, the data currently available in the literature are very limited and show great variability.

The aim of this study is to evaluate the influence of the substrate Biodentine™ and GC Fuji IX conventional glass ionomer cement (GC Corporation, Tokyo, Japan) and the maturation time of these substrates on the bond strength to a resin-based composite material. Conventional glass ionomer cement was used as a control because it has been and is still widely used as a dentine replacement material in standard “sandwich” techniques [24]. The sandwich technique, which can be closed or open, is a procedure in operative dentistry wherein a base material is placed in a cavity and overlaid with a definitive restoration. The objective of this study is to measure the shear bond strength (SBS) of cylinders of resin-based composite restorative material bonded at three different maturation time intervals (short, 12 min; medium, 72 h; and delayed, 2 weeks) of the substrates (Biodentine™ and glass ionomer cement). The null hypotheses are as follows: (H01) the maturation time of the Biodentine™ prior to the bonding procedure has no influence on the shear bond strength of the material to the resin composite and (H02) the nature of the substrate has no influence on the shear bond strength of the material to the resin composite.

Materials and methods

Sample preparation

One hundred fifty identical polytetrafluoroethylene (PTFE) tubes [4 mm inside diameter (ID)] were prepared. They were manually cut at 2 mm height using a scalpel (Swann-Morton carbon steel surgical blade no 15, Sheffield, UK). Half of the tubes were filled with Biodentine™ (n = 75, test groups), and the other half were filled with GC Fuji IX (glass ionomer cement/GIC for posterior restoration) (n = 75, control groups) on a glass plate to standardize the surfaces facing the glass plate, which were used as the bonding surface. The Biodentine™ was prepared according to the manufacturer’s instructions. Five continuous drops of liquid were added to the powder contained in each capsule; the capsule was then mixed in a capsule-mixing unit (3 M™ ESPE Rotomix) for 30 s. The resulting material was handled using a plastic spatula provided by the manufacturer. The material was first placed on a glass plate and then delicately applied to the PTFE tubes. The GC Fuji IX was prepared according to the manufacturer’s instructions. The capsules were first activated using the 3 M™ Aplicap™ Activator/Applier; they were then mixed for 10 s using a capsule-mixing unit (3 M™ ESPE Rotomix) and finally applied to the PTFE tubes using the 3 M™ Aplicap™ Activator/Applier.

The samples were divided into six subgroups (n = 25) according to the material used (Biodentine™ and GC Fuji IX) and to the maturation time allowed before bonding (12 min, 72 h and 2 weeks). The groups were designated as follows: Group BD/12-min, Group GIC/12-min, Group BD/72-h, Group GIC/72-h, Group BD/2-weeks, and Group GIC/2-weeks.

After application of the materials to the PTFE tubes, the samples were left at room temperature for 12 min for (initial) setting. The samples in the early time interval groups (BD/12-min and GIC/12-min) were then immediately bonded to the RC. The samples in the other groups (medium and delayed time intervals) were placed in an incubator at 37° and 100% relative humidity for 72 h (groups BD/72-h and GIC/72-h) or for 2 weeks (groups BD/2-weeks and GIC/2-weeks) before the bonding procedure.

After each specific time interval, a 3-step etch and rinse adhesive system (Optibond FL, Kerr, Orange, USA) was applied according to the manufacturer’s instructions. The standardized BD and GIC surfaces were etched for 15 s with phosphoric acid (Henry Schein Etch Gel 40%), rinsed for 15 s, and gently air dried for 5 s. The primer was applied with a microbrush using a light scrubbing motion for 15 s, and the surface was then gently air dried for 5 s. The adhesive was applied to the entire surface of the substrate using a microbrush to create a thin coating; it was then light-cured for 20 s at a power of 1200 mW/cm2 (BluePhase 20i, Ivoclar Vivadent, Schaan, Liechtenstein). One hundred fifty split PTFE tubes (2 mm ID) were placed and secured on the BD and GIC standardized surfaces. Using a scalpel (Swann-Morton carbon steel surgical blade no 15), the tubes were manually cut at 2 mm height and split vertically on one side to allow the two parts to stay together without any changes in the ID of the tube. If a gap between the two parts of the split tube was detected, the tube was rejected because the change in the inner diameter could affect the bonding surface area and thus the results. The split tubes were filled with a low-flow resin composite restorative material (G-aenial Universal Flo, GC) by syringing and light-cured for 20 s at a power of 1200 mW/cm2 (BluePhase 20i, Ivoclar Vivadent). Table 1 shows the list of materials used in this study.

