Abstract

The coating technique, supposedly invented by Chinese papermakers no later than the 3rd century AD, greatly improved paper sheets’ qualities of color, texture, writability, and printability. Alongside the dispersal of papermaking and surface-treatment techniques beyond China, coated papers were manufactured and used in many other regions of the world. Understanding the manufacture of coated papers, therefore, is crucial for perceiving how surface treatments were developed to meet the need for paper with enhanced properties. However, the characterization of coating and coating pigments on ancient Chinese papers has long remained an unsolved issue, and previous studies on this topic have often produced inconclusive results. To explore a non-invasive methodology that can more reliably characterize coated papers and the coating pigment on them, this article presents the results of a pilot study that applied micro-computed tomography (micro-CT) and Raman spectroscopy to samples of three Qing Dynasty (1644–1911 AD) papers and two handmade papers manufactured in China in the 1990s. Micro-CT revealed the coating layer(s) on Lajian (waxed coated paper) and Lengjinjian (gold-dusted paper) of the Qing Dynasty and characterized the modern raw xuan and bamboo papers as uncoated. Raman spectroscopy, together with handheld X-ray fluorescence analysis, identified the mineral-based pigment in the coating layer, suggesting the use of lead white or kaolin as the coating pigment. Additionally, Raman analysis confirmed the use of other mineral pigments (red lead and cinnabar), beeswax, and organic dyes (gamboge, kermesic acid, and possibly purpurin) in the manufacture of Lajian and Lengjinjian papers. The combination of micro-CT and Raman spectroscopy, it is therefore suggested, is a practical, more reliable approach for non-invasive investigation of coating and coating pigments on ancient Chinese paper specimens.

Similar content being viewed by others

Introduction

Conventionally, the term “paper” and its Chinese counterpart “zhi (纸)” refer to the thin sheets that used plants as sources of fibers and were formed by suspending the pulp on a porous mould [1, p. 3, 2, 3, p. 4]. This particular way of papermaking was invented by Chinese craftsmen in the Western Han Dynasty (202 BC–9 AD), but its widespread use across China became evident only after 105 AD [4, 5]. Beginning in the third century AD, the papermaking technology spread from China to the rest of the world [6,7,8]. Before the papermaking machine was invented in France in 1798 AD [6, 9, p. 16], papermaking activities around the world were heavily hand-based, and many papermakers owed their papermaking technologies to China [6, 7, 9, pp. 5–15, 10,11,12,13,14,15].

Alongside the dispersal of these Chinese-style papermaking technologies, also transmitted was the paper-treatment practice of coating paper sheets with a fine powder of whitish, inorganic substances, in the hope of modifying or enhancing the color (whiteness and brightness), texture (gloss and smoothness), and certain physical properties (opacity, strength, and ink retention) of new paper sheets [6, 16, pp. 145–146]. It is believed that Chinese craftsmen first practiced this sort of coating treatment no later than the third century AD [e.g., 1, pp. 128–132, 16, p. 146]. A coated paper, as discussed below, is a paper subjected to intentional surface treatment after sheet formation by having ground minerals or mineral-based pigments—alone or mixed with other substances—brushed over one or both sides of each sheet [17, 18]. Those ground, often fine-sized minerals are known as the coating pigment. This definition distinguishes a coating pigment from a filler, which refers to the mineral particles often added as opacifiers to the pulp before sheet formation [18, pp. 194–195, 19, pp. 26–27].

Characterization of ancient Chinese coated papers: a short review

The first report describing possibly coated Chinese papers was made by Julius Wiesner, an Austrian botanist, in the 1910s. Wiesner, while conducting a microscopic examination of a 2nd century AD Chinese document, noticed an unusual fine-grained mass, which consisted mainly of mineral substances, among the fibers and partly attached to them [20]. Wiesner ascribed most of the grained particles to a “mineral filling,” which some interpreted later as the earliest coating pigment [e.g., 1, p. 129]. Elsewhere, Wiesner reported the microscopic identification of gypsum (CaSO4·2H2O) as a coating pigment on Chinese papers dated between 220 and 589 AD [1, pp. 128–129, 9, 16].

Chinese scholars did not pay attention to ancient coated papers until the 1960s–70s. Pan Jixing examined the papers unearthed from the Hala Hezhuo Tomb (348 AD) in Xinjiang of northwestern China and, viewing them under an optical microscope, he found mineral particles among the fibers on both surfaces of the examined paper. According to Pan, mineral particles are common on papers dated to the third to the fourth century AD [1, p. 129], and their presence on one or both sides of the paper characterizes a single-sided or double-sided coating [21]. Western scholars at this time also showed interest in the coating of ancient Chinese papers. For example, Collings and Milner proposed, based on examinations using atomic absorption spectroscopy (AAS), that gypsum served as the coating pigment on ancient Chinese documents from the Stein Collection [22]. Since completion of these studies, it has been accepted that coated papers were first manufactured in China, over 1000 years earlier than in the West [1, pp. 128–129, 3, p. 194, 8, 23].

Since the 1980–90s, examination methods using the high-resolution scanning electron microscope (SEM) and energy dispersive X-ray spectrometer (EDX) have been widely applied to ancient Chinese papers. Elemental analysis using EDX sheds light on the types, and the relative concentrations, of metal elements on papers’ surfaces. Because of this, EDX has often been employed as a standard method for characterizing coating pigments. For example, Wang et al. applied SEM/EDX to a great many Chinese historical (105–1911 AD) document papers, calligraphic works, and Buddhist scriptures and reported the wide application, and the diversity, of coating pigments [16]. Wang et al. also characterized papers as single-side coated or double-side coated based on EDX results [16, pp. 188–190]. Through SEM/EDX analysis of more than 200 ancient paper specimens, Chinese scholars discovered that gypsum, kaolin (with kaolinite, Al2O3·SiO2·2H2O, being the dominant mineral), chalk (CaCO3), or talcum powder (3MgO·4SiO2·H2O) was most often used as the coating pigment [1, 16, 24]. Using SEM/EDX and the optical microscope, Rischel noticed that most Chinese documents dated to the 10th century AD or earlier were coated with gypsum [25,26,27].

