Abstract

In the economics literature, measuring the performance of a dairy farm with a total productivity index is common practice. Previous research, on the other hand, has been chastised for failing to account for agricultural emissions in their models when calculating resource use productivity. This study estimated green total factor productivity (GTFP) accounting for dairy farms' CH4 emission to the model. The study is based on unbalanced panel data from 692 specialized dairy farms from 1991 to 2020. To estimate GTFP and its components using multiple input–output environmental production technologies, a stochastic input distance function and a Translog model were used. The average annual growth rate of green production over the research period was 0. 032%. The main reason for the increase in GTFP was positive scale change contributions. Technological change (− 0.031% per year) and efficiency change (− 0.002% per year), on the other hand, had a detrimental effect on GTFP.

Similar content being viewed by others

Introduction

To maintain long-term food security while preserving the environment, policymakers encourage farm businesses to adopt sustainable choices and behaviours. While the costs of inactivity are unknown, it is widely agreed that failure to address climate change will seriously affect future generations. Livestock production accounts for approximately 40% of the gross value of agricultural production and about 11% of global GHG emissions (FAO 2020). Recent efforts, such as the Green Deal, demonstrate that the European Union's agriculture sector places a high priority on climate change mitigation. In all production systems, enhanced husbandry management and practices might cut emissions by 20–30%, resulting in increased productivity and carbon sequestration (FAO & UNSD 2020). Norwegian family farm businesses face new economic, environmental, and social challenges. As environmental concerns have grown, governments have urged farmers to adopt sustainable policies and practices to prevent environmental degradation while also assuring long-term food security and resource efficiency (Alem 2021). In the Global Opportunity Report for 2018 (DNV GL 2018), responsible consumption and production (Goal 12) and climate action (Goal 13) are addressed as two of the four UN Sustainable Development Goals that most likely will not be achieved by 2030 without an extraordinary effort from farmers, policymakers, and researchers.

Family farmers generally manage small and relatively vulnerable farms and, as such, operate within a decision-making environment that focuses primarily on maintaining the existence of businesses (Wilson 2008). From a global perspective, Norwegian agriculture has several advantages in achieving sustainable food production; for example, Norwegian regulations ensure that manure is used as a fertiliser and spread on arable land, many pesticides are banned, and the use of antibiotics in animal production is very low. However, Norwegian agriculture is struggling with several sustainability issues (e.g. a high percentage of emissions from livestock production). Evaluating the performance of agricultural systems while considering environmental concerns is a critical problem for the implementation of policies and practices intended to reveal sustainable development (Alem 2021; Pacini et al. 2003). As a result, farm resource efficiency and productivity must be reviewed and evaluated to pinpoint improvements that will aid agricultural policy in achieving its objectives. In economics, the term productivity refers to a wide idea; however, this research focuses on Green total factor productivity (GTFP) as a useful productivity indicator. GTFP has proven to be useful in policy initiatives aimed at promoting long-term agricultural growth (Manos et al. 2013).

Several studies, such as Koesling et al. (2008), Kumbhakar et al. (2008), Kumbhakar and Lien (2009), Kumbhakar et al. (2012), Lien et al. (2010, 2018), Alem et al. (2019), and Alem (2021), have been carried out to assess the productivity of Norwegian agriculture. Previous research on Norwegian agriculture has yielded useful information on-farm performance and food production. However, we still know relatively little about the Norwegian agricultural sector's performance. As a result, this paper contributes to the economic literature in several ways. Even though it is a critical concern for long-term agricultural development, previous studies have overlooked the dairy industry's environmental impact. We examined the performance of Norwegian dairy farms while accounting for environmental challenges, which meant that we assessed both desirable (dairy production) and undesired (environmental effect) outcomes. As a result, this article calculates Greene Total Productivity (GTFP) at the farm level contributing to the understanding of eco-performance and policy-making that improves farmers' livelihoods. We also had the benefit of working with a large dairy farm panel dataset that covered the years 1991–2020.

The remaining section of the document is structured as follows. "Agriculture and environmental policies in Norway" section discussed Norwegian agricultural and environmental policies, followed by "Theoretical framework" section which discussed the theoretical framework. "Empirical model" section provides the empirical model, and "Description of the data" section examines the data and variable definitions utilized in the empirical model. “Estimation results and discussion” section presents the empirical estimation and outcomes. Our findings and conclusions are summarized in the final section.

