Abstract

Nano-engineering with unique “custom function” capability has shown great potential in solving technical difficulties of nanomaterials in tumor treatment. Through tuning the size and surface properties controllablly, nanoparticles can be endoewd with tailored structure, and then the characteristic functions to improve the therapeutic effect of nanomedicines. Based on nano-engineering, many have been carried out to advance nano-engineering nanomedicine. In this review, the main research related to cancer therapy attached to the development of nanoengineering nanomedicines has been presented as follows. Firstly, therapeutic agents that target to tumor area can exert the therapeutic effect effectively. Secondly, drug resistance of tumor cells can be overcome to enhance the efficacy. Thirdly, remodeling the immunosuppressive microenvironment makes the therapeutic agents work with the autoimmune system to eliminate the primary tumor and then prevent tumor recurrence and metastasis. Finally, the development prospects of nano-engineering nanomedicine are also outlined.

Similar content being viewed by others

Introduction

According to a report released by the World Health Organization in 2020, there were 19.3 million new cancer cases and 1 million cancer deaths worldwide, and the incidence and mortality of cancer were both showing an upward trend, seriously threatening human health [1,2,3,4]. At present, great progress has been made in the research of tumor treatment [5], but the therapeutic effect of nanomedicines is still limited by some problems, such as the poor delivery [6,7,8,9], the drug resistance of tumor cells [10,11,12], the immunosuppressive microenvironment [13,14,15,16] and so on.

In recent years, the development of nanotechnology has provided many new research ideas for tumor treatment, especially the proposal of nano-engineering nanomedicines. Nano-engineering refers to the adjustment of size, surface properties and structure of nanoparticles. Based on nano-engineering, (1) the size can be controlled by adjusting synthesis conditions, and then the circulation, distribution, and excretion of nanomedicines in the body can be improved; (2) the surface properties can be changeed through physical or chemical methods to improve the dispersion, stability, biocompatibility and surface reactivity of nanomedicines; (3) the structure of nanomedicines can be precisely designed to regulate their overall performance. Therefore, nano-engineering can carry out “customized functions” for specific nanomedicines, playing an extremely important role in tumor treatment.

Conventional delivery methods have poor pharmacokinetics and non-specific toxicity [17], which not only have great toxicity and side effects on normal tissues, but also weaken the effect of tumor treatment. Nanocarriers with customized functions based on nano-engineering can prolong the half-life of blood circulation, improve tumor specificity, and effectively accumulate in the tumor area, thus enhancing the therapeutic effect. Drug resistance refers to the resistance of tumor cells to therapeutic agents, resulting in poor effect and ultimately affecting the therapeutic effects [10, 18, 19]. Nano-engineering nanomedicines can effectively inhibit drug resistance by increasing intracellular therapeutic agent accumulation, thus improving tumor treatment effects. In addition, a large number of immunosuppressive cells and immunosuppressive cytokines in the tumor microenvironment, as well as the loss of immunogenicity of tumor cells and immune checkpoints, will suppress the immune response [13, 14]. Nano-engineering nanomedicines with customized functions can effectively alleviate immunosuppression and enhance immune response.

To better understand the application of nano-engineering nanomedicines in cancer therapy, this review firstly introduced the relevant contents of size control, surface modification and structure design from the perspective of nano-engineering. Then, it summarized the applications of nano-engineering for obtaining nanomedicines with customized functions to overcome their deficiency in tumor treatments, including the poor delivery, tumor drug resistance, and the immunosuppressive microenvironment (Scheme 1). Finally, the prospects and challenges of nano-engineering nanomedicines in promoting the development of cancer therapeutics have also been discussed.

Design strategies of nano-engineering

Controlling the size

Due to the surface effects, quantum size effects and macroscopic quantum tunneling effects of nanomaterials, the properties of nanoparticles are significantly dependent on their size, such as acoustic, optical, electrical, magnetic, thermal, mechanical, and chemical catalysis [20]. In addition, size also affects its blood circulation life, distribution and excretion in the body [21]. Therefore, controlling the size of nanoparticles is a very effective way to control the properties of nanoparticles. This section briefly introduces nano-engineering to control the size of nanoparticles, and Table 1 summarizes the parameters that affect the size of nanoparticles.

To control the size of nanoparticles, it is first necessary to understand their growth mechanism. The most common growth mechanism is the LaMer mechanism (Fig. 1a). The LaMer mechanism is divided into three stages: The first is the monomer formation stage, where the concentration of free monomer in the precursor decomposition solution increases rapidly; then there is the nucleation stage, the monomer concentration is higher than the critical nucleation concentration, monomer burst nucleation causes the concentration of free monomer in the solution to drop rapidly, and the nucleation is terminated; the last is the growth stage, where the monomer diffuses to the surface of the core to grow [22,23,24,25]. According to the LaMer mechanism, it is not difficult to conclude that by changing the concentration of reactants, solvent ratio, reaction temperature, and stabilizers, the growth of nanoparticles can be controlled to control the size.

Controlling the ratio of reducing agent to precursor is an important method for changing the size of nanoparticles. It can be explained by the LaMer mechanism: the reducing agent reduces the precursor to form monomer, and controlling the ratio of the reducing agent to the precursor is equivalent to controlling the concentration of the monomer initially used for nucleation. When the ratio of the reducing agent to the precursor is smaller, the fewer seeds are formed in the initial nucleation stage, and the monomers obtained later are used for growth instead of nucleation, so the final size of the nanoparticles obtained is larger. Laura Hippolyte et al. controlled nucleation and growth of Au nanoparticles (NPs) by changing the ratio of NHC-BH3 and Au precursors. When the ratio of NHC-BH3 to Au precursor is 1:1, the size of Au NPs is 10.0 ± 2.7 nm. With the increase of the ratio of NHC-BH3, the size of Au NPs decreases, and when the ratio is 28:1, the size decreased to 4.9 ± 0.9 nm [26]. Minh Tran and colleagues used citric acid to reduce Au to verify that the size of Au nanoparticles depends on the ratio of Na3Ct/HAuCl4 (Fig. 1c) [27]. Yeojin Jeon and his colleagues used FeCl3 and palmitic acid to synthesize Fe3O4 nanoparticles, when the mixing ratio of FeCl3 and palmitic acid is 1:1, the size of the nanoparticles is about 800 nm, the larger the ratio of palmitic acid, the smaller the size of the nanoparticles. When the ratio is 4:1, the size of the nanoparticles is about 40 nm [28].

The reaction time is also an important parameter to control the size of nanoparticles. When the monomer concentration exceeds the critical nucleation concentration and burst nucleation, the remaining monomer diffuses to the surface of the nucleus to grow. Therefore, before the monomer is completely consumed, the longer the reaction time, the larger the size of the nanoparticles. Florian Mayer and colleagues obtained nanoparticles of different sizes by adjusting the reaction time. They found that after 30, 48, and 60 min of reaction, nanoparticles with increasing sizes were obtained, which were 53.6, 71.1, and 79.8 nm, respectively [29]. Kenya Komoda and Takehiro Kawauchi found that the size of nanoparticles would increase with the extension of reaction time. When the reaction time is increased from 10 to 20 min, the particle size of the NPs increases from 142 ± 15 nm to 269 ± 67 nm [30]. This was also demonstrated by Auni Hamimi Idrisa and his colleagues. When the reaction time was increased from 15 to 60 min, the particle size of the iron oxide NPs increased from 4.9 to 8.6 nm [31]. In addition, if the monomer quantity in the solution can be maintained without allowing it to exceed the critical nucleation concentration again, the nanoparticles continue to grow, and their size is proportional to the reaction time, so that the size of the nanoparticles can be precisely controlled by controlling the reaction time. Erika C. Vreeland et al. continuously added precursors to the reaction system to maintain the nanoparticle concentration, so that the nanoparticles could grow steadily for any length of time. During this process, the particle size increases with the reaction time, and the growth rate of the steady-state growth is constant, and the particle size can be predicted by the reaction time (Fig. 1b) [32].

