Abstract

In this paper, optical microscopy, SEM–EDS, Raman and FT-IR analyses were used to investigate different types of corrosion product between layers of glaze and body of Kraak porcelain objects that were excavated from “Nan’ao I” shipwreck, the South China Sea. Several contaminants including NaCl, CaSO4·2H2O, FeOOH and FeS2, were found in many of the pores and cracks of the porcelain objects from Jingdezhen Kiln and Zhangzhou Kiln, even after conservation. While compared with the sample of Jingdezhen Kiln, the contaminants in the sample of Zhangzhou Kilns much more severely. The research pointed out that these contaminants were formed due to the marine environment influence and cross-contamination with other metal relics located in the shipwreck, and more contaminants formed in porous structure, hence reduce the porcelain quality. As regards to conservation, the fragility of ceramic objects from underwater contexts are likely to be caused by various kinds of insoluble ferrous salts and its phase transition pressure. Previous studies on this kind of remains tend to focus on the macro-insoluble salts on the enamel surface. In this paper, preliminary investigations were performed for the first time on different kinds of inner micro-corrosion product in China.

Similar content being viewed by others

Introduction

Kraak porcelain was one of the most famous and fashionable manufactures exported to the entire European continent, when in the period from the Jiangjing reign late-Ming dynasty to the Qianlong reign early-Qing dynasty (~ 1550 A.D. to 1700 A.D.) [1]. It played an essential role in the ancient Maritime Silk Road, and exerted a significant influence in oversea ceramic trade. The “Nan’ao I” shipwreck, which contains over 20,000 Kraak porcelain items, was preliminary identified as a merchant ship of the Jiajing to Longqing reigns (~ 1522 A.D to 1572 A.D.), a period marked by the beginning of an open-sea policy of ancient China. The ship most likely set sail from Port Yue of Zhangzhou city, Fujian province, then travelled to Japan, Kory, Ryukyu through Taiwan, Lusong, the Pescadores Islands, and then it voyaged to Europe via Southeast Asia, West Asia and Africa. This marine trade route is considered as one of the critical elements in the Manila Galleon [2].

The “Nan’ao I” shipwreck which located in Nan’ao island, was discovered by archaeologists from Guangdong institute of cultural relics and archaeology in May 2007. The shipwreck is 25.5 m long and 7.8 m wide and it sank at a depth of 27 m underwater. It has 26 compartments, thus being one of the biggest ships of the Ming dynasty ever found in China [3]. Some of the main excavated artifacts from this shipwreck include ceramics, Kraak porcelain, ironware, bronze ware, tin ware, gold ware, woodenware and stoneware. Among them, Kraak porcelain items account for 90% of the remains [4].

The most common types of diseases that affected porcelains of “Nan’ao I” shipwreck are fragmentation, contamination, peeling of glaze and discoloration. Given the underwater conditions where these materials have been deposited, and its proximity with other materials and marine organisms, they can present fragility and a concretionary surface. Other scholars have previously determined that the surfaces of marine contexts are usually covered with insoluble salts, such as calcium carbonate, calcium sulfate and ferrous compounds, as well as corals and shells. These deposits and crusts on porcelain are caused by long-term marine deterioration, such as seawater corrosion, mineral sedimentation, marine bio-fouling and marine microbial degradation [5,6,7].

Furthermore, underwater ceramics are generally saturated with soluble salts, mainly NaCl, which were deposited in the porous structure. The repeated crystallization of residual salts through the porous structure of ceramics due to changes in temperature and relative humidity would lead to body cracks and glaze flake off, which would accelerate the degradation [8, 9]. Thus, the body of the porcelain can be damaged via physical and chemical transformation [10]. Contaminants including various concretion and soluble salts should decrease the quality of Kraak porcelain and are potentially dangerous to the integrity of porcelain. Therefore, the study of specific contaminants and their potential damage, as well as the strict conservation method for underwater porcelain has profound significance.

