Abstract

Background

Plum (Prunus domestica L.) has a short shelf-life period due to its high respiration rate and is sensitive to low storage temperatures, which can lead to the appearance of chilling injury symptoms. In this investigation, we applied new coating treatments based on chitosan (CTS) and arginine (Arg) to plum fruit (cv. ‘Stanley’).

Results

Fruit were treated with distilled water (control), Arg at 0.25 and 0.5 mM, CTS at 1% (w/v) or Arg-coated CTS nanoparticles (CTS-Arg NPs) at 0.5 and 1% (w/v), and then stored at 1 °C for days. The application of CTS-Arg NPs at 0.5% attenuated chilling injury, which was accompanied by accumulation of proline, reduced levels of electrolyte leakage and malondialdehyde, as well as suppressed the activity of polyphenol oxidase. Plums coated with CTS-Arg NPs (0.5%) showed higher accumulation of phenols, flavonoids and anthocyanins, due to the higher activity of phenylalanine ammonia-lyase, which in turn resulted in higher DPPH scavenging capacity. In addition, CTS-Arg NPs (0.5%) treatment delayed plum weight loss and retained fruit firmness and ascorbic acid content in comparison to control fruit. Furthermore, plums treated with CTS-Arg NPs exhibited lower H2O2 accumulation than control fruit due to higher activity of antioxidant enzymes, including CAT, POD, APX and SOD.

Conclusions

The present findings show that CTS-Arg NPs (0.5%) were the most effective treatment in delaying chilling injury and prolonging the shelf life of plum fruit.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Background

Low-temperature storage is the most important postharvest strategy to preserve horticultural crops, contributing to extend the shelf life and maintain the nutraceutical quality. Low-temperature storage not only reduces respiration rate but also lessens physiological disorders during storage [1]. However, the high sensitivity of plums to low-temperature storage can lead to chilling injury, which causes substantial alterations in the fruit appearance, such as flesh browning, flesh bleeding and flesh translucency [2]. In the last years, diverse treatments, such as modified atmosphere packaging, 1-methylcyclopropane [3], edible coatings [4, 5], nitric oxide fumigation [6], melatonin [7, 8] and chlorine dioxide [9], have been employed for reducing chilling injury and extending the postharvest life of plums. Among these approaches, edible chitosan coatings have been widely used due to their biocompatibility, biodegradability and non-toxicity [10]. Chitosan (CTS), the second most abundant natural polysaccharide in nature after cellulose, is generally obtained from deacetylation of chitin extracted from the exoskeletons of crustaceans [11]. CTS has been effective for many applications in the field of agriculture, such as ameliorating crop yield, promoting plant growth and controlling diseases and physiological disorders in fruits and vegetables [12]. Different studies showed that CTS coating is an effective method to maintain postharvest quality, prolong shelf-life and increase antioxidant activity in fresh fruits such as sweet cherry [13], plum [14], Japanese plum [5, 15] and strawberry [16].

Arginine (Arg), a metabolically active amino acid found in the structural units of many important proteins, has exhibited activity in enhancing the tolerance against chilling stress in horticultural crops. Arg has physiological roles in living cells as a precursor for the biosynthesis of polyamines (PAs), proline, γ-aminobutyric acid (GABA) and signaling molecules such as nitric oxide (NO) [17, 18]. In several studies, Arg inhibited the senescence of strawberry [19], green asparagus [20] and button mushroom [21]. Sohail et al. [22] showed that Arg prevented the senescence of broccoli by maintaining the green color and reducing the levels of ethylene production and respiration. In recent years, researchers have become interested in the impact of Arg on environmental stress responses. Pretreatment of sunflower seeds with Arg increased resistance to drought stress by enhancing the accumulation of polyamines [23]. Babalar et al. [24] stated that postharvest Arg application to pomegranate fruit during cold storage alleviated chilling injury by retaining the membrane cell integrity, increasing the scavenging activity of reactive oxygen species (ROS) and lowering H2O2 accumulation.

Nanotechnology focuses typically on the study and application of nanoparticles (NPs) in the range of 1–100 nm. NPs are extensively used in the horticultural sector, including for the control of postharvest physiological disorders and diseases of fruits and vegetables [25]. NPs exhibit impressive mobility in plants due to different intrinsic characteristics, such as small size, structural variety and high surface to volume ratio, which are associated with increased catalytic activity and changes in plant metabolism [26]. Xing et al. [27] stated that the application of a chitosan/nano TiO2 composite coating retained nutritional quality and extended shelf life of blueberry fruit for up to 32 days of storage. Song et al. [28] showed that a chitosan/nano-silica coating augmented chilling tolerance of loquat fruit by increasing the activity of antioxidant enzymes and decreasing sugars content. In general, the incorporation of NPs into coating formulations for fresh produce can play a crucial role in maintaining the postharvest quality, increasing ROS scavenging activity and extending the shelf life period. In this work, chitosan-Arginine nanoparticles (CTS-Arg NPs) were synthesized and applied to harvested plum fruit to investigate their potential effects on physiological disorders, enzymatic and antioxidant activity, postharvest fruit quality and storability at low temperature.

Results and discussion

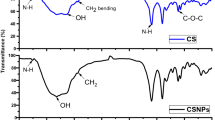

Characterization of CTS-Arg NPs

The freeze-dried nanocomposite powder was characterized by scanning electron microscope (SEM) and transmittance electron microscopy (TEM) techniques. Figure 1A shows the SEM image of nanocomposite composed of spherical nanoparticles. In Fig. 1B, the TEM image is illustrated spherical shape of nanoparticles with the diameter size of ~ 270 nm. The particle size was analyzed using the Dynamic Light Scattering (DLS) technique. The size of CTS-Arg NPs is shown in Fig. 1C. The average particle diameter and polydispersity index (PDI) value were 218 nm and 0.842 nm, respectively. In addition, the results of zeta potential are shown in Fig. 1D. This value was obtained for CTS-Arg NPs + 24 mV.

Chilling injury and membrane integrity

In the current study, plum fruit showed flesh browning and translucency as main symptoms of chilling injury at 1 °C during 40 days of storage (Fig. 2A, B).

Irrespective of the treatments, as well as temperature of storage, chilling injury remarkably enhanced in plum fruits during the whole cold storage. Fruit coated with CTS-Arg NPs (0.5 and 1%) exhibited the lowest rate (4.43 and 5.03%, respectively) of chilling injury in comparison to Arg and CTS individual treatments (Fig. 2C). Also, there were no differences between concentrations of 0.5 and 1% CTS-Arg NPs.