The effect of reaction temperature on nanoparticle size is complex. First, temperature affects the nucleation stage of nanoparticles, according to the classical nucleation theory, as the reaction temperature increases, the nucleation rate accelerates, thus theoretically obtaining smaller size particles. For example, the Au nanoparticles prepared by Minh Tran et al. decreased in size with increasing temperature (Fig. 1c) [27]. And Yuan et al. showed that as the reaction temperature increased from 993 to 1373 K, the average size of TiB2 changed from 22.1 to 171.4 nm [33]. However, in the growth stage, the higher the reaction temperature, the more intense the Brownian motion of the monomer, which increases the probability of the particles contacting each other, and the nanoparticles can continue to grow, resulting in larger-sized nanoparticles. Derrick Mott et al. synthesized highly monodispersed Cu NPs with an average size in the range of 5–25 nanometers in an organic suspension by changing the temperature. Their study proved that the average size of copper nanoparticles increases approximately linearly with temperature [34].

For polymer nanoparticles, their preparation usually requires solvent and non-solvent phases (organic and aqueous phase), which involves complex interfacial hydrodynamic phenomena [35,36,37]. Two-phase mixing causes the polymer in the organic phase to transfer to the aqueous phase and aggregate to obtain polymer nanoparticles. Good mixing conditions and large polymer concentrations will lead to a local supersaturation to reach the critical nucleation concentration, which leads to rapid and large nucleation, and eventually to smaller nanoparticles [38, 39]. It is not difficult to see that the choice of organic solvent and the initial concentration of the polymer in the organic phase affect the size of the polymer NPs. For example, Moritz Beck-Broichsitter et al. demonstrated that organic solvents with higher water affinity can more effectively promote polymers into the aqueous phase to obtain smaller nanoparticles. And with the increase of polymer concentration, the particle size increases linearly. They used Dimethyl sulfoxide (DMSO) and Tetrahydrofuran (THF) as solvents, respectively, to obtain NPs of 66 and 162 nm at an initial concentration of 10 mg ml− 1 and 89 and 223 nm NPs at an initial concentration of 25 mg ml− 1[40]. Miechel L.T. Zweers et al. also demonstrated that increasing polymer concentration leads to an increase in particle size. In their study, by varying the concentration of the polymer, monodisperse poly(lactic-co-glycolic acid) (PLGA) nanoparticles of 100–400 nm size could be obtained [41].

The charge of the polymer also affects the particle size. According to classical nucleation theory, the final size of the nanoparticle depends on nucleation and growth, and the more the number of nucleation and the slower the growth rate, the smaller the resulting nanoparticle size. In the nucleation process of particles, the charged groups can reduce the interfacial tension and increase the nucleation rate; At the same time, due to the existence of charge, the charge repulsion reduces the polymer around the nucleus, reducing the growth rate, resulting in smaller nanoparticles. In the study of Andreas Reisch et al., they introduced negatively charged carboxylate and sulfonate as well as positively charged trimethylammonium groups into polymers. The carboxylate group is easily protonated and have less charge. Finally, carboxylate bearing polymers obtained nanoparticles of 60–100 nm, while the polymer containing sulfonate and trimethylammonium obtained nanoparticles smaller than 25 nm [42]. Vitalii Rosiak et al. also demonstrated that by using sulfonate-containing polymers, the size can be further reduced, resulting in nanoparticles of only 10 nm [43].

Stabilizer is an important parameter that affects the size of nanoparticles. Only when the monomer diffuses to the surface of the nanoparticle, the nanoparticle can grow, and the stabilizer controls the size by affecting the surface state of the nanoparticle. First, the stabilizer can directly aggregate on the nanoparticle surface, competing with the aggregation of reactant monomers on the nanoparticle surface; second, the stabilizer can prevent the reactant monomer from approaching the nanoparticle surface through its own steric hindrance; in addition, the stabilizer alters the properties of the nanoparticle surface, such as hydrophobicity and charge, by interacting with the nanoparticle surface, which controls the aggregation of reactant monomers on the nanoparticle surface, thereby controlling the size of the nanoparticle. Stabilizers include polymers, surfactants, metal complexes and others. Kentaro Ichihashi et al. used an organic polymer polypyrrole (PPy) to coat Pt NP, and obtained nanoparticles with a controllable size [44]. Sang-Wook Kim et al. obtained Pd NPs of different sizes by using different surfactants. They found that when trioctylphosphine (TOP) was used as a surfactant and solvent, particles of about 3.5 nm were obtained. When a mixture of TOP and oleylamine is used, the particle size is 5 and 7 nm, and when only oleylamine is used, the particle size is above 10 nm [45]. Ce ´dric R. Mayer et al. used metal complexes as stabilizers to prepare Ag NP. When the complex has a strong interaction with the Ag NP surface, the surface of the nanoparticle is rapidly coated and the growth is stagnated. Therefore, the stronger the interaction between the complex and the Ag NP surface, the smaller the nanoparticle size, and as the silver/ruthenium (ii) ratio increases, the surface coating decreases and the particle size increases [46].

The effect of stabilizers on polymer nanoparticles is more complex. Katsuhiro Onita and his colleagues found that as polyvinylpyrrolidone (PVP) concentration increased from 3 to 8 wt%, the particle size of polymer particles decreased from 1.8 to 1.2 μm [47]. In the study by Yupaporn Niyom et al., the size of the nanoparticles decreased with increasing surfactant concentration [48]. But Benita et al. demonstrated that particle size increases as stabilizer concentration increases [49]. This data seems contradictory, but in fact there are different theoretical supports behind it. When the stabilizer concentration is low, it covers the surface of the droplet, reduces the interfacial tension, prevents aggregation, and obtains nanoparticles with smaller size; When the concentration exceeds the threshold, the increase in concentration cannot further reduce the interfacial tension, and the stabilizer exists in a continuous phase, and the viscosity in the system increases, thereby increasing the particle size. This is evidenced by the study of Miechel L.T. Zweers et al., who used Polyvinyl alcohol (PVA) as a stabilizer, and in the range of 0–2%, the PLGA particle size decreased as PVA concentration increased; In the range of 2–5%, the particle size is almost constant; By further increasing the concentration, the particle size increases [41].

In short, by adjusting the concentration and ratio of reactants, reaction time, temperature, solvent, charge, stabilizer and other parameters, the number of nucleation or the growth state of nanoparticles can be controlled, thereby effectively controlling the size of nanoparticles. Furthermore, in general, the size of nanoparticles is not controlled by a single factor, but by multiple parameters.

Surface modification

Nanoparticles have the inherent characteristics such as large specific surface area, easy to modify their surface, etc., which have broad application prospects in the fields of biomedicine, catalysis, lithium batteries and so on. However, these characteristics also bring certain problems. On the one hand, nanoparticles with large specific surface area have a large surface Gibbs free energy, which is prone to aggregation or oxidation; on the other hand, there are many unsaturated bonds and dangling bonds on the surface of nanoparticles, which are easily combined with other atoms, resulting in poor stability. These factors hinder the practical application of nanomaterials. Appropriate surface modification of nanoparticles can overcome the disadvantages and obtain the desired materials. Surface modification here refers to the use of physical or chemical methods to change the structure or state of the nanoparticle surface, thereby controlling its surface properties. The surface modification methods of nanomaterials mainly include adsorption, grafting and coupling. These methods are briefly introduced below, and Table 2 summarizes the comparison between the four methods.

Adsorption

Adsorption includes physical adsorption and chemical adsorption, and is usually attached to the surface of nanoparticles with surfactants. Physical adsorption is non-selective monolayer or multi-molecular layer adsorption through van der Waals forces, while chemical adsorption is monolayer adsorption through electrostatic interaction or hydrogen bonding. There is no clear boundary between physical adsorption and chemical adsorption. The same substance may be physically adsorbed at low temperature and chemically adsorbed at high temperature. Through adsorption, the surface charge and hydrophilicity of nanoparticles can be changed, the interaction between particles can be reduced, and the dispersibility and biocompatibility of nanoparticles can be improved. Ahmed Barhoum et al. used hexadecyl trimethyl ammonium Bromide (CTAB) (cationic surfactant) and sodium oleate (anionic surfactant) to modify the surface of calcium carbonate by adsorption. Their research shows that CTAB, as a quaternary ammonium compound (NR4+Br-), can only interact with CaCO3 particles through van der Waals forces, while the carboxyl group (-COO-) of sodium oleate can effectively combine with Ca2+ on the surface of CaCO3 particles through electrostatic interaction. The adsorption capacity of CTAB and oleate are 20% and 75%, respectively. Whether it is surface modification by CTAB or sodium oleate, the surface potential of the nanoparticles is changed, and the dispersion of the particles is effectively improved [50]. Surface modification of nanoparticles by adsorption is one of the easiest ways to improve the performance of nanoparticles. However, because they are fixed on the surface of nanoparticles through relatively weak van der Waals forces or electrostatic interactions and other non-covalent bonds, they are unstable under external stimulation.

