Abstract

In this study, melon peel waste was utilized to isolate peroxidase enzyme through three-phase portioning (TPP) and subsequently immobilized onto magnetite nanoparticles for effective bioremediation of phenol pollutants from water. The optimization of TPP parameters ensured maximum activity recovery and enzyme purity. Magnetite nanoparticles were synthesized and used as a substrate for immobilizing the isolated peroxidase, achieving an activity recovery of 157% and a purification fold of 5.2. Protein homogeneity testing confirmed the purity of the peroxidase enzyme. The magnetite nanoparticles had an average diameter of 62 nm, and the immobilization efficiency reached 93% at pH 8 with an enzyme/nanoparticles v/v ratio of 1:9. The immobilized peroxidase demonstrated the ability to degrade 57% of phenol within 3 h and retained 30% relative activity even after five catalytic cycles. This immobilized melon peel peroxidase on magnetite nanoparticles proves to be a robust, enduring, and reusable biocatalyst with potential for various applications, especially in bioremediation processes.

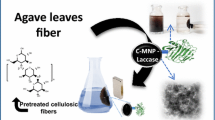

Graphical Abstract

Similar content being viewed by others

Introduction

Peroxidase enzymes (EC: 1.11.1) are a family of oxidoreductase enzymes that are capable of catalyzing the transfer of electrons from hydrogen peroxide or organic hydroperoxides to a variety of both organic and inorganic substrates (Eq. 1) [1]. They exhibit wide distribution in living organisms, including plants, animals, and microorganisms, and play important roles in many physiological processes, such as defense against pathogens, lignin biosynthesis, and hormone metabolism:

Equation 1 General reaction of peroxidases.

Plant peroxidase and polyphenol oxidase are responsible for the browning reaction taking place in different fruits after cutting some parts of them [2]. Structurally, peroxidases are heme-containing enzymes that contain a prosthetic group composed of a central iron atom coordinated to a protoporphyrin IX molecule. The heme group provides peroxidase with the redox ability to catalyze the oxidation of various substrates [3]. Peroxidases can be classified into several classes based on their structural features, including plant peroxidases, animal peroxidases, and fungal peroxidases. They can also be classified based on their mechanisms of action, such as classical peroxidases, catalases, and peroxiredoxins. Concerning its active site, it has a large pocket that accepts a wide range of substrates rendering it a versatile enzyme [4, 5]. Peroxidases play different roles in different organisms. In plants, peroxidases play a critical role in lignification, a process that strengthens cell walls and provides structural support for the plant. In animals, peroxidases are involved in the immune response and can help protect against oxidative stress [6]. Given the fact that peroxidase can accept various substrates, it has a range of applications in biotechnology, including in the production of the bioremediation of environmental micropollutants and the development of analytical biosensors [7]. Nowadays, peroxidase is classified as a green environmental biocatalyst for the removal of pollutants found everywhere in the environments, soils and different types of water bodies [8]. They can also be used to produce. In addition, peroxidases can be used in the development of biosensors for the detection of various analytes, including glucose [9], cholesterol [10], and hydrogen peroxide [11].

TPP (three-phase partitioning) is a powerful bioseparation technique that offers numerous benefits for isolating biomolecules, particularly enzymes, from crude extracts. It has consistently proved its efficacy in terms of achieving high yields of isolated biomolecules. One of the key advantages of TPP as a fractionation method is its ability to operate under mild conditions, making it highly efficient and cost-effective [12, 13]. Moreover, TPP has the potential for the recycling of chemicals used, minimizing waste, and thus can be considered a green tool. In addition, TPP is a time-saving technique that offers a rapid approach to bioseparation which precedes the routinely used chromatographic counterparts [14]. TPP is fractionating components within crude extracts into three phases, i.e., lipids and nonpolar substances can be effectively separated and moved to the t-butanol layer, while certain proteins aggregate at the interface layer retaining the lower layer (aqueous phase) rich in the polar biomolecules. This unique characteristic of TPP contributes significantly to the recovery of the desired enzyme, enhancing the overall efficiency of the separation process [15]. Notably, TPP has successfully been utilized to isolate a wide range of enzymes from diverse sources and waste materials. Prominent examples include the isolation of lipase [16], bromelain [17], papain [18], and other proteases [19], all of which have demonstrated improved activity and purity through the application of TPP.

Some hurdles must be overcome to utilize specificity selectivity and biocompatibility of enzymes for industrial uses. What is meant by hurdles are the negative impact of products and reaction conditions on enzyme activity and the inability to use enzymes for repetitive rounds of biocatalysis [20]. Here, where immobilization techniques come into play. Enzyme immobilization overcomes the limitations imposed on soluble enzymes (improving performance) and enhances other biochemical characteristics, such as temperature and pH. Moreover, and most importantly, repetitive catalysis can be achieved with minimal diminished activity. This leads to lowering the costs of the biotechnological process [21].

Nowadays, the ecosystem has been filled with numerous pollutants, including plastics, phenols, pharmaceutical residues, and dyes. Among the several environmental organic pollutants that constitute major concern to both humans and the environment are phenolic compounds. This is because these chemicals tend to persist for long periods resulting in toxic effects [22]. Phenolic toxicants can result in endocrine system imbalance, muscle weakness, and irregular breathing [23]. Scientists developed novel solutions to overcome these eco-challenges, including immobilized enzymes. Immobilized enzymes such as laccase and peroxidase demonstrated their efficacy for bioremediation of the environmental micropollutants. Enzymatic bioremediation can breakdown those micropollutants into non-toxic products, and, hence, serves as novel intervention against those pollutants [24].