Agriculture and environmental policies in Norway

Norwegian agricultural policies aim to increase food production, sustain agricultural activity across the country, protect the environment, and ensure income development comparable to other groups in society. Norway is one of the countries with the least amount of arable land per capita in the world. According to recent compilations of Statistics Norway data, the arable land area per capita decreased from 1963 m2 in 2000 to 1499 m2 in 2020 (SSB 2021). Livestock production has become the most important agricultural product in Norway, with dairy farming accounting for nearly 30% of all farmers in the country (Alem et al. 2019). The small amount of land that is technically suitable for farming, combined with national policies to maintain and distribute production, determines the use of agricultural land in large part.

Agriculture in Norway has been and continues to be highly regulated, with some of the highest subsidies in the OECD, and farmers are still exempt from GHG emission taxes, and the EU ETS does not apply to agriculture (OECD 2022). The excess nitrogen and phosphorus levels in Norway are among the highest in the OECD, putting pressure on the quality of the soil, water, and air. It ought to shift funding away from goals of income and production in favour of stronger incentives for farmers to enhance agri-environmental outcomes and advance climate-smart agriculture. Farmers could contribute to restoring agricultural landscapes' ecological value in this way. According to the OECD 2022 Environmental Performance Review, Norway is one of the best OECD countries in terms of long-term carbon pricing. To encourage more investments in renewable energy and low-carbon technologies, it offers a strong price signal. Outside of agriculture, climate change initiatives are widespread and ought to result in proportionate reductions across all industries. Norway's focus on national GHG emissions only gives a partial picture of its global carbon footprint because of its small size and open economy.

Even if all policies and regulations are followed, Norwegian livestock farming has significant environmental consequences, including GHG emissions. Among all sources of greenhouse gases emitted into the atmosphere over the previous 40 years, methane emissions were the highest (SSB 2021). As a result, this study concentrated on dairy farms' methane emissions.

Theoretical framework

Environmental production technology

The standard producer theory's starting point is to define the technical link between inputs and outputs using production technology. Dairy farms produce both desirable (such as milk and meat) and undesirable by-products (GHG emissions). Conventional technology can manage the desired outputs. Undesired outputs, on the other hand, require special attention in efficiency analysis. The set of environmental production technologies \(\left( \Psi \right)\) is therefore defined as follows:

where x, y, and b are the vectors of input, desirable output, and undesirable output, respectively. In the context of environmental production technology (Ψ)., it is crucial to mosdel the relationship between desirable and undesirable outputs. The environmental production technology set Ψ is assumed to satisfy three axioms

-

(a)

Null jointness, i.e. if \(((y,b) \in \Psi \;{\text{and}}\;b = 0\;{\text{then}}\;y = 0)\)

-

(b)

The set \(\Psi\) is a closed set and nonempty.

-

(c)

If \(\left( {\left( {y,b} \right) \in \Psi {\text{ and }}y^{\prime} \le {\text{y then }}\left( {y^{\prime},b} \right) \in \Psi } \right)\), that is, the technology set \(\Psi\) satisfies the free disposability of all inputs and outputs.

For details of other properties of the technology set, see Färe et al. (1985) and Chambers et al. (1996). An input or output possibility set can be used to illustrate environmental production technology (Färe et al. 2008). The input set (L) is then defined as follows:

Following Farrell (1957), the technology boundaries (input isoquants) of the technology set \({\Psi }\left( {x,y,b} \right)\) can be defined in terms of a radical as follows:

Decision-making unit (DMU) or farms are efficient if they are within the boundaries of the input requirement set, that is, they are input efficient if \(x \in \partial L\left( y \right)\). On the other hand, DMUs are input inefficient if \(x \notin \partial L\left( y \right).\) Input-inefficient farms use more inputs to produce the same output compared to other input-efficient DMU. This is the case if the inefficient farms experience a slack in inputs.Footnote 1 In the directional distance function (Chambers et al. 1996), Eq. (3) can be represented as follows:

where \(y_{t}\) denotes the output-level targeted by a farmer, given, a vector of undesirable output \(b_{t}\), and a vector of initial capital stocks \(k_{t}\), and a vector of feasible variable inputs \(x_{t}\).

The feasible input set is represented by \(L\left( {y_{t} ,x_{t} ,b_{t} ,k_{t} , t,\omega } \right)\). \(\lambda\) is a scalar (\(\lambda \ge 1\)) assessing possible input reductions, with a minimum value of 1 corresponding to completely efficient production units. \(\omega\) indicates unobserved heterogeneity like farm-effects.