Being coupled with increases of electrolyte leakage and MDA content, chilling injury symptoms appearance and damage of cell membranes were recorded. According to Fig. 3A, B, electrolyte leakage and MDA content at harvest time were 22.53% and 5.75 μmol kg− 1 FW, respectively, which increased in all samples during storage. At the end of the storage period, 0.25 and 0.5 mM Arg-treated plums and control showed higher levels of EL, whereas the application of CTS-Arg NPs (0.5%) delayed EL increase (Fig. 3A). Seemingly, fruits treated with 0.5% CTS-Arg NPs showed the lowest electrolyte leakage (46.84%) after 40 days of storage as compared to control (80.83%) and maintained the highest membranes integrity in contrast to other treated fruits. Increments of MDA content were observed in all untreated and treated plums (Fig. 3B). The highest MDA content was observed in control (13.11 μmol kg− 1 FW) and 0.5 mM Arg (12.69 μmol kg− 1 FW). Compared to control plums, CTS-Arg NPs coatings (0.5 and 1%) remarkably inhibited or buffered the accumulation of MDA (7.99 and 8.24 μmol kg− 1 FW, respectively) at the end of the 40-day storage period, although there were no differences among these treatments (Fig. 3B).

Effect of control (no treatment), arginine (Arg), chitosan (CTS) and CTS-Arg nanoparticles (NPs) treatments electrolyte leakage (A) and MDA accumulation (B) in ‘Stanley’ plums during storage at 1 °C for 40 days. Values shown are means ± standard errors (n = 3). Different letters above the bars indicate significant differences at P < 0.05 according to Duncan’s test

The susceptibility of plum fruit to low temperatures may lead to the appearance of chilling damage symptoms [2, 29]. In the present study, control fruit displayed severe chilling symptoms whereas they decreased substantially in fruit coated with CTS-Arg NPs. Zhang et al. [30] found that exogenous 0.2 mM Arg treatment reduced CI index in comparison with control tomato fruit. Babalar et al. [24] reported that the postharvest application of Arg reduced chilling injury in pomegranate fruit by decreasing EL. Nasr et al. [31] expressed that chitosan-phenylalanine nanoparticles (Cs-Phe NPs) increased persimmon tolerance to chilling injury by maintaining the cell membrane integrity and reducing the levels of reactive oxygen species (ROS). Peroxidation of the cell membrane arising from cold stress and the accumulation of ROS leads to damage the membrane integrity, which can be evaluated by measuring EL and MDA accumulation [32]. The current findings showed that EL and MDA content in treated and control fruit showed an ascending trend during cold storage, but the application of the coating CTS-Arg NPs effectively suppressed the increment of EL and the accumulation of MDA. Similarly, Sohail et al. [22] and Shu et al. [19] reported that EL and MDA content in samples treated with Arg were remarkably lower than in control samples. Moreover, the use of a chitosan / Nano TiO2 coating induced a lower accumulation of MDA in blueberries than the use of CTS alone [27]. In general, it seems that CTS-Arg NPs (0.5%) treatment delayed chilling injury by reducing oxidative stress, maintaining the membrane integrity and controlling EL and the accumulation of MDA.

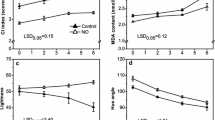

Fruit quality parameters

Weight loss of all treated and control plums showed an upward trend during days of cold storage. All treated fruit retained weight loss in comparison with control fruit, and CTS-Arg NPs at 0.5% was the most effective treatment. At the last sampling time, weight loss in control samples was 7.37% and in plums treated with 0.5 and 1% CTS-Arg NPs 1.06 and 1.85%, respectively (Fig. 4A). The results exhibited that fruit firmness at harvest time was 38.6 N and gradually reduced in all treatments during 40 days of storage at 1 °C (Fig. 4B). The firmness of fruit tissue in all treated plums decreased during storage, but in a lower proportion than in control fruit. The lowest firmness level was measured in control and 0.5 mM Arg (3.83 and 16.13 N), respectively. However, CTS-Arg NPs treatments maintained the higher firmness rate than other treatments at the end of storage. Seemingly, plums coated with CTS-Arg NPs at 0.5% exhibited the lowest softening rate in the interval of 10 to 40 days of cold storage.

Effect of control (no treatment), arginine (Arg), chitosan (CTS) and CTS-Arg nanoparticles (NPs) treatments on weight loss (A) and firmness (B) in ‘Stanley’ plums during storage at 1 °C for 40 days. Values shown are means ± standard errors (n = 3). Different letters above the bars indicate significant differences at P < 0.05 according to Duncan’s test

The main reason accounting for fruit weight loss is water loss produced by increasing transpiration and respiration rates after harvest [33]. The extension of storage time and destruction of cell wall compounds are the main reasons accounting for the increasing softening of fruit tissues [34]. Hassan et al. [35] stated that 0.5 mM L-arginine concentration enhanced fruit firmness and prevented weight loss of cucumber fruits during the whole storage period. Higher integrity of membrane in arginine-treated pomegranate deferred the softening and preserved higher fruit firmness through polyamines accumulation [24]. Meena et al. [36] reported that tomatoes treated with Cu-chitosan NPs maintained fruit firmness during 12 days of storage. According to our results, plums coated with CTS-Arg NPs (0.5%) controlled weight loss and retarded softening of fruit tissue.

Proline content

As shown in Fig. 5, the content of fruit proline at harvest time was 0.58 g kg− 1 FW. The proline content increased in all treated plum samples during the entire storage period. The highest content of proline was seen at the end of storage. After 40 days of storage, the highest (1.96 g kg− 1 FW) and lowest (0.33 g kg− 1 FW) values of proline were registered in plums treated with CTS-Arg NPs (0.5%) and in control plums, respectively. On the other hand, no difference was found between CTS-Arg NPs (1%) and CTS (1%) treatments at the last sampling time (Fig. 5).

Effect of control (no treatment), arginine (Arg), chitosan (CTS) and CTS-Arg nanoparticles (NPs) treatments on proline content in ‘Stanley’ plums during storage at 1 °C for 40 days. Values shown are means ± standard errors (n = 3). Different letters above the bars indicate significant differences at P < 0.05 according to Duncan’s test

The amino acid proline has main functions in higher plants under stress conditions: (1) ROS and OH− radicals scavenging, (2) consolidation of cell membrane structure and (3) the accumulation of energy for metabolism [17, 37]. Zhang et al. [38] noticed that in cherry tomato fruits, Arg treatment enhanced proline content with higher arginase activity, resulting in lower chilling injury during storage at 2 °C. Our results were consistent with the findings of Zhang et al. [38] who reported that proline content increased in tomatoes treated with 0.2 mM Arg along with recovery of chilling injury under chilling stress. Furthermore, the foliar application of Cs-Se NPs remarkably increased proline content in bitter melon under salt stress [39]. Mahmoudi et al. [40] reported that CTS-GB NPs treatment (0.5%) enhanced proline content in plum fruit during storage at 1 °C for 40 days. Accordingly, it can be deduced that the application of CTS-Arg NPs at 0.5% to plum fruit had an effective role in controlling chilling injury by increasing the content of proline.