The previous literature regarding immobilized peroxidase either used the commercial horseradish peroxidase directly for immobilization, isolated peroxidase from plant sources, while the nanoparticles were purchased ready to use, or just immobilized the pre-existing peroxidase and nanoparticles together [25,26,27]. In other words, to our knowledge, no study reported the simultaneous isolation of peroxidase from food/agricultural wastes, synthesis of magnetite nanoparticle, immobilization of the enzyme into the nanoparticles and the subsequent application of the immobilized enzyme for bioremediation. Hence, the current study aims to isolate peroxidase from melon peels using TPP for the first time along with its immobilization onto magnetic nanoparticles and application of the immobilized enzyme for phenol removal.

Materials and methods

Reagents and apparatuses

Sodium dihydrogen phosphate (99%), disodium hydrogen phosphate (99%), phenol (99%), ammonium sulfate (98%), and potassium sodium tartrate (97%) were purchased from Merck, whereas ferric sulfate (99%), ferrous sulfate (99%), sodium citrate (98%), sodium acetate (98%), t-butanol (99%) were purchased from HiMedia, and lactalbumin (97%), ammonia (30%) from Sigma. All of the used chemicals were of analytical grade and were used as received without any further purification. The phosphate buffer used was prepared at pH 7 and 100 mM concentration. The employed apparatuses were: commercial blender (HINDO, Syria), UV–visible spectrophotometry T-60 (PG instruments, England), dynamic light scattering (DLS) Zetasizer Pro (Malvern, England), atomic force microscopy (AFM) Naio (Nanosurf, Switzerland).

Plant preparation and processing

Fresh melon was purchased from the local market of Aleppo City, Syria. The melon peels (2 mm away from the pulp) were excised from the rest of the plant and washed twice with distilled water. Then, 10 g of the melon peels together with 100 ml of cold phosphate buffer (4 °C) (pH 7) were homogenized using a commercial blender. It should be noted here that the buffer used was cold and the blending process has been conducted intermittently to avoid enzyme denaturation. Afterward, filtration and subsequent centrifugation at 5000 rpm for 20 min was done and the supernatant was stored at 4 °C to be used later.

Preparation of TPP

In 15 ml test tubes, 5 ml of the crude extract was mixed with different salt concentrations. Then, various volumes of alcohol were added to the tube and vigorously mixed and settled for 3 h. After that, a brief centrifugation step was conducted to ease in the separation of the three layers (3000 rpm for 5 min). The enzymatic activity was measured for the bottom layer (aqueous phase). However, many parameters were optimized to achieve maximum separation efficiency involving different salt types, salt concentrations (20–35 w/v%), pH degrees (6–9), different alcohol types (1-butanol and t-butanol), and varying the alcohol/crude extract ratios (0.75/1, 1/1, 1.5/1, 2/1) [28]. The used salts were selected based on the examination of ionic salt (ammonium sulfate), two-carbon salt (sodium acetate), four-carbon salt (potassium sodium tartrate) and six-carbon salt (sodium citrate) on the activity and separation of the enzyme. Nonetheless, the temperature was set at 37 °C for all experiments as it was demonstrated to be ideal for bioseparation of enzymes [29].

Determination of peroxidase assay

We followed the method described earlier [30]. In brief, approximately 2.4 ml of phosphate buffer (pH 7) was added to a cuvette, followed by the addition of 300 µl of 5.3% pyrogallol, and 200 µl of 0.6% hydrogen peroxide. The reaction was initiated with the addition of 100 µl of the corresponding enzyme source (total volume of 3 ml) at 420 nm for 4 min.

Determination of protein content

The concentration of protein of the crude extract and the isolated enzyme was performed according to the modified Lowry method [31]. A concentration range of 0.1–0.4 mg/ml of lactalbumin was utilized for plotting the standard curve. The activity recovery, as well as purification fold, were calculated according to the following formulas:

Assessment of purity

To check the efficiency of the isolated melon peel peroxidase, the protein homogeneity module of DLS was used. DLS protein homogeneity is a well-known method for evaluating the purity as well as homogeneity of the isolated proteins, expressed recombinant protein, and the produced monoclonal antibody [32]. The purity of the isolated enzyme was compared to the crude extract.

Synthesis of magnetite nanoparticles

The synthesis protocol of magnetite nanoparticles was performed as previously reported [33]. In brief, a 1:1 ratio of 10 mM ferrous sulfate and ferric sulfate was mixed in a 100 ml conical flask until completely dissolved. Then, 3–5 drops of ammonia solution (25%) were added until the transformation of color to black. Two minutes then, 200 mM of potassium sodium tartrate was added as a dispersing agent to and the solution was vigorously stirred (300 RPM) via the magnetic bar for 30 min at room temperature. The formed precipitate was decanted through a magnet and washed thrice with distilled water. Different parameters such as concentration of iron precursors, ammonia concentration, molar ratio of ferric:ferrous ions, the concentration of potassium sodium tartrate, and the time of incubation were optimized one at a time so as to control and limit the agglomeration of the formed nanoparticles.

Characterization of magnetite nanoparticles

The diameter of the synthesized nanoparticles was measured using DLS. In addition, the morphology and roughness of the synthesized nanoparticles were measured by AFM.

