Abstract

A probable problem of disconnection between chemical fingerprints and drug effects for TCMs would be contrary to the original intention of fingerprint research, and limits the development and application of fingerprints. In this study, Shenmai injection, as a treatment dosage form of coronary heart disease, shock, and viral myocarditis clinically, was applied as the research object. The fingerprint of Shenmai injection was constructed, and the pharmacodynamic test of antioxidant effect was carried out to obtain quantitative characteristics and pharmacodynamic data. On this basis, a monitoring model based on the HPLC pharmacodynamic fingerprint was established to evaluate the quality of Shenmai injections from different batches and different manufacturers. Results showed that the optimized HPLC method had good repeatability, precision, and stability. A total of 28 characteristic peaks were identified to provide more chemical information. Furthermore, 13 ginsenosides and notoginsenoside have been selected as characteristic components of LC/MS fingerprint method. 8 peaks closely related to antioxidant properties by multiple linear regression method, which were identified as Rg1, Re, Rf, Rb1, and some other ginsenosides using MS analysis. The monitoring model based on HPLC pharmacodynamic fingerprint could successfully identify quality differences for Shenmai injections. Based on the case study of Shenmai injection, the novel and practical fingerprint analytical strategy could be further applied to monitor or predict the quality of TCMs.

Similar content being viewed by others

Introduction

Traditional Chinese medicine (TCM) has played a vital role in disease prevention and treatment in China for thousands of years. TCM injections as a new pharmaceutical form in the modernization of TCM, are also widely applied in clinical work [1, 2]. However, an increasing number of adverse drug reactions (ADRs) of TCM injections has been reported [3,4,5], which hinder their broader application and popularity among international healthcare practitioners. Therefore, establishing a rapid and practical quality evaluation method according for TCM injections to the existing problems would be critical for the development of TCM industry [6, 7].

The TCM fingerprint atlas refers to a chromatogram that can mark the characteristics of TCMs has been widely accepted nationally and internationally [8,9,10,11]. The China Food and Drug Administration (CFDA) has officially required all the TCM injections to be standardized by chromatographic fingerprints since 2000 [12]. In addition, this chemical fingerprint method is specified for quality control of herbal medicine by many authorities, including the United State Food and Drug Administration (FDA) and European Medicines Evaluation Agency (EMEA) [13, 14]. However, there is a probable problem of disconnection between chemical fingerprints and drug effects. Attention should also be paid on pharmacodynamics research for comprehensively evaluating TCMs quality [15]. To date, studies focused on chemical fingerprint of TCMs were abundant, while a few studies were reported on the connection between chemical fingerprints and drug effects.

Pharmacodynamic fingerprint refers to “chemical fingerprints are related to their efficacy” analysis [16,17,18], which can make up for a common defect in the current research on chemical fingerprints of TCMs. There are three stages to establish a pharmacodynamic fingerprint of TCM [19]. First is chemical fingerprint acquisition stage. Image or spectrum of component groups that can characterize the chemical composition of the sample is captured by spectroscopic, chromatographic, and coupled techniques for instrumental analysis. The second stage is establishing a suitable pharmacodynamic model to obtain biological fingerprints and multiple effect-related components. The third stage is developing pharmacodynamic fingerprint applying mathematical methods to correlate chemical fingerprints and pharmacological activity data [18]. Therefore, how to obtain representative chemical fingerprints, what pharmacodynamic model or index to use to characterize the efficacy of the drug, and what kind of analysis method is used to assess the overall similarity quickly and simply between different sample fingerprints, are the core link of fingerprint evaluation system.

