Abstract

Background

Personal protection measures using insecticide-treated fabric is one of the most effective strategies to prevent the bites of hematophagous insects. Many countries have had success treating fabrics with pyrethroids on an individual level.

Methods

In the current study, a new combination of insecticides, alpha-cypermethrin (ACP) and deltamethrin (DET), has been impregnated on fabric composed of a 50:50 blend of polyester and cotton. Residual and morphological analysis was performed along with the evaluation of physical parameters. Biological evaluations were performed to check the repellency, knockdown, and mortality of insecticide-impregnated fabric (IIF) against bed bugs (Cimex lectularius) using Petri plate assay and mosquitoes (Aedes aegypti and Aedes albopictus) using cone bioassay.

Results

The results showed the repellency of IIF to be 56.6% for C. lectularius and a knockdown percentage of 53.3% and 63.3% for Ae. aegypti and Ae. albopictus, respectively. A > 80% mortality was found for both species of mosquitoes up to 20 cycles of washing with no significant difference (P > 0.05). From high-performance liquid chromatography (HPLC) analysis, the reduction in the contents of ACP and DET after subsequent washes can be correlated with the overall decrease in bioefficacy. ACP and DET remaining in unit gram of fabric after 20 wash cycles were found to be 5.4 mg and 3.1 mg, respectively. By examining the fabric’s surface morphology using scanning electron microscope (SEM) and utilizing energy-dispersive x-ray (EDX) analysis, it was possible to identify the presence of insecticides that were adhered to the fabric. Differential scanning calorimetry (DSC) showed distinctive endothermic peak of insecticide at 98.3 ºC, whereas no change in thermal behavior was observed from thermo-gravimetric analysis (TGA). Furthermore, the physical attributes of IIF provide conclusive evidence for its firmness.

Conclusion

All experimental findings were consistent with the potential use of IIF as a bed bug- and mosquito-repellent fabric to be used against hematophagous infestations. This fabric can serve as a potential strategy to control vector-borne diseases like dengue, malaria, trench fever, etc.

Graphical Abstract

Similar content being viewed by others

Background

Dengue, malaria, Japanese encephalitis, and filariasis are mosquito-borne illnesses that threaten more than 2 billion people worldwide, predominantly in tropical countries [1, 2]. Recent investigations indicate that Aedes spp. mosquitoes have possible significance in disease transmission in India [3,4,5]. Aedes aegypti and Ae. albopictus are the two most common vectors known to transmit several viral diseases like dengue, chikungunya, yellow fever and Zika [6,7,8,9]. In India, 63,280 cases and 44 fatalities caused by dengue were documented in 2022. Since 31 August 2022, 32,653 cases and 32 fatalities have occurred. The media reported a rapid rise in dengue cases in some other states such as Delhi, Uttar Pradesh, Assam, and West Bengal [10]. The most established way to manage insect vector-borne illnesses is the use of repellents [11, 12]. Many commercial insect repellents are unpleasant and ineffectual [13]. A good insect repellent must be long-lasting and effective against all species. The ideal repellent would prevent bites from a wide variety of insect species, be effective for a long time period, cause no skin or mucous membrane irritation, have no systemic toxicity, and be greaseless and odorless [14].

Pyrethroids are synthetically modified plant-based insecticides that differ from the natural analog, pyrethrum, which is obtained from chrysanthemum flowers [15]. Synthetic pyrethroids were first developed in the 1970s, introducing a new era of selective, highly effective, and environmentally friendly insecticides [1]. When deltamethrin was first released onto the market, it was reported to be 100 times more potent than DDT and had the advantage of not building up in the environment [3, 5]. Among the most commercially used pyrethroids, alpha-cypermethrin (ACP) and deltamethrin (DET) are already in use for the management of various insects [2]. Pyrethroids are safe and less toxic to mammals because of their rapid metabolism and large surface area; however, it is 2250 times more toxic to insects because of their smaller size, low body temperature, and excess expression of sensitive sodium channels [16, 17]. If we discuss its mechanism, among the most proposed theories for its repellency, locomotor excitation upon skin contact is considered to be most profound [3, 12]. The insecticidal effect also occurs via spatial contact mainly causing paralysis of the organism by preventing the voltage-gated Na+ channel from repolarizing in the axonal membrane [11].

There have been numerous attempts using various methods to impregnate pyrethroids on fabric. In general, the three most common methods of impregnation are the absorption method, which involves individually treating fabrics by dipping or spraying, the incorporation method, also referred to as “Eulanisierung,” which involves binding insecticides to wool or silk fibers using heat and salt gradients, and the polymer coating method, which is accomplished by specifically polymerizing pyrethroids onto fabrics prior to the tailoring process [18].

Hematophagous insects are those that feed on mammalian blood, such as bed bugs and mosquitoes. These ectoparasites have a long history of having a profound detrimental effect on human civilization. They are known to spread viruses, bacteria, and protozoans, three essential disease-causing organisms [19, 20]. All racial and socio-economic categories are affected by their infestations. The rate of bed bug infestation on human environments has dramatically increased over the past 2 decades as a result of growing international transportation as well as their resistance to chemical insecticides, raising worries about their detrimental effects [21].