Immobilization of isolated enzyme onto magnetite nanoparticles

To adsorb (immobilize) the isolated peroxidase onto the synthesized magnetic nanoparticles, two factors were optimized to get the maximally possible immobilization efficiency, namely, pH and ratio between enzyme and nanoparticles. A pH range from 4 to 9.5 was assessed. Similarly, enzyme/nanoparticles v/v ratios of 1:1, 1:9, and 9:1 were examined according to the recently employed protocol [34]. The initial enzyme activity was 615 U/mg. The temperature was set at 4 °C during adsorption and the process was conducted overnight to avoid temperature fluctuation influence [35]. Afterward, the immobilized peroxidase was precipitated by applying a magnetic below the tube with measuring the activity in the supernatant [36]. The immobilization efficiency was calculated as follows:

Determination of change in pH and temperature

Various temperatures (25–75 °C) were tested for the potential influence on the isolated as well as immobilized peroxidase. Likewise, to determine the change in pH of the isolated enzyme and the immobilized enzyme, a pH range of 4–10 was examined. The temperature and pH effects were analyzed by monitoring change in enzymic activity [37].

Zeta potential

The zeta potential of the naked and loaded particles was measured by DLS to confirm the peroxidase immobilization on the magnetic nanoparticles [38].

Phenol degradation

The immobilized enzyme was formulated to bioremediate the environmental micropollutants, such as phenol [39]. Phenol was prepared at a concentration of 10 mM. This was followed by the successive additions of 500 µl of hydrogen peroxide and 100 µl of free enzyme/100 mg of immobilized enzyme. pH and temperature were set at 7 and 25 °C, respectively. The degradation of phenol was monitored by observing the reduction in phenol concentration after adding the chromogen (ferric chloride) and measuring the absorbance at 500 nm for 3 h [40]. Phenol degradation was calculated as follows:

Enzyme reusability

The immobilized enzyme should be recycled for many successive rounds of catalysis. To evaluate the reusability, enzymatic activity was measured for catalyzing the same reaction while recycling the precipitating enzyme via a magnet [41].

Statistical analysis

All the experiments were realized in duplicate and the obtained results were expressed as mean ± standard deviation or the represented as error bars on the figures. One-way ANOVA was chosen for comparing the statistical significance at a level of < 0.05 using SPSS® software (version 23) and plotted using Excel® 2019.

Results

Effect of salt type

Among the tested salts for salting-out purposes, potassium sodium tartrate had the highest activity recovery (119%). This is followed by sodium acetate whose recovery was 116%, as shown in Fig. 1.

Effect of salt concentration

The second parameter to optimize was the concentration of salt that gives maximum enzymatic recovery via salting-out. It turned out that at concentrations 20% w/v and 25% w/v potassium sodium tartrate, melon peel peroxidase recovery was maximum (119% and 120%). However, after these concentrations, the recovery declines gradually (Fig. 2).

Effect of pH

A pH range from 6 to 9 was examined for its influence on enzyme fractionation. As the pH increases, activity recovery increases till it reaches maximum at pH 8 (126%), as depicted in Fig. 3. However, beyond this pH, the activity recovery was found to be diminished reaching 102% at pH 9.

Effect of alcohol/crude extract ratio

The last step was to evaluate the influence of changing the ratio between the upper layer (alcohol) and the lower layer (aqueous). It was found that at the ratio of 1:1.5, the highest activity recovery was attained (157%). Nonetheless, raising the ratio above this value posed a negative impact on the fractionation yield, as shown in Fig. 4.

Determination of protein content

After detecting the optimal conditions for isolating melon peel peroxidase using TPP, all these conditions were combined to get the highest yield of enzyme isolation efficiency. A standard curve from lactalbumin was established to infer the corresponding protein concentration (Fig. 5). The standard curve had a coefficient of correlation (R2) of 0.9921 (data not shown) denoting the near-optimal correlation. The total amount of the purified enzyme was 2 ml extracted from a TPP system with total volume of 5 ml containing 2.5 of the crude extract and 2.5 t-butanol. The protein content of the combined optimized yield with activity recovery was utilized for calculating specific activity and purification fold of melon peel peroxidase, as summarized in Table 1.

Assessment of purity

It is well-known that as the purification fold increases, the likelihood of increasing the actual purity of the enzyme increases accordingly. This is what has been obtained during the assessment of the purity of the isolated melon peel peroxidase by using DLS (Fig. 6). The crude extract displayed three peaks with different diameters, indicative of the heterogeneity of the sample composition. On the flip side, the isolated melon peel peroxidase exhibited only a single peak with high intensity. Moreover, this single peak had a very narrow polydispersity index indicating the high purity of the isolated enzyme.

Synthesis of magnetite nanoparticles

The synthesized magnetic nanoparticles via the co-precipitation method with tartrate as a stabilizing agent displayed a narrow range of diameters (polydispersity index of 0.204) smaller than 100 nm. The average diameter of the nanoparticles was 62 nm with most of them being smaller than 50 nm, as elucidated in Fig. 6. Furthermore, the formed magnetic nanoparticles exhibited a spherical morphology and were shown as aggregated particles due to the magnetic attraction nature of the particles. The roughness of those particles was 18, reflecting the small dimensions of the formed particles. The magnetic attraction of the synthesized magnetite nanoparticles was also demonstrated, as shown in Fig. 6D.

Effect of pH on enzyme immobilization

The impact of pH on enzyme immobilization displayed a bell-like curve with pH 7 being the optimal pH for immobilization (85% at pH 7). However, below and above this pH value, the immobilization efficiency decreased, as shown in Fig. 7.

Effect of enzyme/magnetic nanoparticles ratio

It has been found that decreasing the amount of enzyme is associated with a higher immobilization rate. When the enzyme amount was ninefold the amount of the nanoparticles, immobilization efficiency was maximal (93%) (Fig. 8).