Coupling

Coupling refers to the combination of two units to form a molecule, which requires the assistance of a coupling agent. Coupling agents generally have two groups, one hydrophilic and the other hydrophobic. Inorganic nanoparticles (high surface energy) and organics (low surface energy) are difficult to be compatible when mixed due to the difference in surface energy. The hydrophobic groups of the coupling agent can chemically react with the surface of inorganic substances, and the hydrophilic groups can react with or be compatible with organic substances. Therefore, the coupling agents can improve the compatibility between inorganic nanoparticles and organic molecules.

The most commonly used coupling agent is the silane coupling agent ((R'O)3SiR). The silane coupling agent is usually used for inorganic nanoparticles with hydroxyl groups on the surface. The alkoxy group (-OR') condenses with -OH to form a covalent bond to stably modify the surface of the nanoparticle [51]. In addition, the silane coupling agent usually has various other functional groups, which can be used for further modification. Li et al. used KH550 silane coupling agent to modify the surface of TiO2 nanoparticles. The -OR' of the silane coupling agent first forms a hydrogen bond with the -OH on the surface of the TiO2, and then dehydrates and condenses to form a Si-O-Ti bond, which is stably modified on the surface of the nanoparticle. The hydrophilic group and steric hindrance effect of the silane coupling agent effectively improve the dispersion of nanoparticles [52]. Similarly, Li et al. used silane coupling agent to modify Al2O3 NPs to improve their dispersion stability [53]. Hong et al. modified the KH-570 coupling agent on the surface of zinc oxide nanoparticles, and then fixed polystyrene (PS) on the surface of the nanoparticles by grafting to improve the dispersibility [54]. Their research results also show that coupling can effectively improve the compatibility of inorganic nanoparticles and organic molecules. A.I. Barabanova and his colleagues used 3-(triethoxysilyl) propylsuccinic anhydride (TESPSA) to modify SiO2 nanoparticles. They modified the acid anhydride group to the surface of the nanoparticle through the condensation reaction of TESPSA ethoxy group and -OH group on the surface of SiO2. It not only improves the dispersibility of nanoparticles, but also enhances surface activity, so that nanoparticles can further react with other polymers [55]. Seda Kelestemur et al. used a coupling agent to modify bovine serum albumin (BSA) onto the surface of ZnO. They first treated with H2O2 to increase the -OH density on the surface of ZnO NPs, and then modified the silane coupling agent 3-aminopropyltrimethoxysilane (APTMS) on the surface of ZnO to obtain nanoparticles with amine functional groups on the surface. Finally, the EDC/NHS coupling method was used to modify the BSA to the surface of the nanoparticles through the amide bond, which effectively improved the biocompatibility of the nanoparticles (Fig. 2a) [56]. Therefore, the coupling agent is suitable for the composite of inorganic nanoparticles and organics. After the surface of the inorganic nanoparticles is treated with the coupling agent, it can produce high compatibility with organics, and it is conducive to the mono-dispersion of the nanoparticles. In addition, after the coupling agent is modified, other organics can be further modified on the surface to obtain nanoparticles with desired properties.

Grafting

Grafting is a chemical modification method that binds macromolecular chains to the surface of the material through covalent bonds, thereby changing the surface properties of nanoparticles. According to different grafting methods, it can be divided into grafting-to approach and grafting-from approach. The grafting-to approach refers to the direct covalent connection between the polymer and the functional group on the surface of the material. This method can graft high-molecular-weight polymers with low steric hindrance, but the conditions are relatively harsh; The grafting-from approach means that the monomer is directly polymerized in situ on the surface of the material under the action of the initiator, which can accurately control the molecular weight and density of the graft, but in the late stage of the reaction, the steric hindrance is large, and the molecular weight of the grafted polymer is small. In these two grafting methods, the polymer or monomer needs to be activated by physical or chemical methods to initiate the polymerization grafting process. In recent years, conventional free radical polymerization and reversible deactivation radical polymerization (RDRP) have attracted widespread research interest.

In conventional free radical polymerization, photo-initiated grafting is a mature graft modification technology. As early as 1957, Gerald Oster et al. used ultraviolet light to initiate grafting on the polymer surface [57]. Photo-initiated grafting is the use of an initiator to absorb ultraviolet light or visible light to generate free radicals, which are then transferred to the surface of the nanoparticles, and then react with the polymer for grafting. At present, benzophenone is usually used as an ultraviolet light initiator. Sooyeon Kim et al. modified the silica surface by grafting method using methyl methacrylate (MMA) under far-ultraviolet light irradiation. The photo-initiator benzophenone absorbs extreme ultraviolet light (250 nm) to form free radicals, and deprives the hydrogen from -OH on the SiO2 surface to form free radicals on the SiO2 surface. It reacts with MMA to grow the graft chain, and Si-O-C bond is formed on the surface of SiO2. Surface modification improves the stability of nanoparticles, and due to the grafting of active monomers, the surface activity of SiO2 is improved so that it can react with other substances (Fig. 2b) [58]. Lou et al. also used benzophenone as an initiator to photopolymerize N-[2-(acryloyloxy) ethyl]-N, N-dimethyl-N-butylammonium iodide on the surface of polydimethylsiloxane, and its high-density quaternary ammonium salt surface can be applied to sterilization [59]. In the study of Radmila Tomovska et al., TiO2 nanoparticles, which can directly generate highly active free radicals under photocatalysis, react with silane coupling agent (3-chloropropyl) triethoxysilane (TCPEOS) under light, and are successfully grafted through Ti-O-Si bonds to obtain nanoparticles with chloropropyl functional groups on the surface. In addition, the ethoxy group is hydrolyzed and condensed to form a Si-O-Si network on the surface, so that the surface of the nanoparticle has super-hydrophobicity [60]. However, when TCPEOS is used for grafting, free radicals will break the Si-C bond and disappear the functional groups that have been modified on the surface of the nanoparticles. Therefore, they tried another silane coupling agent, 3-triethoxysilyl propyl isocianate (PIC), under the same reaction conditions as the TCPEOS reaction, the Si-C bond does not crack when using PIC [61]. Their research results show that by changing the terminal functional groups of the grafted polymer, the surface properties of nanoparticles can be effectively controlled. The light-initiated grafting reaction conditions are mild, the reaction process is pollution-free, and the post-reaction treatment is simple, so it has a wide range of applications. In addition to photo-initiation, there are other activation methods, such as plasma initiation [62], radiation initiation [63], and microwave initiation [64], which are not described in detail here.

In 1956, Szwar first proposed the concept of living polymerization [65]. After decades of development and improvement, the theory of RDRP has matured. RDRP methods include atom transfer radical polymerization (ATRP), reversible addition-fragmentation chain transfer polymerization (RAFT) and nitrogen oxide mediated polymerization (NMP) [66]. All of these living radical polymerization methods can control the types and density of grafted polymers on the surface of nanoparticles to achieve precise regulation.

ATRP uses organic halides as initiators. The organic halides are first homogenized to generate alkyl radicals (R·), and then the formed R· undergo chain growth through double bond addition, and chain termination occurs through disproportionation or coupling. ATRP can graft polymers with specific functional groups and molecular weights onto the surface of nanoparticles, thereby tailoring the surface properties of nanoparticles according to the required properties [67]. Jung Tae Park et al. first activated the silanol groups (Si-OH) on the surface of SiO2 nanoparticles, and then combined with 2-chloropropionyl chloride (CPC) to convert the surface -OH to -Cl. Finally, using chlorine atom as an initiator, the hydrophilic polymer was grafted onto the SiO2 surface through ATPR. Due to the mutual repulsion and steric hindrance between hydrophilic polymers, the dispersion performance of nanoparticles is improved (Fig. 2c) [68]. Guo et al. directly prepared SiO2 with -Br, using -Br as an ATRP-initiating group to graft azobenzene polymer brush, and then modified with glycine to obtain a photosensitive nano-adsorbent that can selectively remove low-density lipoprotein [69].