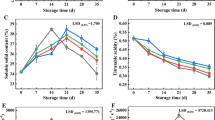

Phenolic compounds and PAL and PPO enzymes activity

Total phenol content, flavonoids, anthocyanins, PAL and PPO at harvest time are reported in Fig. 6. Treatments and storage time exhibited substantial efficacy on total phenols, flavonoids and anthocyanin content of plum fruit stored at 1 °C. Application of CTS-Arg NPs (0.5%) increased the content of phenols, flavonoids and anthocyanins in plums in comparison with control fruit. The amount of these compounds decreased in control samples during the entire cold-storage period (P < 0.01; Fig. 6A, B and C). Furthermore, plums coated with CTS-Arg NPs at 0.5% showed higher values of total phenols, flavonoids and anthocyanins (1.25, 0.3 and 0.59 g kg− 1 FW, respectively) than plums treated with CTS or CTS-Arg NPs (1%) during the 40-day storage period. In all samples, the activity of PAL enzyme increased during cold storage. However, this enhancement was more intensive in treated plums. At the end of the days storage period, the highest (0.3 kat kg− 1) and the lowest (0.17 kat kg− 1) values of PAL enzyme activity were observed in fruit treated with CTS-Arg NPs (0.5%) and control fruit, respectively (Fig. 6D). Furthermore, PAL activity enhanced in treated plums with 0.5 and 1% CTS-Arg NPs 0.3 and 0.29 kat kg− 1, respectively. The performance of 0.5% CTS-Arg NPs was continuously higher than 1% CTS-Arg NPs for increasing PAL activity. PPO enzyme activity increased during storage time in all treated and control fruit. At the end of the cold storage period, the activity of PPO in control fruit was higher than in fruit treated with CTS and CTS-Arg NPs at 0.5 and 1%. However, there were no differences among NPs treatments (Fig. 6E). PPO activity increased from its initial value of 0.01 kat kg− 1 to 0.27 kat kg− 1 in control fruits, while this value enhanced from 0.01 to 0.04 in fruits treated with CTS-Arg NPs after 40 days of cold storage.

Effect of control (no treatment), arginine (Arg), chitosan (CTS) and CTS-Arg nanoparticles (NPs) treatments on total phenols (A), total flavonoids (B), anthocyanins (C), PAL activity (D) and PPO activity (E) in ‘Stanley’ plums during storage at 1 °C for 40 days. Values shown are means ± standard errors (n = 3). Different letters above the bars indicate significant differences at P < 0.05 according to Duncan’s test

Plums are a rich source of phenolic compounds, including phenols, flavonoids and anthocyanins, and the phenylpropanoid pathway is responsible for the biosynthesis and accumulation of these compounds in fruit [41, 42]. PAL is the main enzyme in the phenylpropanoid pathway and catalyzes the conversion of phenylalanine to trans-cinnamic acid, which plays an effective role in attenuating chilling injury [43, 44]. González–Aguilar et al. [45] reported that some edible coatings enhanced the accumulation of secondary metabolites such as phenolics, flavonoids and anthocyanins in tropical fruits. It was observed in the current study that fruit coating with CTS-Arg NPs (0.5%) increased the accumulation of phenolic compounds, which resulted from the higher activity of PAL enzyme. A similar effect was reported in grapes treated with an edible CTS-g-Salicylic acid coating [46]. Moreover, Babalar et al. [24] reported that chilling injury was attenuated in pomegranate fruit in response to Arg treatment, which induced an increment of phenolic compounds due to higher PAL and lower PPO enzymes activity. Our results are also in agreement with those by Xing et al. [27], who noticed that the application of a composite CTS-TiO2 coating maintained the postharvest quality of blueberry by increasing the content of phenolics, flavonoids and anthocyanins as well as preventing pigment demolition. Seemingly, CTS-Arg NPs treatment might activate the biosynthesis pathways of phenolic compounds and indirectly regulate the antioxidant defense systems in plum fruit. Flesh browning in stored fruits is an important problem that occurs due to oxidation and polymerization of phenolic compounds regulated by the activity of the PPO enzyme [47, 48]. The present findings revealed that unlike PAL, PPO enzyme activity had a negative effect on plum phenolic content. The activity of PPO enzyme was enhanced in control plums during the entire period of storage. Coating with CTS-Arg NPs maintained a lower level of PPO enzyme activity, in comparison to control fruit. Petriccione et al. [49] discussed that edible coatings could act as a semi-permeable barrier to oxygen responsible for polyphenol oxidase (PPO) reaction. Song et al. [28] reported that the oxidation of phenolic compounds during days of storage was attenuated in loquat fruit treated with CTS-silica, which was correlated with lower PPO activity in coated than in control fruit. The present findings suggest that CTS-Arg NPs coating induced resistance to chilling injury in plum fruit by decreasing the activity of PPO enzyme.

Ascorbic acid content and DPPH scavenging capacity

The amount of ascorbic acid of plum fruit at harvest was 0.41 g kg− 1 FW in this experiment, which deducted over time (Fig. 7A). During the first 10 days of storage, ascorbic acid content increased and then gradually decreased in both treated and control fruit during cold storage. However, plums coated with CTS-Arg NPs showed a higher accumulation of ascorbic acid than those treated with either CTS or Arg alone. There was no difference between CTS-Arg NPs at 0.5 and 1% concentration. As results in Fig. 7B showed the antioxidant capacity (DPPH scavenging activity) at harvest time was 50.69%. Plums coated with CTS-Arg NPs showed a higher DPPH radical scavenging activity than the rest of fruit during the storage period (Fig. 7B). CTS-Arg NPs at 0.5% were superior to 1% in increasing plum antioxidant capacity.

Effect of control (no treatment), arginine (Arg), chitosan (CTS) and CTS-Arg nanoparticles (NPs) treatments on ascorbic acid content (A) and antioxidant capacity (B) in ‘Stanley’ plums during storage at 1 °C for 40 days. Values shown are means ± standard errors (n = 3). Different letters above the bars indicate significant differences at P < 0.05 according to Duncan’s test

Ascorbic acid acts as (1) ROS scavenger and (2) an electron donor to APX for scavenging H2O2 by AA/GSH cycle [50, 51]. Based on the present results, ascorbic acid content was higher in plums treated with the CTS-Arg NPs coating than in control fruit. It might be thus deduced that higher DPPH scavenging activity in plum fruit coated with CTS-Arg NPs (0.5%) could result from higher content of phenolics, flavonoids, anthocyanins and ascorbic acid. In this sense, Sohail et al. [22] reported that postharvest Arg treatment prevented postharvest senescence of broccoli by reducing the ascorbic acid content and enhancing the antioxidant capacity. Likewise, the foliar application of CTS-phenylalanine nanocomposites at 5 mM concentration enhanced ascorbic acid content in grape fruit [52]. Babalar et al. [24] reported that the higher ascorbic acid accumulation in pomegranate fruit treated with arginine resulted from higher GR/APX system activity or lower AAO enzyme activity and remarkably assisted to increasing the antioxidant capacity of fruits during cold storage at 4 °C for 60 days. The use of chitosan nanoparticles loaded with Citrus.aurantium oil declined the loss of ascorbic acid content and increased the antioxidant capacity of white button mushroom during storage [53].