Shenmai injection as a research object has the largest sales among TCMs in China. There are 66 registration certificates for Shenmai Injection according to the CFDA database. It is prepared from red ginseng and Radix Ophiopogonis, and is considered to invigorate Qi to relieve desertion, nourish Yin, and promote saliva production in Chinese medicine. Clinically, this injection is commonly used in treatment of coronary heart disease, shock, and viral myocarditis [20,21,22]. Convincing clinical experiences also showed Shenmai injection as supplemental treatments has exhibited remarkable efficacy in treatment and rehabilitation of liver cancer and COVID-19 [23,24,25]. There are some studies found Shenmai injection had antioxidant effect, which could decrease oxidative stress [26]. Xiao WH et al. [27] used FRAP, DPPH·, NO·, H202· free radical scavenging methods to test the antioxidant capacity of Shenmai injections. The results show that Shenmai injection has a certain invitro antioxidant capacity, and the activity is concentration-dependent. A recent study also reported that Shenmai injection has antioxidant effects by reducing ROS and eliminating the production of oxidizing effect such as malondialdehyde (MDA), which may decrease the cardiovascular oxidative stress induced by Nitroglycerin (NTG) tolerance [28,29,30]. The mechanism was revealed to be by modulating the Nrf2/Keap1 signal pathway, resisting oxidative stress injury [31]. The efficacy of Shenmai injection is closely related to the antioxidant effect according to the previous reports. The main substance in Shenmai injection is ginsenoside (such as Rg1、Re、Rf、Rg2、Rb1、Rd、Rc), ophiopogonin D, Fructose, et al. [32,33,34]. And ginsenosides have been identified as the most important active ingredient. According to the National Drug Standard (WS3-B-3428-98-2010Z) issued by CFDA [35], the similarity of the 16 characteristic peaks of the chromatographic fingerprint should not be less than 0.85 to ensure standardization. In addition, the content of ginsenosides is specified. However, the separation efficiency of this method is low [36]. To date, only 16 characteristic peaks have been reported, as well as the lack of identification of the characteristic peak components and pharmacodynamic evaluation.

In this study, high-performance liquid chromatography (HPLC) was used to establish a chemical fingerprint for Shenmai injection. Crystal violet method [37, 38] was applied to determine the intensity of antioxidant effect. And the HPLC pharmacodynamic fingerprint of Shenmai injection combined the chemical fingerprint and antioxidant activity data by multivariate statistical analysis was established to evaluate the quality of injections from different manufacturers in different batches. The main components for the characteristic peaks in the fingerprint of the Shenmai injection were identified using mass spectrometry (MS). This research provides technical support for quality control of Shenmai injection and other TCMs.

Experiment and methods

Chemicals and instruments

Reagents

Acetonitrile and methanol are all gradient grade (Merck, Germany). Glacial acetic acid is purchased from Yonghua Chemical Technology Co., Ltd. (HPLC grade, China). Purified water is supplied by Milli-Q Reference. Phosphate buffer is purchased from Shandong Linyi Yong'an Laboratory (pH 7.0, 0.5 mol L−1, China). It was filtered through a membrane filter with a pore size of 0.22 μm. Crystal violet is purchased from Shanghai Qiangshun Chemical Reagent Co., Ltd (Batch No. 20140422, China). Potassium hydrogen phthalate, 30% hydrogen peroxide, and ferrous sulfate heptahydrate are all purchased from Jiangsu Yonghua Chemical Technology Co., Ltd (Batch No. 20140410, 20140815, and 20140630 respectively, China).

Samples and sample preparation

Thirty batches of Shenmai injection were obtained from three manufacturers, which are represented by the letters A, B, and C. Seventeen batches were collected from Manufacturer A, six batches from Manufacturer B, and seven batches from Manufacturer C. Before HPLC and MS analysis, each sample was centrifuged at 10,000 rpm for 10 min and the supernatant was retained.

Instruments

The HPLC (1220 Infinity, Agilent Technologies) equipped with a quaternary gradient pump, online degasser, autosampler, column oven, ultraviolet detector, and ChemStation software were used. The chromatographic column was a ZORBAX SB-C18 (250 mm × 4.6 mm i.d., 5.0 µm particle size; Agilent Technologies). For HPLC/MS, we used a 5600 + quadrupole time-of-flight MS (Sciex). We also used a Vis- spectrophotometer (Spectrumlab 22pc, Shanghai Lengguang Technology Co., Ltd), centrifuge (Eppendorf Minispin, Sigma-Aldrich), ultrasonicator (USC702, Shanghai Bolong Electronic Equipment Co., Ltd), and water purifier (Milli-Q Reference, Millipore Sigma).

Methods

Chromatographic conditions

The HPLC analysis was conducted using the conditions described for Shenmai injection in The National Drug Standards from the CFDA (WS3-B-3428-98-2010Z) [35]. The mobile phase composition, column temperature, and mobile phase gradient were optimized. HPLC/MS separation were used the same column and optimized gradient.

Crystal violet spectrophotometric method [38]

The basic principle of the clearance rate ·OH of crystal violet spectrophotometric method is as follows:

·OH attacks the point of high electron cloud density, and reacts electrophilically with the C=C group in crystal violet to cause crystal violet to fade. ·OH generation the amount can be indirectly measured by capturing the change rate of crystal violet absorbance value. Theoretically, antioxidants can scavenge hydroxyl radicals and increase the absorbance of the system.