Equation (4) must meet certain regularity requirements, such as being non-decreasing in inputs, linearly homogenous, and decreasing in outputs. Following Lovell et al. (1994) normalizing all inputs by one of the inputs is a straightforward technique for applying the homogeneity constraint.

where \(\mathop x\limits_{t}\) is a vector of input ratios with \(\mathop x\limits_{kt} = \frac{{x_{kt} }}{{X_{1} }}, \quad \forall k = 2, \ldots ,K;\) and \(\dot{K}_{t} = \frac{{K_{t} }}{{x_{1} }}\).

Equation (5) can be written in logarithm and a translog functional form as in Coelli et al. (2005) as

Re-arrange Eq. (6) and add the random error term \((v_{it} )\) to make the distance function stochastic.

where \(v_{it}\) is the noise and \(\ln D_{I} () = u_{it} \ge 0\) \(D_{I}\) measures the efficiency measure that is conditional on undesirable outputs which represent the relative excess in input factors due to eco-efficiency.

GTFP measurement and decomposition approaches

Previous research on efficiency has employed various methods for calculating and decomposing TFP (for details see O’Donnell 2010; Kumbhakar et al. 2015; Alem 2018). The Divisia index is commonly used as an easy way to track TFP growth (Kumbhakar et al. 2015). A recent measure of TFP change seeks to decompose TFP change into different sources. TFP was decomposed by Kumbhakar (1996) and Kumbhakar and Lovell (2000) into technical change (TC), scale change (SC), efficiency change (EC), and pricing change components. Several publications, for example, Brümmer et al. (2002), Karagiannis et al. (2004); and Kumbhakar and Lozano-Vivas (2005), decompose the TFP change into four major components.

TFP change (\(T\dot{F}P\)) denotes the difference between the rate of change of an output index (\(\dot{y}\)) and the rate of change of the index of an input \((\dot{x})\) (see Karagiannis et al. 2004). We follow the Divisia index for the productivity change decomposed into TEC, TC, SC, and Allocative efficiency change (AEC) components. In this study, y is the net dairy output that is the difference between desirable output (Y) minus undesirable outputs (b) then estimate the Green TFP change \(\left( {GT\dot{F}P} \right)\).

where \(S_{j}\) is captures the expenditure share of input \(X_{j} \left( {S_{j} = w_{j} x_{j} /C} \right).\) \(C\) denotes the total cost (\(C = \mathop \sum \limits_{j} w_{j} x_{j}\)); and \(w_{ }\) is the vector of input price \(x_{j}\) (\(w_{ }\) = \(w_{1} \ldots \ldots w_{j} )\). As shown by Kumbhakar et al. (2014), by differentiating (8) totally, we get

where a dot above a variable denotes the rate of change for that particular variable. RTS = \(\mathop \sum \limits_{j} \frac{\partial \ln y}{{\partial \ln x_{j} }} = \mathop \sum \limits_{k = 1}^{4} \beta_{k}\) and \(\lambda_{j}\) is the elasticity of production for each input, i.e. \(\lambda_{j} = \frac{{\varepsilon_{j} }}{{{\text{RTS}}}}\), where \(\varepsilon_{j}\) are input elasticities defined at the input distance function \({\text{TL}}\left( {\ln y_{t} ,\ln \mathop x\limits_{t} ,\ln b_{t} ,\ln \dot{K}_{t} , t,\omega } \right)\).

Green total factor productivity change is the sum of technical change (TC), efficiency change (EC), scale change (SC), and allocative efficiency change \(\left( {{\text{AEC}}} \right)\), i.e. \(GT\dot{F}P\) = \({ }{\varvec{TC}} + {\mathbf{SC}} + {\mathbf{EC}} + {\text{AEC}}\). The GTFP change connected to the technology are \({\varvec{TC}} + {\varvec{SC}} + \user2{EC },\) which is the focus of this study.

The first source of the change in GTFP could be technical change (TC), which indicates that there is a change in the frontier. It is proof that best practices have improved because of the use of new technology. The improvement in the firm's capacity to utilise existing technology is the second factor contributing to the change in GTFP owing to efficiency change (EC). EC exhibits a move towards the frontier because of improved farm management, such as reduced resource wastage. With an intensive agricultural extension, inefficient farmers, lately adopting the currently available technology are improving efficiency (Alem 2018). The third component of GTFP is caused by a SC, which indicates movement approaching the frontier. SC illustrates how the company has evolved towards an operational size that is technologically feasible (Kumbhakar et al. 2015). The departure of input prices from the value of their marginal products in the allocation of inputs is captured by the AEC component of the GTFP change. Due to the lack of data on input prices at the farm level, AEC was not estimated for this study.