NMP uses alkoxyamine as initiator to generate free radicals for graft polymerization. It can also precisely design and functionalize the surface of nanoparticles. However, because the preparation of alkoxyamines is more complicated and generally only suitable for styrene, there has been less research in recent years. Jaime C. Cazotti and his colleagues used NMP to modify starch nanoparticles (SNP) to improve the dispersion of nanoparticles. First, the SNP is modified with 4-vinylbenzyl chloride (VBC), and the surface is modified with reactive double bonds. Then, SG1 capped polymethyl methacrylate-styrene copolymer (P(MMA-co-S)) was synthesized. (P(MMA-co-S)) decomposes to form two free radicals: the stable SG1 nitroxide radical and the copolymer chain end radical. The free radicals at the end of the copolymer chain react with the double bonds on the surface of the VBC-SNP to graft the copolymer onto the nanoparticles. Finally, the free radicals are deactivated by nitrogen oxides to terminate (Fig. 2d) [70].

RAFT can modify polymers with controllable molecular weight and structure on the surface of nanoparticles under mild conditions and is easy to functionalize. RAFT is similar to conventional free radical polymerization except that it requires a RAFT agent. Dusadee Tumnantong et al. used poly (styrenesulfonate-sodium)-RAFT agent to prepare polystyrene-silica nanoparticles (PS-co-RAFT-SiO2) through RAFT. Studies have shown that surface grafting improves the thermal and mechanical properties of nanoparticles (Fig. 2e) [71]. Xing et al. first prepared mercaptopropyl modified silica, and then copolymerized 1-vinyl imidazole and acrylic acid by RAFT to form a polymer brush on the surface of silica, which has good heavy metal ion adsorption performance [72].

Grafting has been widely used in the surface modification of nanoparticles. It can not only modify the surface of nanoparticles by selecting different polymers to obtain different properties without affecting the properties of the nanoparticles themselves, but also ensure the controllable introduction of graft chains with high density and precise positioning on the NP surface. In addition, the covalent modification by grafting to the surface of nanoparticles has long-term stability.

In summary, the significance of modifying the surface of nanoparticles by nano-engineering is as follows: (1) Improving the dispersion, stability and biocompatibility of nanoparticles; (2) Improving the surface reactivity of nanoparticles; (3) Changing the physical, chemical and mechanical properties of the surface of nanoparticles. Surface modification can make nanoparticles have more superior properties, become more ideal materials and further customize their functions to have wider applications in different fields.

a Schematic diagram of the surface modification process of ZnO NPs by coupling method. Schematic illustration of graft polymerization from NPs via b UV-induced free radical polymerization; c atom transfer radical polymerization; d nitrogen oxide mediated polymerization and e reversible addition-fragmentation chain transfer polymerization

Structure design

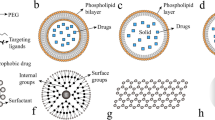

With the development of nanotechnology, the performance of single material is no longer sufficient to meet complex practical needs, so multifunctional nanomaterials that can integrate multiple functions into a single structure are required. In order to obtain nanomaterials with ideal properties, it is necessary to precisely design the structure and composition of the nanoparticles, and combine the advantages of different materials to achieve the same or better effect as the combination of single materials [73]. At present, several types of nanoparticles have been proposed, including core-shell structure, yolk-shell structure, sandwich structure, satellite core structure, etc., all of which have excellent properties, and it has a wide range of applications in various fields such as catalysis, biomedicine, and energy storage.

The core-shell structure is to coat one or more layers of other materials on the surface of the original nanoparticles. The original nanoparticle is called the core, and the surrounding layer is called the shell. The preparation of the core-shell structure usually uses sol-gel or chemical precipitation to form nucleation sites on the surface of the core for nucleation and growth to form a shell [74, 75]. The shell can change the properties of the original nanoparticles, and improve the stability and dispersibility. In addition, the core-shell structure enables core nanoparticles to possess new properties such as light, magnetism, and electron transfer [76, 77]. Therefore, through the direct combination or synergy of the inner core and the outer shell, the nanoparticle can have a novel combination function or optimize the original performance. In addition, the core-shell structure can easily remove the core, thereby constructing a hollow structure with large storage capacity and low density.

The most important advantage of the core-shell structure is that the shell and the core can interact, so that the core-shell nanoparticles have better performance than single nanoparticles. Li et al. proved that the PPy shell reduces the magnetic coupling effect between ZnFe2O4 nanoparticles, increases the surface anisotropy, and makes the dielectric constant and permeability better match. Compared with ZnFe2O4, ZnFe2O4/PPy core-shell nanoparticles have stronger microwave absorption performance and wider absorption band [78]. Similarly, Christopher J. Serpell found that due to the interaction of electrons and lattices in core-shell nanoparticles, the catalytic performance of bimetallic Au@Pd core-shell nanoparticles is better than the same alloy nanoparticles or a mixture of same metal nanoparticles [79].

The shell based on the core-shell structure changes and protects the surface properties of the original nanoparticles, which is of great significance in the field of drug delivery. At present, targeted drug delivery is one of the research hotspots. The design of targeted drug delivery platforms is mainly to encapsulate drugs on the surface or inside of nanoparticles, and then coat them. The coating can be a simple polymer, such as hydrophilic polyethylene glycol (PEG), to enhance the hydrophilicity of the original nanoparticle surface, prolong the half-life of blood circulation, and make it more effective to target the lesion. The coating can also degrade in response to certain stimuli to release drugs, such as external stimuli such as light and heat, or target cell microenvironment stimuli such as PH. This part will be described in detail later in the targeting part.

Core-shell structured nanoparticles can also be used as templates to design and prepare nanoparticles with other types of structures. Wan et al. prepared SiO2@C nanoparticles by a hydrothermal carbonization method, and then obtained yolk-shell structure, hollow structure or satellite core structure through different subsequent preparations. They used TEOS to form another layer of silica shell on the surface of SiO2@C particles, calcined at high temperature to remove the carbon shell, and obtained SiO2@SiO2 spheres with a void in the two SiO2 shells, that is, the yolk–shell structure. Use ammonia water to dissolve the silica core to form a hollow carbon capsule. In addition, they used the carbon shell with strong reducing ability on the surface of SiO2@C to reduce the noble metal salt solution, so that the noble metal nanoparticles were loaded on the SiO2@C carbon shell in situ, and the nanoparticles with the satellite-core structure were obtained (Fig. 3a) [80]. Liu et al. designed a multi-shell hollow nanostructure based on the core-shell structure, which has a large specific surface area and high load capacity. Firstly, SiO2@CeO2 microspheres were prepared by the polyol-assisted hydrothermal method, and then deposited layer by layer, followed by alkali etching to obtain the double shell layer @CeO2/Au@Pd/TiO2 nanospheres (Fig. 3b). The double shell has different components, and different noble metal nanoparticles are loaded on the outer surface of the metal oxide inner shell and the inner surface of the outer shell. The multiple interactions and synergistic effects between the noble metal nanoparticles and the metal oxide shell can effectively improve the catalytic activity, and because the noble metal nanoparticles are attached to the metal oxide shell, they are not easy to aggregate with each other, which improves their catalytic stability [81].

The yolk-shell structure is composed of a shell and a movable core. There is a cavity between the shell and the core, which can be described as core@void@shell structure. The synthesis method of yolk-shell structure can be roughly classified into hard template method, soft template method and self-template. The hard template method is the most commonly used method. The surface of the core nanoparticles is coated with template before continuing to cover the shell, and then the template is removed. The soft template method uses vesicles self-assembled by amphiphilic molecules. Compared with the hard template, the template does not need to be removed [82, 83]. The yolk-shell structure has the common advantages of hollow structure and core-shell structure, with large surface area, large void space and high load capacity. In addition, (1) The shell of the yolk-shell structure allows guest molecules to diffuse in and interact with the movable core; (2) The movable core usually has a large number of active sites to ensure the efficiency of the reaction; (3) The shell can play a protective role and inhibit irreversible aggregation between the cores; (4) The hollow part between the shell and the core can provide space for storage or reaction [76, 82, 84,85,86]. Therefore, compared with traditional core-shell nanostructures, the yolk-shell structure has better performance.