Conservation scientists mainly focus on the removal of different types of surface insoluble and inner-body soluble salts, as well as their potential damage and preservation of underwater ceramics [5,6,7,8,9,10,11]. Studies have shown that underwater ceramics may be stable after the desalination process of soluble salts and the removal process of insoluble salts. Hitherto, few reports have discussed the study of different types of insoluble salts in the inner-body and their potential damage to porcelain. Therefore, in this work, optical microscopy, SEM–EDS, Raman, XRD and FT-IR analyses were employed to observe the different types of corrosion between the glaze and body of Kraak porcelain obtained from “Nan’ao I” shipwreck, which were excavated from the South China Sea. The results indicate that there are numerous contaminants, such as NaCl, CaSO4·2H2O, FeOOH and FeS2, located in the pores or cracks of the porcelain inner-body. The ferrous sediments formed due to the sea environmental corrosion and the cross-contamination from other underwater ferrous artifacts are very difficult to remove from the porcelain and could cause much more severe damage than the soluble salts.

Materials and methods

Materials

A shipwreck of the Ming dynasty was discovered in Nan’ao Island, Shantou city, Guangdong province and was named “Nan’ao I” shipwreck. The surrounding area is part of the South China Sea, branch of the Kuroshio Current. The seawater temperature around the “Nan’ao I” shipwreck is between 22 and 24 °C in winter, and between 22 and 30 °C in summer. The tide range is from 1.0 to 3.0 m, flow velocity range is from 80 to 100 cm/s, and surface layer salinity is between 34.6 and 35.0‰. The compounds with content of more than 1 mg/L in the South China sea water are Na+, Mg2+, Ca2+, K+, Sr2+, Cl−, SO42−, HCO3−, Br−, F−, and H3BO3. There are also several kinds of ores around this area on the offshore shelf, such as ilmenite, zircon, rutile, monazite, and garnet. Various marine animals including calcareous and siliceous microorganisms live in this area [12].

After three excavation seasons (2007, 2011 and 2012) at the “Nan’ao I” shipwreck, archaeologists found 30,000 items, among which Kraak porcelain accounts for a significant proportion [13]. Typology and microelement analysis indicate that Kraak porcelain on “Nan’ao I” has two different provenances, one is from Jingdezhen kiln in Jiangxi province and the other one is from Zhangzhou kiln in Fujian province [14, 15]. Previous studies indicated that the artifacts from Jingdezhen kiln are world-renowned [16]. These porcelain items are fine and smooth, the bodies are white and thin, the glaze is bright and glossy. The Kraak porcelain from Jingdezhen kiln remains in good condition. However, the porcelain items from the Zhangzhou Kiln are different, the bodies are grey and thick, the cracked glaze is turbid and uneven, and the entire porcelain has an excessively weak appearance. This porcelain was rinsed, cleaned, desalinated, protected from light and stored under stable temperature and humidity conditions.

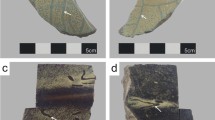

Two representative Kraak porcelain samples as very preliminary analysis objects are discussed here. ZZ-QH porcelain sample is from Zhangzhou kiln which has severely cracked glaze and a large number of orange colored stains. JDZ-QH sample is from Jingdezhen kiln which has a delicate appearance and a few orange colored stains (Fig. 1). A large number of blue and white porcelain items were found in the “Nan’ao I” shipwreck. Among them, the following two pieces were selected because they contain different types of damages and can represent two different kinds of preservation due to their respective preserve conditions, which in turn depends on the raw materials and preparation process.

Methods

The samples were first cut into small pieces, then microscopy, SEM–EDS, Raman, XRD and FT-IR analyses were used to observe the different types of corrosion in the porcelain.

A dual light path microscope (Olympus BX51, Japan) was used to study the morphology and observe the damages on the surface and cross-section of these samples.