1 mL of 1.0 mmol L−1 FeSO4 solution, 0.75 mL of 0.4 mmol L−1 crystal violet, 0.1 mL potassium hydrogen phthalate buffer (PH = 4), and 0.7 mL of a certain concentration of H2O2 solution were added in a 25 mL volumetric flask, dilute to 25 mL with water, then shake well. The absorbance Ab was measured at a certain wavelength after standing for a while, and meanwhile the absorbance A0 at a certain wavelength with no H2O2 solution is measured. The hydroxyl radicals would be generated. The amount is characterized by.

△A = A0 − Ab. If the absorbance AS was measured after a certain volume of Shenmai injection was added, the hydroxyl radical scavenging rate CLR% could be calculated according to Eq. 2.

MS conditions

MS was conducted in both positive and negative ion modes. The scan range was m/z 100–2000. In positive ion mode, the ion source voltage was 5.5 kV, and the ion source temperature was 600 °C. In negative ion mode, the ion source voltage was − 4.5 kV, and the ion source temperature was 550 °C. The gas 1 (air) and gas 2 (air) pressures were set at 50 psi. The curtain gas (nitrogen) pressure was set at 35 psi. The maximum allowable error was ± 5 ppm. The dispersive potential was 100 V and the collision energy was 10 V.

Principal component analysis

PCA is a common multivariate statistical method that reduces the dimensionality to simplify data sets and reduce the number of indices. It is a common pattern recognition method, and is especially useful for evaluating chemical fingerprints. In the present study, the peak area of each identified peak was considered as one dimension in the data set. PCA involves orthogonal transformation of original random variables into new variables that are not related to the original observations [39]. According to the feature extraction point of view, PCA is equivalent to an extraction method that is based on minimum mean square error.

The area and retention time data from the characteristic peaks for the 30 samples were standardized, and PCA was performed using the chemometric software Unscrambler 9.7 (CAMO Software Inc, Woodbridge).

Multiple linear regression

Multiple linear regression attempts to model the relationship between two or more explanatory variables xj (j = 1, 2, 3, …, n) and a response variable y by fitting a linear equation [40]. Every value of the independent variable x is associated with a value of the dependent variable y.

In the Eq. 3, b0 is the regression constant; bj (j = 1, 2, 3, …, n) is the regression parameter; e is the random error.

Similarity evaluation

The similarity method uses a certain number of common and featured indices in two samples as a unified measure [16]. Decision principles are used to describe the degree of matching between these two samples. Compared with chemical pattern recognition, the similarity method focuses more on the mutual influence and intrinsic correlation among vector elements. Methods include the distance coefficient, similarity coefficient, relative correlation degree, improved Nei coefficient, and support vector machine [41, 42], and the included angle cosine method is the most common similarity evaluation method [43]. In this paper, fingerprint similarity was evaluated using a similarity evaluation system published by the Chinese Pharmacopoeia Commission. Based on the included angle cosine method, this system uses the basic equation for the vector angle cosine to calculate the similarity between two fingerprints from Eq. 4.

where xi and yi are components of vector \(\overrightarrow{X}\) and \(\overrightarrow{Y}\) respectively. The resulting similarity close to 1 meaning exactly the same, and with 0 indicating decorrelation.

Results and discussion

Optimization of the HPLC conditions

Mobile phase composition

Methanol–water, methanol-acetic acid–water, methanol-phosphate buffer-water, acetonitrile–water, and acetonitrile–phosphate buffer-water were compared as mobile phase systems. Among these systems, the separation of acetonitrile–phosphate buffer-water is slightly better than the acetonitrile–water system, but it was not easy to maintain the instrument (especially for column and pump) and had a poor repeatability. The mobile phase system containing methanol (including methanol–water, methanol-acetic acid–water, and methanol-phosphate buffer-water) was inferior to mobile phase systems containing acetonitrile. Finally, acetonitrile–water was selected as the mobile phase.

Column temperature

With acetonitrile–water as the mobile phase, and 203 nm as the detection wavelength, we investigated the method performance with column temperatures of 25 °C, 30 °C, and 40 °C. The column temperature had a relatively small effect on the fingerprint of the Shenmai injection, and there was only a slight difference in the retention time with changes in the temperature. Therefore, a column temperature of 25 °C (i.e. room temperature) was selected for HPLC.