Enzymatic antioxidant system activity and H2O2 content

The activity of antioxidant enzymes and H2O2 content at harvest time are reported in Fig. 8. In the interval of 10 to 40 days of storage, the activity of antioxidant enzymes increased in all treated samples (Fig. 8A-D). Fruit coated with CTS-Arg NPs (0.5%) exhibited a higher activity of CAT, POD, APX and SOD than fruit treated with either CTS or Arg alone. Furthermore, control (no treatment) samples exhibited the highest enzyme activity up the first 20 days of storage and then gradually decreased. CAT activity enhanced in all treatments during cold storage. The activity of CAT enzyme was more stimulated than in control fruit after 40 days of storage. This enzyme activity in control fruit reduced after 20 days of storage (Fig. 8A). CTS-Arg NPs treatment increased the POD activity compared to the control fruit. There were significant different between CTS-Arg NPs and other treatments during the whole cold storage. In general, the concentration of 0.5% CTS-Arg NPs was the most effective treatment for increasing POD activity in plum fruits during 40 days of storage (Fig. 8B). Postharvest treatment of CTS-Arg NPs significantly increased the activity of SOD in plum fruits. The most activity of SOD was measured in treated plums with 0.5% CTS-Arg NPs (1.11 kat kg-1). The lowest SOD activity was found in control fruits after 20 days of storage (Fig. 8C). In all tested samples during 40 days of storage, APX activity enhanced in plum fruits. The highest APX activity was found in plums treated with CTS-Arg NPs in the storage period. The concentration of 0.5% CTS-Arg NPs was the most efficient treatment to increase the APX activity of plums during cold storage (Fig. 8D). As the storage period extended, the content of H2O2 increased in both treated and untreated fruit, although CTS-Arg NPs treatment alleviated the accumulation of H2O2 content (Fig. 8E). The highest and lowest values of H2O2 content were observed in control fruit (11.49 μmol kg− 1 FW) and fruit treated with CTS-Arg NPs at 0.5% (7.47 μmol kg− 1 FW), respectively. However, there was no substantial difference between control and 0.5 mM Arg treatments.

Effect of control (no treatment), arginine (Arg), chitosan (CTS) and CTS-Arg nanoparticles (NPs) treatments on catalase (A), peroxidase (B), superoxide dismutase (C) and ascorbate peroxidase (D) enzymes activity and H2O2 content (E) in ‘Stanley’ plums during storage at 1 °C for 40 days. Values shown are means ± standard errors (n = 3). Different letters above the bars indicate significant differences at P < 0.05 according to Duncan’s test

ROS are reduced forms of oxygen that cause oxidative stress under abiotic stress due to their producing and scavenging imbalance [54]. In order to scavenge accumulated ROS, two systems including enzymatic (CAT, POD, APX, SOD) and non-enzymatic (ascorbic acid) antioxidant systems are employed [29, 55]. SOD enzyme is responsible for scavenging ROS that converts superoxide (O2•-) radicals into H2O2 and O2•. Then, CAT catalyzes H2O2 into H2O and O2. Meanwhile, APX enzyme changes H2O2 into H2O through receiving an electron from ascorbate in the ascorbic acid/glutathione cycle [56, 57]. POD due to the oxidation of polyphenol compounds in presence of H2O2 is known in the browning process of fruits and vegetables [58]. Many studies showed that the increment of CAT, APX, SOD and POD activity was effective in controlling chilling injury and attenuating oxidative damage in plum fruit. Panahirad et al. [59] reported that pectin and carboxymethyl cellulose edible coatings reduced the accumulation of ROS due to the increases in POD activity. The application of L-cysteine after harvest reduced the browning of plum by increasing the activity of antioxidant enzymes (CAT, APX and SOD) and decreasing membrane degradation [60]. Our findings showed that plum coated with CTS-Arg NPs (0.5%) enhanced the activity of antioxidant enzymes during the storage period. Zhang et al. [61] stated that Arg treatment improved the CAT, POD and SOD activity, which increased disease resistance in tomato fruit. Likewise, in button mushrooms, Arg treatment inhibited cap browning and delayed senescence caused by undesirable environmental conditions through an increment of POD and SOD activity. In accordance with our results, previous studies found that the application of CTS NPs enhanced the activity of antioxidant enzymes in horticultural products such as loquat [28], plum [5] and tomato [62]. Shu et al. [19] reported that the antioxidant enzymes activities (CAT, POD, SOD, APX) enhanced after application of Arg 1 mM. They stated that the inducing effects of Arg on enzymatic antioxidant system activity may be one of its main mechanisms for preserving fruit quality. The present findings showed that the application of 0.5% CTS-Arg NPs remarkably decreased H2O2 content during cold storage. Babalar et al. [24] observed that pomegranate treated with Arg exhibited lower H2O2 content, resulting from the higher activity of antioxidant enzymes. Seemingly, the reduction of H2O2 content in CTS-Arg NPs-treated (0.5%) plums might be the consequence of the increased activity of antioxidant enzymes, as they are responsible for the elimination of H2O2.

Heat map clustering and principal component analysis

Due to the high number of dependent and independent variables involved in this study, heat map clustering and principal component analysis (PCA) were used to analyze and visualize the results. According to the heat map clustering analysis, the findings are correlated and clear discrimination into two major clusters was observed for the treatments. The first cluster was mainly composed of CTS and its conjugation with Arg, with the exception of 1% CTS at day 10 and 1% CTS at day 20. The second cluster included the control and Arg groups. In the case of quality parameters, H2O2, MDA, EL, CI, PPO, weight loss, PAL, phenolic, flavonoid, and Ascorbic acid contents were sorted into the same cluster (Fig. 9 A, B).

In general, relevant values were more pronounced for Arg and control groups, whilst they were lower for CTS and its conjugations. On the contrary, the higher values of antioxidant enzymes activity, firmness, anthocyanin and DPPH scavenging activity were observed for CTS and related groups. In addition, two PCA analyses with Eigenvalues > 1.0 (F1: 58.3%, F2: 33.7% accounting for 92.00% variability of the original data) showed that the first component (F1) had positive correlations with Ascorbic acid content, proline content, firmness, SOD, POD, PAL, CAT, APX, DPPH, phenolics, flavonoid and anthocyanin whereas the second component (F2) was positively correlated with H2O2, MDA, EL, chilling injury, PPO, and weight loss (Fig. 10A, B).

Conclusion

The present results revealed that fruit coating with CTS-Arg NPs increased the chilling tolerance by reducing the accumulation of MDA and H2O2, increasing proline accumulation and ROS scavenging CAT, POD, APX and SOD enzymes activity and retaining the higher value of ascorbic acid in plum fruit stored at 1 °C and 90% RH for days. Moreover, the increment in PAL/PPO activities ratio lead to enhanced accumulation of phenolic compounds (phenols, flavonoids and anthocyanins), higher capacity of DPPH and reduced chilling injury in stored plums. Therefore, postharvest application of CTS-Arg NPs (especially at a concentration of 0.5%) showed potential as a harmless and safe treatment for retaining fruit quality and delaying ripening of plum fruit during cold storage.