A scanning electron microscope (SEM, Hitachi S-3600N, Japan) and X-ray energy disperse spectrometer (EDS, Genesis 2000XMS) were used to observe the micro-contaminations at high magnification and analyze their elementary composition. The sample was sprayed with gold and then pasted on to the SEM sample platform with carbon conductive adhesive. The acceleration voltage was 20.0 kV. The orange stains on ZZ-QH were analyzed by micro Raman spectroscopy.

The micro Raman spectra were recorded by a confocal-micro-Raman spectrometer (LABRAM-HR, France) at room temperature employing 514.5 nm argon-ion laser. The wave number range of 100–2800 cm−1 was selected, the instrument’s precision is ± 1 cm−1, and its spot size is 1 mm.

Fourier transform infrared spectroscopy (FT-IR, MAGNA-IR 750, Nicolet Instrument Co., U.S.A) with KBr pellet method was used to analyze the salt crystals on the surface of porcelain glaze. The spectrum range was from 400 to 4000 cm−1, and the maximum resolution was 0.1 cm−1.

X-ray diffraction (XRD, Rigaku D/max-rA, Japan) with rotating target method was used to examine the coagulum on the bronze ware, ironware and woodenware obtained from the “Nan’ao I” shipwreck. This analysis aimed to find the possible source of the contaminants on the porcelain, for the seawater and porcelain do not contain enough elements to form the micro coagulum. The XRD analyses were performed with Cu target Kα radiation, voltage of 40 kV, electric current of 100 mA, scan angle range from 10° to 70°, and scanning speed of 4.00°/min.

Analysis results

Microscope observation

At a magnification of 100, it was observed that ZZ-QH had a large number of orange colored stains and cracks with contaminants on the surface. The body was entirely covered by orange colored contaminants. On the surface of JDZ-QH sample, there were hardly any stains or cracks. However, through the picture of a section of JDZ-QH sample, the stains were found concealed below the surface. Unlike the ZZ-QH sample, the glaze of JDZ-QH was bright and smooth, and the body seemed pure white. At a magnification of 200, it was found that the orange stains on the ZZ-QH sample had an average diameter of about 200 µm. Minute orange stains of JDZ-QH were seen through the surface (Fig. 2). The appearance of the orange stains was quite clear under the microscope observation, and the composition of the stains needed to be determined by additional tests.

Microscopy images of the samples from “Nan’ao I” shipwreck. a–c The porcelain sample from Zhangzhou kiln in Fujian province, d–f micrographs of the porcelain sample from Jingdezhen kiln in Jiangxi province, (a, b, d, e) surface of the porcelain items, (c, f) cross sections of the porcelain items. a, d, c, f Images shot in a magnification of 100, b, e images shot in a magnification of 200. b A close view of the orange colored stain

SEM–EDS results

SEM–EDS results of ZZ-QH showed that there were three distinct forms of contaminants, such as crystals of acicular, nodular and spherical morphology (Fig. 3). The main components of acicular crystal were Fe and Si, and it also contained small amounts of S, Cl and Al. The main element of the nodular crystal was Fe, and the minor elements were Si and Al. The main components of the spherical crystal were Fe and S, with a small amount of Si. These contaminants may have a severe impact on the structure of ZZ-QH resulting in physical instability.

SEM–EDS results of JDZ-QH showed that the salts filled in the pores contained elements such as Si, Fe, Na, K, Ca, and Cl. The cracks were filled with contaminants having Fe and Ca as the main elements, and Pb, Cl, and Al as the minor elements. The complex pollutants of JDZ-QH can cause potential damage to porcelain and hinder its preservation efforts (Fig. 3). Pores are from the original structure of the porcelain while the cracks were resulted from the longtime immersion in seawater. This is likely to be related with different combinations of salts which produce different types of damage.

The current status of ZZ-QH and all the other porcelain from Zhangzhou kiln was inferior to that of JDZ-QH and porcelain from Jingdezhen kiln. The contaminants and salts found on the ZZ-QH sample were more diverse and much higher compared to the JDZ-QH sample.