Mobile phase gradient

Chromatographic separation is greatly affected by the mobile phase gradient, and optimization of the mobile phase gradient conditions enables good separation of major peaks. In the presents study, using the optimized mobile phase composition and column temperature, we optimized the mobile phase gradient. The optimum mobile phase gradient elution procedure is detailed in Table 1.

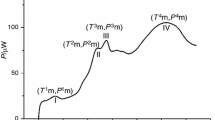

In summary, the optimum HPLC conditions for analysis of the Shenmai injection were as follows: detection wavelength of 203 nm, column temperature of 25 °C, chromatographic column of ZORBAX SB-C18 (4.6 mm × 250 mm, 5.0 µm; Agilent Technologies), mobile phase of acetonitrile–water, injection volume of 20 µL, and the mobile phase gradient shown in Table 1. Under these conditions, the sample was analyzed to obtain a HPLC fingerprint of Shenmai injection (Fig. 1).

Establishment of the HPLC fingerprint for shenmai injection and method validation

A chromatographic fingerprint for Shenmai injection was established by determining what peaks were characteristic. Among the chromatographic peaks detected for the 30 batches of Shenmai injection from the three manufacturers, 28 peaks were detected in all of the samples. These peaks showed good separation and high peak intensities, and could be used as fingerprint peaks for Shenmai injection (Fig. 2). Combined, these 28 peaks accounted for more than 90% of the total peak area.

Precision

We injected sample A1 6 times using the optimized conditions detailed in “Chemicals and Instruments”, and recorded and analyzed the peak areas and retention times of the 28 characteristic peaks. The retention time RSDs of the 28 characteristic peaks were all less than 1%, and the peak area RSDs were less than 5%, except for peaks 2 and 27 (Additional file 1: Table S1). The areas of peaks 2 and 27 were less than 10% of the total area, which means they do not have a large contribution to the overall precision. Therefore, the chromatographic fingerprinting method has a good precision.

Repeatability

Six samples from the same batch from Manufacturer A were used to investigate the repeatability. The RSDs for the peak areas and retention times of the 28 characteristic peaks were calculated. The retention time RSDs for the 28 characteristic peaks were all less than 1%, and the peak area RSDs were all less than 5%, except for those for peaks 2, 9, 16, 17, 18, and 27 (Additional file 1: Table S2). Combined, these 6 peaks contributed less than 10% of the total peak area. They do not account for a large proportion of the peak area, which means they do not have a large contribution to the overall repeatability. Therefore, this method has good repeatability.

Stability

One sample from Manufacturer A was analyzed at 0, 4, 8, 12, 16, 20, and 24 h. The retention time RSDs of the 28 characteristic peaks were all less than 1%, and the peak area RSDs were all less than 5%, except for those for peaks 2, 9, and 24 (Additional file 1: Table S3). These 3 peaks contributed less than 5% of the total peak area, which means they do not have a large contribution to the overall stability. Therefore, the Shenmai injection is relatively stable for up to 24 h.

In summary, the HPLC fingerprint obtained from the Shenmai injection sample under the optimized conditions (“Chemicals and Instruments”) had 28 characteristic peaks, which is far more than the 16 characteristic peaks in the relevant standard (WS3-B-3428-98-2010Z) [35].

Therefore, the chromatographic fingerprint established in this paper contains more features for identification than the current standard. In addition, the developed method has good precision, stability, repeatability, and reproducibility.

Antioxidant determination

Through the screening of detection wavelength, reaction time, and H2O2 concentration, the optimal conditions were determined for the antioxidant experiment as follows: detection wavelength was 590 nm, reaction time was 40 min, and H2O2 solution concentration was 0.005%. The RSDs of precision, stability, repeatability, and reproducibility of Antioxidant determination method were all below 1.0%.

According to the final optimized antioxidant test conditions, a total of 30 batches of Shenmai injection from 3 manufacturers were tested for free radical scavenging rate, and the antioxidant properties of the samples were obtained. The results are shown in Table 2.

Table 2 shows that the free radical scavenging rates of 30 batches of Shenmai injection are all above 90%, which indicating injections have better antioxidant properties, except for sample C2.