Thus, this study has been designed to improve the personal protection by treating a polyester cotton blend fabric with a combination of pyrethroids, i.e., ACP and DET, that is effective against both mosquitoes and bed bugs. Combining cotton and polyester makes the fabric less prone to piling and static. The main advantage of polyester-cotton (PC) blends is that they are cheap and durable; being wrinkle-free, they also do not require ironing [22]. Insecticides like DDT are not suitable for treating fabrics because they act too slowly and allow insects to make contact and escape before they pick up a lethal dose [23,24,25]. The literature suggests that the suspension concentrate of ACP and DET is already used as acceptable treatment for insecticide-treated nets [26]. The bio-efficacy of developed fabric was confirmed by performing in vivo Petri plate assay and cone bioassay. The residual content after consequent wash cycles, surface morphological studies, and physical parameters were also considered to support the bioassay and quality attributes of the developed fabric for prevention of vectors, especially Ae. aegypti and Ae. albopictus species of mosquitoes and Cimex lectularius categories of common bed bugs that can transmit disease pathogens.

Materials and methods

Materials

Insecticides (alpha-cypermethrin and deltamethrin) were procured from Sigma Aldrich, St. Louis, MO, USA; polyvinyl acetate (PVA) (HiMedia Laboratories Pvt. Ltd., Mumbai, India); acetone (Fisher Scientific, Mumbai, India); acetonitrile, methanol, and water (Merck Life Science Pvt. Ltd., Mumbai, India) were procured and used in this study.

Experimental methodology

Preparation of insecticide-impregnated fabric (IIF)

The dipping method was used for the impregnation of insecticides into the fabric. The fabric is a blend of polyester and cotton (50:50). Briefly, 1% w/w of ACP and 2% w/w of DET were dissolved in a pre-mixed solution of acetone with 4% w/v PVA (as a binder). Then, the fabric was dipped into the above solution for 30 min and air dried [18]. The prepared fabric was used for further analysis.

Washing procedure of the fabric samples

The washing technique recommended by the World Health Organization (WHO) was followed with a slight modification [27, 28]. Briefly, 400 ml of 2 g/l detergent solution in distilled water with pH adjusted to 10–11 (0.1 N HCl) was prepared. Samples were soaked and kept in a water bath at 30 ºC for 10 min at 155 rpm. After that, the fabric samples were rinsed twice in deionized water and dried at room temperature. The same procedure was repeated for further washes [29].

Residual analysis of IIF using high-performance liquid chromatography (HPLC)

Insecticide extraction procedure from the fabric sample

In this experiment, the ultrasonication method was used for the extraction of insecticides from fabric samples. Briefly, fabric samples were cut into ~ 1 g (8 cm × 8 cm) randomly from three different areas. It was chopped and soaked in a conical flask containing 7 ml extraction solvent (acetonitrile). Then flasks were heated at 75 °C in a water bath for 20 min with continuous shaking. Then, it was allowed to cool down to room temperature. Furthermore, the conical flasks were placed in an ultrasonic water bath and sonicated for 20 min at 30 °C. The supernatant was collected, filtrated using nylon filter (0.22 µm), and injected into HPLC for further analysis [30, 31].

Preparation of calibration curve and insecticidal residual analysis

Individual stock solutions of 1000 µg/ml were prepared for ACP and DET in acetonitrile. The calibration curves were prepared by diluting stock solutions with final concentrations of 2, 4, 6, 8, and 10 µg/ml. The chromatographic separations were performed on Thermo Scientific HPLC (Dionex Ultimate 3000, GmbH, Germany) coupled with Agilent reverse phase column (C18), 3.5 µm, and 4.6 × 250 mm with variable wavelength detector. For determination of maximum wavelength (λmax), 10 µg/ml solutions of each standard insecticide were scanned from 200–400 nm in a UV–VIS spectrophotometer (Cecil Instrumentation Services Ltd. C≡7200 series). The chromatographic experiments were performed under isocratic elution according to Additional file 1: Table S1. The amounts of ACP and DET contained in the extraction solvents were quantified according to their respective calibration curve generated using HPLC.

Surface morphology study using SEM and EDX

The surface morphologies of the IIF and control fabric were examined using a scanning electron microscope (SEM), JEOL JSM-6390LV, at an accelerating voltage of 15 kV. Representative electron micrographs were obtained, and the individual particles in a selected area were counted with data magnification of 50×, 200×, 500×, and 1000×. Scanning electron microscope (SEM) equipped with energy-dispersive x-ray (EDX) spectroscopy for surface elemental composition analysis was utilized for this purpose [32].

DSC-TGA analysis

Differential scanning calorimetry (DSC) and thermo-gravimetric analysis (TGA) were conducted using a PerkinElmer STA 6000 apparatus using samples of 2.5 mg of control fabric and 2.6 mg of IIF placed in a micro-perforated ceramic pan for internal pressure control to completely remove the water and other volatile substances from the testing pans. The test was conducted starting from an initial temperature of 30 °C to 600 °C at 10 °C/ min rise under 10 ml/min N2 flux [33].

Physical properties of fabrics

Flexural rigidity

The fabric bending length is calculated using a stiffness tester (Sri Balaji Chemicals & Instruments, Ashok Vihar, Delhi, India). At first, the overhanging length was obtained when the tip of the specimen (25 × 200 mm) had just reached a plane passing though the edge of the platform and was inclined at an angle of 41.5° below the horizontal. Then, flexural rigidity was calculated from the value of the bending length and weight per meter square area of the fabric (GSM) [34].

where W = fabric weight in grams per meter square area and C = bending length of specimen in mm.