From the year 2000 till now, an interest in ancient Chinese paper-based materials has continued to grow, and diverse analytical approaches—including those suitable for phase identification—have been used for studying the manufacture and surface treatment of handmade Chinese papers. Using Raman spectroscopy, Li et al. reported that chalk was a coating or filling pigment on paper currencies of the Late Qing Dynasty (manufactured and issued in the 1890s) [28, 29]. On the other hand, Wang et al. reported the X-ray diffraction (XRD) identification of kaolin as the coating pigment on Tripitakas dated between 1271 and 1644 AD [30], and Gong et al. suggested, also based on XRD identification results, that the Western Han papers unearthed at the Xuanquanzhi site in Dunhuang of Gansu Province were coated with diverse whitish pigments, including gypsum, kaolin, and talcum powder [31]. Recently, Clifford pointed out that mica, a whitish coating pigment, played a central role in the manufacture of the 18th-century Chinese wallpapers in British country houses [32]. Table 1 lists the main findings of representative technical studies on ancient Chinese coated papers.

An unsolved issue and the objectives of the present study

Microscopic examination, elemental analysis, and phase identification have undoubtedly contributed to the characterization of coating and coating pigments on ancient Chinese papers. However, to what extent they have helped identify, or distinguish between, coated and uncoated papers has varied from one case study to another, depending on which criteria the investigators have used for determining the presence or absence of a coating layer or pigment. Some investigators have seen the presence of mineral particles among or attached to a paper’s fibers as suggesting the presence of a coating treatment on the paper [1, pp. 129–131, 21, 38, 49]. Other investigators have thought that a joint application of microscopic observation and elemental analysis—the latter of which often indicates the types, and the relative abundances, of metal elements—could suffice both to characterize a paper as coated and to characterize the coating pigment used [22, 24,25,26,27]. Still others have believed that only phase characterization can reliably identify a paper’s coating pigment [28,29,30,31, 50]. Uncertainties and ambiguities, therefore, stand out in review of the studies above, and comparisons between the studies are not easily made.

Probably the most noticeable issue that remains unsolved is that each analytical approach—whether the data it provides is microscopic, compositional, or spectrometric—seems insufficient to justify concluding that a coating layer was present, that any such layer present was applied in a specific way, or that some exact mineral was used as its coating pigment [29, 50]. Microscopic examination is a useful yet inconclusive means to identify a coating layer, and it is somewhat simplistic to assume that mineral particles filling spaces between, or attached to, the fibers must be (residues of) the coating pigment [50]. Compositional data may reveal the relative abundance of (especially) inorganic elements on a paper. However, the elemental concentration values are usually obtained from averaging over a small study area, thus only representative of this target area. Furthermore, the detected values may be a result of both sides of paper (since paper is normally thin) and often fail to reflect the compositional difference between the two surfaces of paper or between the surfaces of paper and the fiber layer between them. Spectrometric techniques are ideal for fast, in situ, and accurate phase identification, which is key to the characterization of coating pigment(s); however, without microscopic observation and compositional data, spectrometric techniques alone can hardly reveal, or visually present, how a method of surface coating was practiced. Microscopic, compositional, and spectrometric data, of course, complement each other, but multi-analytical studies as such have, unfortunately, been very few in number.

The present work attempts to tackle this issue of the coating on ancient Chinese papers by jointly applying methods of analysis using optical microscope, handheld X-ray fluorescence analyzer, micro-computed tomography (micro-CT), and Raman spectroscopy to a sample of three ancient and two modern Chinese papers. It is hoped that, through such a multi-analytical and non-invasive investigation, some standard methods can be established for characterizing ancient coated paper and the coating pigment on it, which may eventually lead to a better understanding of the coating practice used in the manufacture of ancient Chinese papers. Related issues of the coating treatment and manufacture of coated papers (such as dyeing and waxing), although not the focus of the present paper, will also be briefly discussed.

The ancient papers to be investigated were sampled from Lajian (waxed coated paper) and Lengjinjian (gold-dusted paper), both of which are high-quality, specialty papers whose manufacture remains poorly understood. Pan Jixing, on the basis of textual analysis, suggests that waxed yellowish papers, dyed with huangbo extracted from the bark of Phellodendron amurense, were manufactured in the Tang Dynasty (618–907 AD), implying the use of an early form of Lajian as early as the 7th century AD [1, pp. 132–134]. The practice of combining dyeing, coating, and waxing to make Lajian was well established in China no later than the 10th century AD, and it remained a popular method for manufacturing high-quality coated papers through the Tang to Qing dynasties (618–1911 AD) [51]. Although it is widely accepted that some standard treatments—e.g., dyeing, coating, and waxing—were used in the production of Lajian and its variants, knowledge of how these treatments were applied to the paper sheets remains sparse [51, pp. 145–146]. Not until very recently did technical and experimental studies start to shed light on the manufacture of Lajian in the Qing Dynasty, confirming a variety and complexity in the manufacturing techniques utilized [46, 47, 52, 53]. Lengjinjian manufacture used many of the same techniques (dyeing, coating, and waxing) employed in the production of Lajian; to an extent, Lengjinjian was a variant of Lajian. Lengjinjian was decorated with very thin metal foils or with metal powder; however, Lajian barely used metals for decorative purpose [54].

Materials and methods

Ancient and modern Chinese paper specimens

The main aim of this study is to establish a paradigm for characterizing a coated paper and the coating pigment on it. Two groups of paper specimens have been collected for this purpose:

- 1.

Group A consists of three paper specimens, two from Lajian (waxed coated paper) and one from Lengjinjian (gold-dusted paper). The two Lajian paper specimens—one in purple-red and the other in bright yellow—are labeled separately as QP and QY; these specimens, according to the results of fiber analysis (Dr. Zhou Gu, personal communication, 30 December 2018), contains 30% blue sandalwood fiber and 70% rice straw fiber. By contrast, the Lengjinjian paper specimen, labeled as QR, is in dark wine red. The three paper specimens were sampled from document papers supposedly used by the royal families of the Qing Dynasty, and they were offered for analysis by the China Printing Museum (Beijing). Figure 1 shows the Lajian and Lengjinjian paper specimens to be investigated in the present study.

- 2.

Group B consists of two modern Chinese handmade paper specimens, one sampled from raw xuan, which is made from blue sandalwood (Pteroceltis tatarinowii Maxim.) and rice straw (with a 6:4 ratio of fibers), and one sampled from a paper made from pure bamboo fibers. Both papers were produced in the 1990s at papermaking mills in South China, following traditional Chinese papermaking techniques and using locally grown plants. By ‘raw xuan’, it refers to the newly formed sheets of Xuan paper that undergo no further processing. Neither of the raw xuan or bamboo paper received such surface treatment as dyeing, coating, or waxing. The two handmade papers were kindly offered by Professor Enami Kazuyuki at the RyuKoku University (Japan). The raw xuan paper is labeled as ENA#1, the bamboo paper as ENA#2 (Table 2).