Shear bond test

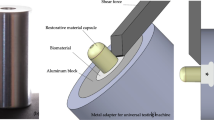

After bonding, the samples were placed in an incubator (37 °C and 100% relative humidity) for 90 min. The split tubes were removed carefully, and the samples were then tested for shear bond strength (SBS) using a universal test machine equipped with a 250 N load cell (Lloyd LRX Plus, Lloyd Instruments, Ametek, Pennsylvania, USA). A load was applied perpendicularly to the RC cylinder as close as possible to the bonding surface using a knife-edge blade at a crosshead speed of 1.0 mm/min until fracture occurred. The values obtained were recorded in Newtons and converted into MPa by dividing the peak load at fracture by the surface area of the RC cylinder base, which was 3.141 mm2 (Fig. 1).

Schematic illustration of the shear bond test setup. A resin-based composite (RC) cylinder is bonded on Biodentine™ (BD) or glass ionomer cement (GIC) contained in a polytetrafluoroethylene (PTFE) tube. A load is applied perpendicularly at the base of the RC cylinder using a knife-edge blade at a crosshead speed of 1.0 mm/min until fracture occurs

Fracture analysis

After observation under a stereomicroscope at 20× magnification, the specimens were categorized into one of four groups:

-

1.

Adhesive: 100% adhesive failure between BD/GIC and the restorative materials (A);

-

2.

Cohesive: 100% cohesive failure within the tested material (BD/GIC) (CT);

-

3.

Cohesive: 100% cohesive failure within the restorative materials (CR);

-

4.

Mixed: mixed failure including both adhesive and cohesive failure of BD/GIC or the restorative materials (M).

All the fractures were observed and assessed by the same person.

Statistical analysis

Statistical analyses were performed using IBM SPSS software version 23. The results were analyzed using two-way ANOVA at a significance level of .05 followed by Bonferroni post hoc tests. The first factor was the maturation time interval of the substrates (12 min, 72 h and 2 weeks). The second factor was the material used as a substrate (Biodentine™ and glass ionomer cement).

Results

The results are presented in Table 2 and Fig. 2.

Plot showing the mean SBS values (MPa) of resin-based composite to Biodentine™ (BD) and glass ionomer cement (GIC) resulting from the interaction between material type (BD and GIC) and the maturation time interval. *Indicates a significant difference at p < .05 between Group BD/72-h and group BD/2-weeks. **Indicates a highly significant difference at p < .001 between group BD/12-min and group BD/72-h and between group B/12-min and group BD/2-weeks

At each time interval examined, Biodentine™ (BD) showed lower SBS values compared to glass ionomer cement (GIC). The SBS values for BD were especially low (2.796 ± 2.704 MPa) for the group BD/12-min; they showed a statistically significant increase as the maturation time interval increased, being 7.986 ± 2.100 MPa for group BD/72-h and 10.553 ± 3.281 MPa for group BD/2-weeks. The increases in SBS value between group BD/12-min and groups BD/72-h and BD/2-weeks were statistically highly significant, with respective p-values of 1.300−8 and 4.701−16. The increase in SBS value between group BD/72-h and group BD/2-weeks was also statistically significant, with a p value of .008 but a lower level of confidence (p < .05) (Tables 2, 3). The SBS values of the GIC/12-min, GIC/72-h and GIC/2-weeks groups were 14.094 ± 2.62 MPa, 14.376 ± 2.673 MPa, and 13.772 ± 3.769 MPa, respectively (Table 2).

The factor “Material” showed a p-value of 1.931−29 and appeared to have an influence of 59.7% on the SBS. The factor “Maturation time interval” showed a p-value of 9.388−9 and had an apparent influence of 23.2% on the SBS. The interaction between the factors “Material*Maturation time interval” showed a p-value of 1.356−9 and an apparent influence of 25.2% on the SBS.