Chromatographic-pharmacodynamic relationship

Taking the peak area of the 28 common peaks in the HPLC fingerprint of 30 batches of Shenmai injection as the independent variable (x), and the dependent variable is the antioxidant value (y), Using PASW Statistics 18 statistical analysis software to establish multiple regression linear equations. Filter out 8 variables, namely \(x_{2} , \, x_{3} , \, x_{4} , \, x_{5} , \, x_{6} , \, x_{9} , \, x_{11} , \, x_{13}\) to get the linear equation:

MS results for the characteristic peaks

The 28 characteristic peaks in the chemical fingerprint of a batch of Shenmai injection were analyzed by HPLC/MS. According to the 3.4, the 8 molecular ions as well as other characteristic peaks, main fragment ions and proposed formulae of the compounds are summarized in Table 3. The characteristic peaks were identified based on their LC–MS results, and by comparison with the literature [44,45,46]. The main active components of Shenmai injection, such as Rg1, Re, Rf, Rb1, and some other ginsenosides were identified among the HPLC fingerprint peaks. For example, the first and second order mass spectra of peak 8 are shown in Fig. 3. The first order mass spectrum showed a strong signal at m/z 845, which was attributed to the molecular ion peak with a formic acid (m/z 799). The product ion spectrum of the m/z 799 precursor ion had peaks at m/z 637 and 475, along with other characteristic peaks. The fragment ion at m/z 475 was attributed to a ginseng triol-type saponin, and that at m/z 637 was formed by loss of a sugar chain from the m/z 799 compound. Signals at m/z 945 and 991 were stronger in the first order spectrum than the second order spectrum. The peak at m/z 991 was attributed to formic acid adduct ions (m/z 945). The product ion spectrum of the m/z 945 precursor ion contained characteristic peaks at m/z 799, 637, and 475. These were formed by removal of 162 sugar chains in succession from the precursor. The fragment ion at m/z 637 produced from the parent ion at m/z 945, was attributed to the loss of a disaccharide consisting of a deoxyhexose and a hexose, which indicated that the hexose in the disaccharide was directly attached to the saponin aglycone. Similarly, the fragment ion at m/z 475 was produced by loss of all three sugar units from the parent ion at m/z 945. Finally, two components were identified as Rg1 and Re in comparison with the retention time and mass spectral data with those of the standard, and the reported literature [45, 46].

In the MS results, the two main components of peak 8 were not completely separated. This occurred because the retention behaviors of Rg1 and Re are similar, and the chromatographic conditions should be optimized for this in future. Reports of complete separation of Rg1 and Re are rare in the literatures [44, 45]. A few studies [47, 48] optimized the gradient elution to solve this problem, but this resulted in a lengthy analysis.

Because of the complexity of the injection process (preparation of the actual Shenmai injection including extraction, concentration, purification, et al.), the MS results for some components were affected by components from the matrix, such as plasticizers. Consequently, the spectra lacked characteristic fragments or contained new components produced by chemical reactions that occurred during processing. Because of a lack of relevant data in the literature, the structures of seven characteristic peaks (peak 1, 2, 22, 23, 26, 27, 28) in the spectra were unable to be identified. These unidentified components were thought to form from ginsenoside diol and triol saponins, but further experimental analysis is required to confirm this.

Establishment and application of a quality control model for shenmai injection

PCA analysis

Fingerprint data from the 30 batches of Shenmai injection were standardized and then imported into Unscrambler software (Version 9.7) for PCA analysis. Two principal components, PC1 and PC2, explained 92% of the variance. The distributions of Shenmai injections from the three manufacturers were significantly different in the score plot (Fig. 4). The quality differences between the batches from Manufacturer A were small (i.e., the sample distribution was relatively concentrated). Quality differences between samples from manufacturer C and those from manufacturers A and B were obvious, and between-batch quality differences were large. This method is visual and intuitive and can be used to distinguish Shenmai injections from different manufacturers and different batches.

Similarity analysis

The fingerprint data for the 30 batches of Shenmai injection from three manufacturers were imported into a similarity evaluation system published by the Chinese Pharmacopoeia Commission.

First, the average fingerprints of the Shenmai injections for each manufacturer were used as standard spectra to calculate the similarity among different batches of Shenmai injection from the same manufacturer (Table 4). The obtained similarity (R) was greater than 95%, indicating that between-batch quality differences were small and the quality was stable and uniform.

Next, the spectra from all 30 batches of samples were averaged to produce a standard fingerprint and calculate the similarity of the fingerprints of Shenmai injection (Table 5). The similarity of the Shenmai injection spectra between different manufacturers was greater than 90% for all samples, except for sample C2. It indicated that indicating that different manufacturers’ quality differences were also small. Observing the specific similarity value, the Shenmai injections produced by manufacturers A and B were similar (no statistical difference in similarity), whereas the spectral similarity of the Shenmai injections produced by Manufacturer C was relatively poor. This result is consistent with the PCA analysis results.