Table 2 The paper specimens investigated in this study

Optical microscope

A Zeiss Axio Imager M2 microscope, which allows for high-quality Differential Interference Contrast (DIC) imaging, was employed for carrying out stereoscopic analysis of the five selected paper specimens.

Micro-CT scanner

Micro-computed tomography (micro-CT) is a three-dimensional (3D) imaging technique ideal for investigating the microstructure of a given sample non-invasively. X-rays, while passing through the examined sample, are absorbed to different degrees by different parts of the sample, depending mainly on the compositional differences in the sample [55, 56]. The varying absorption of X-rays generates different grayscale values on the resultant X-ray tomographic image, by which one can distinguish between, for example, the fibers (organics such as cellulose and lignin) and mineral pigments (inorganics such as chalk, gypsum, and kaolin). In the case of paper-based materials, CT images can complement the examination of a sample’s surface(s) by scanning electron microscopy or optical microscope.

Applications of micro-CT to archaeological objects have mainly focused on inorganic materials such as bronze [57], ceramics [58], stone and jade [59], and faience or glass beads [60,61,62,63]. Regarding organic-based materials, micro-CT analysis has only recently started to show its power and potential uses. For example, Baumann et al. [55] and Allegra et al. [64] have reported micro-CT investigations for virtual unrolling of parchments and papyri scrolls. Prior to this study, there has been no report of the micro-CT investigation of ancient Chinese papers and paper-based materials.

The main procedures used in our micro-CT analysis may be described as follows: (1) A 2 mm by 2 mm paper specimen was put into a plastic tube, and the tube was then glued onto the sample holder (Fig. 2a). (2) The paper specimen in the tube was scanned with an EasyTom High-Resolution X-ray Micro CT System (RX Solutions, France). Scans were performed with voxel sizes of 3.5 µm, at 50 kV source voltage and 100 µA source current, over a 360° sample rotation. (3) When micro-CT scanning was finished, about 1440 images were collected for each paper specimen, and these were then imported into Amira (Thermo Fisher Scientific, USA) to generate a three-dimensional (3D) digital model showing the 3D structure—in this study, the virtual cross section—of the investigated paper specimen (Fig. 2b).

a Positioning of paper specimen for the micro-CT scanning. The red arrow indicates the sample holder while the blue one shows the paper specimen (Lajian QY) in a plastic tube; and b a reconstructed paper specimen with a cross-sectional image, with the brighter layers corresponding to the coating layers and the darker layer to the fibers in between

Handheld X-ray fluorescence analyzer

A handheld XRF (hhXRF) analyzer (Thermo Scientific Niton XL3t 950 GOLDD ++) was used for investigating the surface chemical composition of each paper specimen non-invasively. The hhXRF analyzer is equipped with a 50 kV X-ray tube (100 µA, 2 W maximum), an Ag anode target excitation source, and a silicon drift detector (SDD) with an active area of 5 mm2 fitted with a polymer window (MOXTEK AP 3.3 film) that ensures superior X-ray transmission in the low-energy range down to Be Kα. The X-ray beam’s focal-spot size is about 3 mm in diameter. All spectra were acquired using a standard metal mode and a 120-s total analysis time. The calibration of the instrument was done by the Fundamental Parameters (FP) method designed by the manufacturer (Niton).

Raman spectroscopy

Raman spectroscopy has been well recognized as a powerful tool for phase characterization and identification, and its applications to paper-based Chinese materials have increased substantially in the past two decades [65]. In the present study, Raman spectroscopy was used to identify the coating pigment as well as other substances (e.g., wax, mineral-based pigment, and organic dyes) in the coating layer, all of these being important to the manufacture of coated papers.

Raman analysis was performed using the DXR 2xi Raman imaging microscope (Thermo Fisher Scientific, USA). A 532 nm diode laser was used as the excitation source. The size of the light spot was 1 μm and the maximum laser power used at the sample was about 3 mW. The spectral resolution was ~ 4 cm−1. The 50 × objective lens was used for positioning. Raman spectra are subject to smoothing but no baseline subtraction. Raman analysis is also applied to modern natural beeswax which was obtained from a Chinese beekeeper. Assignments of Raman peaks for dyes, especially gamboge, the yellow dye which contains α- and β-gambogic acids (namely a mixture of C38H44O8 and C29H36O6), were made with reference to the online Raman Spectroscopic Library at University College London (http://www.chem.ucl.ac.uk/resources/raman/).

Results and discussion

Microscopic observation of the surface of paper specimens

Microscopic observation helps one to understand the undisturbed microstructure of papers [27]. In particular, it shows how the fibers, pigments, and other substances are distributed across a certain area of one’s paper specimen.

Figure 3 reveals the information obtained through our microscopic observations, showing that: (1) Lajian QP has a waxy surface on both sides, underneath which whitish particles and fibers are seen. The fibers’ morphological characteristics, however, are vague and barely recognizable. (2) Compared to Lajian QP, Lajian QY has a very smooth and dense surface texture, suggesting the presence of a dense coating layer. Fibers are completely invisible. (3) Lengjinjian QR is different from the two Lajian papers mainly in that a large quantity of particles is distributed among the fibers on QR, forming a powdery, loose coating layer. (4) The two modern handmade papers (ENA#1 and ENA#2) show distinctive features compared to the Lajian and Lengjinjian papers: they both are very thin and porous, and their fibers show much clearer micro-morphological characteristics.

Microscopic characteristics of the ancient (QP, QY, and QR) and modern (ENA#1 and ENA#2) Chinese papers. Figures cited from Ref. [66], with permission from the publisher

Given the microscopic observations described above, the three ancient papers (QP, QY, and QR) retains some features of surface treatment, seen especially by a recognizable coating or waxy layer; the two modern ones (ENA#1 and ENA#2), by contrast, are uncoated. Microscopic observations, however, are unable to identify which coating pigment was used in each case.

Characterization of the coating layer by micro-CT

With micro-CT images, a 3D digital model is generated for each investigated paper specimen and, based on this model, a virtual cross section can be obtained for each specimen. On the cross-sectional image, the darker area, due to the low absorption of X-rays, indicates the fiber layer; while the brighter area, resulting from a relatively high absorption of X-rays, corresponds to the coating layer.