Bursting strength (BS)

Bursting strength of the fabric was measured using a diaphragm hydraulic bursting strength tester (Sri Balaji Chemicals & Instruments, Ashok Vihar, Delhi, India). Three circular fabric specimens (≥ rubber diaphragm area 100 cm2) were taken from three different places on the whole fabric sample and tested by applying the force via diaphragm with an increasing order until the specimens burst. The results were reported in the form of mean ± standard deviation. A similar procedure was followed for the control fabric as well as for the IIF after several washes.

Bursting index (BI)

The bursting index is calculated as bursting strength per GSM of the fabric samples.

Tex

Ten yarn samples were taken from both warp and weft directions (each 50 cm), and individual weights were recorded. The Tex values were calculated with the help of the following formula.

pH

Three pieces of fabric samples (0.5 cm × 0.5 cm) along with 100 ml distilled water were taken for fabric pH testing. All samples were placed in distilled water and shaken for 1 h. pH was measured using a digital pH meter (Oakton EUTECH Instruments), and values were recorded [35]. Studies were performed in triplicate, and results were reported as mean ± standard deviation.

In vivo studies

Petri plate assay

Plastic Petri plates of 8.5 cm diameter and 1.4 cm height were used to quickly evaluate the comparative repellency of untreated and IIF against bed bugs (C. lectularius) [maintained at Defence Research Laboratory (DRL), DRDO, Assam; maintained at room temperature of 25–28 °C, humidity 60 ± 15%, and 12:12 h photo period)]. Petri plate surface was divided into two equal halves; one half was covered with IIF and the other with control fabric. Ten bed bugs (7 days unfed adults) were released in the center of each Petri plate. The numbers of bed bugs present on each side of the plates were recorded after 24 h and calculated for percentage repellency [36]. Experiments were performed after the 0, 1st, 2nd, 5th, 10th, and 20th wash cycles in triplicate, and results were reported as mean ± standard deviation. The percentage repellency was calculated using the following formula.

Here, NC = number of bed bugs on control fabric, NIIF = number of bed bugs on IIF, and NT = total number of bed bugs.

Cone bioassay

Mosquitoes (Ae. aegypti and Ae. albopictus) were reared at the Defence Research Laboratory, DRDO, Assam; maintained in a temperature range of 25–28 ºC, relative humidity 60 ± 15%, and 12:12 h photo-period. Larval stages were maintained in plastic trays (5 l) with (1:1) yeast powder and PUREPET™, Abis Exports (I) Pvt. Ltd., Chhattisgarh, India, as larval food source. Adult mosquitoes emerged from pupae were then maintained in wooden cages (30 × 30 × 30 inches) and provided with cotton soaked in 10% sugar solution.

The cone bioassay was performed according to WHO 2005 protocol. Ten non-blood-fed 2–5-day-old females were exposed to IIF and control fabric under a standard WHO cone for 3 min [37, 38]. Later, the exposed mosquitoes were transferred to a small cup (6.5 × 8.5 cm) with access to sugar solution and observed for their knockdown at 15, 30, and 60 min followed by mortality after 24 h of exposure [39]. Experiments were performed after the 0, 1st, 2nd, 5th, 10th, and 20th wash cycles in triplicate, and results were reported in the form of mean ± standard deviation.

Results

The results showed that alpha-cypermethrin and deltamethrin-impregnated PC blend fabric was effective in repelling bedbugs (C. lectularius) and mosquitoes (Ae. aegypti and Ae. albopictus), also maintaining its various physical properties like stiffness, GSM, bursting strength, bursting index, etc., at different time intervals after different cycles of washings.

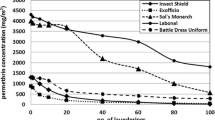

Insecticide residual analysis of IIF by HPLC after different wash cycles

The results of wavelength maxima for ACP and DET were found to be 277 nm and 268 nm, respectively (Fig. 1). Various aliquot concentrations were used to make the standard curves (Fig. 2). The retention times were 5.8 min and 5.0 min for ACP and DET, respectively. From the standard curves obtained, the calculations for insecticide residues were done, and the results for 0, 1st, 2nd, 5th, 10th, and 20th washes were reported in Table 1 and graphically representated in Fig. 3.

SEM and EDX analysis of control fabric and IIF

SEM was used to study the structural morphology of the fabric samples. The results have been shown for the control fabric as well as IIF. The samples were scanned with separate magnification at 50×, 200×, 500×, and 1000×. The SEM micrographs of control fabric and IIF are shown in Fig. 4. A clear distinction can be made on IIF that shows depostion of particles on the surface of the fabric, which are indicated by arrowheads. Additionally, the EDX spectra have been shown for both the control and IIF (Fig. 5). The EDX spectrum of control fabric shows the presence of only carbon and oxygen, whereas IIF shows the presence of carbon, oxygen, nitrogen, chlorine, and bromine.

DSC-TGA analysis of control fabric and IIF

DSC-TGA analysis of control fabric and IIF has been shown in Figs. 6 and 7. The DSC thermogram of control fabric and IIF showed characteristic endothermic peaks. For control fabric, it showed peaks at 252 °C, 363 °C, and 450 °C, and for IIF, the endothermic peaks were found at 98.3 °C, 255.5 °C, and 443.8 °C. The TGA curve also showed a similar curve pattern for both control fabric and IIF. For control fabric, initial mass loss was observed after 260 °C. The mass loss up to 369 °C was 49.2%. A second mass loss was observed after 369 °C to 444 °C, which was 75.1%. As the temperatures rose to 600 ºC, final mass loss was found to be 91.0%. For IIF, initial mass loss was observed after 260 ºC. The mass loss to 369 °C was 43.4%, and a second mass loss was observed after 369 °C to 444 °C, which was 80.7%. As the temperatures rose to 600 °C, the final mass loss was 94.8%.