As we all know, noble metal nanoparticles have excellent catalytic performance as a catalyst, but because they are very easy to aggregate, the catalytic performance will be greatly reduced. The yolk-shell structure can effectively solve this problem. The noble metal nanoparticles can be loaded on the original core, or the noble metal nanoparticles themselves can be used as the core and encapsulated in the shell. The reactant can diffuse into the internal cavity through the shell and be catalyzed by the noble metal nanoparticles, and the original core or shell protects the noble metal nanoparticles, prevents their mutual aggregation, improves their stability, and improves their catalytic activity. Wang et al. prepared Au@ mesopore SnO2 yolk-shell NPs. Au NPs move freely in the SnO2 shell, and there are abundant pores between SnO2 NPs. The reactant molecules can effectively contact with Au NPs for catalysis through the abundant pores of the SnO2 shell, and the SnO2 shell can separate the Au NPs from each other well, avoiding the aggregation of Au NPs, thereby improving the stability and catalytic activity of the catalyst [85]. Du et al. designed a yolk-shell structure with dendritic porous core and mesoporous shell. Many noble metal NPs are loaded on dendritic porous silica spheres (DPSSs), and the outer protective mesoporous silica shell (MSS) has vertically arranged pores. On the one hand, the dendritic structure of the core provides a large specific surface area for loading ultrafine Au or Pt NPs, and a large number of loaded noble metal nanoparticles ensure the effectiveness of the catalytic reaction. On the other hand, the pore channel of the core also acts as a physical barrier to separate and restrict the loaded noble metal nanoparticles, avoid their aggregation, and improve the stability of the catalyst. In addition, MSS with vertically arranged pores can shorten the diffusion path of reactants, which is beneficial to the occurrence of catalytic reactions. The research results show that the yolk-shell structure effectively improves the activity and stability of the catalyst [87].

The yolk-shell structure material can also be used for lithium-ion batteries. The large surface area and large void space of the yolk-shell structure can provide more active sites for lithium-ion storage and increase battery capacity. More importantly, the hollow area can buffer the volume change caused by the reaction process of the lithium-ion battery, improve the structural stability, and give it better cycle performance. Leng et al. designed a multi-layer porous shell yolk-shell structure. Both the multilayer shell and the core can be in contact with the electrolyte, providing more active sites for lithium-ion storage, so the reversible capacity is significantly improved. Secondly, the porous structure of the shell can provide a penetration path for the electrolyte and shorten the lithium-ion diffusion path, so it has excellent rate performance. In addition, the voids inside the yolk-shell structure serve as a buffer for volume changes, increasing the cycle life [88]. Therefore, the yolk-shell structure material they designed has excellent electrochemical properties such as high reversible capacity, long cycle life, and good rate performance.

The cavity and porous shell of the yolk-shell structure make it an attractive carrier for drug delivery. In addition, due to its core@void@shell structure, it can be used for graded drug delivery to achieve safe and effective drug delivery. The initial rapid release of part of the drug is used to alleviate the condition, and then the remaining dose is subsequently released to maintain or optimize the therapeutic effect. In addition, different drugs can be loaded in different areas for sequential delivery. Liu et al. encapsulated different nanoparticles in porous silica shells to obtain yolk-shell structured nanoparticles, such as silica balls, mesoporous silica NPs, gold particles, magnetic particles, etc. (Fig. 4a). The obtained yolk-shell nanoparticles can release the loaded drugs in three steps. First, the drug adsorbed on the shell surface is quickly released, reaching a plateau, and then the drug in the inner hollow space is released again, reaching another plateau, and finally the drug adsorbed on the core is released [86]. The yolk-shell structure can achieve precise controlled release of drugs.

The sandwich structure is a multifunctional composite structure constructed by attaching thin rigid panels on both sides of low-density materials. It has the advantages of low density, large specific surface area, and high structural stability [89]. In addition, the sandwich structure can effectively increase the rigidity of the structure without adding weight, and can improve the energy absorption and storage properties of the material [90]. These advantages of the sandwich structure make it widely used in lithium-ion batteries, biomedicine and other fields.

The excellent performance of the sandwich structure depends on the configuration of the structure and the choice of the sandwich material. By precisely controlling the structural configuration and adjusting the inner core material and the panel material, the material has high specific surface area while having high stability, so that there are more active sites for reaction, better performance and longer life. Lv et al. designed a graphene nanosheet/NiO (GNS/NiO) with a multilayer sandwich structure. GNSs serve as a substrate to fix NPs and prevent NPs from re-aggregating, while NPs serve as spacers to prevent GNSs from re-stacking to form a stable structure, effectively maintaining the active surface, leaving a stable and open channel for ion transfer, and the sandwich structure provides a buffer for volume changes. Therefore, this nanomaterial can be effectively applied to electrochemical energy storage [91]. Elham Kamali Heidari and his colleagues grow NiFe2O4 nanoparticles on both sides of graphene sheets and then apply carbon coatings (Fig. 4b). The graphene layer not only improves conductivity, but also acts as a buffer to relieve the stress caused by volume expansion. In addition, the NiFe2O4 nanoparticles grown on the graphene layer can maintain good dispersion, avoid aggregation, and have a larger specific surface area to provide more active sites for lithium-ion reactions. The carbon coating is used to prevent NiFe2O4 nanoparticles from falling off the graphene matrix and improve the cycling stability of the electrode. The carbon layer can also be used as a stress buffer and an electronic conductor to further improve the performance of the electrode. Based on the synergistic effect of each layer of sandwich structure nanoparticles, a lithium-ion battery negative electrode material with significantly enhanced cycle stability and electrochemical performance is obtained [92]. Guo et al. combined Fe3O4-COOH nanoparticles with polyallylamine hydrochloride (PAH) and inserted them into graphene oxide-COOH sheets through electrostatic interaction. The obtained multilayer sandwich structure hinders the accumulation of GO-COOH flakes, increases the specific surface area, increases the adsorption active sites, and improves the adsorption capacity. In addition, the structure has good stability and can be used repeatedly [93].

The core-satellite structure is to grow many smaller nanoparticles on the surface of larger nanoparticles. The smaller nanoparticles are called satellites, and the larger nanoparticles serve as the core. The core-satellite structure is prepared by forming heterogeneous nanoparticles on the surface of the core particles by chemical deposition, seed growth, chemical reduction, etc. By controlling the surface and free energy of the material, the growth position can be controlled [94]. Core-satellite structured nanoparticles usually have excellent optical properties and have important applications in biosensing, imaging and other optical fields.

Local surface plasmon resonance (LSPR) is the collective oscillation of free electrons on the surface of nano-scale metals or particles under the same light wave as their resonance frequency. When a substance is on the surface of a nano-scale metal structure/particle or is very close to the surface, the Raman scattering signal of the substance will be significantly enhanced. This phenomenon is called surface-enhanced Raman scattering (SERS). The enhancement of SERS is the amplification caused by the enhancement of the local electromagnetic field generated by LSPR, and the enhancement factor can reach 1014, realizing single-molecule detection. In the nanoparticles designed by Xiong et al., AuNPs are randomly distributed on the surface of the CGNR core as satellites, and they have strong surface plasmon coupling. By increasing the size and number density of satellite nanoparticles or reducing the thickness of the silica spacer between the nucleus and the satellite particles, the plasma band can be redshifted and the surface enhanced Raman scattering can be enhanced, which is effectively used in sensing and imaging [95].

The core and satellite of the core-satellite structure can be used as donors and acceptors, respectively, to effectively transmit electrons and energy for biosensing. Resonance energy transfer (FRET) is the transfer of energy from the donor’s excited state to the acceptor through dipole-dipole interaction without radiation resonance. The energy transfer efficiency is extremely sensitive to distance, and a highly sensitive nanometer can be made. Han et al. designed a temperature-responsive polymer-connected core-satellite structure (Fig. 4c). As the temperature rises, the polymer chain shrinks and the distance between the core and the satellite decreases, which causes the surface plasmon coupling band to redshift and increase. Therefore, this temperature-responsive polymer-connected core-satellite structure can be used as a temperature-responsive biosensor [96]. Temperature-responsive polymers can be replaced with other stimulus-responsive polymers that are sensitive to pH, light, or redox, for broader biosensing.