Figure 4 shows the virtual cross sections for the five paper specimens, from which one may conclude that: (1) The three ancient papers all show a layered structure. Each Lajian sample (QP and QY) has a coating layer on each side of the paper, suggesting a double-sided coating. By contrast, Lengjinjian QR shows the coating layer only on one of its sides, implying a single-sided coating. Also noticeable is the more or less tight, evenly distributed layers of the Lajian and Lengjinjian papers, which indicates that their coating treatment was done using heavy and repeated pressing. (2) The two modern papers (ENA#1 and ENA#2) show no layered structure, and each of them has a loose, unevenly distributed fiber layer, which conforms to the expectation that those papers would have received no surface treatment.

Virtual cross sections of the five investigated papers reconstructed by micro-CT (the yellow arrow indicates the coating layer while the green arrow stands for the fiber layer). Scale bar = 100 μm. Figures cited from Ref. [66], with permission from the publisher

Micro-CT results conform well to microscopic observations and, even better, micro-CT analysis offers a straightforward and non-destructive way to identify the presence or absence of a coating layer as well as to distinguish between the coated (QP, QY, and QR) and uncoated (ENA#1 and ENA#2) papers. Additionally, micro-CT results suggest, through the contrast between the brighter and darker areas seen in the grayscale images produced, the (near) absence of inorganic substances in the fiber layer of each of the three ancient papers (QP, QY, and QR). This observation seems to rule out the presence of large quantities of minerals among the fibers as fillers. In other words, micro-CT may have potential use in concluding the presence, or absence, of fillers (Table 3).

Characterization of the coating pigment by hhXRF

Based on the microscopic observations and micro-CT scanning described above, we determined that the three ancient papers—Lajian QP, Lajian QY, and Lengjinjian QR—retained features of coating. They were therefore chosen for a hhXRF study to reveal the coating pigment used in each case. For each paper, both sides were investigated by hhXRF, and the elemental compositions of their surfaces were compared.

The hhXRF results are shown in Fig. 5. The Lajian papers (QP and QY) are rich in lead (> 90% Pb, wt%) on both the front and the back sides. On the other hand, the Lengjinjian paper (QR) shows high concentrations of mercury (67.0% Hg, wt%) and sulfur (15.6% S, wt%) on the red surface, which distinguishes it from the two Lajian papers.

Although lead or mercury content is high on the three papers, neither metal can be simply designated as the coating pigment, given that all the papers are colored and the coloring pigment(s), if present, might have contributed to the high concentration of lead or mercury. Lajian QY shows a bright yellow color, excluding the possibility that lead found on it exists in the form of red lead (Pb3O4), a red mineral pigment. That being said, Lajian QY is more likely to have been coated by a whitish or yellowish lead-based pigment. Lajian QP, on the other hand, is a purple-red paper. The lead on QP may or may not have come from red lead. As for the wine-red Lengjinjian QR, its mercury is attributable to cinnabar (HgS) and, due to the absence of lead on it, lead-based pigments are unlikely to have served as its coating pigment.

In brief, hhXRF results do not suffice to identify any of these paper’s coating pigment.

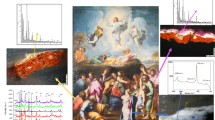

Characterization of the coating pigment by Raman spectroscopy

Raman analysis was applied to both sides of the three ancient papers, in the hope of characterizing phases in the coating layer, which might relate directly to the coating pigment. Seventeen high-quality Raman spectra were collected, of which five were from Lajian QP, seven from Lajian QY, and five from Lengjinjian QR. Raman analysis confirmed that the same pigments or dyes were used on both sides of each examined paper. Here, a “dye” refers to an organic extract from natural plants while a “pigment” to an inorganic colorant.

Figure 6 shows some of the most representative results of the Raman analysis. Given that the examined Lajian and Lengjinjian papers were manufactured and used between the middle 17th and the early 20th century AD, the assignments of Raman peaks and the characterization of phases targeted the pigments and dyes most often used in China during that period [67,68,69]. At the same time, hhXRF results were taken into consideration in phase identification.

Raman spectra in Figs. 6a, b were obtained from the purple-red Lajian QP, whose surfaces are rich in lead (Pb). In Fig. 6a, Raman peaks are noticeable at 144, 390, 635, 976, 1045, and 1319 cm−1, which do not conform to any single phase. The assignments of these Raman peaks can be given as follows: 144 and 390 cm−1 to massicot (β-PbO), an orthorhombic crystal of lead monoxide [70, 71]; 635 and 976 cm−1 to lead sulfate (PbSO4) [71]; and 1045 cm−1 to lead white (Pb(OH)2·2PbCO3) [72]. As for the Raman spectrum in Fig. 6b, Raman peaks at 120, 140, 222, 310, 383, 477, and 543 cm−1 fit well with those of red lead (Pb3O4); on the other hand, the broad Raman peak between 1050 and 1090 cm−1 indicates the presence of a carbonate group [70]. Given the purple-red color, it would be reasonable to assume that Pb3O4 served as the major, if not the only, coloring material. Carbonates are present in the coating layer, and hhXRF results show a high concentration of lead, results which, taken together, indicate the presence of lead white. As for lead monoxide and lead sulfate, they can either be heat-reduced products of lead white [73] or impurities associated with lead white [74]. Relating the Raman results to the hhXRF and micro-CT data, one concludes that lead white was most likely applied to Lajian QP as the coating pigment.

Raman spectra in Figs. 6c, d were collected from Lajian QY, whose surfaces are also rich in lead (Pb) but show a bright yellow color. The Raman spectrum in Fig. 6c shows a noticeable peak at 1050 cm−1 as well as two others at 320 and 410 cm−1, results which altogether conform to those of lead white [75], a common white pigment in ancient China. The Raman spectrum in Fig. 6d also shows a strong peak at 1050 cm−1, indicative of lead white. Also, it has Raman peaks at 1434, 1592, 1626, and 2932 cm−1, which fits with the Raman peaks of gamboge that contains α- and β-gambogic acids. Gamboge is a yellow dye extracted from the Garcinia (Garcinia Linn.) tree. Lead white is found on both sides of Lajian QY, corresponding to the two coating layers. Gamboge, being an organic yellow dye, does not form a coating layer itself. Therefore, the coating pigment on both sides of Lajian QY, we conclude, was prepared from lead white.

