Abstract

Background

Phosphorus recycling is an important cornerstone of sustainable phosphorus management and required to establish a circular economy in line with the EU Green Deal. Animal bones contain phosphate which can be recovered and processed into bone char. Animal bone char has a fertiliser potential. In the past, the EU lacked measures to market these fertilisers on the internal market. With the adoption of the Fertilising Products Regulation in 2019, the EU sought to incentivise recycling fertiliser production. Against this backdrop, the aim of this paper is to first provide the key elements of the new regulation and to second assess the extent to which it enables marketing bone chars as fertilisers. To this end, a qualitative governance analysis is applied.

Results

Results show that the Fertilising Products Regulation closes an important regulatory gap by establishing the legal framework for diverse recycling fertilisers, including bone char fertilisers. However, a lengthy adoption process hinders the marketing of bone char fertilisers and contaminant limits require improvement.

Conclusions

Ultimately, the promotion and use of recycling fertilisers is a necessary but complementary approach for the circular economy. A comprehensive transformation of the sector is needed to align it with global environmental goals.

Similar content being viewed by others

Background

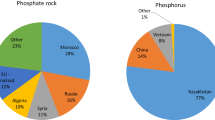

Phosphorus (P) is essential for food production [1,2,3,4,5]. However, most states are highly dependent on P imports from a few supplier countries, including Marocco/Western Sahara and Russia, thus facing the risk of supply shortages [4, 6,7,8,9,10]. In the EU, 92% of phosphate is imported from third countries [11], which makes rock phosphate a critical raw material [12,13,14]. Currently, as a result of the Russian invasion of Ukraine, the import dependency of the EU from fertilisers and inputs for fertiliser production adds further pressure on the EU agricultural sector [15, 16]. Apart from that, the predominantly sedimentary rock phosphate deposits are increasingly contaminated with heavy metals and radioactive substances, bearing environmental and health risks [17,18,19,20,21]. Although there is a high potential for substituting rock phosphate with recovered P [22,23,24], P use in the EU is mostly linear and a considerable amount of P-rich waste remains unused for fertilisation [25].

To reduce short-term supply shortages and ensure long-term availability of P for future generations, efficient P fertilisation and increased P recycling are necessary [26,27,28]. Improving P efficiency and circularity would also counteract the environmental issues of unstainable P management. The agriculturally used P is a major driver of eutrophication and exceeds planetary boundaries (oceans) [29,30,31,32]. Eutrophication causes dead zones with (very) little or no biodiversity [33, 34]. Intensive animal husbandry in particular causes high P surpluses and disturbed P cycles [24, 35,36,37]. Hence, unsustainable P management has negative implications for biodiversity. At the same time, climate change is expected to be a major driver of soil erosion [38] which will likely increase P transfers from arable fields into freshwater and marine ecosystems [39]. Thus, these environmental issues (P, biodiversity, climate) must be analysed together and addressed comprehensively [36, 40]. More sustainable P management, including P recycling, and an agricultural sector which is in line with the legally binding goals of the Paris Agreement [41, 42] and the Convention on Biological Diversity (since 2022 concretised by the Montreal–Kunming targets [43]) are necessary. Sustainability is understood as ‘extending the idea of justice, i.e., the normative question of the right society […], in spatio-temporal terms, i.e., towards intertemporal and global cross-border justice’ [44].

The EU acknowledges these challenges for the agricultural sector and P management. The Farm to Fork Strategy [45, 46] at the heart of the European Green Deal [47] seeks to redesign the EU's agri-food sector towards sustainability, inter alia by aiming more sustainable nutrient management especially for phosphate and nitrate. One objective of the Farm to Fork Strategy requires the reduction of nutrient losses by at least 50% resulting in at least 20% less fertiliser use by 2030. Another building block of the Green Deal is the Circular Economy Action Plan which promotes food-waste reduction, more sustainable nutrient application and market stimulation for recovered nutrients through a yet to be published Integrated Nutrient Management Plan [48]. In accordance with these measures, the EU's updated Bioeconomy Strategy aims at promoting sustainable food and farming systems, including nutrient recycling [49, 50].