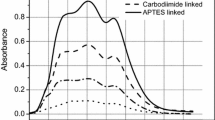

Zeta potential

To ensure the immobilization of enzyme onto magnetic nanoparticles, the zeta potential of the loaded and naked nanoparticles was measured. It turned out that the naked nanoparticles had a surface charge of − 23.6 mV, whereas the loaded nanoparticles had a surface charge of − 34.8 mV, as depicted in Fig. 9. Such a significant decrease in zeta potential confirms the immobilization of melon peel peroxidase onto the magnetic nanoparticles.

Optimal pH and temperature

The influence of pH and temperature on the activity of the free as well as immobilized peroxidase was detected. The optimal temperature of the immobilized enzyme showed flatting with an optimal temperature of 65 °C. Nevertheless, the immobilized enzyme exhibited a thermostability below and above this optimal temperature. This is in contrast to the free enzyme which displayed normal temperature influence (bell curve) with optimal temperature at 45 °C. In other words, a shift in temperature was obtained. On the other hand, a shift in optimal pH from 8 (in the free enzyme) to 7 (in the immobilized enzyme) was observed (Fig. 10). This mirrors the enhancement in the tolerance to pH and temperature of the immobilized enzyme which renders it more feasible industrially.

Phenol degradation

After 3 h of reaction with phenol, the degradation efficiency of the free enzyme was 42%, while the immobilized enzyme reached 57%, as illustrated in Fig. 11. This confirms the advantage of enzyme immobilization in the bioremediation of environmental micropollutants, such as phenol.

Enzyme reusability

Besides the enhanced activity, and tolerance to pH and temperature, immobilized peroxidase onto magnetic nanoparticles pose an extraordinary biotechnological feature, i.e., reusability. The ease with which magnetic nanoparticles-immobilized peroxidase can be recycled outcompete the traditional supports that necessitate extra filtration/centrifugation step. The immobilized peroxidase exhibited tolerance and preserved acceptable activity after five catalytic rounds (30%) (Fig. 12).

Discussion

Food and agricultural wastes involve a large group of residual materials generated during/after agricultural activities, such as coffee pulp from the coffee industry, husks from the cereal industry, and peels from the starch-based industry [42]. Indeed, huge amounts of these wastes are generated year after year requiring downstream processing for simultaneous removal of the concomitating adverse effects and valorization of such wastes. Agro-industrial wastes have been valorized to be a rich resource for enzymes, biofuels, vitamins, antioxidants, antimicrobials, and animal feed [43].

The recent reports concerning immobilized peroxidase suffer from some limitations, including (i) using the commercial horseradish peroxidase which is costly, (ii) isolation of peroxidase from non-waste plant sources that would make the process economically unfeasible, (iii) immobilization onto non-magnetic nanoparticles which create an obstacle regarding the reusability, since it requires additional centrifugation step, (iv) covalent immobilization requires the use of toxic bifunctional reagents and hinders the mobility of the enzyme negatively impacts the activity, and (v) the use of large amount of the immobilized enzyme for bioremediation purposes [44,45,46]. Hence, the goal of this study was to isolate peroxidase from melon peels for the first time and the subsequent immobilization onto synthesized magnetite nanoparticles for the removal of phenol pollutants from water. In simple words, we cleaned the water pollutants using food waste.

TPP parameters had to be optimized to get the highest possible enzyme recovery and purification fold. This involves precipitating salt type, salt concentration, pH, and the ratio between alcohol and crude extract. When all optimized conditions were combined, an activity recovery and purification fold of 157% and 5.2 of melon peel peroxidase was obtained in the bottom phase, whereas other proteins and phenolic compounds were accumulated in the middle and upper phases, respectively. This denotes that almost all of the enzyme has been moved to the aqueous phase reflecting the high separation efficiency. In addition, the best-extracting salt (potassium sodium tartrate) had a slight activating action on peroxidase activity which accounts for the extra in the percentage over 100%. An optimized alcohol/crude extract ratio of 1.5:1 indicates the high nonpolar moieties in the extract needed to be fractioned to concentrate the enzyme in the bottom layer. These nonpolar compounds had inhibiting behaviour on the enzymatic activity as indicated by the increase in activity recovery after increasing alcohol volume [47]. Several researchers reported the application of TPP to isolate and purify peroxidase from different sources. For example, Vetal and Rathod [48] upon applying the optimized TPP setup for peroxidase separation from orange peels, the obtained recovery percentage of the enzyme was 93% after 180 min. Karakus et al. [30] purified peroxidase enzyme from the flowering plant Amsonia orientalis via the TPP tool. 162% activity recovery was found after only 30 min with more than 18-fold purity. Moreover, TPP can be coupled with the ultrasonicator instrument to further reducing the time of enzyme fractionation. This approach was employed to purify peroxidase enzyme from orange peels with activity recovery and purification fold of 91% and 24.28 within only 6 min [49]. However, introducing ultrasonication negatively impacted the enzyme yield in our study.