Raman spectra in Figs. 6e, f were obtained from Lengjinjian QR, whose surfaces are wine red. The Raman spectrum in Fig. 6e shows peaks at 144, 195, 397, 514, and 637 cm−1, all attributable to kaolin (Al2O3·SiO2·2H2O) [29, p. 67]. Kaolin was an important white pigment in ancient China, and its use on wall paintings and painted artifacts began as early as the Western Han Dynasty (206 BC–24 AD) [76, 77] and continued through the Qing Dynasty [78]. Also, kaolin was widely used as a filling or coating pigment in papermaking [18, p. 195]. Thus, the present study proves that kaolin was used as a coating pigment in the manufacture of Lengjinjian QR. The Raman spectrum in Fig. 6f shows three peaks at 252, 285, and 345 cm−1, which conforms well with those of cinnabar (α-HgS). Cinnabar serves as the major, if not the only, red colorant on Lengjinjian QR, which explains the concentration of mercury indicated by the hhXRF results.

Given the findings above, one may conclude that Raman analysis helps characterize and identify the coating pigment as well as the coloring materials on these three ancient papers. One may also conclude that Raman results are compatible with those of hhXRF and micro-CT analyses.

Two additional issues: waxing and dyeing

Microscopic observations, micro-CT, hhXRF, and Raman results have altogether suggested that (1) The Lajian and Lengjinjian papers were colored or dyed, with Lajian QP having been colored by red lead, Lajian QY by gamboge, and Lengjinjian QR by cinnabar. (2) Both Lajian QP and Lajian QY were coated using lead white as the coating pigment; by contrast, Lengjinjian QR was coated using kaolin as the coating pigment. The coating treatment having now been well understood, two additional issues central to the manufacture of these three papers remain to be explored: waxing and dyeing.

As discussed in "Microscopic observation of the surface of paper specimens", microscopic observations suggest that the manufacture of Lajian and Lengjinjian should also have involved waxing, the purpose of which would have been to form a waterproof layer. Figure 7a shows a Raman spectrum collected from Lajian QY, with strong Raman peaks at 1050, 1134, 1290, 1440, 1465, 2724, 2845, and 2885 cm−1. These Raman peaks fit well with those of natural beeswax we obtained from a Chinese beekeeper (shown in Fig. 7b) or Raman peaks of beeswax (1062, 1129, 1295, 1440, 2723, 2849, and 2881 cm−1) reported elsewhere [71]. It appears, therefore, that beeswax was used for waxing Lajian QY. Beeswax does not appear to have been detectable for Lajian QP and Lengjinjian QR, however.

As for paper dyeing, our Raman analysis confirmed that gamboge was the only coloring material used on Lajian QY. Lajian QP and Lengjinjian QR were colored, respectively, with red lead and cinnabar, but the Raman analysis suggested the presence of organic dyes on these two papers, which would also have contributed to the red color. For example, Fig. 7c shows Raman peaks at 470, 660, 810, 1022, 1316, 1476, and 1607 cm−1, which fit with the characteristic Raman peaks (479, 653, 811, 1028, 1317, 1484, 1603 cm−1) of kermesic acid (C16H10O8), a red dye extracted from Kermes scale insects [79]. Figure 7d, on the other hand, shows Raman peaks at 1206, 1316, and 1412 cm−1, which are usually attributable to the presence of C-C, C-O, NH2, or ring structures; given these Raman peaks, natural mineral-based pigments, starch, protein, and wax materials are excluded [80, 81]. Purpurin (C14H8O5), a red dye extracted from madder plants, seems a possible candidate as it shows Raman peaks at 1213, 1277, 1319, and 1401 cm−1 within 1200 to 1450 cm−1 wavelength range [79]. Further analysis will be needed to confirm the red dye on Lengjinjian QR.

Once again, Raman analysis has shown its power to characterize phases (and to then determine waxes, pigments, and dyes) used in the manufacture of coated papers (Table 4).

Discussion and Summary

This study was carried out to establish a methodology that can characterize the coating layer and coating pigment on ancient Chinese papers non-invasively and more accurately. The purpose of this study is twofold: to demonstrate the weakness in the conventional approaches (microscopic observation and compositional analysis); to explore the potential of micro-CT and Raman spectroscopy in studying ancient coated papers.

The study began with microscopic examination of the selected paper specimens, followed by a handheld XRF analysis. Needless to say, both approaches are helpful for retrieving instant information regarding the distribution of fibers and mineral particles as well as the possible composition of mineral particles. However, neither approach can reveal the distribution of the coating layer or identify the coating pigment. By contrast, micro-CT images show—by means of reconstructed cross sections—not only the presence or absence of the coating layer but also the thickness and the distribution pattern of the coating layer. Combined with micro-CT images, Raman analysis provides convincing results when characterizing and identifying a paper’s coating pigment. In short, we believe that a combination of micro-CT scanning and Raman spectroscopy can resolve difficulties attending the study of ancient coated papers better than conventional approaches.

As mentioned in "Characterization of the coating layer by micro-CT", we also believe that micro-CT scanning has potential for distinguishing a coating pigment from a filler, the two of which, according to our present knowledge, were often prepared from different minerals or from the same mineral but applied with different contents and thus, importantly, would generate different X-ray absorption spectra. However, without actually cross-sectioning the paper specimen and performing spot tests (such as Raman mapping) on the cross section, it is difficult to confirm the fillers or to compare the coating pigment with the fillers.

Based on the findings of the present study, we can describe the general procedures used in the manufacture of ancient coated papers such as Lajian and Lengjinjian: chosen (dyed) papers were first coated by having finely ground powder of inorganic substances (e.g., lead white and kaolin) brushed over one or both sides of the paper; then, pigments prepared from inorganic materials such as red lead and cinnabar, alone or mixed with organic dyes extracted from natural plants (such as gamboge, kermesic acid, and purpurin), were brushed over the surface of the paper, for the purpose of dyeing or coloring; finally, waxy materials (for example, beeswax) were applied to the paper to form a waterproof layer. Similar procedures have been described elsewhere, in technical studies of ancient Lajian papers [46], as well as in experimental studies on the manufacture of modern Lajian papers [51]. What is new about the present study, however, is that it shows, even with a small sampling, the complexity and diversity in the use of materials for manufacturing Lajian papers. This shows the necessity of carrying out technical studies on a much larger sampling of Lajian and its variants, in order to reveal a fuller understanding of the Lajian manufacture.