GHG emissions estimate

In the current study, the Intergovernmental Panel on Climate Change (IPCC 2006) methodology's Tier 2 approach is used, which incorporates country-specific forecasts from the Norwegian Environment Agency (NIR 2020). The basic equation to calculate the emission factor for enteric fermentation is provided in IPCC 2006 as follows.

where

-

\({\text{GE}}_{{\text{D}}}\) = gross energy intake for dairy farms, MJ/day

-

Ym = methane conversion rate, %

-

The factor 55.65 (MJ/kg CH4) is the energy content of methane

-

Milk305 = Lactation output of energy-adjusted milk at 305 days

-

Concentrate proportion is the percentage of concentrates in the diet as a whole calculated using net energy. Equation (11) takes an annual emission factor into account (365 days).

Methane yearly emissions resulting from manure management of dairy cattle (CH4 emissions Dairy FARM) in each farm were derived by multiplying the farm-specific emission factor \(({\text{EF}}_{{\text{D}}} )\) with the number of raised dairy cattle (\(N_{{\text{D}}}\)). Furthermore, country-specific emissions factors for non-dairy cattle (CH4 emissions, not dairy FARM) are derived by multiplying the number of non-dairy cattle (\(N_{{{\text{notD}}}}\)) by the CH4 emissions from non-dairy farms \(({\text{EF}}_{{\text{notD }}} )\), i.e.

Empirical model

Because of its flexibility, we used a translog (TL) specification of Eq. (7) in our empirical study; consequently, Eq. (7) defined as a TL input distance function in log form is:

where \(\ln \dot{y}_{m,it}\) is desirable outputs in log \(\left( {m = 1, \ldots ,M} \right). \;\ln \mathop x\limits_{k,it}\) is inputs in log divided by labour input \(\left( {j = 1, \ldots ,J} \right)\) by farms \(\left( {i = 1, \ldots ,N} \right)\) and time \(\left( {t = 1, \ldots ,T} \right)\). \(b_{ht}\) is undesirable outputs (\(= 1, \ldots ,H)\) and capital stocks \(k_{t}\) \(\left( {\ln \dot{k}_{p, it} = \frac{{\ln I_{pt} }}{{X_{1} }},\quad \forall p = 1, \ldots ,P} \right)\). As discussed above \(\mathop {\ln x}\limits_{kt} = \frac{{\ln x_{kt} }}{{X_{1} }},\; \forall k = 2, \ldots ,K\). Greek letters are all variables that must be estimated, and \(D_{t}\) is the time variable to capture the technological change. The white noise error term \((v_{it} )\) representing the usual statistical noise and unexpected stochastic change in a production environment and assumed \(v_{it}^{iid} \sim N\left( {0,\sigma_{v}^{2} } \right)\). \(\omega_{i}\) portrays unobserved heterogeneity and \(u_{it}\) is capturing the effects of technical inefficiency and assumed \(u_{it} \sim N^{ + } (\mu_{it} ,\sigma_{u}^{2}\)). Equation (14) is estimated using Greene's (2005) true fixed-effect model specifications.Footnote 2 The Battese and Coelli (1988) approach is used to calculate eco-efficiency (Eco-TE).

where \({\varvec{\varepsilon}}_{{{\varvec{it}}}} = v_{it} - u_{it}\).

The efficiency change (EC) component is computed as \(= \frac{{ {\text{TE}}_{it} - {\text{TE}}_{it - 1} }}{{0.5\left( { {\text{TE}}_{it} + {\text{TE}}_{it - 1} } \right)}}\).

We compute the returns to scale (RTS) component following Panzar and Willig's (1977) definition, which states that, for many outputs, the economies of scale are equal to the inverse of the sum of all partial cost elasticities, i.e. \({\text{RTS}} = \frac{1}{{\sum \partial \ln x_{1t} /\partial \ln y_{mt} }}\). Following Eq. (10) we estimate the Scale change SC = \(\left( {{\text{RTS}} - 1} \right)\mathop \sum \limits_{j} \lambda_{j}\). Where \(\lambda_{j} = \frac{{\varepsilon_{j} }}{{{\text{RTS}}}}\), and \(\varepsilon_{j}\) are input elasticities estimated from Eq. (14). Additionally, we compute technical change (TC) following Caves et al. (1981) as \({\text{TC}} - \frac{{\partial \ln x_{1} }}{\partial t}\).