The core-satellite structure of nanoparticles can also compound multiple functions, integrating the excellent performance of each building block into the nanoparticles. It can be used for multi-modal imaging guided therapy and applied in the field of biomedicine. Ma et al. designed nanoparticles with a hollow-satellite shell structure to integrate multiple functions into one. The MRI contrast agent Fe3O4 is used as a satellite to be distributed on the organic silicon nanocapsule (OSNC) shell for imaging. The OSNC shell provides good dispersion and biocompatibility in water, and the hollow part can be used to encapsulate the therapeutic agent. The nanoparticles they designed can effectively treat cancer through high-intensity focused ultrasound therapy guided by magnetic resonance imaging [97].

a Schematic illustration of the preparation of yolk shell structures with mesoporous shells. b Illustration of the synthesis procedure for graphene-NiFe2O4-carbon nanocomposites with a sandwich structure. c Illustration of the synthesis procedure for thermo-responsive plasmonic core-satellite nanostructures

Nano-engineering in tumor treatment

Nano-engineering can customize the function of nanoparticles, endow them with various desired properties, and make them have broader application prospects. In this section, we will focus on the application of nano-engineering in tumor treatment. Targeted delivery of therapeutic agents, tumor drug resistance and immunosuppression are the main difficulties and treatment obstacles for the application of nanoparticles in tumor therapy, and nano-engineering nanomedicines with customized functions can solve these problems well to obtain the best tumor treatment effect.

Targeted delivery

Because traditional delivery methods have low selectivity for tumor cells, high metabolic rate, low treatment efficiency, and high toxicity and side effects on normal tissues [17], nanomedicines have entered people’s field of vision. Nanomedicines has a large specific surface area, adjustable morphology and surface properties, can be used for targeting and controlled/sustained release, and can protect the payload from degradation, improve the stability and half-life of the payload in the blood circulation, and at the same time, it can concentrate multiple functions into one delivery system, which plays an indispensable and important role in tumor therapy [6, 98, 99]. However, most of the nanomedicines will be phagocytosed and cleared by the reticuloendothelial system (RES) in the blood circulation, and have no specific recognition ability for tumors, which will reduce the accumulation of nanoparticles at the tumor site and damage the RES organ [6]. Nano-engineering nanomedicines can overcome the above-mentioned problems, and maximize the effective delivery of therapeutic agents to the tumor area. This is mainly based on two types of targeting: passive targeting and active targeting.

Passive targeting

Passive tumor targeting is generally achieved through the enhanced permeability and retention (EPR) effect. The EPR effect is a phenomenon in which the accumulation of nanoparticles of suitable size in tumor tissues is much higher than that in normal tissues [6]. The reason for this phenomenon: In the process of tumor tissue growth, a large number of tumor blood vessels are needed to provide oxygen and nutrients. However, due to the rapid growth, the tumor blood vessels have not matured and differentiated, and there are gaps between the blood vessel walls. Nanoparticles can penetrate into the tumor tissue through the gap. At the same time, due to the imperfect development of the return system such as lymphatic vessels, it is difficult for the nanoparticles to exit the tumor tissue, and the nanoparticles can accumulate in the tumor tissue and then play a role. Matsumura and Maeda and their colleagues first discovered the EPR effect [100], and they have been playing an extremely important role in cancer treatment since then. The EPR effect is affected by the size, shape, and surface properties of nanoparticles [101, 102]. Through nano-engineering, controlling the size of nanomedicines, or modifying their surface, such as hydrophilic groups and biomimetic preparations, which can largely avoid the phagocytosis and removal of nanomedicines by RES, and prolong the time in the blood circulation, so that it has more opportunities to gather in the tumor area through the EPR effect, so as to exert its best effect.

In order to enhance the accumulation of nanomedicines at the tumor site through the EPR effect, the most commonly used method is to change the size of the nanoparticles. When the size of nanoparticles is too small (< 4-5 nm), they will be filtered by the kidneys and excreted from the body. When the size of nanoparticles is too large (> 200 nm), they are easy to be recognized by RES, and it is difficult to penetrate the tumor tissue through the gap of the blood vessel wall. Therefore, the size of the nanomedicines should be between 10 and 200 nm, which have a long half-life in blood circulation and effectively enter the tumor tissue through the EPR effect [6, 99]. Liu et al. prepared AuNC@CBSA@HA nanoparticles (100 nm, 200 nm, 300 nm) of different sizes by adjusting the ratio of ligands. They proved that AuNC@CBSA@HA with a size of 100 and 200 nm has similar passive tumor accumulation, which is about 1.5 times of the accumulation of 300 nm [103]. Hye Lan Kim prepared monodisperse silica nanospheres of different sizes and studied the effect of size on the accumulation of nanoparticles in mouse U87MG tumors. Their research showed that the accumulation of MSN with a size of 100–150 nm in the tumor site is 4-6.5 times higher than that of MSN with a size of < 30 nm or > 300 nm [104]. By controlling the size of nanoparticles, the EPR effect can be enhanced.

The above-mentioned researches all directly adjust the size of nanoparticles to enhance the EPR effect. However, studies have shown that nanoparticles with a larger size (> 100 nm) have a longer blood circulation time and can remain in the blood circulation for a long time, so that the nanoparticles can effectively accumulate in the tumor tissue. Nanoparticles with a smaller size (< 50 nm) have strong permeability to tumor tissue and can quickly spread to the entire tumor tissue [105]. Nanoparticles of a single size cannot meet the two requirements of long circulation and high permeability at the same time. Therefore, nanomedicines with switchable sizes have attracted people’s attention. This method is usually associated with active targeting, so we will discuss it in detail later in the active targeting section.

After nanomedicines enter the blood circulation, they will interact with blood components and be phagocytosed and removed by RES. This problem can be effectively avoided by modifying the surface of nanomedicines. The most commonly used strategy is to modify the nanomedicines with hydrophilic PEG, which increases the hydrophilicity of the surface of the nanomedicines while reducing the ability to bind to proteins in the blood, making the nanomedicines “invisible”, thereby reducing the uptake of RES, prolonging the circulation of nanomedicines in the blood vessel, and targeting the tumor through the EPR effect.

Wang et al. used PEG derivatives to modify nanoparticles. Compared with unmodified nanoparticles, after modification with PEG derivatives, the binding rate of nanoparticles and proteins is reduced by more than half, prolonging their residence time in the blood circulation, and improving the stability of drug-loaded nanoparticles [106]. However, only PEG modification is not enough to increase the blood circulation half-life of nanomedicines. Therefore, based on PEG, a more effective strategy has been developed. Gao et al. used hydrophilic PEG and hydrophobic Poly(2-Vinylpyridine) (P2VP) fragments to prepare a series of microphase-separated mixed-shell micelles (MSMs) with different hydrophilic-hydrophobic ratios. Among them, MSMs-50 with a hydrophilic/hydrophobic ratio of 5/5 has a much higher blood retention time than other MSMs. Their research showed that by simply adjusting the hydrophilicity and hydrophobicity of nano-engineering, long-cycle nanoparticles can be obtained [107]. Amphiphilic materials have both positively and negatively charged groups, but the overall display is neutral, which can effectively replace PEG, resist non-specific protein adsorption, and avoid interaction with blood components [6]. Ou et al. used amphiphilic materials poly(2-methacryloyloxyethyl phosphorylcholine) (PMPC) combined with poly(b-amino ester) (PAE) to form MSMs on the surface of nanoparticles. Under normal blood pH (7.4), PAE chain invades, and the amphiphilic material prolongs the blood circulation half-life of nanoparticles. In the slightly acidic tumor site, PAE is protonated and the surface is positively charged, which enhances cellular uptake [108].