Similarity analysis by angle cosine in this paper was not sensitive to the change in the concentration of the constituents. When the peak area of fingerprint distribution was wide, the methods are not sensitive to the difference of data. Therefore, the similarity change caused by the change of the characteristic peaks content in the fingerprint could not be accurately evaluated.

In summary, results showed the good performance of the quality control framework for Shenmai injection. HPLC pharmacodynamic fingerprint of Shenmai injection enriched chemical and pharmacodynamic information for identification. The number of characteristic peaks was expanded from 16 to 28 compared with the standard method by optimizing the original HPLC method. Among them, 8 peaks identified as Rg1, Re, Rf, Rb1, and some other ginsenosides using MS analysis were closely related to antioxidant properties by MLR method. Furthermore, the monitoring model based on HPLC pharmacodynamic fingerprint could successfully identify differences in quality for Shenmai injections from different manufacturers and different batches.

Conclusions

In this study, the HPLC pharmacodynamic fingerprint of Shenmai injection as a quality control strategy was constructed. The optimized HPLC method with good repeatability, precision, and stability provided 28 characteristic peaks, and the pharmacodynamic test of antioxidant effect was carried out to obtain quantitative characteristics and pharmacodynamic data. Among these characteristic peaks, 8 peaks identified as Rg1, Re, Rf, Rb1, and some other ginsenosides using MS analysis, were closely related to antioxidant properties by MLR method. The monitoring model based on HPLC pharmacodynamic fingerprint could successfully identify quality differences for Shenmai injections. The results provide technical support for the basic research on Shenmai injection.

Based on this study and correlative reports of the ginsenosides’ bio-activities, further pharmacology tests of the ginsenosides in Shenmai injecion would be designed and the indexes for pharmacodynamic fingerprint could be optimized to improve the quality control efficiency in future research. And the novel and practical HPLC pharmacodynamic fingerprint analytical strategy could be further applied to monitor or predict the quality of TCM injections, which can greatly facilitate the development of quality evaluation, enhance the clinical safety and effectiveness of TCMs.

Availability of data and materials

All data generated in this study are included in this article and additional files. Material is available from the corresponding author on reasonable request.

Abbreviations

- TCM:

-

Traditional Chinese medicine

- CFDA:

-

China Food and Drug Administration

- LC–MS:

-

Liquid chromatography- mass spectrometry

- HPLC:

-

High-performance liquid chromatography

- PCA:

-

Principal component analysis

References

Han W, He EX, Cao JM. Use of TCM theory to use traditional Chinese medicine injections. Chin J Chin Materia Med. 2012;37(16):2498–500.

Li HN, Wang SW, Yue ZH, et al. Traditional Chinese herbal injection: current status and future perspectives. Fitoterapia. 2018;129:249–56.

Li GQ, Duke CC, Roufogalis BD. The quality and safety of traditional traditional Chinese medicines. Aust Prescr. 2003;26:128–30.

Li HN, Deng JX, Deng LW, et al. Safety profile of traditional Chinese herbal injection: an analysis of a spontaneous reporting system in China. PDS. 2019;28(2):1002–13.

Huang R, Cai YX, Yang LH, et al. Safety of traditional Chinese medicine injection based on spontaneous reporting system from 2014 to 2019 in Hubei Province. China Sci Rep. 2021;11:8875.

Wang P, Nie L, Zang HC. A useful strategy to evaluate the quality consistency of traditional Chinese medicines based on liquid chromatography and chemometrics. J Anal Met Chem. 2015. https://doi.org/10.1155/2015/589654.

Huang HX, Lv YY, Sun XY, et al. Rapid determination of tannin in Danshen and Guanxinning injections using UV spectrophotometry for quality control. JIOH. 2018;11(6):1850034.

Lu XF, Bi KS, Zhao X, et al. Authentication and distinction of Shenmai injection with HPLC fingerprint analysis assisted by pattern recognition techniques. J Pharm Anal. 2012;2(5):327–33.

Huang HX, Qu HB. A comparative fingerprint study using HPLC, UV, and NIR to evaluate the quality consistency of Danshen injections produced by different manufactures. Anal Met. 2013;5:474–82.

Huang ZP, Huang YL, Xu SQ, et al. Discrimination of the traditional Chinese medicine from schisandra fruits by flash evaporation-gas chromatography/mass spectrometry and fingerprint analysis. Chromatographia. 2015;78(15–16):1083–93.