Materials and methods

Chemical and plant material, treatments and storage

All chemicals including Chitosan (CTS) (Molecular Weight = 110 kDa and Deacetylation Degree = 84%, purity = 99%) sodium tripolyphosphate (TPP) (Molecular Weight = 367.847 g mol− 1), L-Arginine (Arg) (Molecular Weight = 174.20 g mol− 1) were purchased from Sigma - Aldrich, USA. Plum fruit (Prunus domestica cv. ‘Stanley’) at maturity stage were collected from a commercial orchard located in Khorramdareh (Zanjan Province, Iran) and transferred to the laboratory of postharvest physiology, University of Zanjan. Then, 504 plums were selected in terms of shape, size, colour, maturity and absence of visual damage. The fruits were harvested in commercial maturity stage and randomly assigned into 6 groups of 21 fruits for each treatment in triplicate (7 fruit per replicate) for 4 different storage time. The following treatments were applied as 10-min dips at 25 °C: control (distilled water), Arg at two concentrations (0.25 and 0.5 mM), CTS at 1% and Arg-CTS nanoparticles (CTS-Arg NPs) at two concentrations (0.5 and 1%, w/v). All nanomaterials were synthesized at laboratory of Nanochemsitry, University of Maragheh, Maragheh, Iran according to Nasr et al. [31] and Mahmoudi et al. [40]. A scanning electron microscope (SEM, VEGAII, XMU, Czech Republic) and transmission electron microscope (TEM; Philips CM10) was used to examine the surface morphology and the size of CTS-Arg NPs. Particle size and zeta potential for CTS-Arg NPs was recorded using a laser-scattering technique (DLS/Zeta; Zetasizer Nano ZS90; Malvern Instruments). Treated fruits were air-dried at room temperature and immediately stored at 1 °C and 90% relative humidity (RH) for 40 days. Sampling for assessment of physiological and biochemical characteristics was conducted at regular intervals of 10, 20, 30 and 40 days. For each evaluation time, prior to the performance of measurements and analyses, fruits were subjected to a shelf-life period of 2 day at 25 °C. Furthermore, fruit pulp was used to evaluate the biochemical attributes.

Chilling injury, electrolyte leakage (EL) and malondialdehyde (MDA) content

Chilling injury (CI) index was assessed by estimating the area of the internal fruit tissue showing browning symptoms after 10, 20, 30, and 40 days of storage at 1 °C followed by 2 day of shelf life at 20 °C. Three independent replicates (n = 7 fruit each) were used for each treatment. Internal browning was computed as follows:

The browning index (%) was calculated as in Aghdam et al. [63]:

The method of Promyou et al. [64] was used for determining the electrolyte leakage (EL):

Determination of MDA content was carried out using the thiobarbituric acid (TBA) method proposed by Dhindsa et al. [65]. The content of MDA was expressed on a fresh weight basis, in μmol kg− 1 fresh weight (FW).

(A: absorbance; W: weight samples; V: total volume of the aqueous extract)

Weight loss and firmness fruit

The weight of fruit was measured using a digital balance at the beginning and end of each storage period and weight loss was calculated as the percentage of initial weight using the following formula [66]:

The firmness of plum fruit was analyzed using a texture analyzer (FT011), fitted with an 8-mm spherical probe and expressed as Newtons (N).

Determination of proline content

The proline content was estimated according to the method described by Sánchez et al. [67]. Proline concentration was calculated using a standard curve constructed using proline and expressed as g kg− 1 FW.

Total phenols, flavonoids, anthocyanin, and phenylalanine ammonia-lyase (PAL) and polyphenol oxidase (PPO) enzymes activity

The procedure of Folin–Ciocalteu was applied for evaluating total phenols content [68] They were expressed as gallic acid equivalents (GAE) on FW basis, g kg− 1. Total amount of flavonoids in the extracts was quantified according to the aluminum chloride colorimetric method, as described by Zhishen et al. [69]. The accumulation of flavonoids was expressed as quercetin equivalents (QE) on FW basis, g kg− 1. The pH-differential procedure described by Giusti and Wrolstad [70] was employed for determining total anthocyanin content, which was expressed as cyanidin-3-glucoside on FW basis, g kg− 1. The activities of PAL and PPO were quantified as described by Nguyen et al. [71] and expressed as katals produced per mass of protein, kat kg− 1.

Ascorbic acid content and 2,2-diphenyl-1-picrylhydrazyl (DPPH) scavenging capacity

Total ascorbic acid content in plum fruit was evaluated using the 2,6-dichlorophenol indophenols method [72] and expressed on FW basis, g kg− 1. Free radical DPPH• scavenging activity was measured as described by Dehghan and Khoshkam [73] and calculated with the formula:

Determination of antioxidant system activity and hydrogen peroxide (H2O2) content

In order to reveal the activity of the enzymatic antioxidant system in the fruit samples, the activities of catalase (CAT), peroxidase (POD), superoxide dismutase (SOD), and ascorbate peroxidase (APX) were measured [74] and expressed as katals produced per mass of protein, kat kg− 1. Bradford [75] method was applied to determine protein content using bovine serum albumin (BSA) as a standard. H2O2 content was quantified according to the method of Alexieva et al. [76] and expressed in μmol kg− 1, considering a standard curve.

Statistical analysis

The experiments were performed using a completely randomized factorial design. Each treatment was applied to three replications of seven fruit each. Analysis of variance (ANOVA) was carried out with SPSS software version 20 (SPSS Inc., Chicago, IL, USA). Differences between means were determined by Duncan’s test, with differences considered significant at P ≤ 0.05. For multivariate analysis; Clustvis and JAMOVI software were used.

Availability of data and materials

The datasets used and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Aghdam MS, Bodbodak S. Postharvest heat treatment for mitigation of chilling injury in fruits and vegetables. Food Bioprocess Technol. 2014;7:37–53. https://doi.org/10.1007/s11947-013-1207-4.

Crisosto CH, Mitchell FG, Ju Z. Susceptibility to chilling injury of peach, nectarine, and plum cultivars grown in California. HortSci. 1999;34:1116–8. https://doi.org/10.21273/HORTSCI.34.6.1116.

Erkan M, ESKİ H. Combined treatment of modified atmosphere packaging and 1-methylcyclopropene improves postharvest quality of Japanese plums. Turk J Agric For. 2012;36:563–75. https://doi.org/10.3906/tar-1111-34.

Thakur R, Pristijono P, Golding JB, Stathopoulos CE, Scarlett CJ, Bowyer M, et al. Development and application of rice starch based edible coating to improve the postharvest storage potential and quality of plum fruit (Prunus salicina). Sci Hortic. 2018;237:59–66. https://doi.org/10.1016/j.scienta.2018.04.005.

Liu K, Yuan C, Chen Y, Li H, Liu J. Combined effects of ascorbic acid and chitosan on the quality maintenance and shelf life of plums. Sci Hortic. 2014;76:45–53. https://doi.org/10.1016/j.scienta.2014.06.027.