Physical properties of control fabric and IIF

The results of physical parameters are presented in the form of mean ± standard deviation in Table 2. The fabric GSM and flexural rigidity were found to increase after insecticide impregnation. For control fabric, the values were 169.09 ± 0.85 g/m2 and 21.81 ± 2.52 µNm, whereas the same for IIF at zero wash were 172.50 ± 1.41 g/m2 and 49.80 ± 2.92 µNm, respectively; this further reduced to 169.36 ± 0.65 g/m2 and 12.96 ± 1.62 µNm for IIF after the 20th wash. The pH of the fabric was found to be near neutral within 7.03 ± 0.12 to 7.47 ± 0.06. The bursting strength and bursting index for control fabric were 15.07 ± 0.47 KN and 0.0891 ± 0.0032 KN.m2/gm whereas the same for IIF at zero wash were found to be 15.10 ± 0.6KN and 0.0876 ± 0.004 KN.m2/gm, respectively. This further reduced to 13.76 ± 0.72 KN and 0.0813 ± 0. 0044 KN.m2/gm at the 20th wash.

Petri plate assay for repellency of bed bugs

The results of Petri plate assay are represented in Table 3. At zero wash, the percentage repellency of IIF against bed bugs (C. lectularius) was 80.0% after 24 h of exposure, which gradually decreased to 56.7% after the 20th wash. The results are graphically represented in Fig. 8.

Cone bioassay for knockdown and mortalities of mosquitoes

The results of cone bioassay for the percent knockdown of Ae. aegypti and Ae. albopictus mosquitoes exposed to IIF after different cycles of washings at different time points are shown in Fig. 9. IIF without any washing could produce a percentage knockdown of about 23.3%, 73.3%, and 86.6% for Ae. aegypti mosquitoes and 43.3%, 76.6%, and 100% for Ae. albopictus mosquitoes at 15, 30, and 60 min post-exposure, respectively. Also, a percentage knockdown of > 50% and > 60% post-exposure (60 min) was observed in case of Ae. aegypti and Ae. albopictus mosquitoes respectively up to 20 cycles of washings. A mortality rate of around 80.0% was observed for both after 24 h of exposure. The mortality pattern of Ae. aegypti and Ae. albopictus mosquitoes exposed to IIF has been shown in Table 4. The results were statistically evaluated using one-way ANOVA followed by Tukey’s multiple comparison test using GraphPad Prism 7.00.

Cone bioassay of insecticide-impregnated fabric (IIF) at different wash cycles against Aedes aegypti mosquitoes (a) and Ae. albopictus (b). The percentage knockdown/mortality observed up to 24 h (1440 min). Each value is represented as mean ± standard deviation. The values were non-significant, P > 0.05 (one-way ANOVA followed by Tukey’s multiple comparison test)

Discussion

Many insect repellent formulations have been documented and marketed to date, but only a few are available that can show promising effective repellency throughout the complete shelf life. Unlike traditional formulations, which demand topical administrations and require extra efforts, this study was focused upon a unique fabric-oriented impregnation method as an alternate method to resist those disease spreading vectors in a more effortless and convenient way. We demonstrated that IIF is effective enough to repel lab-reared Ae. albopictus and Ae. aegypti mosquitos and also has sufficient repellency against laboratory-reared common bed bugs (C. lectularius) up to 20 launderings. According to recent research studies, bed bugs can also be effective vectors for infections including Bartonella quintana and Trypanosoma cruzi [40]. Aedes spp. are widely recognized for transmitting dengue fever in many areas across the globe. Climate change has also contributed to mosquito range extension and pesticide resistance; hence, minimal insecticide exposure is suggested in anti-mosquito activities [41]. Personal protection by impregnating insecticides on a fabric is one of the successful methods for repelling and preventing bites from various hematophagous insects like mosquitoes, tsetse, mites, ticks, etc. [15, 18, 42,43,44,45]. The previous literature shows that pyrethroids can serve as a potent spatial repellant producing excito-repellency of mosquitoes and bed bugs. In fact, both ACP and DET at particular concentrations can elicit behavioral avoidance leading to inhibition of blood feed and eventually resulting in termination of the insects [42, 44, 46].

In this study, insecticides were impregnated on a polyester cotton (PC) blend fabric using the dipping method. The impregnated fabrics were evaluated for their potential in repelling bed bugs (C. lectularius) and mosquitoes (Ae. aegypti and Ae. albopictus) along with their physical properties at various time intervals after different cycles of washing. The results from in vivo assays were consistent with the previous findings. In the Petri plate assay, the bed bugs were given equal opportunity to move to two equal halves of the Petri plates containing untreated as well as impregnated fabric. The Petri plate assay using DEET-impregnated fabric performed by Wang et al. in 2013 showed this to be a fast and simple method for studying the repellency of bed bugs [47]. Many herbal and essential oil-based formulations are currently available on the market but due to their short duration of action (lasting up to 8–12 h) the applicability is limited; contrarily our developed IIF will be effective for a relatively longer period of time, up to a few months (minimum of 20 washing cycles) [48]. In the current study by utilizing a similar assay protocol, the repellency was found to be 80% after 24 h of exposure for unwashed fabric and gradually deceased to 56.6% after the 20th wash. A cone bioassay was performed adopting WHO guidelines (WHO 2005), which revealed the percentage knockdown and mortalities of mosquitoes up to 60 min and 24 h post exposure [38]. The percentage knockdown decreased after successive washes but was still capable of causing > 50% knockdown after the final wash. As compared to a previous study conducted by Sukumaran et al., in 2014, a 100% mortality rate was observed up to the 25th washing cycle, which further decreased after subsequent washes [49]. Contrarily, 83.3% mortality was seen in the present study against both species of mosquitoes, and the values were found to be non-significant (P > 0.05). The slight decrease in mortality rate can be attributed to the manual dipping method [18].