Endogeneity problems may arise during the econometric estimate of distance functions (see Sauer and Latacz-Lohmann 2015; Minviel and Sipiläinen 2018). Cuesta and Zofío (2005), on the other hand, claim that implementing the homogeneity criterion indicates that certain regressors are directly impacted by the error term, while others are inversely influenced; consequently, the ratios and product regressors can be deemed exogenous. We imposed homogeneity of degree one in inputs before estimation which implies that \(\mathop \sum \limits_{k = 1}^{K} \beta_{k} = 1\), \(\mathop \sum \limits_{k = 1}^{K} \beta_{kp} = \mathop \sum \limits_{k = 1}^{K} \beta_{kh} = \mathop \sum \limits_{k = 1}^{K} \beta_{km} = 0\) while quadratic symmetric implies \(\beta_{kp} = \beta_{pk}\); \(\beta_{kh} = \beta_{hk}\) \(\beta_{km} = \beta_{mk}\). We impose these restrictions before the estimate. The frontier and efficiency components of Eq. 14 were computed concurrently using farm-level data and maximum likelihood estimation.

Description of the data

Every year NIBIO (Norwegian Institute of Bioeconomy Research) conducted a farm-level survey. The survey collects data on agricultural production and economics from about 1000 farms each year. An unbalanced panel of 6229 observations was selected on 692 Norwegian dairy farms participating in dairy production from 1991 to 2020. To guarantee that dairy farming is the principal farm output, we select farms where dairy product sales account for at least 80% of total farm income (see Alem 2020).

The environmental production technology is modelled by two outputs and four inputs. Desirable output is the overall farm revenue generated by dairy products. Undesirable output (CH4 emission) estimated based on Eqs. 11–13. The value of farm-level CH4 emission was calculated using data from Statistics Norway (SSB 2021). Agricultural land (x1) is measured in hectares and labour (x2) is calculated for all labour inputs. Feed, fuel goods, energy, animal protection fees, and other expenditures are included in the materials (x3). Capital assets (K) include the implicit quantity index calculated by deflating the value of machinery, buildings, and animals at the start of the year.

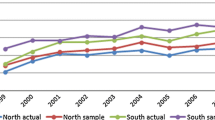

All values are in NOK and have been adjusted to 2015 prices using the consumer price index (CPI). The descriptive statics of the model variables used in the translog functions are shown in Table 1. Furthermore, Figs. 1 and 2 depict the progression of output-input utilization over the last 30 years.

Farms in Norway are small. The yearly average annual dairy revenue was around 1,5 million, which has been increasing over time, resulting in an average annual CH4 emission of 0.99 tonnes and increasing over time. However, because of price differences over time, the average annual CH4 emission value fluctuates (Fig. 1). All production input used in the dairy farm increase over time (Fig. 2). Table 1 shows the descriptive statics of all the input–output used for the analysis.

Estimation results and discussion

Estimation and model specification tests

The Translog function in the empirical model Eq. (14) is estimated using STATA® version 17. Table 2 shows the predicted parameters and related standard errors. A generalised likelihood ratio test (LR) using suggests the suitability of the SFA approach as opposed to OLS (see Schmidt & Lin 1984). The parameter \(\gamma\) \((\gamma\) = 0.94) in Table 2 illustrates the proportion of the departure from the frontier that may be attributed to inefficiency and the remainder to noise (Battese & Corra 1977; Coelli et al. 2005). An LR test rejects a TL to Cobb–Douglas simplification. First-order parameters in the estimated model are positive and significant, proving that the model used in this study satisfies the monotonicity requirement as would be anticipated for a well-behaved function.

Before estimating, all variables are normalized by setting the trend variable to zero and dividing all other variables by their respective means. As a result, the first-order parameters can be considered geometric mean elasticities. For labour, materials, and capital, the input distance elasticity (cost elasticity) was 0.33, 0.27, and 0.15, respectively. The input share of labour was the highest, while the input share of capital was the lowest. Ceteris paribus, if labour utilization in the production system rises by 1%, outputs will rise by around 0.33%. Dairy production will increase by around 0.27% if material prices go up by 1%. If the land increases by 1%, the output will increase by about 0.25%. Elasticities for desirable and undesired outputs were 0.438 and 0.018, respectively. This indicates that if dairy output grows by 1%, production costs (inputs) increase by around 0.44%, ceteris paribus.