A purification fold of 5.2 predicts the good purity of the isolated enzyme which was proven via DLS protein homogeneity findings (single, intense, narrowed peak). This renders the enzyme ready for the immobilization process. The magnetic nanoparticle synthesis protocol unveiled the feasibility of this method given the small dimensions of the formed nanoparticles (62 nm). These magnetic nanoparticles were used as a support for the adsorption of the isolated peroxidase owing to the high surface-to-volume ratio, magnetism, and high reactivity [50]. Optimal pH and enzyme/magnetic nanoparticle ratio were 7 and 1:9, respectively, yielding an immobilization efficiency of 93% which was emphasized through the variation in zeta potential of the naked and loaded nanoparticles (− 23.6 vs − 34.8 mV). The reference surface charge (zeta potential) of magnetite nanoparticles is − 20 mV [51]. In our study, we get a surface charge of − 23.6 mV which can be attributed to the added tartrate salt having a negative charge which further reduced the surface charge. However, the immobilization of the enzyme significantly reduced the zeta potential to − 34.8 mV confirming its adsorption onto the synthesized magnetite nanoparticles. Moreover, the pH and temperature profile of the immobilized enzyme prominently transformed from that of free version which can be interpreted by the fact that the immobilized enzyme gain some of the magnetic nanoparticles thermostability, and pH change tolerability (enzyme–carrier interactions) [52].

In adsorption, the enzyme is linked to the magnetite nanoparticles through ionic interactions formed between the negative carboxyl moieties of the tartrate-modified magnetite nanoparticles and the positively charged amino acid residues present on the enzyme surface. In addition, hydrogen bonds and van der Waals interactions greatly contribute to the immobilization process, since the two molecules were in close proximity. These interactions are favourably to occur in neutral pH, ionizing all charged functional groups from both sides, facilitating their bonding [53]. This is in ideal agreement with our results, since the optimal pH of immobilization was 7.

Finally, the immobilized peroxidase was used for the degradation of phenol. A prominent difference was obtained between the free (42%) and the immobilized version (57%) after 3 h. Moreover, the enzyme retained 30% of its relative activity after five rounds of catalysis. Such a decrease in relative activity could be traced to the weak physical method of immobilization (adsorption). The enhanced activity is attributable to the fixation of the enzyme in a rigid, open conformation facilitating the continuous access of the substrates into the active site which, in turn, increases the number of reactions the enzyme catalyzes, leading to enhanced activity. Furthermore, ordered spatial orientation as well as substrate channelling are another contributing factors [52, 54].

The enzyme catalyzes the oligomerization or polymerization of phenol using hydrogen peroxide as an oxidant. The key step is the formation of a catalytic triad intermediate and hydroxyl radical (OH·) and hydroperoxyl radical (HOO·) that generate phenol radicals. These radicals react with the enzyme, restoring its original state, and with each other to form water molecules, while phenol radicals react with each other forming aromatic polymers [55, 56].

Niu et al. [57] reported encapsulating HRP in the electrospun fibrous membrane to eliminate pentachlorophenol. 83% (about twofold the free enzyme activity) of pentachlorophenol was eliminated at room temperature and 60% retained activity after six catalytic rounds. Chang and Hang [58] successfully degraded 2,4-dichlorophenol using NH2-modified Fe3O4-immobilized HRP. About 80% of the phenol derivative was broken down in 180 min at 303.15 K. The enzyme retained 85% of the initial activity even after round 4. Peroxidase was also immobilized into polyacrylamide cryogel synthesized using cryo-polymerization technology at sub-zero degrees in another elegant work. The type of binding between enzyme and cryogel support was covalent attachment. Phenol and bisphenol A removal rates were 96% and 75%, respectively [59]. Even at high phenol concentration (2500 mg/L), immobilized HRP onto reduced graphene oxide nanosheets was recorded to destroy phenols. The immobilized HRP exhibited 60% of initial activity after 10 rounds and 50% after being stored after 35 days in the same study. In contrast to those reports, in our study, the enzyme preserved 30% of its activity after 5 rounds. This diminishment in activity upon reusability can be traced to the immobilization method, adsorption, which is a weak physical method that does not involve the linkage of the enzyme with the carrier covalently [53].

Indeed, surface water, groundwater and drinking water are the most suitable hotspots for enzyme application to bioremediate them from the relevant pollutants [60, 61].

Conclusion

This was an unprecedented study utilizing the TPP tool to isolate peroxidase from the melon peel. The optimized conditions for the isolation were as follows: 25% potassium sodium tartrate for salting-out, pH 8, and alcohol/crude extract ratio of 1.5:1. This yielded an activity recovery of 157% along with a purification fold of 5.2. This suggested the potential high purity of the isolated enzyme. Moreover, an assessment of the purity was conducted by DLS protein homogeneity measurement which confirmed a highly purified enzyme. In addition, magnetite nanoparticles were synthesized by the co-precipitation method giving an average diameter of 62 nm. An immobilization efficiency of 93% was obtained at pH 8 and an enzyme/nanoparticles ratio of 1:9. The immobilized peroxidase degraded 57% of phenol after 3 h of exposure and reused for five catalytic rounds retaining 30% of its relative activity. This magnetite nanoparticles-immobilized peroxidase can, thus, be considered as a powerful green biocatalyst (isolated from melon peel wastes) for the degradation of pollutants such as phenol and, at the same time, is economic given that 100 mg of it can degrade half of the phenol present in the water in 3 h. With this study, we simultaneously utilized the food wastes for the cleaning of water pollutants. This protocol should be tested further in large scale and in situ. In addition, the immobilization of the enzyme isolated from this study using chemical immobilization methods are highly recommended.

Availability of data and materials

Not applicable.

Abbreviations

- AFM:

-

Atomic force microscopy

- DLS:

-

Dynamic light scattering

- TPP:

-

Three-phase partitioning

References

de Oliveira FK, Santos LO, Buffon JG. Mechanism of action, sources, and application of peroxidases. Food Res Int. 2021;143: 110266.

Passardi F, Longet D, Penel C, Dunand C. The class III peroxidase multigenic family in rice and its evolution in land plants. Phytochemistry. 2004;65:1879–93. https://doi.org/10.1016/j.phytochem.2004.06.023.