Singh SP, Singh Z, Swinny EE. Postharvest nitric oxide fumigation delays fruit ripening and alleviates chilling injury during cold storage of Japanese plums (Prunus salicina Lindell). Postharvest Biol Technol. 2009;53:101–8. https://doi.org/10.1016/j.postharvbio.2009.04.007.

Yan R, Xu Q, Dong J, Kebbeh M, Shen S, Huan C, et al. Effects of exogenous melatonin on ripening and decay incidence in plums (Prunus salicina L. cv. Taoxingli) during storage at room temperature. Sci Hortic. 2022;292:110655. https://doi.org/10.1016/j.scienta.2021.110655.

Du H, Liu G, Hua C, Liu D, He Y, Liu H, et al. Exogenous melatonin alleviated chilling injury in harvested plum fruit via affecting the levels of polyamines conjugated to plasma membrane. Postharvest Biol Technol. 2021;179:111585. https://doi.org/10.1016/j.postharvbio.2021.111585.

Chen Z, Zhu C. Combined effects of aqueous chlorine dioxide and ultrasonic treatments on postharvest storage quality of plum fruit (Prunus salicina L.). Postharvest Biol Technol. 2011;61:117–23. https://doi.org/10.1016/j.postharvbio.2011.03.006.

Ngo TMP, Nguyen TH, Dang TMQ, Do TVT, Reungsang A, Chaiwong N, et al. Effect of pectin/Nanochitosan-based coatings and storage temperature on shelf-life extension of “elephant” mango (Mangifera indica L.). Fruit Polym. 2021;13:3430. https://doi.org/10.3390/polym13193430.

Kanmani P, Aravind J, Kamaraj M, Sureshbabu P, Karthikeyan S. Environmental applications of chitosan and cellulosic biopolymers: a comprehensive outlook. Bioresour Technol. 2017;242:295–303. https://doi.org/10.1016/j.biortech.2017.03.119.

Xu D, Li H, Lin L, Liao MA, Deng Q, Wang J, et al. Effects of carboxymethyl chitosan on the growth and nutrient uptake in Prunus davidiana seedlings. Physiol Mol Biol Plants. 2020;26:661–8. https://doi.org/10.1007/s12298-020-00791-5.

Abdipour M, Malekhossini PS, Hosseinifarahi M, Radi M. Integration of UV irradiation and chitosan coating: a powerful treatment for maintaining the postharvest quality of sweet cherry fruit. Sci Hortic. 2020;264:109197. https://doi.org/10.1016/j.scienta.2020.109197.

Kumar P, Sethi S, Sharma RR, Srivastav M, Varghese E. Effect of chitosan coating on postharvest life and quality of plum during storage at low temperature. Sci Hortic. 2017;226:104–9. https://doi.org/10.1016/j.scienta.2017.08.037.

Adiletta G, Gliottone G, Di Matteo M, Petriccione M. Response of qualitative traits and antioxidant systems to chitosan postharvest treatment in ‘black Golden’ Japanese plum. Foods. 2022;11:853. https://doi.org/10.3390/foods11060853.

Nguyen VT, Nguyen DH, Nguyen HV. Combination effects of calcium chloride and nano-chitosan on the postharvest quality of strawberry (Fragaria x ananassa Duch.). Postharvest Biol Technol. 2020;162:111103. https://doi.org/10.1016/j.postharvbio.2019.111103.

Aghdam MS, Bodbodak S. Physiological and biochemical mechanisms regulating chilling tolerance in fruits and vegetables under postharvest salicylates and jasmonates treatments. Sci Hortic. 2013;156:73–85. https://doi.org/10.1016/j.scienta.2013.03.028.

Morris SM Jr. Arginine metabolism: boundaries of our knowledge. J Nutr. 2007;137:1602S–9S. https://doi.org/10.1093/jn/137.6.1602S.

Shu P, Min D, Ai W, Li J, Zhou J, Li Z, et al. L-arginine treatment attenuates postharvest decay and maintains quality of strawberry fruit by promoting nitric oxide synthase pathway. Postharvest Biol Technol. 2020;168:111253. https://doi.org/10.1016/j.postharvbio.2020.111253.

Wang X, Gu S, Chen B, Huang J, Xing J. Effect of postharvest L-arginine or cholesterol treatment on the quality of green asparagus (asparagus officinalis L.) spears during low temperature storage. Sci Hortic. 2017;225:788–94. https://doi.org/10.1016/j.scienta.2017.07.058.

Li B, Ding Y, Tang WG, Wu S, Li X, Huang X, et al. Effect of l-arginine on maintaining storage quality of the white button mushroom (Agaricus bisporus). Food Bioprocess Technol. 2019;12:563–74. https://doi.org/10.1007/s11947-018-2232-0.

Sohail M, Wills RBH, Bowyer MC, Pristijono P. Beneficial impact of exogenous arginine, cysteine and methionine on postharvest senescence of broccoli. Food Chem. 2021;338:128055. https://doi.org/10.1016/j.foodchem.2020.128055.

Hassan AM, Mohamed HE. L-arginine pretreatment enhances drought resistance of sunflower (Helianthus annuus L.) plants by increase in polyamines content. J Plant Growth Regul. 2019;38:600–5. https://doi.org/10.1007/s00344-018-9873-0.

Babalar M, Pirzad F, Sarcheshmeh MAA, Talaei A, Lessani H. Arginine treatment attenuates chilling injury of pomegranate fruit during cold storage by enhancing antioxidant system activity. Postharvest Biol Technol. 2018;137:31–7. https://doi.org/10.1016/j.postharvbio.2017.11.012.

Feregrino-Perez AA, Magaña-López E, Guzmán C, Esquivel K. A general overview of the benefits and possible negative effects of the nanotechnology in horticulture. Sci Hortic. 2018;238:126–37. https://doi.org/10.1016/j.scienta.2018.03.060.

Ma X, Geiser-Lee J, Deng Y, Kolmakov A. Interactions between engineered nanoparticles (ENPs) and plants: phytotoxicity, uptake and accumulation. Sci Total Environ. 2010;408:3053–61. https://doi.org/10.1016/j.scitotenv.2010.03.031.

Xing Y, Yang S, Xu Q, Xu L, Zhu D, Li X, et al. Effect of chitosan/Nano-TiO2 composite coating on the postharvest quality of blueberry fruit. Coatings. 2021;11:512. https://doi.org/10.3390/coatings11050512.

Song H, Yuan W, Jin P, Wang W, Wang X, Yang L, et al. Effects of chitosan/nano-silica on postharvest quality and antioxidant capacity of loquat fruit during cold storage. Postharvest Biol Technol. 2016;119:41–8. https://doi.org/10.1016/j.postharvbio.2016.04.015.

Singh SP. Postharvest oxidative stress in plums: mechanism and implications for storage and fruit quality (Doctoral dissertation, Curtin University). 2010. http://hdl.handle.net/20.500.11937/551.

Zhang X, Shen L, Li F, Meng D, Sheng J. Amelioration of chilling stress by arginine in tomato fruit: changes in endogenous arginine catabolism. Postharvest Biol Technol. 2013;76:106–11. https://doi.org/10.1016/j.postharvbio.2012.09.012.