Change in GTFP and components

We reported the estimated percentile and components of GTFP in Table 3. The table also illustrates how the farms in the sample are distributed based on their GTFP. GTFP for 1% of the farms was − 0.985 per year, while GTFP was 0.144 per year for 75% of the sample farms. During the period 1991–2020, the average yearly change in the GTFP growth rate in dairy products was 0.032%. The GTFP increases with time (Fig. 3).

Green total factor productivity (GTFP) was not quantified in previous dairy farm performance studies, so our results cannot be directly compared. Research conducted in other nations, which did not consider environmental factors, found different results regarding the change in TFP. For example, Sipiläinen et al. (2013) reported a positive TFP change for Finland and Norway dairy farms, while a survey conducted in 22 European countries reported a decline in TFP change (Madau et al. 2017).

The component of scale change (SC) averaged 0.056% per year during the study period, demonstrating that the scale has a positive impact on the overall change in GTFP. Moreover, the Returns to scale (RTS) averaged 1.84, indicating an increasing return to scale in which output grows in proportion to input increases (Table 3). This demonstrates that Norwegian dairy farmers have not completely tapped into the benefits of scale economics. The efficiency change (EC), which measures the difference in output between observed and best-practice farmers, was − 0.002% each year, resulting in a negative GTFP growth effect. However, from 1991 to 2020, the EC is improving (see Fig. 3).

As shown in Table 3, during the sample period, the technological change (TC) on average was − 0.031% per year, with a slightly accelerating over time (see Fig. 3). Furthermore, According to Wang and Ho (2010), the first-order coefficients of the temporal trend variable provide estimates of the average yearly rate of TC (see also Alem 2018). At the 1% level of significance, the estimated parameter of the trend variable is negative and statistically distinct from zero, indicating a technological regress for Norwegian dairy output over the research period (Table 2. The major reason for regression might be because Norwegian dairy-producing farms are small-scale family farms with milk output quotas. As a result, if economies of scale exist in the manufacturing of dairy-producing technologies, there may be a shift in long-run average dairy farm costs that impacts small farms in the long run.

The non-neutrality of Hicks in technological regress is shown to be a significant interaction parameter with time (t) to input utilization (Table 2). TC has a positive impact on material costs but a negative impact on labour and capital input. As a result, during the research period, TC was not neutral. In terms of scale, the interaction parameter with time for desirable output (t \(\ln y_{1} )\) is negative and statistically significant, implying that the cost-increasing impacts of technical regress weaken as dairy production grows. According to the empirical findings, small-scale dairy farms are more affected by technical regress. The undesirable output ((tlnb) on the other hand is positive but not statistically significant. The detailed yearly mean GTFP and its component score are shown in Table 4 in "Appendix".

Concluding remarks

Existing studies on performance analysis have consequently overlooked the intertemporal element of agricultural emissions. This study varies from the previous one in that it estimates green total productivity (GTFP) and its components in Norwegian dairy farms while accounting for dairy farms' CH4 emissions in the model. We used a farm-level unbalanced panel of 6229 observations from 692 farms for the years 1991 to 2020. We employed a stochastic input distance function with multiple input–output environmental production technologies to estimate GTFP and its components. According to empirical findings, the GTFP change in dairy output grew by 0.032% every year between 1991 and 2020. The increase is mostly due to the positive impact of average scale change (0.035% each year). However, technological change (− 0.031% per year) and efficiency change (− 0.002% per year) result in a negative GTFP growth effect.

Farm green productivity would improve through interventions to improve dairy farm performance and technology use. Within the current Norwegian agricultural policy system, this paper offers two primary measures to boost GTFP in the dairy-producing sector. To begin with, technical change (TC) is the key driver of productivity growth, and it captures the technological transition, which is negative in our empirical research. As a result, for sustainable agricultural development in Norway, policymakers in Norway must prioritize dairy production research and development so that new technology can be developed to reduce dairy farm emissions and improve TC. Furthermore, the analysis shows a negative change in efficiency, showing that farmers are still trailing behind best-practice farmers. As a result, extensive agricultural extension and dissemination effort is required to assist farmers in adapting to contemporary technologies. The article only considered livestock CH4 emissions in its assessment of the GTFP of resources used to promote sustainable agricultural development. Other environmental issues, such as farm emissions of N2O, CO2, NH3, and NO3, may be explored in the future.

Availability of data and materials

Not applicable.

Notes

For example, Labour or capital inputs (e.g. a tractor) may not be fully used. Even if the workers put in their best effort, the farm may not use the improved technology properly because of a lack of training.