Raman results

Raman spectroscopy was utilized to detect the molecular structure of the orange stains on the surface of ZZ-QH. The main spectrum peaks were at 250.4 cm−1, 300.5 cm−1, 377.5 cm−1 and 526.4 cm−1, which were characteristic peaks of γ-FeOOH (lepidocrocite) [17, 18] (Fig. 4).

FT-IR results

After excavated from the marine environment, the porcelain was transported into the laboratory, and immersed in seawater simultaneously in order to ensure the preservation conditions consistent with ocean burial environment. Then the selected samples were taken out and putted in a dry environment for examinations for about 24 h, hereafter, a small amount of salt crystallized was found on the surface of JDZ-QH. The FT-IR spectrum showed peaks at 602.38 cm−1, 669.77 cm−1, 1116.44 cm−1, 1621.08 cm−1, 3405.77 cm−1 and 3546.98 cm−1, which were consistent with the infrared standard peaks of CaSO4·2H2O [19] (Fig. 5). This is in accordance with the EDS results which showed the presence of calcium (Fig. 3).

Discussion

The experimental result of primary study on the micro-contaminants from underwater Kraak Porcelain, which indicated the disease types, disease sources and potential dangers of the contaminants of JDZ-QH and ZZ-QH were differ in degree rather than in kind.

Disease types

Different types of contaminants with elemental components of Fe, S, Ca, Na, Mg, Cl were found in the pores or cracks of the porcelain items by SEM-EDS. Among several contaminants, FeOOH and CaSO4·2H2O are confirmed by Raman spectroscopy and FT-IR analysis. Moreover, based on the research on harmful salts in underwater porcelain, it can be inferred that there are two kinds of harmful salts in the inner part of the porcelain. One is soluble salt, such as NaCl [8, 11]. The other is insoluble salts, such as FeOOH, FeS2, and CaSO4·2H2O.

Disease sources

These two types of diseases mentioned above (stains and cracks) are a result of a long term burial in the marine environment. Sources of the contaminants probably from seawater and/or other associated items in the shipwreck.

It was showed that, sea water contains a large number of ions, such as Na+, K+, Mg2+, Ca2+ and Cl− [20], and its pH value is stable in the range of 7.8–8.2. Slightly alkaline surface waters with a large number of ions make an undesirable environment for porcelain preservation [21]. These ions have small ionic radii (Na+: 102 pm, K+: 138 pm, Ca2+: 100 pm, Fe3+(hs): 65 pm, Cl−: 167 pm). Therefore, they can quickly enter to the porcelain through pores (about 50–100 µm), and finally cause corrosion and precipitation of sediments inside the porcelain. According to the detrital mineral grains statistics of Northern South China Sea, the average content of magnetite (Fe3O4) is 3.9%, and its kurtosis is 9.3. The average content of pyrite (FeS2) is 2.4%, and its kurtosis is 51.6 [22]. These data indicate that Fe and S are common elements in seawater. Moreover, it has been reported that FeS2 generally exists in artifacts excavated from the marine environment [23,24,25].

The redox in seawater influences the contaminant formation and transformation, and the process could be described by the following reactions:

The above chemical equations are reduction reactions in the marine environment from left to right, and oxidizing reactions from right to left. Equation (1) describes variation of the content of pyrite and its transformation, Eq. (2) describes the modification of the content of sodium chloride, and Eqs. (3), (4) and (5) describe variations of the content and conversion of iron hydroxides, from ferric hydroxide to ferrous hydroxide. Thus, as the environment changes, some of the crystals of soluble salts and contaminants would deform and cause damage in the vicinity.