Lastly, it is necessary to evaluate the practicality and applicability of the proposed methodology. The advantages are self-evident: (1) in all analyses the sample size can be very small (the smallest paper-specimen size in this study was about 2 mm by 2 mm); (2) there is no need to further compromise the paper specimens; that is, no further cutting or pre-analysis sample preparation is needed for the proposed analyses; (3) performed with care in the course of analyses, no aspect the proposed approach would cause (visual) damage to the investigated samples, nor would the samples be contaminated by such things as organic and inorganic chemicals, dirt, and liquids; (4) the data collection and interpretation are relatively straightforward. Given these advantages, we believe that the proposed methodology (especially the combination of micro-CT and Raman spectroscopy) is ideal for paper fragments that are too small or too precious to allow for destructive sampling or analysis. At the same time, this methodology’s ability to work with paper fragments—which, unlike whole ancient documents of great value, may readily be transported to a testing site—might reduce concerns arising from the low portability of micro-CT scanners and Raman spectroscopy equipment.

Conclusion

A multi-analytical, non-invasive study was carried out on three ancient (two Lajian and one Lengjinjian) and two modern (raw xuan and bamboo paper) Chinese handmade papers, with the goal of addressing one central question: whether a paper was coated or not and, if it was coated, how its coating layer and coating pigment might be correctly characterized and identified. To approach that goal, microscopic observations, surface elemental analysis, micro-CT imaging, and Raman spectroscopy were applied to the selected paper specimens.

The results show that neither microscopic observation nor elemental analysis suffices to characterize the coating layer or the coating pigment. They also show that micro-CT imaging is a more reliable tool for identifying and characterizing the coating layer, and that Raman spectroscopy is a more accurate technique for identifying the phases in the coating layer. The combination of micro-CT and Raman spectroscopy could serve as a better solution to the difficulties of investigating the coating treatment on papers. Besides that, Raman spectroscopy has shown its power in identifying other substances (such as wax, pigments, and dyes) that might have been used in the manufacture of coated papers.

In sum, the present study provides a novel, practical approach for non-invasively characterizing ancient Chinese coated papers.

The research presented here was translated, with substantial changes and additional information, from a paper that appeared in China Paper & Pulp (a Chinese journal): 李涛, 刘闯, 谷舟, 王冬梅. 无损鉴别古纸涂层及涂料的新方法. 中国造纸, 2019, 38(12):27–34.

Availability of data and materials

All data supporting the conclusions of this article can be obtained from the corresponding authors upon reasonable request.

Abbreviations

- OM:

-

Optical microscope

- SEM/EDX:

-

Scanning electron microscope/elemental dispersive X-ray spectrometry

- hhXRF:

-

Handheld X-ray fluorescence analyzer

- AAS:

-

Atomic absorption spectrometry

- micro-CT:

-

Micro-computed tomography

- Raman:

-

Raman spectroscopy

- XRD:

-

X-ray diffraction

References

Pan J. History of science and technology in China: volume on papermaking and printing. Beijing: Science Press; 1998 (in Chinese).

Tsien T-H. Raw materials for old papermaking in China. J Ame Orient Soc. 1973;93:510–9.

Hunter D. Papermaking: the history and technique of an ancient craft. New York: Dover Publications, Inc.; 1974.

Li T. Identifying sources of fibre in Chinese handmade papers by phytoliths: a methodological exploration. Star. 2018. https://doi.org/10.1080/20548923.2018.1475454.

Pan J. Review of debates concerning paper history during the last 30 years in China. Chin J Hist Sci Tech. 2011;32:561–71 (in Chinese).

Browning BL. The nature of paper. Libr Q. 1969. https://doi.org/10.1086/619812.

Pan J. The four great inventions of ancient China: their origin, development, spread and influence in the world. Hefei: University of Science and Technology of China Press; 2002 (in Chinese).

Collings T, Milner D. A new chronology of papermaking technology. Pap Conserv. 1990. https://doi.org/10.1080/03094227.1990.9638387.

Sindall RW. The manufacture of paper. New York: D. Van Nostrand Company; 1908.

Cressey PF. Chinese traits in European civilization: a study in diffusion. Am Sociol Rev. 1945;10:595–604.

Jones R. European and Asian papers in Malay manuscripts: a provisional assessment. Manuscr Indonesia. 1993;149:474–502.

Haynes W. Oldest material: newest uses. Sci Mon. 1953;76:71–6.

O’hanlon R. Performance in a world of paper: Puranic histories and social communication in early modern India. Past Present. 2013;219:87–126.

Hannawi AA. The role of the Arabs in the introduction of paper into Europe. Mela Notes. 2012;85:14–29.

Han Y-H, Enomae T, Isogai A, et al. Traditional papermaking techniques revealed by fibre orientation in historical papers. Stud Conserv. 2006;51:267–76.

Wang J. History of papermaking engineering in ancient China. Taiyuan: Shanxi Education Press; 2006 (in Chinese).

Baker M, Van der Reyden D, Ravenel N. FTIR analysis of coated papers. http://cool.conservation-us.org/coolaic/sg/bpg/annual/v08/bp08-01.html. Accessed 13 Jan 2020.

Biermann CJ. Handbook of pulping and papermaking. San Diego: Academic Press; 1996.

Parham RA, Kaustinen HM. Papermaking materials: an atlas of electron micrographs. Appleton: USA Graphic Communications Center, Inc.; 1974.

Wiesner J. Über die ältesten bis jetzt aufgefundenen Hadernpapiere: ein neuer Beitrag zui Geschichte des Papiers. In: Sitzungsberichte Der Akademie Der Wissenschaften in Wien, Philosophisch-Historische Klasse 168. 1911; pp. 1–26.

Pan J. Study of ancient papers unearthed from Xinjiang. Cultur Relics. 1973;10:52–60 (in Chinese).

Collings T, Milner D. An examination of early Chinese paper. Restaurator. 1979. https://doi.org/10.1515/rest.1979.3.4.129.

Bundy WM, Ishley JN. Kaolin in paper filling and coating. Appl Clay Sci. 1991. https://doi.org/10.1016/0169-1317(91)90015-2.

Niu D, Wang J. Exploring the papermaking in the Western Xia period: A case study of the document papers unearthed at the Fangta Temple in Baisigou, Helan of Ningxia Province. J Nat Museum China. 1999;2:72–82 (in Chinese).

Rischel A-G. Analysis of the papermaker’s choice of fibrous materials and technology along the paper road. In: Graziaplena R, Livesey M, editors. Paper as a Medium of Cultural Heritage, Archaeology and Conservation: Proceedings of the 26th Congress of the International Paper Historians Association. Rome: Istituto centrale per la patologia del libro; 2002. pp. 202–08.