Table 4 shows the failure modes of the specimens after the shear bond test and the percentage of failures associated with each mode. We observed a majority of cohesive fractures within the test material; for Biodentine™, 84.5% of the fractures were CT, whereas for GIC, 84% of the fractures were CT.

Discussion

Currently, limited information is available in the literature on the influence of the maturation time of a tricalcium silicate-based endodontic material such as Biodentine™, used as a dentine replacement material, on its shear bond strength to a resin-based composite restorative material.

The results of our study showed that within the BD groups, the influence of the “maturation time interval” factor was statistically highly significant (p = 2.052−15; Tables 2 and 3). The first null hypothesis (H01) is therefore rejected. Our results show very low shear bond strength (SBS) values for bonding on an initially set Biodentine™; the SBS values show high standard deviation, indicating that the bonding efficiency at this maturation time is unpredictable. These values (2.796 ± 2.704 MPa) are lower than the value of 30 MPa that is recommended in the literature for the bond between resin composite and enamel [25,26,27]. Our results are in accordance with those of Meraji and Camilleri [28]; those authors concluded that bonding an RC to BD, which is a water-based material, is very challenging and that clinicians should be cautious when considering bonding to BD immediately after initial setting. However, they evaluated the shear bond strength at only one specific setting time (15 min). Our results are also in accordance with those of Hashem et al. [23]; in that study, the authors investigated the micro shear bond strength (μSBS) of Biodentine™ (BD), GIC and resin-modified GIC to RC bonded with a self-etching (SE) adhesive at different aging intervals of the substrate. They reported low μSBS values in the “early aging” BD groups (0, 5, 20 and 24 h after an initial setting time of 12 min) compared to the “delayed aging” BD groups (2 weeks and 1, 3 and 6 months). However, some authors [29,30,31,32] reported contrasting results, showing that there is, indeed, great heterogeneity in the outcomes of different studies. Altunsoy et al. [29] reported lower SBS (1.2 to 1.64 MPa) when bonding on Biodentine™ after 72 h of maturation compared to our results (7.986 ± 2.100 MPa; Table 2). Schmidt et al. [31] evaluated the SBS of 3 different lining materials to MTA Angelus® and to Biodentine™ at 3 different time intervals (3 min, 15 min, and 2 days after mixing). Surprisingly, the authors reported similar SBS values (ranging from 4.84 ± .63 MPa to 6.65 ± .48 MPa) for all time intervals. However, after the bonding procedure, the authors stored the samples for 28 days before testing them for SBS; this could have allowed penetration of the adhesive into the initially set material, leading to micromechanical retention and the development of increased physico-mechanical properties during the 28-day storage period. In our study, the interval between bonding and SBS testing was 90 min; this reflects the clinical situation, in which the material is almost immediately subjected to occlusal forces.

The different adhesive systems used (etch-and-rinse/ER and self-etch/SE) can also explain the heterogeneity in the results. Previous studies using similar material (MTA) [22] indicated that the use of an SE adhesive on initially set material improved the shear bond strength, while the use of an ER adhesive system is recommended for fully matured material [33, 34]. Several authors reported similar results using Biodentine™ [29, 31]. The high values obtained with SE adhesive on an initially matured calcium silicate material can be explained by penetration of the adhesive system into the unset material, leading to micromechanical retention. The 3-step ER adhesive system is currently the “gold standard” [35] and requires separate etching with phosphoric acid (37 to 40%). The effect of etching on MTA was studied, and the authors observed that etching at 4 h after mixing (initial setting for MTA) significantly reduced the compressive strength of the material [36]. Because the compositions of MTA and Biodentine™ are similar, the use of an ER adhesive technique on freshly mixed BD might weaken the material and could explain the low SBS obtained in the present study. This might also explain the high SBS values obtained in some studies in which SE adhesive was used on MTA and BD [22, 31]. However, on fully matured BD and MTA, etching can cause surface changes that improve the adhesion of resinous material [36, 37] by micromechanical retention. The pH of the phosphoric acid (.1–.4) is very low [38], whereas the pH of SE adhesive is higher and varies according to its category: mild (pH > 2.5), moderate (pH ± 1), and strong (pH < 1) [39]. Therefore, due to its very low pH, the application of phosphoric acid can create more microretention on the surface of fully set Biodentine™ than any SE adhesive and thereby improve the retention. Further research is needed to evaluate the bond strength obtained when different adhesive systems are used and to determine whether the adhesion is mainly or solely established by microretention and whether the adhesive system contains components that chemically bind to BD components. During its hydration, crystals of calcium hydroxide are formed within Biodentine™. This calcium can react with the 10-MDP monomers present in some SE adhesives, thereby improving the chemical bonding [40]. Other methods of surface treatment that could increase mechanical microretention, such as airborne particle abrasion using aluminum oxide, should also be further investigated.