The “Nan’ao I” shipwreck contains artifacts made of diverse materials such as ironware, bronze ware and woodenware. After the metal material was eroded by the seawater, the corrosion products might interact with each other or were transported by seawater from one object to another. Generally, high salinity environment can turn Fe into FeOOH easily and FeS2 is widespread in the wooden material in the sea. Other kinds of ferrous contaminants could come from the ironware corrosion [26, 27]. To evaluate whether cross-contamination occurs in the marine environment, sediments in different kinds of artifacts were analyzed by XRD. It was found that there was FeS2 in woodenware, FeFe2O4 and Fe8(O, OH)16Cl1.3 in bronze ware and FeOOH in ironware. From the XRD results (Fig. 6), it can be seen that different kinds of iron chemical compounds exist in different kinds of artifacts in the shipwreck. Therefore, it can be confirmed that cross-contamination occurred in the marine environment among all of the remains.

Marine microorganisms can cause biodegradation and biodeterioration, and cause several kinds of inorganic products including ammonia, nitrate, phosphate, carbon dioxide and hydrogen sulfide. These products might also affect the contaminants and salts formation in the porcelain body. These processes should be further explored in the future.

Potential dangers

An previous study suggested that the dissolving and recrystallization process of NaCl can lead to a fracture pressure of 221.9 mPa (2190 atmospheres equals to 221.9 mPa). High-pressure expansion or constriction in a small pore or crack can cause a detrimental impact in porcelain on a micro level [28]. Previous studies also reported that the repeated crystallization process of NaCl is the main cause of porcelain glaze cracking and peeling off [29]. However, as it was shown above, NaCl, CaSO4·2H2O, FeOOH and FeS2 are all found in the pores and cracks of the two kinds of porcelain items. The phase transition pressure of Fe2O3, FeOOH, and FeS2 can reach up to 60–120 GPa [30,31,32], which is at least 270 times higher than the dissolving or crystallization pressure of NaCl. Theoretically, it can be inferred that ferrous contaminants can cause severe damage to the underwater porcelain.

Potential dangers to JDZ-QH

Deionized water desalination method was used for JDZ-QH to preliminarily investigate the effect of ferrous contaminants. After 1 day of soaking, it was found that the NaCl crystals in the crack disappeared, but the ferrous contaminants expanded and the crack enlarged. The changes in size are shown in Fig. 7, and it can be seen that the amount of maximum deformation was 147%. This data indicates that, the ferrous contaminants can increase the crack size or make the pores irregular.

During drying, iron salts may expand to fill voids caused by unrelated forces. They may also grow to provoke fractures. Any reduction in the concentration of the ionic matrix (e.g., desalination bath) may cause a change in the separation of micro-cracks through alteration of Van der Waals forces, which may cause an expansion in the cracks filled with ferrous salts.

Potential dangers to ZZ-QH

As showed in Figs. 1 and 2c, the cracks at the porcelain are filled with orange contaminants, after the above experiments we can speculate that this orange contaminants are probably ferric or ferrous compounds. And deterioration of ZZ-QH caused by these contaminants is megascopic, the cracks are already been broadened and a whole porcelain item could rupture during the deionized water immersion.

Conclusion

The analyses conducted on two pieces of Kraak porcelain from the “Nan’ao I” shipwreck showed that NaCl was not the only inner contaminant. Other major contaminant presented below the glaze surface were FeOOH, FeS2 and CaSO4·2H2O, which originate from the marine environment and from corrosion interaction with other materials in the “Nan’ao I” shipwreck. It was much more difficult to remove ferrous contaminants from the inside of the porcelain than NaCl, and the potential damage of ferrous contaminants is likely to be much more severely. The phase transition pressure of ferrous contaminants was as high as 60–120 GPa, which is at least 270 times higher than the dissolving or crystallization pressure of sodium chloride and could broaden the cracks in porcelain within a short time. Therefore, more attention should be given to the ferrous contaminants and their concealed danger in the conservation work of underwater ceramics. Thus, We can avoid porcelain crack and shatter more likely if we remove ferrous contaminants of the porcelain items in the first place than just immerse them in water. But how to remove the ferrous contaminants safely still need to be study.