Patil PD, Nadar SS, Marghade DT. Photo-Enzymatic Green Synthesis The Potential of Combining Photo-Catalysis and Enzymes. In: Inamuddin BR, Ahamed MI, Khan A, editors. Advances in Green Synthesis Avenues and Sustainability. Cham: Springer International Publishing; 2021. p. 173–89. https://doi.org/10.1007/978-3-030-67884-5_9.

Bilal M, Zdarta J, Jesionowski T, Iqbal HMN. Manganese peroxidases as robust biocatalytic tool—an overview of sources, immobilization, and biotechnological applications. Int J Biol Macromol. 2023;234: 123531. https://doi.org/10.1016/j.ijbiomac.2023.123531.

Gan J, Bilal M, Li X, Hussain Shah SZ, Mohamed BA, Hadibarata T, et al. Peroxidases-based enticing biotechnological platforms for biodegradation and biotransformation of emerging contaminants. Chemosphere. 2022;307: 136035. https://doi.org/10.1016/j.chemosphere.2022.136035.

Martínez ÁT, Ruiz-Dueñas FJ, Martínez MJ, del Río JC, Gutiérrez A. Enzymatic delignification of plant cell wall: from nature to mill. Curr Opin Biotechnol. 2009;20:348–57. https://doi.org/10.1016/j.copbio.2009.05.002.

Pandey VP, Awasthi M, Singh S, Tiwari S, Dwivedi UN. A comprehensive review on function and application of plant peroxidases. Biochem Anal Biochem. 2017. https://doi.org/10.4172/2161-1009.1000308.

Basumatary D, Yadav HS, Yadav M. The role of peroxidases in the bioremediation of organic pollutants. Natural Prod J. 2023;13:60–77. https://doi.org/10.2174/2210315512666220410132847.

Amor-Gutiérrez O, Costa Rama E, Costa-García A, Fernández-Abedul MT. Paper-based maskless enzymatic sensor for glucose determination combining ink and wire electrodes. Biosens Bioelectron. 2017;93:40–5. https://doi.org/10.1016/j.bios.2016.11.008.

Rastogi L, Dash K, Sashidhar RB. Selective and sensitive detection of cholesterol using intrinsic peroxidase-like activity of biogenic palladium nanoparticles. Current Res Biotechnol. 2021;3:42–8. https://doi.org/10.1016/j.crbiot.2021.02.001.

Singh G, Kushwaha A, Sharma M. Intriguing peroxidase-mimic for H2O2 and glucose sensing: a synergistic Ce2(MoO4)3/rGO nanocomposites. J Alloy Compd. 2020;825: 154134. https://doi.org/10.1016/j.jallcom.2020.154134.

Yan J-K, Wang Y-Y, Qiu W-Y, Ma H, Wang Z-B, Wu J-Y. Three-phase partitioning as an elegant and versatile platform applied to nonchromatographic bioseparation processes. Crit Rev Food Sci Nutr. 2018;58:2416–31. https://doi.org/10.1080/10408398.2017.1327418.

Chew KW, Ling TC, Show PL. Recent developments and applications of three-phase partitioning for the recovery of proteins. Sep Purif Rev. 2019;48:52–64.

Vidhate GS, Singhal RS. Extraction of cocoa butter alternative from kokum (Garcinia indica) kernel by three phase partitioning. J Food Eng. 2013;117:464–6.

Ketnawa S, Rungraeng N, Rawdkuen S. Phase partitioning for enzyme separation: an overview and recent applications. Int Food Res J. 2017;24:1.

Kublicki M, Koszelewski D, Brodzka A, Ostaszewski R. Wheat germ lipase: isolation, purification and applications. Crit Rev Biotechnol. 2022;42:184–200. https://doi.org/10.1080/07388551.2021.1939259.

Gul A, Khan S, Arain H, Khan H, Ishrat U, Siddiqui M. Three-phase partitioning as an efficient one-step method for the extraction and purification of bromelain from pineapple crown waste. J Food Process Preserv. 2022;46: e16973. https://doi.org/10.1111/jfpp.16973.

Jain J. Review on isolation and purification of papain enzyme from papaya fruit. Int J Eng Appl Sci Technol. 2020;5:193–7.

Eyssen LE, Goldring JPD, Coetzer THT. Three-phase partitioning (TPP) of proteases from parasites, plants, tissue and bacteria for enhanced activity. Three Phase Partitioning: Elsevier; 2021. p. 133–54.

Datta S, Christena LR, Rajaram YRS. Enzyme immobilization: an overview on techniques and support materials. 3 Biotech. 2013;3:1–9. https://doi.org/10.1007/s13205-012-0071-7.

Salvi HM, Yadav GD. Process intensification using immobilized enzymes for the development of white biotechnology. Catal Sci Technol. 2021;11:1994–2020.

Sun R, Wang Y, Ni Y, Kokot S. Spectrophotometric analysis of phenols, which involves a hemin–graphene hybrid nanoparticles with peroxidase-like activity. J Hazard Mater. 2014;266:60–7.

Zhou M, Zhang J, Sun C. Occurrence, ecological and human health risks, and seasonal variations of phenolic compounds in surface water and sediment of a potential polluted river basin in China. Int J Environ Res Public Health. 2017;14:1140.

Bilal M, Lam SS, Iqbal HMN. Biocatalytic remediation of pharmaceutically active micropollutants for environmental sustainability. Environ Pollut. 2022;293: 118582. https://doi.org/10.1016/j.envpol.2021.118582.