Xue YD, Zhu L, Yi T. Fingerprint analysis of resina draconis by ultra-performance liquid chromatography. Chem Cent J. 2019;13:7.

State Drug Administration of China. Technical requirements of the fingerprint in injection of Chinese materia medica (tentative standard). Chin Tradit Pat Med. 2000;22:671–8.

Food and Drug Administration. Botanical drug development: guidance for industry. 2016. https://www.fda.gov/media/93113/download.

European Medicines Agency. Guidance on quality of herbal medicinal products/traditional herbal medicinal products. 2022. https://www.ema.europa.eu/en/documents/scientific-guideline/final-guideline-quality-herbal-medicinalproducts/traditional-herbal-medicinal-products-revision-3_en.pdf.

Zhang ZY, Wu B, Tang YH, et al. Characterization of major flavonoids, triterpenoid, dipeptide and their metabolites in rat urine after oral administration of Radix Astragali decoction. J Anal Methods in Chem. 2013;68:716–21.

Liang SW, Cui YX, Wang SM, et al. Pharmacodynamic fingerprint of Flos Lonicerea by HPLC. Chinese Trad Herbal Drugs. 2006;037(010):1489–93.

Ding YS, Li QY, Bian LH, et al. Spectrum-effect relationship of the blood-activating efficacy of Notoginseng Radix et Rhizoma. China J Chin Materia Med. 2021;46(18):4736–43.

Yu L, Zhang YY, Zhao XX, et al. Spectrum-effect relationship between HPLC fingerprints and antioxidant activity of Yangyin Tongnao prescription. J Anal Methods Chem. 2021;2021:6650366.

Xu GL, Xie M, Yang XY, et al. Spectrum-effect relationships as a systematic approach to traditional Chinese medicine research: current status and future perspectives. Molecules. 2014;19:17897–925.

Li JS, Wang HF, Yu XQ, et al. Shenmai injection for chronic pulmonary heart disease: a systematic review and meta-analysis. J Altern Compl Med. 2011;17(7):579–87.

Lu LY, Zheng GQ, Wang Y. An overview of systematic reviews of Shenmai injection for healthcare. Evid Based Compl Alternat Med. 2014. https://doi.org/10.1155/2014/840650.

Shi LW, Xie YM, Liao X, et al. Shenmai injection as an adjuvant treatment for chronic cor pulmonale heart failure: a systematic review and meta-analysis of randomized controlled trials. BMC Compl Altern Med. 2015;15:418.

Zhang D, Wang KH, Zheng JW, et al. Comparative efficacy and safety of Chinese herbal injections combined with transcatheter hepatic arterial chemoembolization in treatment of liver cancer: a bayesian network Meta-analysis. J Tradit Chin Med. 2020;40(2):167–87.

Lyu M, Fan GW, Xiao GX, et al. Traditional Chinese medicine in COVID-19. Acta Pharmaceutica Sinica B. 2021;11(11):3337–63.

Xu XF, Shen Q, Wang H, et al. Pharmacokinetics and metabolism of traditional chinese medicine in the treatment of COVID-19. Curr Drug Metab. 2022;23(7):508–20.

Yang XY, He TM, Han SJ, et al. The role of traditional Chinese medicine in the regulation of oxidative stress in treating coronary heart disease. Oxid Med Cell Longev. 2019;2019:3231424.

Xiao WH, Yang ZW, Li Y. In vitro experimental study on antioxidant activity of Shenmai injection. Tianjin J Trad Chin Med. 2019;36:697–700.

Zhao X, Bai Y, Jin J, et al. Role of vascular endothelial active facters in gas exchange impairment induced by tourniquet and the effect of shenmai injection. China J Chin Materia Med. 2011;36(15):2153–6.

Yu J, Xin YF, Gu LQ, et al. One-month toxicokinetic study of SHENMAI injection in rats. J ethnopharmacol. 2014;154(2):391–9.

Zhou Q, Sun Y, Tan WX, et al. Effect of Shenmai injection on preventing the development of nitroglycerin-induced tolerance in rats. PLoS ONE. 2017;12(4): e0176777.

Zhou P, Gao G, Zhao CC, et al. In vivo and in vitro protective effects of shengmai injection against doxorubicin-induced cardiotoxicity. Pharm Biol. 2022;60:638–51.

Xia CH, Wang GJ, Sun JG, et al. Simultaneous determination of ginsenoside Rg1, Re, Rd, Rb1 and ophiopogonin D in rat plasma by liquid chromatography/electrospray ionization mass spectrometric method and its application to pharmacokinetic study of ‘SHENMAI’ injection. J Chromatogr B. 2008;862(1–2):72–8.