At its early setting stage, Biodentine™ is a weak material. Its maturation continues with Si–O polymerization, and adequate physico-mechanical properties are ultimately achieved [19]. These initial low physico-mechanical properties can explain the occurrence of pretest failures and the fact that the majority of the fractures observed in the present study were cohesive fractures within the BD structure. The low SBS value for bonding after initial setting obtained in the present study might be related to the weak adhesion obtained, the weakness of BD at the early setting stage, or both; either would lead to its early fracture. In a recent study by Naoum et al. [3], the authors studied the polymerization shrinkage stress developed at the adhesive-restorative composite interface of 5 different resin-based adhesive systems. After the first 220 s, the authors reported values ranging from 2.89 MPa to 3.49 MPa; there were no statistically significant differences in the values obtained for the different resin-based adhesive systems used. These values represented 71 to 102% of the total stress developed after 6 h of analysis. The very low SBS values and high standard deviation reported in the present study when bonding RC to initially set BD (2.796 ± 2.704 MPa) indicate that a large fraction of the samples are unable to resist the shrinkage stress that occurs during RC polymerization. Therefore, it might not be clinically safe to directly bond on Biodentine™. Of course, more studies are needed to investigate whether the RC polymerization shrinkage stress results in destruction of the Biodentine™ cement matrix. If the layer of BD is very thin, it can be assumed that the RC polymerization shrinkage stress could be transmitted to the Biodentine-dentine interface, thereby dislodging Biodentine™ from the dentinal surface and creating a gap that could be infiltrated by bacteria. Assuming that no gap between the two materials is created, the adherence of BD to the dentine is another pertinent point for investigation. The weakness of the material and the weakness of the bond after the initial setting would suggest that the material should be covered with a provisional restoration such as a (resin-modified) glass ionomer cement until a second session.

When the shear bond strength (SBS) of a resin composite (RC) restorative material was compared to that of Biodentine™ (BD) and to that of conventional glass ionomer cement (GIC), the differences were statistically highly significant (p = 1.931−29). The nature of the substrate has an influence on the shear bond strength of a resin composite. Therefore, the second null hypothesis (H02) is rejected. The results of our study are in accordance with the results reported by Hashem et al. [23]. Moreover, our study showed SBS values for surface-etched conventional GIC (Fuji IX, GC) bonded to RC similar to those obtained in previous studies [23, 41, 42]. The bond between GIC and RC is mediated by an adhesive system and relies on micromechanical retention [43, 44], which can be enhanced by surface etching with phosphoric acid [41, 42]. GIC develops most of its mechanical strength quickly (within 1 day to 1 week) [45], and this can explain the similar SBS values observed at different maturation time intervals. However, GIC remains a weak material in terms of compressive strength, with SBS values of approximately 150 MPa [45, 46]. Unetched Biodentine™ after mixing shows similar compressive strength values [37]. Our study found significantly higher SBS values for the GIC groups than for the BD groups regardless of the maturation time allowed. This difference could be explained if the strong phosphoric acid etching resulted in structural and chemical changes to the surface of the initially set Biodentine™ that produced changes in its compressive strength [37]. This should be further investigated.