Bayramoglu G, Akbulut A, Arica MY. Utilization of immobilized horseradish peroxidase for facilitated detoxification of a benzidine based azo dye. Chem Eng Res Des. 2021;165:435–44. https://doi.org/10.1016/j.cherd.2020.11.017.

Lopes LA, Dias LP, da Costa HPS, da Silva Neto JX, Morais EG, de Oliveira JTA, et al. Immobilization of a peroxidase from Moringa oleifera Lam. roots (MoPOX) on chitosan beads enhanced the decolorization of textile dyes. Proc Biochem. 2021;110:129–41. https://doi.org/10.1016/j.procbio.2021.07.022.

El-Naggar ME, Abdel-Aty AM, Wassel AR, Elaraby NM, Mohamed SA. Immobilization of horseradish peroxidase on cationic microporous starch: physico-bio-chemical characterization and removal of phenolic compounds. Int J Biol Macromol. 2021;181:734–42. https://doi.org/10.1016/j.ijbiomac.2021.03.171.

Narayan AV, Madhusudhan MC, Raghavarao KSMS. Extraction and purification of ipomoea peroxidase employing three-phase partitioning. Appl Biochem Biotechnol. 2008;151:263. https://doi.org/10.1007/s12010-008-8185-4.

Panadare DC, Rathod VK. Extraction of peroxidase from bitter gourd (Momordica charantia) by three phase partitioning with dimethyl carbonate (DMC) as organic phase. Process Biochem. 2017;61:195–201. https://doi.org/10.1016/j.procbio.2017.06.028.

Yuzugullu Karakus Y, Acemi A, Işık S, Duman Y. Purification of peroxidase from Amsonia orientalis by three-phase partitioning and its biochemical characterization. Sep Sci Technol. 2018;53:756–66. https://doi.org/10.1080/01496395.2017.1405990.

Markwell MAK, Haas SM, Bieber LL, Tolbert NE. A modification of the Lowry procedure to simplify protein determination in membrane and lipoprotein samples. Anal Biochem. 1978;87:206–10. https://doi.org/10.1016/0003-2697(78)90586-9.

Stetefeld J, McKenna SA, Patel TR. Dynamic light scattering: a practical guide and applications in biomedical sciences. Biophys Rev. 2016;8:409–27. https://doi.org/10.1007/s12551-016-0218-6.

Özel F, Karaagac O, Tokay E, Köçkar F, Köçkar H. A simple way to synthesize tartaric acid, ascorbic acid and their mixture coated superparamagnetic iron oxide nanoparticles with high saturation magnetisation and high stability against oxidation: characterizations and their biocompatibility studies. J Magn Magn Mater. 2019;474:654–60. https://doi.org/10.1016/j.jmmm.2018.11.025.

Sarno M, Iuliano M. Immobilization of horseradish peroxidase on Fe3o4/au_go nanoparticles to remove 4-chlorophenols from waste water. Chem Eng Trans. 2019;73:217–22. https://doi.org/10.3303/CET1973037.

Pota G, Gallucci N, Cavasso D, Krauss IR, Vitiello G, López-Gallego F, et al. Controlling the adsorption of β-Glucosidase onto Wrinkled SiO2 nanoparticles to boost the yield of immobilization of an efficient biocatalyst. Langmuir. 2023;39:1482–94. https://doi.org/10.1021/acs.langmuir.2c02861.

Sharma A, Vázquez LAB, Hernández EOM, Becerril MYM, Oza G, Ahmed SSSJ, et al. Green remediation potential of immobilized oxidoreductases to treat halo-organic pollutants persist in wastewater and soil matrices—a way forward. Chemosphere. 2022;290: 133305. https://doi.org/10.1016/j.chemosphere.2021.133305.

Zdarta J, Jesionowski T, Pinelo M, Meyer AS, Iqbal HMN, Bilal M, et al. Free and immobilized biocatalysts for removing micropollutants from water and wastewater: recent progress and challenges. Biores Technol. 2022;344: 126201. https://doi.org/10.1016/j.biortech.2021.126201.

Varamini M, Zamani H, Hamedani H, Namdari S, Rastegari B. Immobilization of horseradish peroxidase on lysine-functionalized gum Arabic-coated Fe3O4 nanoparticles for cholesterol determination. Prep Biochem Biotechnol. 2022;52:737–47. https://doi.org/10.1080/10826068.2021.1992780.

Liu J-J, Kim J-G, Kim H-B, Abeysinghe S, Lin Y-W, Baek K. Covalent immobilizing horseradish peroxidase on electrochemically-functionalized biochar for phenol removal. Chemosphere. 2023;312: 137218. https://doi.org/10.1016/j.chemosphere.2022.137218.

Apostică AG, Ichim T, Radu VM, Bulgariu L. Simple and rapid spectrophotometric method for phenol determination in aqueous media. Bull Polyt Inst Jassy Const Archit Sect. 2018;64:9–18.

Kalsoom U, Ahsan Z, Bhatti HN, Amin F, Nadeem R, Aftab K, et al. Iron oxide nanoparticles immobilized Aspergillus flavus manganese peroxidase with improved biocatalytic, kinetic, thermodynamic, and dye degradation potentialities. Process Biochem. 2022;117:117–33. https://doi.org/10.1016/j.procbio.2022.04.002.

Sadh PK, Duhan S, Duhan JS. Agro-industrial wastes and their utilization using solid state fermentation: a review. Biores Bioproc. 2018;5:1. https://doi.org/10.1186/s40643-017-0187-z.

Yusree FIFM, Peter AP, Mohd Nor MZ, Show PL, Mokhtar MN. Latest advances in protein-recovery technologies from agricultural waste. Foods. 2021;10:2748. https://doi.org/10.3390/foods10112748.