Zhan SY, Shao Q, Fan XH, et al. Development of a sensitive LC-MS/MS method for simultaneous quantification of eleven constituents in rat serum and its application to a pharmacokinetic study of a Chinese medicine Shengmai injection. Biomed Chromatogr. 2015;29(2):275–84.

Zhan T, Yao N, Wu LN, et al. The major effective components in Shengmai formula interact with sodium taurocholate co-transporting polypeptide. Phytomedicine. 2019;59: 152916.

State Drug Administration of China. CFDA drug standards (no. WS3-B-3428-98-2010Z) Drug Standards China. 2011;12:158–60.

Dong L, Gan JW, Li M, et al. Rapid determination of Shenmai Injection fingerprint by HPLC. Chinese Trad Patent Med. 2016;3(38):599–602.

Ma YQ, Yu X, Huang XL, et al. Antibacterial and antioxidative effects of extract from schisandra fructus. Food Fermen Ind. 2010;006(036):45–8.

Zhang M. Several Evaluation Study of in Vitro Antioxidant Detection Methods [D]. Xi’an: Shaanxi Normal University; 2010.

Herve A, Lynne JW. Principal component analysis, Wiley Interdisciplinary review: computational statistics. WIREs Comp Stats. 2010;2(4):433–59.

Jobson JD. Multiple linear regression applied multivariate data analysis: regression and experimental design. New York: Springer; 1991.

Zenon G. Principal component analysis versus factor analysis. Zeszyty Naukowe WWSI. 2013;9(7):27–35.

Yang B, Wang Y, Shan LL, et al. A novel and practical chromatographic “fingerprint-ROC-SVM” strategy applied to quality analysis of traditional Chinese medicine injections: using KuDieZi injection as a case study. Molecules. 2017;22:1237–47.

Amit S. Modern information retrieval: a brief overview. IEEE Data Eng Bull. 2001;24(4):35–43.

Fan XH, Wang Y, Cheng YY. LC/MS fingerprinting of Shenmai injection: a novel approach to quality control of herbal medicines. J Pharm Biomed Anal. 2006;40(3):591–7.

Yu K, Ma YH, Shao Q, et al. Simultaneously determination of five ginsenosides in rabbit plasma using solid-phase extraction and HPLC/MS technique after intravenous administration of ‘SHENMAI’ injection. J Pharm Biomed Anal. 2007;44:532–9.

Zhan S, Shao Q, Fan X, Li Z. Development of a sensitive LC-MS/MS method for simultaneous quantification of eleven constituents in rat serum and its application to a pharmacokinetic study of a Chinese medicine Shengmai injection. Biomed Chromatogr. 2015;29(2):275–84.

Cao SP, Nie LX, Wang LG, et al. HPLC simultaneous determination of nine ginsenosides in Shenmai injection. Chin J Pharm Anal. 2011;31(3):476–8.

Wang RL, Fan XH, Yuan W, et al. Simultaneous determination of nine ginsenosides in Shenmai injection by HPLC. Chinese Trad Patent Med. 2019;5(41):487–990.

Acknowledgements

We thank Zhiwei Ge from Zhejiang University for providing the MS data analysis support.

Funding

This study was supported by Teacher Professional Development Project (Grant No. FX2021109), the State Administration of Traditional Chinese Medicine of Zhejiang Province Project (Grant No. 2015ZQ022), National Natural Science Foundation of China (Grant No. 81802975), Medical Health Science and Technology Project of Zhejiang province (Gran No. 2019KY361, 2020KY101), Public Welfare Technology Research Project of Zhejiang (Grant No. LGF21H300001), and Hangzhou Science and Technology Foundation of China (Grant No. 20191203B48).

Author information

Authors and Affiliations

Contributions

Conceived and designed the experiments: GY and HHX. Performed the experiments: GY and SL. Data analyses: GY, SL and HXH. Contributed to the writing of the manuscript: HXH, XYS, and YYL. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

All authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Additional file 1.

The HPLC fingerprint evaluation of precision, repeatability, and Stability.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Yang, G., Li, S., Sun, X. et al. Quality monitoring of Shenmai injection by HPLC pharmacodynamic fingerprinting. BMC Chemistry 17, 28 (2023). https://doi.org/10.1186/s13065-023-00920-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s13065-023-00920-7