Nasr F, Pateiro M, Rabiei V, Razavi F, Formaneck S, Gohari G, et al. Chitosan-phenylalanine nanoparticles (Cs-Phe Nps) extend the postharvest life of persimmon (Diospyros kaki) fruits under chilling stress. Coatings. 2021;11:819. https://doi.org/10.3390/coatings11070819.

Chongchatuporn U, Ketsa S, van Doorn WG. Chilling injury in mango (Mangifera indica) fruit peel: relationship with ascorbic acid concentrations and antioxidant enzyme activities. Postharvest Biol Technol. 2013;86:409–17. https://doi.org/10.1016/j.postharvbio.2013.07.023.

Zhu X, Wang Q, Cao J, Jiang W. Effects of chitosan coating on postharvest quality of mango (Mangifera indica L. cv. Tainong) fruits J Food Process Preserv 2008;32:770–784. https://doi.org/10.1111/j.1745-4549.2008.00213.x.

Sturm K, Koron D, Stampar F. The composition of fruit of different strawberry varieties depending on maturity stage. Food Chem. 2003;83:417–22. https://doi.org/10.1016/S0308-8146(03)00124-9.

Hasan MU, Rehman RNU, Malik AU, Haider MW, Ahmed Z, Khan AS, et al. Pre-storage application of L-arginine alleviates chilling injury and maintains postharvest quality of cucumber (Cucumis sativus). J Hortic Sci Technol. 2019;2:102–8. https://doi.org/10.46653/jhst190204102.

Meena M, Pilania S, Pal A, Mandhania S, Bhushan B, Kumar S, et al. Cu-chitosan nano-net improves keeping quality of tomato by modulating physio-biochemical responses. Sci Rep. 2020;10:1–11. https://doi.org/10.1038/s41598-020-78924-9.

Ashraf M, Foolad MR. Roles of glycine betaine and proline in improving plant abiotic stress resistance. Environ Exp Bot. 2007;59:206–16. https://doi.org/10.1016/j.envexpbot.2005.12.006.

Zhang X, Shen L, Li F, Zhang Y, Meng D, Sheng J. Up-regulating arginase contributes to amelioration of chilling stress and the antioxidant system in cherry tomato fruits. J Sci Food Agric. 2010;90:2195–202. https://doi.org/10.1002/jsfa.4070.

Sheikhalipour M, Esmaielpour B, Behnamian M, Gohari G, Giglou MT, Vachova P, et al. Chitosan–selenium nanoparticle (Cs–se NP) foliar spray alleviates salt stress in bitter melon. Nanomater. 2021;11:684. https://doi.org/10.3390/nano11030684.

Mahmoudi R, Razavi F, Rabiei V, Gohari G, Palou L. Application of Glycine betaine coated chitosan nanoparticles alleviate chilling injury and maintain quality of plum (Prunus domestica L.) fruit. Int J Biol Macromol. 2022;207:965–77. https://doi.org/10.1016/j.ijbiomac.2022.03.167.

Raynal J, Moutounet M. Intervention of phenolic compounds in plum technology. 2. Mechanisms of anthocyanin degradation. J Agric Food Chem. 1989;37:1051–3. https://doi.org/10.1021/jf00088a051.

Vogt T. Phenylpropanoid biosynthesis. Mol Plant. 2010;3:2–20. https://doi.org/10.1093/mp/ssp106.

Siboza XI, Bertling I, Odindo AO. Salicylic acid and methyl jasmonate improve chilling tolerance in cold-stored lemon fruit (Citrus Limon). J Plant Physiol. 2014;171:1722–31. https://doi.org/10.1016/j.jplph.2014.05.012.

Ngadze E, Icishahayo D, Coutinho TA, Van der Waals JE. Role of polyphenol oxidase, peroxidase, phenylalanine ammonia lyase, chlorogenic acid, and total soluble phenols in resistance of potatoes to soft rot. Plant Dis 2012;96:186–192. https://doi.org/https://doi.org/10.1094/PDIS-02-11-0149.

Gonzalez-Aguilar GA, Villa-Rodriguez JA, Ayala-Zavala JF, Yahia EM. Improvement of the antioxidant status of tropical fruits as a secondary response to some postharvest treatments. Trends Food Sci Technol. 2010;21:475–82. https://doi.org/10.1016/j.tifs.2010.07.004.

Shen Y, Yang H. Effect of preharvest chitosan-g-salicylic acid treatment on postharvest table grape quality, shelf life, and resistance to Botrytis cinerea-induced spoilage. Sci Hortic. 2017;224:367–73. https://doi.org/10.1016/j.scienta.2017.06.046.

Ali S, Khan AS, Malik AU, Shahid M. Effect of controlled atmosphere storage on pericarp browning, bioactive compounds and antioxidant enzymes of litchi fruits. Food Chem 2016;206:18–29. https://doi.org/https://doi.org/10.1016/j.foodchem.2016.03.021.

Ding Z, Tian S, Wang Y, Li B, Chan Z, Han J, et al. Physiological response of loquat fruit to different storage conditions and its storability. Postharvest Biol Technol. 2006;41:143–50. https://doi.org/10.1016/j.postharvbio.2006.03.012.

Petriccione M, Mastrobuoni F, Pasquariello MS, Zampella L, Nobis E, Capriolo G, et al. Effect of chitosan coating on the postharvest quality and antioxidant enzyme system response of strawberry fruit during cold storage. Foods. 2015;4:501–23. https://doi.org/10.3390/foods4040501.

Bartoli CG, Yu J, Gomez F, Fernández L, McIntosh L, Foyer CH. Inter-relationships between light and respiration in the control of ascorbic acid synthesis and accumulation in Arabidopsis thaliana leaves. J Exp Bot. 2006;57:1621–31. https://doi.org/10.1093/jxb/erl005.

Cordenunsi BR, Genovese MI, do Nascimento JRO, NMA H, dos Santos RJ, Lajolo FM. Effects of temperature on the chemical composition and antioxidant activity of three strawberry cultivars. Food Chem. 2005;91:113–21. https://doi.org/10.1016/j.foodchem.2004.05.054.

Gohari G, Zareei E, Kulak M, Labib P, Mahmoudi R, Panahirad S, et al. Improving the berry quality and antioxidant potential of flame seedless grapes by foliar application of chitosan–phenylalanine nanocomposites (CS–Phe NCs). Nanomater. 2021;11:2287. https://doi.org/10.3390/nano11092287.

Karimirad R, Behnamian M, Dezhsetan S, Sonnenberg A. Chitosan nanoparticles-loaded Citrus aurantium essential oil: a novel delivery system for preserving the postharvest quality of Agaricus bisporus. J Sci Food Agric. 2018;98:5112–9. https://doi.org/10.1002/jsfa.9050.

Hodges DM, Lester GE, Munro KD, Toivonen PM. Oxidative stress: importance for postharvest quality. HortSci. 2004;39:924–9. https://doi.org/10.13140/2.1.3929.1526.