Against the backdrop of the current global mineral fertiliser crisis caused by disrupted supply chains due to the COVID-19 pandemic and the Russian invasion of Ukraine, P recycling has once again moved upwards on the EU's political agenda. In November 2022, the EU Commissions published a Fertiliser Communication. The Communication aims at ensuring availability and affordability of fertilisers in the EU through production diversification and reliable fertiliser supply chains. For the medium and long terms, the Commission emphasises the need to substitute rock phosphate-based fertilisers with more sustainable alternatives, such as organic fertilisers and recycling fertilisers. Moreover, the Commission highlights that the current fertiliser crisis is ‘an opportunity to accelerate the transition to a sustainable agriculture […] system’ [15]. Yet, the targets of the Commissions' Communications are not legally binding. They have to be implemented through binding legislation, i.e., regulations or directives according to Article 288 TFEU. One such legislation is the Fertilising Products Regulation (FPR). As little research has so far discussed the new EU FPR, this article first aims to present the key elements of the new regulation. To this end, the article introduces one phosphate recycling fertiliser, bone char, which it uses as an example throughout the analysis. On this basis, the article second aims to assess the extent to which the new FPR enables the placing on the market of bone char fertilisers and thereby contributes to sustainable P management [37, 51] and the goal of the Convention on Biological Diversity.

Materials and methods

This article assesses EU fertilising legislation. The research scope covers the legal provisions for the placing on the market of recycling fertilisers and in particular bone char fertilisers. The scope does not extend to, e.g., the construction and operation of P recycling facilities or the application of these fertilisers on the land. For each of these areas, different legal measures such as the Industrial Emissions DirectiveFootnote 1 or the CAP Strategic Plan RegulationFootnote 2 are relevant. Hence, the present analysis assesses provisions of the new Fertilising Products RegulationFootnote 3 and the preceding Fertiliser Regulation,Footnote 4 the Mutual Recognition RegulationFootnote 5 and the Animal by-products Regulation.Footnote 6

For this assessment, a qualitative governance analysis is applied. The qualitative governance analysis aims to identify effective policy instruments to achieve a policy goal. Relevant for the analysis of this article is in particular the goal of the Convention on Biological Diversity. The legally binding goal requires stopping and reversing global biodiversity loss [52]. While new biodiversity goals have been adopted recently (Sect. "Background"), their legal status is still unclear which is why this analysis excludes them and instead focuses on the Convention on Biological Diversity.

The qualitative governance analysis is built on findings from behavioural studies and findings from natural sciences. Results from natural sciences can highlight issues that need to be addressed by policy instruments, such as, e.g., contamination levels of recycling fertilisers and the energy intensity of manufacturing. Against this backdrop, we reviewed literature on bone char fertilisers. Being part of an interdisciplinary project on sustainable P management, where research on bone char fertilisers has been undertaken (https://www.innosoilphos.de/), we primarily used the project findings to underpin our analysis. We supplemented these studies with recent as well as relevant older international scientific publications on (bone) char-based fertilisers. The results of this review can be found in the section hereafter.

Alongside findings from natural sciences, insights from behavioural studies forms a basis of the qualitative governance analysis. In contrast to the research on bone char fertilisers, we have not performed a review on behavioural studies as we have extensively discussed this topic in earlier publications [44, 53]. In short, studies show that typical barriers that policy instruments need to overcome include emotional factors such as convenience and habits, concepts of normality and self-interest [e.g., 54,55,56]. (Lacking) knowledge, awareness and values frequently play a subordinate role [e.g., 57,58,59]. These barriers have not only direct implications for designing policy instruments, e.g., the indication that purely voluntary and educational instruments such as fertilising guidelines are (predominantly) of limited effectiveness effective, but can also point to some typical governance problems. Alongside geographical and sectoral shifting effects, the effectiveness of policy instrument can be limited by enforcement problems, rebound effects and issues of depicting. The latter is a typical challenge of policy instruments which target very complex (environmental) compartments, such as peatlands, greenhouse gas fluxes and biodiversity [60,61,62]. When qualitatively assessing fertilising policies, these results are factored in, i.e., in the discussion, we assess the FPR with regard to potential governance problems and in light of the Convention on Biological Diversity. In doing so, the qualitative analysis offers a comprehensive assessment of the FPR, including how it can be improved, potentially supplemented by alternative/additional instruments and the extent to which it contributes to global environmental goals.