In this work, we used the 'true' fixed-effect model rather than the 'true' random-effect model. Estimates show a robust relationship between farm impacts and the regressors (not reported here).

.

References

Alem H (2018) The contribution of productivity and price change to farm-level profitability: a dual approach analysis of crop production in Norway. In: Greene W, Khalaf L, Makdissi P, Sickles R, Veall M, Voia MC (eds) Productivity and inequality. NAPW 2016. Springer Proceedings in Business and Economics. Springer, Cham. https://doi.org/10.1007/978-3-319-68678-3_12

Alem H (2020) Performance of the Norwegian dairy farms: a dynamic stochastic approach. Res Econ 74(3):263–271

Alem H (2021) The role of technical efficiency achieving sustainable development: a dynamic analysis of Norwegian dairy farms. Sustainability 13(4):1841

Alem H, Lien G, Hardaker JB, Guttormsen A (2019) Regional differences in technical efficiency and technological gap of Norwegian dairy farms: a stochastic meta-frontier model. Appl Econ 51(4):409–421

Battese GE, Coelli TJ (1988) Prediction of farm-level technical efficiencies with a generalized frontier production function and panel data. J Econom 38(3):387–399

Battese GE, Corra GS (1977) Estimation of a production frontier model: with application to the pastoral zone of Eastern Australia. Austral J Agric Resour Econ 21(3):169–179

Brümmer B, Glauben T, Thijssen G (2002) Decomposition of productivity growth using distance functions: the case of dairy farms in three European countries. Am J Agric Econ 84(3):628–644

Caves DW, Christensen LR, Swanson JA (1981) Productivity growth, scale economies, and capacity utilization in US railroads, 1955–74. Am Econ Rev 71(5):994–1002

Chambers RG, Fāure R, Grosskopf S (1996) Productivity growth in APEC countries. Pacific Econ Rev 1(3):181–190

Coelli TJ, Rao DSP, O’Donnell CJ, Battese GE (2005) An introduction to efficiency and productivity analysis. Springer, Cham

Cuesta RA, Zofío JL (2005) Hyperbolic efficiency and parametric distance functions: with application to Spanish savings banks. J Prod Anal 24(1):31–48

DNV GL (2018) Global opportunity report 2018, 88 pp. https://www.dnv.com/feature/gor2018.html

FAO and UNSD (2020) System of environmental-economic accounting for agriculture, forestry and fisheries: SEEA AFF. FAO, Rome, Italy. https://doi.org/10.4060/ca7735en

FAO (2020) FAOSTAT emissions shares. http://www.fao.org/faostat/en/#data/EM

Färe R, Grabowski R, Grosskopf S (1985) Technical efficiency of Philippine agriculture. Appl Econ 17(2):205–214

Färe R, Grosskopf S, Zelenyuk V (2008) Aggregation of Nerlovian profit indicator. Appl Econ Lett 15(11):845–847

Farrell MJ (1957) The measurement of productive efficiency. J R Stat Soc Ser A (General) 120(3):253–281

Greene W (2005) Fixed and random effects in stochastic frontier models. J Prod Anal 23(1):7–32

IPCC (2006) Guidelines for national greenhouse gas inventories. Publications - IPCC-TFI (iges.or.jp)

Karagiannis G, Midmore P, Tzouvelekas V (2004) Parametric decomposition of output growth using a stochastic input distance function. Am J Agricul Econ 86(4):1044–1057

Koesling M, Flaten O, Lien G (2008) Factors influencing the conversion to organic farming in Norway. Int J Agric Resour Gov Ecol 7(1):78–95

Kumbhakar SC (1996) Efficiency measurement with multiple outputs and multiple inputs. J Prod Anal 7(2):225–255

Kumbhakar SC, Lien G (2009) Productivity and profitability decomposition: a parametric distance function approach. Food Econ Acta Agric Scand Sect C 6(3–4):143–155

Kumbhakar SC, Lovell CK (2000) Stochastic frontier analysis. Cambridge University Press, Cambridge

Kumbhakar S, Lozano-Vivas A (2005) Deregulation and productivity: the case of Spanish banks. J Regul Econ 27(3):331–351

Kumbhakar SC, Lien G, Flaten O, Tveterås R (2008) Impacts of Norwegian milk quotas on output growth: a modified distance function approach. J Agric Econ 59(2):350–369

Kumbhakar S, Lien G, Hardaker JB (2012) Technical efficiency in competing panel data models: a study of Norwegian grain farming. J Prod Anal 41(2):321–337. https://doi.org/10.1007/s11123-012-0303-1