Another common strategy is to use cell membranes to coat nanomedicines [109]. Red blood cell (RBC) membrane has a “self-labeled” transmembrane protein CD47 [110], through the coating of the red blood cell membrane (RBCm), the nanomedicines can be disguised as cells, making them invisible in the blood circulation, avoiding the uptake of phagocytes, and achieving long circulation. Su et al. prepared nanoparticles that mimic red blood cells (RVPNs), using RBC mimic vesicles (RV) to coat hybrid polymeric nanoparticles (PNs) loaded with the anticancer drug paclitaxel (PTX). In vivo pharmacokinetic studies have shown that compared with PNs, RVPNs have increased blood circulation half-life several times. In their research, RVPNs can also effectively penetrate the tumor area by combining with the tumor penetrating peptide iRGD (Fig. 5a) [111]. The above research directly uses RBCm to coat nanomedicines, uses the proteins and sugars on the RBCm to avoid recognition by the immune system, and the use of RBC morphology can also prolong blood circulation time. Chen et al. controlled synthesis of mesoporous carbon nanoparticles (MCNs) with RBC morphology and hollow core/mesoporous shell nanostructures. Through TEM characterization, it can be known that the mesoporous carbon shell forms a unique red blood cell surface shape (Fig. 5c). Nanoparticles with RBC morphology can achieve long blood circulation time and have more opportunities to be delivered to the tumor site through the EPR effect [112]. Nishit Doshi et al. also studied the synthesis of materials that mimic RBC, including the synthesis of particles with RBC biconcave disc-like morphology through templates, or the synthesis of particles with RBC intrinsic hemoglobin through layer-by-layer assembly (LBL).These materials are good candidates for targeted delivery [113].

a Schematic illustration of RBC-mimicking NPs with extended blood circulation and enhanced tumor penetration. b Pharmacokinetics and biodistribution of RBC-mimicking NPs in 4T1 tumor-bearing mice. Reproduced with permission [111]. Copyright 2016, WILEY-VCH. c Schematic illustrations of the synthetic procedures for HMCNs. d TEM images of SiO2@SiO2/C and HMCNs. e Schematic illustration of HMCNs interacting with DOX via π-stacking, and DOX release from HMCNs. f Schematic illustration of DOX-loaded HMCNs exerting anti-tumor efficacy. Reproduced with permission [112]. Copyright 2014, WILEY-VCH.

In conclusion, by adjusting the size and surface properties of nanomedicines, it can effectively improve the stability of the material, avoid the phagocytosis and clearance of nanoparticles by RES, prolong the half-life of blood circulation, and make the nanomedicines have more opportunities to target and aggregate to the tumor area through the EPR effect.

Active targeting

Nanomedicines can be passively targeted and delivered to tumor tissues through the EPR effect, but as mentioned above, the EPR effect depends on the characteristics of tumor blood vessels. In tumor areas where blood vessels have not yet formed, or large tumor central areas or necrotic areas where blood vessels are insufficient, nanoparticles cannot be effectively reached by the EPR effect [114], and only through passive targeting, most nanoparticles still cannot effectively aggregate to the tumor area. Therefore, when passive targeting is insufficient for effective delivery to the tumor area, active targeting enters people’s field of vision.

There are many studies on active targeting, which can be roughly divided into various receptor-mediated targeting and stimulus-response targeting strategies [8, 115, 116]. Nano-engineering nanomedicines designed according to the above targeting strategies play an important role in tumor treatment. Special emphasis was placed on stimulus-response-targeted nanodrugs as a new active targeting strategy, and their " smart " response change characteristics make it have broad research potential.

Receptor-mediated targeting is to specifically recognize receptors overexpressed on the surface of tumor cells by modifying targeted ligands on the surface of nanoparticles, thereby increasing the accumulation of nanoparticles at the tumor site [117]. The main receptors on the surface of tumor cells include folate receptor (FR) [118, 119], transferrin receptor (TfR) [120], epidermal growth factor receptor (EGFR) [121], human epidermal growth factor receptor 2 (HER2) [122], Cluster of differentiation (CD) receptors-CD44 [123], αvβ3 integrin receptor [124, 125], estrogen receptor (ER), biotin receptor, interleukin (IL) receptor, etc [126]. By modifying the ligands corresponding to the above receptors on the surface of nanomedicines, tumor cells can be specifically targeted and the accumulation of nanomedicines can be promoted, thereby improving the effect of tumor treatment.

Stimulus response targeting is subtle changes in nanoparticles under internal (tumor microenvironment) and external stimuli (magnetic field, light, etc.), thereby effectively accumulating and functioning at the tumor site [8, 127]. Stimulus-responsive targeted nanodrugs can often be associated with “smart switches” and are currently a research hotspot. Therefore, this section focuses on the application of nano-engineering nanomedicines in the field of stimulus-response targeting.

The tumor area has a unique microenvironment, including overexpression of certain enzymes, high levels of glutathione (GSH) in the cell, and low pH in the tumor area [6, 98]. Based on these characteristics, stimulus-responsive nanomedicines that specifically respond to the tumor microenvironment can be designed and delivered in a specific location. Such stimulus-responsive nanomedicines are of great significance to effectively accumulate in the tumor area and reduce toxicity and side effects on normal tissues. Therefore, based on nano-engineering, nanomedicines can be prepared by using ligands that respond to the characteristics of the tumor area, so as to achieve the purpose of directional delivery to the target area.

Enzymes play an indispensable role in life activities. The expression of enzymes is different in different tissues of different states. In the tumor area, the expression of matrix metalloproteinase 2 (MMP-2) is much higher than that of other normal tissues [128]. This feature has been widely used in the design of targeting structures. Nanomedicines obtained by surface modification or structural design with MMP-2 sensitive peptides can utilize the mutual recognition between enzymes and substrates to construct a highly sensitive targeting system to target tumor cells with high MMP-2 expression. Xue and his colleagues used MMP-2 sensitive peptides to modify the multifunctional dendrimer containing PEG on the surface of the delivery nanoplatform containing folic acid (FA) (Fig. 6a). PEG prolongs the blood circulation time of the delivery system. The MMP-2 sensitive peptide breaks in response to the high expression of MMP-2 in the tumor area, thereby removing the PEG shield, and then effectively targeting the tumor through FA, accumulating in the tumor and exerting therapeutic efficacy [129]. Enzyme-responsive degradation of nanomedicines is also available based on MMP-2, and this part can be linked to the size-switchable nanomedicines mentioned above. The smaller size nanoparticles are combined with itself or other substances through the MMP-2 sensitive peptide to form larger size nanoparticles, and the larger size is used for long circulation. In the tumor area, the MMP-2 sensitive peptide specifically binds to the highly expressed MMP-2 and breaks, allowing smaller-sized nanoparticles to be released for effective penetration. For example, He et al. used MMP-2 sensitive peptide (pp) to link MSN to star-shaped PEG to construct a nanoparticle with a special structure. The longer blood circulation half-life of MSNs-pp-PEG can effectively accumulate nanoparticles in the tumor area. After reaching the tumor area, pp is destroyed in response to MMP-2, MSNs nanoparticles are released, and the smaller size of MSN quickly spreads throughout the tumor tissue. The penetration of fluorescently-labeled nanoparticles in the 3D model shows that MSN has the highest penetration rate compared to the larger-sized MSNs-PEG. The final accumulation of MSNs-pp-PEG in tumors was 1.74 times and 2.05 times higher than that of MSNs and MSNs-PEG, respectively [130]. Therefore, the accumulation of the size-switchable nanomedicines in tumor is significantly increased, and it can be expected that it will have the best therapeutic effect.

GSH is a tripeptide composed of glutamic acid, cysteine and glycine, containing γ-amide bond and sulfhydryl group, which is overexpressed in tumors. And it has two forms, oxidized state (G-S-S-G) and reduced state (GSH), which can be used to construct redox-sensitive targeting systems and have important applications in various tumor-targeted nanomedicines [131, 132]. Nanomedicines with disulfide bonds can be degraded in response to GSH, so by designing the structure, a GSH-triggered targeted delivery system with disulfide bonds can be constructed [133]. Li et al. used disulfide bonds to connect the silica network to obtain mesoporous silicone nanoparticles (MONs), and modified PEG on the surface while loading anticancer drugs to construct a targeted drug delivery system (Fig. 6b). The drug delivery system has a long blood circulation half-life, and the disulfide bonds in MONs can be broken in response to the over-expressed GSH in tumor cells to release drugs for targeted delivery [134]. Chen et al. designed cationic block copolymers with PEG and disulfide bonds to load genetic biological macromolecules through electrostatic interactions. In the microenvironment with high levels of GSH in the tumor area, after the disulfide bond is cleaved in response to GSH, the cationic polymer is transformed into a neutral polymer, and the electrostatic interaction disappears, so that genetic biological macromolecules can be effectively released [135]. In addition, GSH consumption can reduce the high redox state of the tumor site and effectively improve the tumor treatment effect [136, 137].