Bian S, Jiang Y. Reactive oxygen species, antioxidant enzyme activities and gene expression patterns in leaves and roots of Kentucky bluegrass in response to drought stress and recovery. Sci Hortic. 2009;120:264–70. https://doi.org/10.1016/j.scienta.2008.10.014.

Pan Y, Chen L, Chen X, Jia X, Zhang J, Ban Z, et al. Postharvest intermittent heat treatment alleviates chilling injury in cold-stored sweet potato roots through the antioxidant metabolism regulation. J Food Process Preserv. 2019;43:e14274. https://doi.org/10.1111/jfpp.14274.

Wang Y, Luo Z, Du R, Liu Y, Ying T, Mao L. Effect of nitric oxide on antioxidative response and proline metabolism in banana during cold storage. J Agric Food Chem. 2013;61:8880–7. https://doi.org/10.1021/jf401447y.

Tomás-Barberán FA, Espín JC. Phenolic compounds and related enzymes as determinants of quality in fruits and vegetables. J Sci Food Agric. 2001;81:853–76. https://doi.org/10.1002/jsfa.885.

Panahirad S, Naghshiband-Hassani R, Bergin S, Katam R, Mahna N. Improvement of postharvest quality of plum (Prunus domestica L.) using polysaccharide-based edible coatings. Plants. 2020;9:1148. https://doi.org/10.3390/plants9091148.

Banin Sogvar O, Razavi F, Rabiei V, Gohari G. Postharvest application of L-cysteine to prevent enzymatic browning of “Stanley” plum fruit during cold storage. J Food Process Preserv. 2020;44:e14788. https://doi.org/10.1111/jfpp.14788.

Zhang X, Min D, Li F, Ji N, Meng D, Li L. Synergistic effects of L-arginine and methyl salicylate on alleviating postharvest disease caused by Botrysis cinerea in tomato fruit. J Agric Food Chem. 2017;65:4890–6. https://doi.org/10.1021/acs.jafc.7b00395.

Zhu Y, Li D, Belwal T, Li L, Chen H, Xu T, et al. Effect of nano-SiOx/chitosan complex coating on the physicochemical characteristics and preservation performance of green tomato. Mol. 2019;24:4552. https://doi.org/10.3390/molecules24244552.

Aghdam MS, Kakavand F, Rabiei V, Zaare-Nahandi F, Razavi F. γ-Aminobutyric acid and nitric oxide treatments preserve sensory and nutritional quality of cornelian cherry fruits during postharvest cold storage by delaying softening and enhancing phenols accumulation. Sci Hortic. 2019;246:812–7. https://doi.org/10.1016/j.scienta.2018.11.064.

Promyou S, Ketsa S, van Doorn WG. Salicylic acid alleviates chilling injury in anthurium (anthurium andraeanum L.) flowers. Postharvest Biol Technol. 2012;64:104–10. https://doi.org/10.1016/j.postharvbio.2011.10.002.

Dhindsa RS, Plumb-Dhindsa PAMELA, Thorpe TA. Leaf senescence: correlated with increased levels of membrane permeability and lipid peroxidation, and decreased levels of superoxide dismutase and catalase. J Exp Bot. 1981;32:93–101. https://doi.org/10.1093/jxb/32.1.93.

Meng X, Li B, Liu J, Tian S. Physiological responses and quality attributes of table grape fruit to chitosan preharvest spray and postharvest coating during storage. Food Chem. 2008;106:501–8. https://doi.org/10.1016/j.foodchem.2007.06.012.

Sánchez E, López-Lefebre LR, García PC, Rivero RM, Ruiz JM, Romero L. Proline metabolism in response to highest nitrogen dosages in green bean plants (Phaseolus vulgaris L. cv. Strike). J Plant Physiol. 2001;158:593–8. https://doi.org/10.1078/0176-1617-00268.

Singleton VL, Rossi JA. Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Am J Enol Vitic. 1965;16:144–58.

Zhishen J, Mengcheng T, Jianming W. The determination of flavonoid contents in mulberry and their scavenging effects on superoxide radicals. Food Chem. 1999;64:555–9. https://doi.org/10.1016/S0308-8146(98)00102-2.

Giusti MM, Wrolstad RE. Anthocyanins. Characterization and measurement with UV-visible spectroscopy. Curr Protoc Food Anal Chem. 2001;1:1–3. https://doi.org/10.1002/0471142913.faf0102s00.

Nguyen TBT, Ketsa S, van Doorn WG. Relationship between browning and the activities of polyphenoloxidase and phenylalanine ammonia lyase in banana peel during low temperature storage. Postharvest Biol Technol. 2003;30:187–93. https://doi.org/10.1016/S0925-5214(03)00103-0.

Terada M, Watanabe Y, Kunitomo M, Hayashi E. Differential rapid analysis of ascorbic acid and ascorbic acid 2-sulfate by dinitrophenylhydrazine method. Anal Biochem. 1978;84:604–8. https://doi.org/10.1016/0003-2697(78)90083-0.

Dehghan G, Khoshkam Z. Tin (II)–quercetin complex: synthesis, spectral characterisation and antioxidant activity. Food Chem. 2012;131:422–6. https://doi.org/10.1016/j.foodchem.2011.08.074.

Zhang Z, Huber DJ, Rao J. Antioxidant systems of ripening avocado (Persea americana mill.) fruit following treatment at the preclimacteric stage with aqueous 1-methylcyclopropene. Postharvest Biol Technol. 2013;76:58–64. https://doi.org/10.1016/j.postharvbio.2012.09.003.

Bradford MM. A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem. 1976;72:248–54. https://doi.org/10.1016/0003-2697(76)90527-3.

Alexieva V, Sergiev I, Mapelli S, Karanov E. The effect of drought and ultraviolet radiation on growth and stress markers in pea and wheat. Plant Cell Environ. 2001;24:1337–44. https://doi.org/10.1046/j.1365-3040.2001.00778.x.

Acknowledgments

We are grateful to Prof. Gholam Reza Mahdavinia and Mr. Hessam Jafari for their critical support and help in nanomaterials synthesis and characterization. We also thank Dr. Muhittin Kulak for PCA and Heatmap analysis and critical reading of the manuscript.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

All authors have contributed to carry out this research. F.R., V.R. and G.G., supervisor and designed the experimental setup. R.M., performed greenhouse experiments, biochemical and gene expression analysis. R.M., F.R. and G.G., analyzed data and results, R.M., F.R. and G.G., wrote the first draft of manuscript while R.M., G.G. and L.P., wrote and edited the final version of manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

The experimental research on plants is comply with relevant institutional, national, and international guidelines and legislation.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Mahmoudi, R., Razavi, F., Rabiei, V. et al. Postharvest chitosan-arginine nanoparticles application ameliorates chilling injury in plum fruit during cold storage by enhancing ROS scavenging system activity. BMC Plant Biol 22, 555 (2022). https://doi.org/10.1186/s12870-022-03952-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s12870-022-03952-8