Rischel A-G. Looking at Central Asian paper of Turkish, Tibetan and Chinese origin from the Silk Roads. IPH Congress Book. 1998;12:176–84.

Rischel A-G. Technical examinations of the documents. In: The Report of Written Materials Excavated from the Sands (Part 2: Documents from Central Asia). Kyoto. 2001. pp. 215–49.

Shi J, Li T. Technical investigation of 15th and 19th century Chinese paper currencies: fiber use and pigment identification. J Raman Spec. 2013. https://doi.org/10.1002/jrs.4297.

Li T. Technical investigation of ancient Chinese paper-based materials with non-destructive chemical methods. Ph.D. dissertation. Beijing: University of Chinese Academy of Sciences; 2010 (in Chinese).

Wang H, Cheng A, Wang Z, et al. The manufacture technology of Tripitaka paper collected by Wuwei Museum in Gansu Province. Transact Chin Pulp Paper. 2014;29:33–7 (in Chinese).

Gong D, Yang H, Li X. The manufacture, and the filling pigment, of papers unearthed at the Xuanquanzhi site in Dunhuang of Gansu Province. Cultur Relics. 2014;9:85–90 (in Chinese).

Clifford H. Chinese wallpaper: from Canton to country house. In: Finn M, Smith K, editors. East India Company at Home, 1757-1857. London: UCL Press; 2018. pp. 39–67.

Li X, Wang H, He C. The era and relevant problems of ancient paper unearthed in the Xuanquan site, Gansu. Stud Hist Nat Sci. 2012;31:277–87 (in Chinese).

Li X. Preliminary study on the papers of the Han Dynasty unearthed at Zhongyan in Fufeng, Shaanxi Province. Cultur Relics. 2012;7:93–6 (in Chinese).

Li X, Guo J, Wang B. Studies of ancient papers unearthed at the Eastern Han tombs in Minfeng, Xinjiang. Cultur Relics. 2014;7:94–6 (in Chinese).

Wang J, Li Y. Preliminary discussion on the invention of papermaking in China: evidence from analytical results of several papers of the Han Dynasty. Cultur Relics. 1980;1:78–85 (in Chinese).

Li X. Study of the unearthed ancient paper from the Xuanquan site of the Han Dynasty in Gansu. J Guangxi Univ Nationalities. 2010;16:7–16 (in Chinese).

Li X, Jia J. Preliminary analysis of the Buddhist script papers unearthed from Dunhuang in Gansu Museum. J Dunhuang Stud. 2013;3:164–74 (in Chinese).

Li X, Zheng B, Wang B. Studies of ancient papers unearthed at the Asitana-Hala Hezhuo tombs in Turfan, Xinjiang. West Reg Stud. 2012;1:62–8 (in Chinese).

Li X, Jia J. Preliminary study on the Western Xia papers. NorthWest J Ethnol. 2014;1:123–8 (in Chinese).

Li X. Studies on the paper of a Buddhist Sutra of the Song-Yuan Dynasties collected in the Dali Fotu Tower. China Pulp Paper. 2018;37:36–9 (in Chinese).

Tan M, Wang Y. Non-destructive and micro-invasive analysis of paper cultural relics. Sci Conserv Archaeol. 2014;26:115–23 (in Chinese).

He X. Study of the linen paper of Shanxi Qinyuan in the Qing Dynasty. In: Proceedings of the 6th UNESCO subregional symposium on paper conservation: paper conservation and paper making traditions in East Asia. Beijing: UNESCO; 2016. pp. 221–27 (in Chinese).

Yan Y, Wang C. Studies of the microstructure and chemical composition of paper-based materials. Cultural Relics Conservation and Restoration. 2016:607–13 (in Chinese).

Wang S, Gu S, Yan W, et al. Study on the paper of Wu Xu archives in Qing Dynasty and their restoration materials. In: Proceedings of the 6th UNESCO Subregional Symposium on Paper Conservation: Paper Conservation and Paper Making Traditions in East Asia. Beijing: UNESCO; 2016. pp. 286–98 (in Chinese).

Luo Y, Chen J, Yang C, et al. Analyzing ancient Chinese handmade Lajian paper exhibiting an orange–red color. Herit Sci. 2019. https://doi.org/10.1186/s40494-019-0306-6.

Luo Y, Wang Y, Zhang X. A combination of techniques to study Chinese traditional Lajian paper. J Cult Herit. 2019. https://doi.org/10.1016/j.culher.2019.01.008.

Chang X, Gong Y, Li G, et al. Study on the manufacture process and characteristics of the ancient screen paper collected in the museum. China Pulp Paper. 2018;37:27–32 (in Chinese).

Pan J. Analysis of the papers of Buddhist scripture discovered in the Dunhuang Library Cave. Cult Relics. 1966;3:39–47 (in Chinese).

Li T. Indigo- and madder-dyed 11th- to 13th-century Chinese papers unearthed at Khara Khoto in northwestern China. Tangut Res. 2017;3:3–14 (in Chinese).

Guo W, Zhang X, Zhang X. A study and reconstruction of Lajian paper. Palace Museum J. 2006;6:145–52 (in Chinese).

Jin Y, Li X. A preliminary study on reconstruction of yinghuang (Hard Yellow) paper with hot wax graft. Sci Conserv Archaeol. 2013;25:20–4 (in Chinese).

Wei L, Chen W, Jin G, et al. Scientific analysis of tie luo, a Qing Dynasty calligraphy artifact in the Palace Museum, Beijing, China. Herit Sci. 2018. https://doi.org/10.1186/s40494-018-0193-2.

Pan J. Ten types of further processed papers in ancient China. Cult Relics. 1979;2:38–48 (in Chinese).

Baumann R, Porter DC, Seales WB. The use of micro-CT in the study of archaeological artifacts. In: The 9th International Conference on NDT of Art. Jerusalem. 2008. pp. 1–9.

Bello SM, Groote ID, Delbarre G. Application of 3-dimensional microscopy and micro-CT scanning to the analysis of Magdalenian portable art on bone and antler. J Archaeol Sci. 2013. https://doi.org/10.1016/j.jas.2012.12.016.

Castellano A, Quarta S, Palamà G, Brunetti A, et al. Radiographic films as a detection system for a CT-scanner. Radiat Phys Chem. 2001. https://doi.org/10.1016/S0969-806X(01)00395-4.