Within the limitations of this study, waiting 72 h for Biodentine™ maturation before performing a bonding procedure is expected to result in improved SBS of RC material, although the SBS will still be lower than the recommended SBS between 2 materials [25, 26]. It also seems relevant to add that clinicians should keep in mind that improved shear bond strength will be obtained with (i) the use of an SE adhesive system on initially set material (BD or MTA) [22] and (ii) the use of an ER adhesive system on fully mature material [33, 34]. No conclusions can be drawn from the present study concerning the interaction of the different adhesive systems because only one system (3-step ER) was used. Although interesting and promising results were obtained in the present study, further research is needed (i) to investigate the influence of different adhesive systems on SBS, especially at different setting times and when different bond strength testing methods are used; (ii) to understand the exact mechanism of the adhesion between RC and BD and between BD and dentine and their interactions; and (iii) to understand and evaluate the bonding between BD and restorative materials other than RC, such as the all-ceramic materials that are used in indirect fixed partial dentures.

Conclusions

Within the limitations of this study and in the light of the results obtained, it can be concluded that (i) Biodentine™ presents significantly lower shear bond strength to resin-based composite than glass ionomer cement even after long-term maturation (2 weeks); (ii) bonding a resin-based composite restorative material on Biodentine™ with a maturation time of at least 72 h will result in a statistically significant increase in shear bond strength; and (iii) initially set Biodentine™ presents very low SBS values.

Availability of data and materials

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- BD:

-

Biodentine™

- CH:

-

calcium hydroxide

- ER:

-

etch-and-rinse

- GIC:

-

glass ionomer cement

- ID:

-

inside diameter

- MTA:

-

mineral trioxide aggregate

- RC:

-

resin-based composite

- SBS:

-

shear bond strength

- SE:

-

self-etch

References

Blum IR, Younis N, Wilson NH. Use of lining materials under posterior resin composite restorations in the UK. J Dent. 2017;57:66–72. https://doi.org/10.1016/j.jdent.2016.12.008.

Anastasiadis K, Koulaouzidou EA, Palaghias G, Eliades G. Bonding of composite to base materials: effects of adhesive treatments on base surface properties and bond strength. J Adhes Dent. 2018;19:1–14. https://doi.org/10.3290/j.jad.a40302.

Naoum SJ, Mutzelburg PR, Shumack TG, Thode D, Martin FE, Ellakwa AE. Reducing composite restoration polymerization shrinkage stress through resin modified glass-ionomer based adhesives. Aust Dent J. 2015;60(4):490–6. https://doi.org/10.1111/adj.12265.

Peliz MI, Duarte S Jr, Dinelli W. Scanning electron microscope analysis of internal adaptation of materials used for pulp protection under composite resin restorations. J Esthet Restor Dent. 2005;17(2):118–28.

Cox CF, Subay RK, Ostro E, Suzuki S, Suzuki SH. Tunnel defects in dentin bridges: their formation following direct pulp capping. Oper Dent. 1996;21(1):4–11.

Murray PE, Garcia-Godoy F. The incidence of pulp healing defects with direct capping materials. Am J Dent. 2006;19(3):171–7.

Bergenholtz G, Cox CF, Loesche WJ, Syed SA. Bacterial leakage around dental restorations: its effect on the dental pulp. J Oral Pathol. 1982;11(6):439–50.

Brannstrom M, Mattsson B, Torstenson B. Materials techniques for lining composite resin restorations: a critical approach. J Dent. 1991;19(2):71–9.

Cohenca N, Paranjpe A, Berg J. Vital pulp therapy. Dent Clin North Am. 2013;57(1):59–73. https://doi.org/10.1016/j.cden.2012.09.004.

Faraco IM Jr, Holland R. Response of the pulp of dogs to capping with mineral trioxide aggregate or a calcium hydroxide cement. Dent Traumatol. 2001;17(4):163–6.

Parirokh M, Torabinejad M. Mineral trioxide aggregate: a comprehensive literature review—Part III: clinical applications, drawbacks, and mechanism of action. J Endod. 2010;36(3):400–13. https://doi.org/10.1016/j.joen.2009.09.009.

Torabinejad M, Chivian N. Clinical applications of mineral trioxide aggregate. J Endod. 1999;25(3):197–205. https://doi.org/10.1016/S0099-2399(99)80142-3.

Torabinejad M, Hong CU, McDonald F, Pitt Ford TR. Physical and chemical properties of a new root-end filling material. J Endod. 1995;21(7):349–53. https://doi.org/10.1016/S0099-2399(06)80967-2.