The residual analysis was performed to quantify the contents of insecticides remaining after different wash cycles. For this, the WHO procedure was adopted for washing, followed by ultrasonic extraction method. The extraction was performed at a constant temperature of 75 ºC with continuous stirring using acetonitrile as an extraction solvent. The temperature was chosen as such because of the presence of a binder (PVA) used in the fabric which melts above 70 ºC [50]. The optimized chomatographic conditions used in the study for individual insecticides are given in Additional file 1: Table S1. The chomatograms showed good separation peaks for both ACP and DET. From the results of insecticide residual analysis, 85.9% reduction in the content of DET and 40.7% reduction in the concentration of ACP were found after 20 washes. These reductions in the residual contents can correspond to the overall reduction of in vivo bioefficacy of IIF tested against both mosquitoes and bed bugs.

For the surface morphology, SEM and EDX analyses are considered to be the evaluation methods that can indicate successful impregnation [49, 51]. The SEM micrographs of control and IIF (Fig. 4) show clear deposition of insecticidal agents between the fibers. The elemental analysis of IIF performed using EDX (Fig. 5) further shows the identification lines for the large emission energies of elements as evident from the spectrum. As structural skeleton of ACP and DET contains chlorine, bromine, and nitrogen atoms in addition to carbon and oxygen. Thus, the appearance of these particular elements suggests the presence of alpha-cypermethrin (C22H19Cl2NO3) and deltamethrin (C22H19Br2NO3) being impregnated on the fabric. In the control sample, however, no such elements were observed.

The DSC-TGA analysis was performed to observe the changes in heat capacity resulting from endothermic and exothermic transitions along with the thermal degradation behavior of the control fabric and IIF. For IIF, a distinguishable endothermic peak was observed at 98.3 °C, which may be due to the presence of pyrethroids. From TGA thermograms, the initial mass loss was observed beyond 260 ºC, which may be due to initiation of polyester fiber melting. After this, two mass loss steps were observed, one at around 340–370 °C (40–50%), which may have been due to cotton fiber degradation, and the other at around 440–455 °C (70–80%), which was due to the final degradation of polyester fibers from the fabric samples [52]. As the temperature rose up to 600 °C, final weight loss was observed by 90–95%. Total weight losses of the samples were identified, and the decomposition of control fabric was found to be slightly lower than in the test. Thus, from the DSC-TGA analysis, the significant endothermic peak and weight loss pattern show successful impregnation and do not cause any hindrance to the thermal properties of the fabric [41].

Concerning the physical properties, the GSM values of the fabric increased after impregnation because the insecticides adhered to the surface of the fabric [53,54,55,56]. In the current study, the GSM value of unwashed IIF was found to be increased compared with the control sample. According to the ISO-specified requirement of standard pH, the direct use fabric should be within the range of 4.0–7.5 [35]. Higher or lower values not only affect the performance of the textile but also may harm human health. No such deviations of pH were observed in the fabric after impregnation, while the bursting strength, which is usually a determining parameter of specimen’s integrity, slightly decreased after each washing. Similarly, fabric stiffness was also observed to be decreased because of reduction of inter-yarn friction within the fabric. The binder used in the impregnation was known to cause a small reduction in the fiber lubrication, which was also observed in the present study [57]. The flexural rigidity of a fabric generally depends on the yarn properties. The initial increase in the value may be attributed to the deposition of insecticides and polymer solution, which reduces the internal friction of the fibers [58]. Additional decrease after subsequent washes can be due to the loss of active ingredients and fibers protruding from fabric surfaces [35].

Conclusion

In conclusion, the insecticide-impregnated fabric (IIF) can serve as a potential barrier to pathogenic vectors with a good durability and long-lasting property. This may be attributed to the incorporation of pyrethroids in combination, which provides the optimum efficacy; this is conclusively supported by the values found from the present study. Future studies could be interesting to look for other target vectors to evaluate their repellant characteristics.

Availability of data and materials

All data generated or analyzed during this study are included in the final manuscript.

Abbreviations

- ACP:

-

Alpha-cypermethrin

- DET:

-

Deltamethrin

- IIF:

-

Insecticide-impregnated fabric

- HPLC:

-

High-performance liquid chromatography

- SEM:

-

Scanning electron microscopy

- EDX:

-

Energy-dispersive x-ray

- DSC:

-

Differential scanning calorimetry

- TGA:

-

Thermo-gravimetric analysis

- PC:

-

Polyester cotton

- PVA:

-

Polyvinyl acetate

- WHO:

-

World Health Organization

- RPM:

-

Rotations per minute

- GSM:

-

Gram per square meter

- ANOVA:

-

Analysis of variance

- DEET:

-

N, N-Diethyl-meta-toluamide

- ISO:

-

International Organization for Standardization

References

Gaber M, Ahmad AA, El-Kady AM, Tolba M, Suzuki Y, Mohammed SM, et al. Dengue fever as a reemerging disease in upper Egypt: Diagnosis, vector surveillance and genetic diversity using RT-LAMP assay. PLoS ONE. 2022;17:1–12. https://doi.org/10.1371/journal.pone.0265760.