This experiment suggests that ferrous contaminants are more destructive than NaCl. As this is the first study mainly focus on this topic in China, more experimentation need to be done in order to clarify or deepen into the degradation process triggered by the ferrous contaminants.

Availability of data and materials

The datasets generated and analyzed during the current study are included in this published article.

Abbreviations

- A.D.:

-

Anno Domini

- SEM–EDS:

-

scanning electron microscope–energy disperse spectroscopy

- XRD:

-

X-ray diffraction

- FT-IR:

-

Fourier transform infrared spectroscopy

- ZZ-QH:

-

blue and white porcelain of Zhangzhou kiln

- JDZ-QH:

-

blue and white porcelain of Jingdezhen kiln

- KPa:

-

kilopascal

- MPa:

-

megapascal

- Gpa:

-

gigapascal

References

Rinaldi M. Kraak porcelain: a moment in the history of trade. London: Bamboo Publishing; 1989.

Guo X. The age, sea route and character of “Nan’ao I” shipwreck. Archaeol Cult Relics. 2016;6:118–32 (in Chinese).

Guo X, Wu Z, Chen D. Hidden pearl of the Guangdong Sea—evaluation of archaeology tourism development of “Nan’ao I”. China Venture Cap. 2013;20:148–9 (in Chinese).

Yang Y, Chen Z. The historical mark of “Nan’ao I” in the view of regional culture. Lingnan Cult Hist. 2014;2:35–9 (in Chinese).

Norquest S. Preventing poultice problems: a study of ceramic stain reduction. Winterthur: University of Delaware Program in Art Conservation; 2008. p. 1–24.

Gheorghe SV. Incised ceramics (1650–1250 B.C.)—degradations caused by the microclimate in the storage area. Mus Microclim. 2007;11:31–2.

Casaletto MP, Ingo GM, Riccucci C, et al. Chemical cleaning of encrustations on archaeological ceramic artefacts found in different Italian sites. Appl Phys A. 2008;92:35–42.

Jang S, Nam B, Park D, et al. Desalination characteristics for ceramics excavated from Taean shipwreck, Korea. J Cult Herit. 2013;14:229–37.

Hamilton DL. Methods for conserving archaeological material from underwater sites. Texas: Texas A&M University; 1999.

Feng J, Liu M. Trilogy of conservation of “Nan’ao I” shipwreck. China Soc Sci Daily. 2010;06:08 (in Chinese).

Yue C. A study on method of desalination of ceramics from the Huaguangjiao I shipwreck. Jianghan Archaeol. 2013;126:117–21 (in Chinese).

Lv B, Sun Z. Marine environment and geology. Shanghai: Tongji University Press; 1997 (in Chinese).

Cui Y. 2007 survey and excavation of the ship Nan’ao No. 1 of the Ming dynasty. Cult Relics. 2011;5:25–47 (in Chinese).

Cui Y. Excavation of the ship Guangdong Nan’ao No. 1 of the Ming dynasty. China Cult Herit News. 2011;8:30 (in Chinese).

Du J, Chen Y, Li N, et al. A study on provenance of Kraak porcelain from “Nan’ao I” shipwreck. Spectrosc Spectr Anal. 2015;35:1746–50 (in Chinese).

Dillon M. Transport and marketing in the development of the Jingdezhen porcelain industry during the Ming and Qing Dynasties. J Econ Soc Hist Orient. 1992;35:278–90.

Faria D, Silva SV, Oliveira M. Raman microspectroscopy of some iron oxides and oxyhydroxides. J Raman Spectrosc. 1997;28:873–8.

Burgio L, Clark RJH. Library of FT-Raman spectra of pigments, minerals, pigment media and varnishes, and supplement to existing library of Raman spectra of pigments with visible excitation. Spectrochim Acta Part A Mol Biomol Spectrosc. 2001;57:1491–521.