Camilleri J, Montesin FE, Brady K, Sweeney R, Curtis RV, Ford TR. The constitution of mineral trioxide aggregate. Dent Mater. 2005;21(4):297–303. https://doi.org/10.1016/j.dental.2004.05.010.

Formosa LM, Mallia B, Camilleri J. The effect of curing conditions on the physical properties of tricalcium silicate cement for use as a dental biomaterial. Int Endod J. 2012;45(4):326–36. https://doi.org/10.1111/j.1365-2591.2011.01980.x.

Torabinejad M, Watson TF, Pitt Ford TR. Sealing ability of a mineral trioxide aggregate when used as a root end filling material. J Endod. 1993;19(12):591–5. https://doi.org/10.1016/S0099-2399(06)80271-2.

Bates CF, Carnes DL, del Rio CE. Longitudinal sealing ability of mineral trioxide aggregate as a root-end filling material. J Endod. 1996;22(11):575–8. https://doi.org/10.1016/S0099-2399(96)80023-9.

Parirokh M, Torabinejad M, Dummer PMH. Mineral trioxide aggregate and other bioactive endodontic cements: an updated overview—part I: vital pulp therapy. Int Endod J. 2018;51(2):177–205. https://doi.org/10.1111/iej.12841.

Bachoo IK, Seymour D, Brunton P. A biocompatible and bioactive replacement for dentine: is this a reality? The properties and uses of a novel calcium-based cement. Br Dent J. 2013;214(2):E5. https://doi.org/10.1038/sj.bdj.2013.57.

Kaup M, Schafer E, Dammaschke T. An in vitro study of different material properties of Biodentine compared to ProRoot MTA. Head Face Med. 2015;11:16. https://doi.org/10.1186/s13005-015-0074-9.

Dawood AE, Parashos P, Wong RHK, Reynolds EC, Manton DJ. Calcium silicate-based cements: composition, properties, and clinical applications. J Investig Clin Dent. 2017;8(2):e12195. https://doi.org/10.1111/jicd.12195 (Epub 2015 Oct 5).

Neelakantan P, Grotra D, Subbarao CV, Garcia-Godoy F. The shear bond strength of resin-based composite to white mineral trioxide aggregate. J Am Dent Assoc. 2012;143(8):e40–5.

Hashem DF, Foxton R, Manoharan A, Watson TF, Banerjee A. The physical characteristics of resin composite-calcium silicate interface as part of a layered/laminate adhesive restoration. Dent Mater. 2014;30(3):343–9. https://doi.org/10.1016/j.dental.2013.12.010.

Suzuki M, Jordan RE. Glass ionomer-composite sandwich technique. J Am Dent Assoc. 1990;120(1):55–7.

Causton BE. Repair of abraded composite fillings. An in vitro study. Br Dent J. 1975;139:286–8.

Puckett AD, Holder R, O’Hara JW. Strength of posterior composite repairs using different composite/bonding agent combinations. Oper Dent. 1991;16:136–40.

Shahdad SA, Kennedy JG. Bond strength of repaired anterior composite resins: an in vitro study. J Dent. 1998;26(8):685–94.

Meraji N, Camilleri J. Bonding over dentin replacement materials. J Endod. 2017;43(8):1343–9. https://doi.org/10.1016/j.joen.2017.03.025.

Altunsoy M, Tanriver M, Ok E, Kucukyilmaz E. Shear bond strength of a self-adhering flowable composite and a flowable base composite to mineral trioxide aggregate, calcium-enriched mixture cement, and biodentine. J Endod. 2015;41(10):1691–5. https://doi.org/10.1016/j.joen.2015.06.013.

Cengiz E, Ulusoy N. Microshear bond strength of tri-calcium silicate-based cements to different restorative materials. J Adhes Dent. 2016;18(3):231–7. https://doi.org/10.3290/j.jad.a35934.

Schmidt A, Schafer E, Dammaschke T. Shear bond strength of lining materials to calcium-silicate cements at different time intervals. J Adhes Dent. 2017;19(2):129–35. https://doi.org/10.3290/j.jad.a38100.

Cantekin K, Avci S. Evaluation of shear bond strength of two resin-based composites and glass ionomer cement to pure tricalcium silicate-based cement (Biodentine(R)). J Appl Oral Sci. 2014;22(4):302–6.