Rezza G. Aedes albopictus and the reemergence of dengue. BMC Public Health. 2012;12:72. https://doi.org/10.1186/1471-2458-12-72.

Velusamy D, Jayakumar S, Ramakrishnan V, Veeramanoharan R, Gupta B, Paramasivan R, et al. Epidemiological and demographic characteristics of dengue and chikungunya infections over five years from 2014–2018, in Tamil Nadu, India. Int J Community Med Public Health. 2021;8:2287. https://doi.org/10.18203/2394-6040.ijcmph20211747.

Banerjee S, Aditya G, Saha GK. Pupal productivity of dengue vectors in Kolkata, India: Implications for vector management. Indian J Med Res. 2013;137:549–59.

Dutta P, Khan SA, Khan AM, Borah J, Chowdhury P, Mahanta J. First evidence of chikungunya virus infection in Assam, Northeast India. Trans R Soc Trop Med Hyg. 2011;105:355–7. https://doi.org/10.1016/j.trstmh.2011.02.004.

Corbel V, Durot C, Achee NL, Chandre F, Coulibaly MB, David JP, et al. Second WIN International Conference on integrated approaches and innovative tools for combating insecticide resistance in vectors of arboviruses, October 2018, Singapore. Parasites Vectors. 2019;12:1–19. https://doi.org/10.1186/s13071-019-3591-8.

Chareonviriyaphap T, Bangs MJ, Suwonkerd W, Kongmee M, Corbel V, Ngoen-Klan R. Review of insecticide resistance and behavioral avoidance of vectors of human diseases in Thailand. Parasites Vectors. 2013;6:1–28. https://doi.org/10.1186/1756-3305-6-280.

Chadee DD. Resting behaviour of Aedes aegypti in Trinidad: With evidence for the re-introduction of indoor residual spraying (IRS) for dengue control. Parasites Vectors. 2013;6:2–7. https://doi.org/10.1186/1756-3305-6-255.

Thanispong K, Achee NL, Bangs MJ, Grieco JP, Suwonkerd W, Prabaripai A, et al. Irritancy and repellency behavioral responses of thee strains of Aedes aegypti exposed to DDT and α-cypermethin. J Med Entomol. 2009;46:1407–14. https://doi.org/10.1603/033.046.0622.

Prajapati AK, Singh NP, Jain PK, Srivastava DK, Prajapati R. Dengue in India: an overview. Nat J Community Med. 2022;13:49–57. https://doi.org/10.5455/njcm.20211204035455.

Hazarika S, Dhiman S, Rabha B, Bhola R, Singh L. Repellent activity of some essential oils against simulium species in India. J Insect Sci. 2012;12:1–9. https://doi.org/10.1673/031.012.0501.

Kalyanasundaram M, Mathew N. N, N-diethyl phenylacetamide (DEPA): a safe and effective repellent for personal protection against hematophagous arthopods. J Med Entomol. 2006;43:518–25. https://doi.org/10.1093/jmedent/43.3.518.

Revay EE, Junnila A, De XR, Kline DL, Bernier UR, Kravchenko VD, et al. Evaluation of commercial products for personal protection against mosquitoes. Acta Trop. 2013;125:226–30. https://doi.org/10.1016/j.actatropica.2012.10.009.

Fradin MS. Mosquitoes and mosquito repellants: a clinician’s guide. Ann Intern Med. 1998;128:931–40. https://doi.org/10.7326/0003-4819-128-11-199806010-00013.

Faulde MK, Uedelhoven WM, Robbins RG. Contact toxicity and residual activity of different permethin-based fabric impregnation methods for Aedes aegypti (Diptera: Culicidae), Ixodes ricinus (Acari: Ixodidae), and Lepisma saccharina (Thysanura: Lepismatidae). J Med Entomol. 2003;40:935–41. https://doi.org/10.1603/0022-2585-40.6.935.

Bradberry SM, Cage SA, Proudfoot AT, Vale JA. Poisoning due to pyrethroids. Toxicol Rev. 2005;24:93–106. https://doi.org/10.2165/00139709-200524020-00003.

Costa LG. The neurotoxicity of organochlorine and pyrethoid pesticides. Handb Clin Neurol. 2015;131:135–48. https://doi.org/10.1016/B978-0-444-62627-1.00009-3.

Faulde MK, Uedelhoven WM, Malerius M, Robbins RG. Factory-based permethin impregnation of uniforms: residual activity against Aedes aegypti and Ixodes ricinus in battle dress uniforms worn under field conditions, and cross-contamination during the laundering and storage process. Mil Med. 2006;171:472–7. https://doi.org/10.7205/MILMED.171.6.472.

Silva-Cardoso L, Dias FA, Fampa P, Pereira MG, Atella GC. Evaluating the effects of anticoagulants on Rhodnius prolixus artificial blood feeding. PLoS ONE. 2018;13:1–15. https://doi.org/10.1371/journal.pone.0206979.

Akhoundi M, Bruel C, Izri A. Harmful effects of bed bug-killing method of diatomaceous earth on human health. J Insect Sci. 2019;19:2018–9. https://doi.org/10.1093/jisesa/iez095.

Hwang SW, Svoboda TJ, De Jong IJ, Kabasele KJ, Gogosis E. Bed bug infestations in an urban environment. Emerg Infect Dis. 2005;11:533–8. https://doi.org/10.3201/eid1104.041126.