Makreski P, Jovanovski G, Dimitrovska S. Minerals from macedonia. XIV. Identification of some sulfate minerals by vibrational (infrared and Raman) spectroscopy. Vib Spectrosc. 2005;39:229–39.

Chen M. Chemical oceanography. Beijing: China Ocean Press; 2009 (in Chinese).

Taylora P, Lichtschlagb A, Tobermana M, et al. Impact and recovery of pH in marine sediments subject to a temporary carbon dioxide leak. Int J Greenh Gas Control. 2014;1:1750–5836.

Shi X. China offshore oceanography, seabed sediment. Beijing: China Ocean Press; 2012. p. 382–4 (in Chinese).

Wetherall KM, Moss RM, Jones AM, et al. Sulfur and iron speciation in recently recovered timbers of the Mary Rose revealed via X-ray absorption spectroscopy. J Archaeol Sci. 2008;35:1317–28.

Fors Y, Jalilehvand F, Risberg ED, et al. Sulfur and iron analyses of marine archaeological wood in shipwrecks from the Baltic Sea and Scandinavian waters. J Archaeol Sci. 2012;39:2521–32.

Zhang X. Manual of practical chemistry. Beijing: National Defence of Industry Press; 1986 (in Chinese).

Legodi MA, Waal DD. Raman analysis of red-brown and gray shards from 16th and 17th century Portuguese shipwrecks. Cryst Eng. 2003;6:287–99.

Li Q, Wang Z, Han W, et al. Characterization of the rust formed on weathering steel exposed to Qinghai salt lake atmosphere. Corros Sci. 2008;50:365–71.

Koob SP, Ng WY. The desalination of ceramics using a semi-automated continuous washing station. Stud Conserv. 2000;45:265–73.

Jang S, Nam B, Park D, et al. A study on the soluble salt and deterioration of ceramics from Taean shipwreck. Stud Conserv. 2009;30:190–202.

Ono S, Kikegawa T, Ohishi Y. High-pressure phase transition of hematite, Fe2O3. J Phys Chem Solids. 2004;65:1527–30.

Ono S, Kikegawa T. High-pressure study of FeS, between 20 and 120 GPa, using synchrotron X-ray powder diffraction. Am Miner. 2006;91:1941–4.

Gleason AE, Quiroga CE, Suzuki A, et al. Symmetrization driven spin transition in ε-FeOOH at high pressure. Earth Planet Sci Lett. 2013;379:49–55.

Acknowledgements

This research is supported by the University of Chinese Academy of Sciences (No. 2019-Y954026XX2), the Youth Innovation Promotion Association of CAS, the National Scholarship Fund of China (CSC NO. 201404910198), the National Natural Science Foundation of China (Grant No. 41471167), and the National Social Science Fund of China (No. 13BKG004). Dr. Wugan Luo would like to thank the University of Missouri Research Reactor Center for supporting the visiting scholar’s project. We are grateful to anonymous reviewers whose comments greatly improved the quality of the manuscript.

Funding

The University of Chinese Academy of Sciences (No. 2019-Y954026XX2), the Youth Innovation Promotion Association of CAS, the National Scholarship Fund of China (CSC NO. 201404910198), the National Natural Science Foundation of China (Grant No. 41471167), and the National Social Science Fund of China (No. 13BKG004).

Author information

Authors and Affiliations

Contributions

JD and WL conceived the study, performed the analyses of the manuscripts, carried out interpretation of the results, and drafted the manuscript. JD carried out the analytical experiments. NL participated in the coordination of the study, helped to draft the manuscript, and CW supervised the project. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated.

About this article

Cite this article

Du, J., Luo, W., Li, N. et al. Characterization of the micro-contaminants from the inner-body of Kraak porcelain excavated from the “Nan’ao I” shipwreck, the South China Sea. Herit Sci 7, 85 (2019). https://doi.org/10.1186/s40494-019-0328-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40494-019-0328-0