Somu P, Narayanasamy S, Gomez LA, Rajendran S, Lee YR, Balakrishnan D. Immobilization of enzymes for bioremediation: A future remedial and mitigating strategy. Environ Res. 2022;212: 113411. https://doi.org/10.1016/j.envres.2022.113411.

Sharma B, Dangi AK, Shukla P. Contemporary enzyme based technologies for bioremediation: a review. J Environ Manage. 2018;210:10–22. https://doi.org/10.1016/j.jenvman.2017.12.075.

Yaashikaa PR, Devi MK, Kumar PS. Advances in the application of immobilized enzyme for the remediation of hazardous pollutant: a review. Chemosphere. 2022;299: 134390. https://doi.org/10.1016/j.chemosphere.2022.134390.

Gagaoua M, Hafid K. Three phase partitioning system, an emerging non-chromatographic tool for proteolytic enzymes recovery and purification. Biosensors J. 2016;5: 100134.

Vetal MD, Rathod VK. Three phase partitioning a novel technique for purification of peroxidase from orange peels (Citrus sinenses). Food Bioprod Proc. 2015;94:284–9. https://doi.org/10.1016/j.fbp.2014.03.007.

Vetal MD, Rathod VK. Ultrasound assisted three phase partitioning of peroxidase from waste orange peels. Green Proc Synt. 2016;5:205–12. https://doi.org/10.1515/gps-2015-0116.

Lavorato GC, de Almeida AA, Vericat C, Fonticelli MH. Redox phase transformations in magnetite nanoparticles: impact on their composition, structure and biomedical applications. Nanotechnology. 2023;34: 192001.

Favela-Camacho SE, Samaniego-Benítez EJ, Godínez-García A, Avilés-Arellano LMA, Pérez-Robles JF. How to decrease the agglomeration of magnetite nanoparticles and increase their stability using surface properties. Colloids Surf A: Physicochem Eng Aspects. 2019;574:29–35. https://doi.org/10.1016/j.colsurfa.2019.04.016.

Zhang Y, Ge J, Liu Z. Enhanced activity of immobilized or chemically modified enzymes. ACS Catal. 2015;5:4503–13. https://doi.org/10.1021/acscatal.5b00996.

Maghraby YR, El-Shabasy RM, Ibrahim AH, Azzazy HME-S. Enzyme immobilization technologies and industrial applications. ACS Omega. 2023;8:5184–96. https://doi.org/10.1021/acsomega.2c07560.

Zhou W, Rao Y, Zhuang W, Ge L, Lin R, Tang T, et al. Improved enzymatic activity by oriented immobilization on graphene oxide with tunable surface heterogeneity. Compos B Eng. 2021;216: 108788. https://doi.org/10.1016/j.compositesb.2021.108788.

Lakshmi S, Shashidhara GM, Madhu GM, Muthappa R, Vivek HK, Nagendra Prasad MN. Characterization of peroxidase enzyme and detoxification of phenols using peroxidase enzyme obtained from Zea mays L waste. Appl Water Sci. 2018;8:207. https://doi.org/10.1007/s13201-018-0820-9.

Ding Y, Li Z, Jiang W, Yuan B, Huang T, Wang L, et al. Degradation of phenol using a peroxidase mimetic catalyst through conjugating deuterohemin-peptide onto metal-organic framework with enhanced catalytic activity. Catal Commun. 2020;134: 105859. https://doi.org/10.1016/j.catcom.2019.105859.

Niu J, Xu J, Dai Y, Xu J, Guo H, Sun K, et al. Immobilization of horseradish peroxidase by electrospun fibrous membranes for adsorption and degradation of pentachlorophenol in water. J Hazard Mater. 2013;246:119–25.

Chang Q, Tang H. Immobilization of horseradish peroxidase on NH2-modified magnetic Fe3O4/SiO2 particles and its application in removal of 2, 4-dichlorophenol. Molecules. 2014;19:15768–82.

Akpınar F, Evli S, Güven G, Bayraktaroğlu M, Kilimci U, Uygun M, et al. Peroxidase immobilized cryogels for phenolic compounds removal. Appl Biochem Biotechnol. 2020;190:138–47.

Zdarta J, Jankowska K, Bachosz K, Degórska O, Kaźmierczak K, Nguyen LN, et al. Enhanced wastewater treatment by immobilized enzymes. Curr Pollution Rep. 2021;7:167–79. https://doi.org/10.1007/s40726-021-00183-7.

Husain Q. Remediation of Phenolic Compounds from Polluted Water by Immobilized Peroxidases. In: Bharagava RN, Chowdhary P, editors. Emerging and Eco-Friendly Approaches for Waste Management. Singapore: Springer; 2019. p. 329–58. https://doi.org/10.1007/978-981-10-8669-4_15.

Acknowledgements

Special thanks to Dr. Lama Alchab from Physics Department, Aleppo University for performing AFM measurements of the nanoparticles.

Funding

No funding was obtained for this study.

Author information

Authors and Affiliations

Contributions

HA has conceptualized, designed and written the manuscript draft, while WA analysed the nanoparticles findings VY has revised the manuscript critically. All authors have read and approved the manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Al-Madhagi, H., Yazbik, V. & Abdelwahed, W. Food wastes clean water wastes: melon peel peroxidase isolation and immobilization onto magnetite nanoparticles for phenol removal. Chem. Biol. Technol. Agric. 10, 121 (2023). https://doi.org/10.1186/s40538-023-00494-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40538-023-00494-5