Saade H, De Leon-Gomez RD, Treviño ME, Rodriguez-Fernandez OS, Soriano-Corral F, Borjas JJ, et al. Performance of cotton, cotton-polyester, and polyester-elastane fabrics impregnated with ultrafine polymeric nanoparticles loaded with lavender oil. J Nanomater. 2021;2021:1–10. https://doi.org/10.1155/2021/6665327.

Bomzan DP, Bhavya ML, Chandu AGS, Manivannan S, Lavanya G, Ramasamy K, et al. Potential of pyrethoid-synergised pyrethum on stored product insects and implications for use as prophylactic sprays. J Food Sci Technol. 2018;55:2270–8. https://doi.org/10.1007/s13197-018-3144-8.

Mosha FW, Lyimo IN, Oxborough RM, Matowo J, Malima R, Feston E, et al. Comparative efficacies of permethin-, deltamethrin- and α-cypermethin-treated nets, against Anopheles arabiensis and Culex quinquefasciatus in northern Tanzania. Ann Trop Med Parasitol. 2008;102:367–76. https://doi.org/10.1179/136485908X278829.

WHO. Vector control: methods for use by individuals and communities, prepared by Jan A. Rozendaal. World Health Organization. 1997. https://apps.who.int/iris/handle/10665/41968. Accessed 18–30 Sept 2022.

Zaim M, Aitio A, Nakashima N. Safety of pyrethoid-treated mosquito nets. Med Vet Entomol. 2000;14:1–5. https://doi.org/10.1046/j.1365-2915.2000.00211.x.

Oxborough RM, Weir V, Irish S, Kaur H, N’Guessan R, Boko P, et al. Is K-O Tab 1–2-3® long lasting on non-polyester mosquito nets? Acta Trop. 2009;112:49–53. https://doi.org/10.1016/j.actatropica.2009.06.005.

WHO. Guidelines for laboratory and field-testing of long-lasting insecticidal nets. 2013. https://apps.who.int/iris/handle/10665/80270. Accessed 18–30 Sept 2022.

WHO. Report of the seventeenth WHOPES working group meeting. WHO/HQ, GENEVA. 15–19 September 2014. 2014. https://apps.who.int/iris/bitstream/handle/10665/137514/9789241508032_eng.pdf?sequence=1. Accessed 18–30 Sept 2022.

Dieval F, Bouyer J, Fafet JF. An improved extraction method for surface dosage of insecticides on treated textile fabrics. Malar J. 2017;16:1–10. https://doi.org/10.1186/s12936-016-1647-1.

Rezic I. Optimization of ultrasonic extraction of 23 elements from cotton. Ultrason Sonochem. 2009;16:63–9. https://doi.org/10.1016/j.ultsonch.2008.04.007.

Ibrahim NA, Eid BM, El-Aziz EA, Abou Elmaaty TM, Ramadan SM. Multifunctional cellulose-containing fabrics using modified finishing formulations. RSC Adv. 2017;7:33219–30. https://doi.org/10.1039/C7RA05403C.

Manich A, Alonso C, Perez-Rentero S, Coderch L, Marti M. Thermal analysis (DSC, TGA ) of textile flame retardants with lower environmental impact. In: Proceedings of the 19th World Textile Conference-Autex. 2019.

Morton WE. The textile institute. Nature. 1952;169:786. https://doi.org/10.1038/169786a0.

Tebeta RT, Ahmed NA, Fattahi AM. Experimental study on the effect of compression load on the elastic properties of HDPE/SWCNTs nanocomposites. Microsyst Technol. 2021;27:3513–22. https://doi.org/10.1007/s00542-020-05098-9.

Gangloff-Kaufmann J, Hollingsworth C, Hahn J, Hansen L, Kard B, Waldvogel M. Bed bugs in America: a pest management industry survey. Am Entomol. 2006;52:105–6.

Gray L, Florez SD, Barreiro AM, Vadillo-Sanchez J, Gonzalez-Olvera G, Lenhart A, et al. Experimental evaluation of the impact of household aerosolized insecticides on pyrethoid resistant Aedes aegypti. Sci Rep. 2018;8:1–11. https://doi.org/10.1038/s41598-018-30968-8.

Allossogbe M, Gnanguenon V, Yovogan B, Akinro B, Anagonou R, Agossa F, et al. WHO cone bio-assays of classical and new-generation long-lasting insecticidal nets call for innovative insecticides targeting the knock-down resistance mechanism in Benin. Malar J BioMed Central. 2017;16:1–11. https://doi.org/10.1186/s12936-017-1727-x.

Debboun M, Strickman D. Insect repellents and associated personal protection for a reduction in human disease. Med Vet Entomol. 2013;27:1–9. https://doi.org/10.1111/j.1365-2915.2012.01020.x.

Lai O, Ho D, Glick S, Jagdeo J. Bed bugs and possible transmission of human pathogens: a systematic review. Arch Dermatol Res. 2016;308:531–8. https://doi.org/10.1007/s00403-016-1661-8.

Chattopadhyay P, Dhiman S, Devi KA, Banerjee S, Rabha B, Chaurasia A, et al. Ultra low concentration deltamethrin loaded patch development and evaluation of its repellency against dengue vector Aedes (S) albopictus. Parasites Vectors. 2013;6:1–10. https://doi.org/10.1186/1756-3305-6-284.

Vaughn MF, Meshnick SR. Pilot study assessing the effectiveness of long-lasting permethin-impregnated clothing for the prevention of tick bites. Vector Borne Zoonotic Dis. 2011;11:869–75. https://doi.org/10.1089/vbz.2010.0158.