The following section introduces recycling fertilisers and in particular bone char fertilisers. Thereafter, the new FPR is introduced and a potential legal pathway for putting bone char fertilisers on the EU internal market assessed. Discussion and conclusions follow.

Recycling P fertilisers and bone char

Recycling fertilisers play a crucial role in making the agricultural sector more sustainable and resilient. Recycling P fertilisers can substitute rock phosphate-based, chemically industrially processed fertilisers and, thereby, improve circularity and close the supply gap for P fertilisers due to import dependency and rising energy prices (Sect. "Background").

Fertiliser based on ‘secondary raw materials’, i.e., materials that can be recycled and send back into the production processes as new raw materials [63], can be derived from various wastewater and waste streams, such as animal and human excreta, and food processing and food waste [6, 22, 64, 65]. Recovery precedes recycling and creates intermediates, so-called recyclates [66]. Source materials, processing, P content (as well as other elements, especially N and C, and their ratio), plant availability of P, pollutant levels, cost intensity, energy input, and transport requirements vary between recyclates. Hence, different products may be recommended for different soil parameters, farm characteristics and regions [22, 67].

Since the largest P losses are found in the wastewater sector of the EU [68], research and development focus on P recovery from wastewater. The technical requirements for P recovery from sewage sludge and/or sewage sludge ashes are well-developed. Still, up to now, industrial-scale P recovery is implemented sparsely and many processes for P recovery not only from sewage sludge but also from other waste and wastewater are not yet ready for the market—including animal bones. Similarly, many P recyclates are not yet economically competitive with conventional fertilisers [2, 3, 9, 22].

Using the diversity of potential secondary raw materials will help to establish the circular economy for P. The heterogeneity of soils, P fluxes and P losses, as well as the different P requirements and P availabilities of different agricultural systems mean that P recovery strategies and fertiliser products should be as diverse as possible. In fact, P recovery is conceivable from all waste streams along the value chain. Following the waste water sector, the food processing sector, in particular the slaughter of animals and removal of P-rich waste materials, such as meat and bones, accounts for the second largest amount of P losses [68, 69]. At least part of these losses is not necessarily lost forever, but could be avoided and materials used for fertilisation when properly treated. For instance, animal bones, which have a very high P content compared to other animal waste, have been used as fertilisers in the eighteenth and nineteenth century [69, 70]. Especially in organic farming, meat and bone meal has been used as a major source for P in the past. However, as a result of the bovine spongiform encephalopathy (BSE) crisis in 1999, the use of meat and bone meal has been largely prohibited [71].

Nowadays, pyrolysis of animal by-products—not only meat and bone meals but bone chips and grist—has been established to eliminate pathogens while retaining C and P content [69, 72]. Pyrolysis is process of heating organic substances in the absence of oxygen, which transforms the material into three components, i.e., solid, gas and liquid. The properties of the output charred products, i.e., biochars, depend on (the plant) or animal-derived source material and the pyrolysis technology and conditions [25, 69, 73]. While plant biochar has high C contents but no or low nutrient contents, animal bone chars have high P and calcium contents and low C content [69]. The agronomic efficiencyFootnote 7 of pyrolysis materials derived from slaughter by-products varies depending on input material, production process, and soil and plant characteristics. Hence, a direct comparison between bone char fertilisers and mined and synthetic P fertilisers is difficult [25]. Depending on the soil characteristics, the P solubility of bone char is between those of rock phosphates and triple super phosphate, with the P solubility of the sulfur-enriched bone char being enhanced [74, 75]. Bone chars can be produced from defatted, optionally gelatinized, bones by pyrolysis at about 800 °C [76,77,78]. Further processing is feasible, such as surface-modification and sulfur-enrichment to create small-scale local hotspots of acidity from microbial S0-oxidation to SO42− which enhances the dissolution of bone char particles and the release of nutrients, such as P and S, resulting in a "Bone Charplus" [79, 80]. Bone chars have several environmental and economic advantages, making them a promising recycling fertiliser. The porosity of bone char particles provides a good habitat for microorganisms, including beneficial microorganisms, such as P-mobilising or antipathogenic bacteria and fungi [81]. Furthermore, since porosity affects water retention, bone char application to soil can improve the soil moisture status for cropping by retaining more soil water from percolating and holding it in the root zone [69, 76, 77]. Besides that, bone char is free from organic contaminants, such as pharmaceuticals and contains—in contrast to rock phosphate-based fertilisers—no heavy metals [80].