Barron A, Turner M, Beeching L, et al. Micro-CT reveals domesticated rice (Oryza sativa) within pottery sherds from early Neolithic sites (4150–3265 cal BP) in Southeast Asia. Sci Rep. 2017;7:7410.

Yang Y, Yang M, Xie Y, et al. Application of micro-CT: a new method for stone drilling research. Microsc Res Tech. 2009;72:343–6.

Liu N, Yang Y, Wang Y, et al. Nondestructive characterization of ancient faience beads unearthed from Ya’er cemetery in Xinjiang, Early Iron Age China. Ceram Int. 2017;43:10460–7.

Gu Z, Xie R, Yang Y, et al. A micro-CT research on early faience: a case study of the Peng State faience. Nucl Tech. 2012;35:265–9 (in Chinese).

Gu Z, Zhu J, Xie Y, et al. Nondestructive analysis of faience beads from the Western Zhou Dynasty, excavated from Peng State cemetery, Shanxi Province, China. J Anal Atom Spectrom. 2014;29:1438–43.

Bertini M, Mokso R, Krupp EM. Unwinding the spiral: discovering the manufacturing method of Iron Age Scottish glass beads. J Archaeol Sci. 2014;43:256–66.

Allegra D, Ciliberto E, Ciliberto P, et al. X-ray computed tomography for virtually unrolling damaged papyri. Appl Phys A. 2016. https://doi.org/10.1007/s00339-016-9796-1.

Li T. Investigating pre-1949 Chinese paper-based materials by Raman spectroscopy: short review (2000-2017). Int J Conserv Sci. 2019;10:15–24.

Li T, Liu C, Gu Z, et al. New approach for non-destructive investigation of the coated ancient Chinese papers. Chin Pulp Paper. 2019;38:27–34 (in Chinese).

Yu F-A. Studies of Chinese painting colors. Beijing: Beijing Joint Publishing; 2013 (in Chinese).

Xia Y. Chinese historical pigments in polarized light microscope. Beijing: Science Press; 2017 (in Chinese).

Fei X, Liu J, Wang J. Chinese historical pigments and dyes and advances in the technical characterization of pigments and dyes. In: The Fifth Annual Conference of Chinese Cultural Heritage Conservation Association. Beijing: Science Press; 2013. pp. 305–13. (in Chinese).

Bell IM, Clark RJH, Gibbs PJ. Raman spectroscopic library of natural and synthetic pigments (pre- ≈ 1850 AD). Spectrochim Acta A. 1997. https://doi.org/10.1016/S1386-1425(97)00140-6.

Burgio L, Clark RJH. Library of FT-Raman spectra of pigments, minerals, pigment media and varnishes, and supplement to existing library of Raman spectra of pigments with visible excitation. Spectrochim Acta A. 2001. https://doi.org/10.1016/S1386-1425(00)00495-9.

Gunasekaran S, Anbalagan G, Pandi S. Raman and infrared spectra of carbonates of calcite structure. J Raman Spec. 2006. https://doi.org/10.1002/jrs.1518.

Li T, Ji J, Zhou Z, et al. A multi-analytical approach to investigate date-unknown paintings of Chinese Taoist priests. Archaeol Anthrop Sci. 2017. https://doi.org/10.1007/s12520-015-0293-9.

Lussier SM, Smith GD. A review of the phenomenon of lead white darkening and its conversion treatment. Stud Conserv. 2007. https://doi.org/10.1179/sic.2007.52.Supplement-1.41.

Frost RL, Martens W, Kloprogge JT, et al. Raman spectroscopy of selected lead minerals of environmental significance. Spectrochim Acta A. 2003. https://doi.org/10.1016/S1386-1425(03)00054-4.

Feng J, Xia Y, Blaensdorf C, et al. Analysis of pigments of Western Han Dynasty’s tomb mural excavated in the new campus of Xi’an Technology University. J Northwest Univ. 2012;42:771–6 (in Chinese).

Rong B, Lan D, Wang L, et al. Study and analysis of the pigment of polychrome pottery during the Han Dynasty excavated in Xianyang. Relics Museol. 2009;6:266–8 (in Chinese).

Ma Y, Zhang J, Hu D. Scientific analysis of a Ming Dynasty polychrome star sculpture from Shanxi Art Museum, Taiyuan, China. Sci Conserv Archaeol. 2015;27:50–60 (in Chinese).

Whitney AV, Van Duyne RP, Casadio F. An innovative surface-enhanced Raman spectroscopy (SERS) method for the identification of six historical red lakes and dyestuffs. J Raman Spectrosc. 2006. https://doi.org/10.1002/jrs.1576.

Vandenabeele P, Wehling B, Moens L, et al. Analysis with micro-Raman spectroscopy of natural organic binding media and varnishes used in art. Anal Chim Acta. 2000. https://doi.org/10.1016/S0003-2670(99)00827-2.

Edwards HGM, Farwell DW, Daffner L. Fourier-transform Raman spectroscopic study of natural waxes and resins. I. Spectrochim Acta A. 1996. https://doi.org/10.1016/0584-8539(96)01730-8.

Acknowledgements

The authors thank Mrs. Anna-Grethe Rischel for sharing her translation of Julius Wiesner’s 1911 paper, Dr. Zhou Gu for providing the Lajian and Lengjinjian paper specimens, Professor Enami Kazuyuki for furnishing the Chinese raw xuan and bamboo papers, Dr. Leijie Jia for his help with microscopic observations, and Ms. Yujia Luo for her help with the literature search. The authors also thank the four anonymous reviewers for their constructive criticisms and suggestions which improves the overall coherence and clarity of the manuscript.

Funding

The research received financial support from the Research Funds for Double First-Class Initiative at Wuhan University (Grant No: 1105-60046001, granted to Tao Li) and the Fundamental Research Funds for Central Universities (Grant No: 1105-413000072, granted to Tao Li).

Author information

Authors and Affiliations

Contributions

TL and CL conceptualized the experiments, interpreted the data, and wrote early drafts of the manuscript. TL carried out the microscopic examinations and hhXRF analysis; CL carried out the micro-CT analysis; and D. Wang performed the Raman analyses. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Li, T., Liu, C. & Wang, D. Applying micro-computed tomography (micro-CT) and Raman spectroscopy for non-invasive characterization of coating and coating pigments on ancient Chinese papers. Herit Sci 8, 22 (2020). https://doi.org/10.1186/s40494-020-00366-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40494-020-00366-3