Williams K, Willis MS. Bedbugs in the 21st century: the reemergence of an old foe. Lab Med. 2012;43:141–8. https://doi.org/10.1309/LM1TBJG6S7USSKEN.

Pennetier C, Chabi J, Martin T, Chandre F, Rogier C, Hougard JM, et al. New protective battle-dress impregnated against mosquito vector bites. Parasites Vectors. 2010;3:1–7. https://doi.org/10.1186/1756-3305-3-81.

Faulde MK, Albiez G, Nehing O. Insecticidal, acaricidal and repellent effects of DEET-and IR3535-impregnated bed nets using a novel long-lasting polymer-coating technique. Parasitol Res. 2010;106:957–65. https://doi.org/10.1007/s00436-010-1749-6.

Sathantriphop S, Paeporn P, Ya-Umphan P, Mukkhun P, Thanispong K, Chansang C, et al. Behavioral action of deltamethrin and cypermethin in pyrethoid-resistant Aedes aegypti (Diptera: Culicidae): implications for control strategies in Thailand. J Med Entomol. 2020;57:1157–67. https://doi.org/10.1093/jme/tjaa019.

Wang C, Lu L, Zhang A, Liu C. Repellency of selected chemicals against the bed bug (Hemiptera: Cimicidae). J Econ Entomol. 2013;106:2522–9. https://doi.org/10.1603/EC13155.

Dhiman S, Rabha B, Chattopadhyay P, Das NG, Hazarika S, Bhola RK, et al. Field evaluation of repellency of a polyherbal essential oil against blackflies and its dermal toxicity using rat model. Trop Biomed. 2012;29:391–7.

Sukumaran D, Sharma AK, Wasu YH, Pandey P, Tyagi V. Knockdown and repellent effect of permethin-impregnated army uniform cloth against Aedes aegypti after different cycles of washings. Parasitol Res. 2014;113:1739–47. https://doi.org/10.1007/s00436-014-3819-7.

Huang X, Guo Q, Zhou P, Lu C, Yuan G, Chen Z, et al. Poly(vinyl alcohol)/artificial marble wastes composites with improved melt processability and mechanical properties. Compos Part B Eng. 2020;182:107628. https://doi.org/10.1016/j.compositesb.2019.107628.

Specos MMM, Garcia JJ, Tornesello J, Marino P, Vecchia DM, Tesoriero DMV, et al. Microencapsulated citronella oil for mosquito repellent finishing of cotton textiles. Trans R Soc Trop Med Hyg. 2010;104:653–8. https://doi.org/10.1016/j.trstmh.2010.06.004.

Manich AM, Perez-Rentero S, Alonso C, Coderch L, Marti M. Thermal analysis of healthy and ecological friendly flame retardants for textiles. Kn Eng. 2020;2020:129–41. https://doi.org/10.18502/keg.v5i6.7028.

Prasad RK, Shahid MA, Dulal M. A comparative study between one bath dyeing method for Polyester Cotton (PC) blended fabric over conventional two bath dyeing method. Eur Sci J. 2015;11:270–80.

Chowdhury KP, Chowdhury S, Hosain MA, Mamun Al A, Alahi SN, Rahman MS. Comparative enactment of fluorocarbon-free and fluorocarbon-based water repellent finishes on cotton single jersey fabrics. Int J Curr Eng Technol. 2018;8:393–9. https://doi.org/10.14741/ijcet/v.8.2.34.

Chowdhury KP. Effect of special finishes on the functional properties of cotton fabrics. J Text Sci Technol. 2018;04:49–66. https://doi.org/10.4236/jtst.2018.42003.

Yildiz Z, Gungor A, Onen A, Usta I. Synthesis and characterization of dual-curable epoxyacrylates for polyester cord/rubber applications. J Ind Text. 2016;46:596–610. https://doi.org/10.1177/1528083715594980.

Nampi PP, Kume S, Hotta Y, Watari K, Itoh M, Toda H, et al. The effect of polyvinyl alcohol as a binder and stearic acid as an internal lubricant in the formation, and subsequent sintering of spray-dried alumina. Ceram Int. 2011;37:3445–50. https://doi.org/10.1016/j.ceramint.2011.05.149.

Gorensek M, Bukosek V. Zinc and alginate for multipurpose textiles. Acta Chim Slov. 2006;53:223–8.

Acknowledgements

The authors thank Dr. Dev Vrat Kamboj, Director, Defence Research Laboratory (DRL), DRDO, Tezpur, Assam, for providing infrastructural facilities and adequate resources for conducting this research work.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

All the authors have contributed significantly to this study. PC, DG and YB conceptualized, helped in resource management and supervised this article. AK and PD have performed the analytical experimentation and morphological studies. AB and BS have performed the bio-assay and physical parameter testing of the prepared IIF. SK1 and SK2 have helped in the resource provision and investigation part. AK and PD have prepared and revised the original manuscript. PC critically reviewed the final manuscript. The opinions contained herein are the personal views of the authors only and are not to be considered as official views of the Defence Research Laboratory (DRL), DRDO, Government of India. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Additional file 1:

Table S1. HPLC chromatographic conditions for ACP and DET.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Kakati, A., Banerjee, A., Das, P. et al. Development of insecticide-impregnated polyester/cotton blend fabric and assessment of their repellent characteristics against Cimex lectularius and dengue vectors Aedes albopictus and Aedes aegypti. Parasites Vectors 16, 122 (2023). https://doi.org/10.1186/s13071-023-05740-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s13071-023-05740-1