Low pH is one of the important characteristics of tumor areas. Due to the rapid growth of tumor cells and insufficient oxygen supply, the anaerobic respiration of the cells causes the accumulation of lactic acid, which makes the pH of the tumor microenvironment significantly lower than the surrounding normal tissues. Therefore, the pH difference between tumor tissue and normal tissue can be exploited to design a pH-responsive delivery system to achieve targeted delivery and efficient accumulation of nanomedicines in the weakly acidic environment of tumors. Xie et al. coated the surface of magnetic nanoparticles with calcium carbonate and loaded photothermal agent to construct pH-sensitive targeted delivery system. The calcium carbonate shell decomposes in response to the acidic microenvironment of the tumor, and the release rate of the photothermal agent increases significantly with the decrease of pH. Based on this pH-responsive delivery system, magnetic nanoparticles and photothermal agents can be efficiently accumulated in tumor tissues, so that effective diagnosis and treatment can be performed [138]. pH targeting is usually combined with other active targeting. pH targeting is often combined with other active targeting. Zhang et al. modified reactive oxygen species (ROS)-responsive methoxy polyethylene glycol (TK-PEG) and pH-responsive DNA cross-linkers on Fe3O4 nanoparticles to prolong blood circulation and improve tumor accumulation and retention of nanoparticles. In the tumor area, the labile TK-PEG layer was shed off in response to overexpressed ROS, after which DNA folded in response to tumor acidity and drove nanoparticles’ aggregation, accumulating at the tumor site, thereby enhancing magnetic resonance imaging and ultrasound ablation (Fig. 6c) [139]. Pharmacy Department and others also designed a pH and GSH dual response nanomedicines through surface modification. In acidic and redox environments, nanomedicines can respond to pH and GSH to release doxorubicin (DOX). Compared with free DOX, its cytotoxicity to MCF-7 cells is 2.14 times higher, while reducing its toxicity to normal tissues [140].

a Schematic illustration of the synthesis of ACC@DOX.Fe2+-CaSi-PAMAM-FA/mPEG and its therapeutic effect. Reproduced with permission [129]. Copyright 2020, American Association for the Advancement of Science. b Schematic illustration of the synthesis of NPs and GSH-responsive degradation. Reproduced with permission [134]. Copyright 2020, American Chemical Society. c Schematic diagram of the synthetic route of FSIC5P and the function of FSIC5P in response to ROS and pH in tumor tissues. Reproduced with permission [139]. Copyright 2022, American Chemical Society

External stimulus targeting is in response to external factors, such as magnetism, light, etc., to make nanomedicines aggregate at specific locations. It has high local accuracy, and can be accurately released by manual adjustment. At present, magnetic nanoparticles (MNPs) for magnetic targeting have attracted a lot of attention. Magnetic targeting usually uses magnetic nanoparticles as a carrier, placing an external magnetic field at a position corresponding to the tumor area in vitro, and directing the magnetic nanoparticles to the tumor site to effectively accumulate. The study of Michael Chorny et al. showed that when MNPs are delivered to arteries under the uniform magnetic field, the accumulation of MNPs can be 4–10 times higher than that of the non-magnetic control group [141]. Wang et al. designed an azo-magnetic mesoporous silica nanoparticle for magnetic and optical dual targeted delivery. On the one hand, the use of magnets to adsorb nanoparticles proved that nanoparticles can be guided to any specific site for targeted aggregation in the presence of an external magnetic field. On the other hand, the covalently modified azobenzene derivatives in the pores of MSN have both cis and trans configurations, and both absorb light at 450 nm. Using the dynamic swing caused by the cis-trans configuration of the azobenzene chain under light stimulation, the substances encapsulated in the mesopores can effectively diffuse out (Fig. 7a) [142]. This light-controlled delivery system with a “switch” can use a specific wavelength of light to turn on the release switch at a specific tumor site, thereby targeted delivery. Some substances that can react under light can also be used to design light-responsive delivery systems. Liu et al. used lipids that are degradable in response to light and pH to prepare micelles as nanocarriers. The o-nitrophenyl ester bond can be broken in response to pH and light to degrade the micelles and release the loaded substances, and by changing the illumination time or wavelength, manual control of precise local release can be achieved. Compared with the non-responsive control group, the dual-response targeting nanocarriers significantly increased the accumulation in tumor tissues (Fig. 7b) [143].

In short, nano-engineering plays an important role in various targeted delivery of nanomedicines. Nano-engineering can endow nanomedicines with better targeting properties through functional customization for efficient delivery to tumor areas. Thus, the tumor treatment effect is improved and the toxicity and side effects to normal tissues are reduced, so that the treatment has higher efficacy and safety.

a Schematic diagram of the preparation and controlled release process of magnetic and optical targeted delivery systems. Reproduced with permission [142]. Copyright 2012, American Chemical Society. b Schematic illustration of the assembly of DOX/FOBD liposomes and liposomes degradation in response to pH and light. Reproduced with permission [143]. Copyright 2019, American Chemical Society

Resistance

Chemotherapy is one of the most common and effective ways to treat cancer. However, the efficacy of chemotherapy is limited by the drug resistance of tumor cells. Drug resistance refers to the resistance of tumor cells to chemotherapy drugs, which will significantly reduce the therapeutic effect of chemotherapy drugs. Drug resistance can be divided into primary and acquired. Primary drug resistance refers to the ability of tumors to evade initial treatment and is generally thought to be due to innate genetic alterations, or the rapid adaptation of cells to therapy; Acquired drug resistance refers to the decline of tumor treatment efficacy after long-term treatment, which may be due to genetic mutations in some cells during tumor treatment, resulting in a small number of resistant cells, which survive and proliferate after drug treatment, or activating downstream signaling pathways that allow tumor cells to bypass signal expression, which leads to drug resistance [144,145,146,147]. Tumor cells avoid the toxic of chemotherapy drugs through these resistant methods, Therefore, drug resistance can seriously hinder the treatment of tumors.

The mechanism of drug resistance is complex, several typical resistance mechanisms are as follows:

-

i)

Reduce drug uptake: the heterogeneity of tumor extracellular matrix hinders drug penetration and reduces drug exposure. At the same time, the high interstitial hydraulic pressure of the tumor microenvironment makes the drug accumulate around the tumor cells, making it difficult to enter the tumor cells, thereby gradually inducing drug resistance [148, 149].

-

ii)

Drug-specific target changes: the therapeutic effects of some drugs may be related to specific cellular targets. Mutations in target genes or changes in protein expression may lead to drug resistance [150, 151].

-

iii)

DNA damage repair (DDR): DDR includes direct repair, base excision repair, nucleotide excision repair, DNA mismatch repair and double-strand break damage repair. For DNA-damaging drugs, tumor cells can initiate varieties of different DDR pathways to rapidly repair DNA damage, leading to resistance to such drugs [151, 152].

-

iv)

Heterogeneity: there are differences in gene expression, proliferation and metastatic potential among different tumor cells. When chemotherapy drugs are used on tumor cells, the sensitive cells are killed, while a small number of resistant cells survive and proliferate, resulting in drug resistance [153].

-

v)

Tumor stem cell-like cells (CSCs): CSCs have high tumorigenicity, invasiveness and drug resistance, which are important reasons for the metastasis and recurrence of many malignant tumors [152, 154].

-

vi)

Efflux pumps: the overexpression of energy-dependent drug efflux pumps, such as the drug efflux transporter p-glycoprotein (P-gp), is a well-established mechanism of resistance. P-gp is encoded by the MDR-1 (ABCB1) gene and belongs to a family of energy-dependent transport proteins called ATP-binding cassette (ABC) protein family [155]. These proteins provide energy through ATP to pump chemotherapeutic drugs out of the cell, reducing the accumulation of intracellular drugs and reducing the effective drug concentration, thereby reducing the cytotoxicity of chemotherapeutic drugs to tumor cells [156].

As mentioned above, the mechanism of drug resistance in tumor cells is complex and multiple, and in-depth study is still needed to fully understand it. The mechanisms by which efflux pump proteins, such as P-gp, alter intracellular drug accumulation are best understood. In recent years, the application of nanomaterials in cancer chemotherapy has made great progress, but it is still inevitably affected by drug resistance, and there are still many difficulties in practical application. Nano-engineering with “functional customization” properties, as an efficient bridge between nanomedicine and tumor therapy, can solve the difficulties in its practical application. This review focuses on “increasing the intracellular accumulation of drugs”, and describes the key role of nano-engineering nanomedicines in overcoming tumor resistance.

To alter the cellular internalization mechanism of the drug