Kumbhakar SC, Lien G, Hardaker JB (2014) Technical efficiency in competing panel data models: a study of Norwegian grain farming. J Prod Anal 41(2):321–337

Kumbhakar S, Wang H-J, Horncastle A (2015) A practitioner’s guide to stochastic frontier analysis using Stata. Cambridge University Press, Cambridge

Lien G, Kumbhakar SC, Hardaker JB (2010) Determinants of off-farm work and its effects on farm performance: the case of Norwegian grain farmers. Agric Econ 41(6):577–586

Lien G, Kumbhakar SC, Alem H (2018) Endogeneity, heterogeneity, and determinants of inefficiency in Norwegian crop-producing farms. Int J Prod Econ 201:53–61

Lovell CA, Walters LC, Wood LL (1994) Stratified models of education production using modified DEA and regression analysis. In: Data envelopment analysis: theory, methodology, and applications. Springer, Dordrecht, pp 329–351

Madau FA, Furesi R, Pulina P (2017) Technical efficiency and total factor productivity changes in European dairy farm sectors. Agric Food Econ 5(1):1–14

Manos B, Bournaris T, Chatzinikolaou P, Berbel J, Nikolov D (2013) Effects of CAP policy on farm household behaviour and social sustainability. Land Use Policy 31:166–181

Minviel JJ, Sipiläinen T (2018) Dynamic stochastic analysis of the farm subsidy-efficiency link: evidence from France. J Prod Anal 50(1):41–54

NIR (2020) Norwegian Environment Agency 2020 Greenhouse Gas emissions 1990–2018, National Inventory Report (NIR 2020). https://www.miljodirektoratet.no/globalassets/publikasjoner/m1643/m1643.pdf

O’Donnell CJ (2010) Measuring and decomposing agricultural productivity and profitability change. Aust J Agric Resour Econ 54(4):527–560

OECD (2022) OECD environmental performance reviews: Norway 2022. In: OECD environmental performance review. OECD Publishing, Paris. https://doi.org/10.1787/59e71c13-en

Pacini C, Wossink A, Giesen G, Vazzana C, Huirne R (2003) Evaluation of sustainability of organic, integrated, and conventional farming systems: a farm and field-scale analysis. Agric Ecosyst Environ 95(1):273–288

Panzar JC, Willig RD (1977) Economies of scale in multi-output production. Quart J Econ 481–493

Sauer J, Latacz-Lohmann U (2015) Investment, technical change and efficiency: empirical evidence from German dairy production. Eur Rev Agric Econ 42(1):151–175

Schmidt P, Lin T-F (1984) Simple tests of alternative specifications in stochastic frontier models. J Econom 24(3):349–361

Sipiläinen T, Kumbhakar SC, Lien G (2013) The performance of dairy farms in Finland and Norway from 1991 to 2008. Eur Rev Agric Econ 41(1):63–86

SSB (2021) Environmental accounting. Emissions from Norwegian economic activity. Statistics-Norway. https://www.ssb.no/statbank/table/09298/

Wang H-J, Ho C-W (2010) Estimating fixed-effect panel stochastic frontier models by a model transformation. J Econom 157(2):286–296

Wilson GA (2008) From ‘weak’ to ‘strong’ multifunctionality: conceptualising farm-level multifunctional transitional pathways. J Rural Stud 24(3):367–383

Acknowledgements

The Research Council of Norway funded this research for a SYSTEMIC project with project number 299289. The SYSTEMIC project provided funding for this study. The SYSTEMIC project “an integrated approach to the challenge of sustainable food systems: adaptive and mitigatory strategies to address climate change and malnutrition”, Knowledge Hub on Nutrition and Food Security, has received funding from national research funding parties in Belgium (FWO), France (INRA), Germany (BLE), Italy (MIPAAF), Latvia (IZM), Norway (RCN), Portugal (FCT), and Spain (AEI) in a joint action of JPI HDHL, JPI-OCEANS, and FACCE-JPI launched in 2019 under the ERA-NET ERA-HDHL (no. 696295).

Funding

NIBIO and SYSTEMIC project.

Author information

Authors and Affiliations

Contributions

100% Dr. Habtamu Alem. The author have read and approved the final version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

See Table 4.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Alem, H. The role of green total factor productivity to farm-level performance: evidence from Norwegian dairy farms. Agric Econ 11, 2 (2023). https://doi.org/10.1186/s40100-023-00243-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40100-023-00243-0