Tunc ES, Sonmez IS, Bayrak S, Egilmez T. The evaluation of bond strength of a composite and a compomer to white mineral trioxide aggregate with two different bonding systems. J Endod. 2008;34(5):603–5. https://doi.org/10.1016/j.joen.2008.02.026.

Atabek D, Sillelioglu H, Olmez A. Bond strength of adhesive systems to mineral trioxide aggregate with different time intervals. J Endod. 2012;38(9):1288–92. https://doi.org/10.1016/j.joen.2012.06.004.

Peumans M, Kanumilli P, Demunck J, Vanlanduyt K, Lambrechts P, Vanmeerbeek B. Clinical effectiveness of contemporary adhesives: a systematic review of current clinical trials. Dent Mater. 2005;21(9):864–81.

Kayahan MB, Nekoofar MH, Kazandag M, Canpolat C, Malkondu O, Kaptan F, et al. Effect of acid-etching procedure on selected physical properties of mineral trioxide aggregate. Int Endod J. 2009;42(11):1004–14. https://doi.org/10.1111/j.1365-2591.2009.01610.x.

Camilleri J. Investigation of Biodentine as dentine replacement material. J Dent. 2013;41(7):600–10. https://doi.org/10.1016/j.jdent.2013.05.003.

Pashley DH, Tay FR, Breschi L, Tjäderhane L, Carvalho RM, Carrilho M, et al. State of the art etch-and-rinse adhesives. Dent Mater. 2011;27(1):1–16. https://doi.org/10.1016/j.dental.2010.10.016.

De Munck J, Vargas M, Iracki J, Van Landuyt K, Poitevin A, Lambrechts P, et al. One-day bonding effectiveness of new self-etch adhesives to bur-cut enamel and dentin. Oper Dent. 2005;30(1):39–49.

Van Landuyt KL, Snauwaert J, De Munck J, Peumans M, Yoshida Y, Poitevin A, et al. Systematic review of the chemical composition of contemporary dental adhesives. Biomaterials. 2007;28(26):3757–85. https://doi.org/10.1016/j.biomaterials.2007.04.044.

Subrata G, Davidson CL. The effect of various surface treatments on the shear strength between composite resin and glass-ionomer cement. J Dent. 1989;17(1):28–32.

Otsuka E, Tsujimoto A, Takamizawa T, Furuichi T, Yokokawa M, Tsubota K, Miyazaki M. Influence of surface treatment of glass-ionomers on surface free energy and bond strength of resin composite. Dent Mater J. 2013;32(5):702–8.

Zhang Y, Burrow MF, Palamara JE, Thomas CD. Bonding to glass ionomer cements using resin-based adhesives. Oper Dent. 2011;36(6):618–25. https://doi.org/10.2341/10-140-L (Epub 2011 Aug 24).

Chadwick RG, Woolford MJ. A comparison of the shear bond strengths to a resin composite of two conventional and two resin-modified glass polyalkenoate (ionomer) cements. J Dent. 1993;21(2):111–6.

Williams JA, Billington RW. Changes in compressive strength of glass ionomer restorative materials with respect to time periods of 24 h to 4 months. J Oral Rehabil. 1991;18(2):163–8.

Yap AU, Cheang PH, Chay PL. Mechanical properties of two restorative reinforced glass-ionomer cements. J Oral Rehabil. 2002;29(7):682–8.

Acknowledgements

The author thanks Mr. Dave Gilbert and Dr. Mark Packer for their support and valuable advice. This project was conducted as a final-year research project for the degree of Master in Clinical Dentistry (MClinDent) in prosthodontics at King’s College London.

Funding

This study was partially funded by the Faculty of Dentistry, Oral & Craniofacial Sciences at King’s College London, London, UK.

Author information

Authors and Affiliations

Contributions

HTH conceived and designed the work, performed the acquisition, analysis, and interpretation of the data, and drafted the manuscript. The author read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Ha, HT. The effect of the maturation time of calcium silicate-based cement (Biodentine™) on resin bonding: an in vitro study. Appl Adhes Sci 7, 1 (2019). https://doi.org/10.1186/s40563-019-0118-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40563-019-0118-7