When developing and using recycling fertilisers from various residual materials, it is also necessary to consider properties, such as interactions with other substances in the soil. For instance, bone char and sulfur-enriched bone char have different soil cadmium (Cd) mobilisation properties, depending on soil pH and P content [76]. Cd is a heavy metal that harms human health when, e.g., taken up with contaminated food [82]. By nature, Cd is a relatively mobile element. Bone char leads to increasing pH values and the formation of Cd phosphates, thus favouring Cd immobilization and reducing Cd uptake of plants. Hence, bone char immobilises Cd in soil while having a positive effect on P mobilisation for plant nutrition [72, 76, 79, 83]. In contrast, sulfur-enriched bone char tends to increase Cd solubility and hence plant uptake. Therefore, this bone char can only be recommended for slightly Cd-contaminated soils [76, 79, 83].

Another crucial factor for the successful establishment of recycling fertilisers is their applicability. One important element of applicability is particle size. The particle size, in turn, influences the effectiveness of fertiliser products. Bone char particle size affects P release, distribution in the soil and reactivity with other soil compounds. In an experiment, bone chars achieved the highest P release with relatively low Cd release into the soil solution at particle sizes of 0.5 mm to 1 mm, i.e., not necessarily at the smallest particle sizes. Fertilisers with particles of this size can be applied by common agricultural machinery, while smaller particles require palletisation, also to comply with health and safety precautions established in fertiliser legislation [79]. Besides applicability, nutrients in substitutes for rock phosphate-based fertilisers need to be available to plants, both in the long term and the short term [25, 67, 71, 80]. Likewise, P losses to the aquatic environment have to be low, even in the case of recycling fertilisers, which makes efficient, site-adapted and needs-based fertilisation necessary. In addition, when using P recyclates, soil protection needs be taken into account, e.g., maintaining or increasing soil organic matter. Finally, other environmental protection concerns must be considered, especially climate protection concerns. This implies that the production of recycling fertilisers has to be as energy-efficient as possible and undertaken using renewable energies. In fact, zero greenhouse gas emission pyrolysis for P recovery already exists [69, 84]. Hence, the development and application of recycling fertilisers alone will not suffice to combat environmental issues and establish the circular economy. Instead, sustainable P and soil management as well as comprehensive transitions in the agricultural sector are needed. Still, one step towards creating the circular economy is the replacement of rock phosphate-based fertilisers with recycling fertilisers. Against this backdrop and as bone chars are still in the research stage and not (yet) sold on the market, the following section investigates if the EU FPR establishes a pathway to market these products.

Results: the EU fertilising products regulation

The results are divided into two parts. The first part discusses the key elements of the FPR. The second part investigates a (potential) regulatory pathway to market bone char fertilisers through the FPR in the EU.

Aims and general provisions

The EU establishes harmonised rules for placing fertilisers on the internal market. Where a fertiliser complies with these rules, it is eligible for the CE marking and free movement between the member states of the EU. Until 2022, the EU Fertiliser Regulation (EC) 2003/2003 determined the legal framework for EU fertilisers. It was repealed by the EU Fertilising Products Regulation (EU) 2019/1009 in July 2022. Fertilisers which have been placed on the market before the entering into force of the new FPR can continue to be marketed after the repeal of the fertiliser regulation 2003/2003 (Art. 52 FPR). In general, applying for CE marking is optional. Fertiliser manufacturers can also put fertilisers on the national market of a member state when complying with national rules. Yet, this article focusses on the EU provisions.

The previous Fertiliser Regulation (EC) 2003/2003 hindered the introduction of innovative fertilisers. To be marketed as EC fertiliser, a fertiliser had to belong to a fertiliser type listed in Annex I of the regulation. However, this annex it did not cover organic fertilisers and recycling fertilisers and hence excluded their placing on the internal market. Besides, threshold values for heavy metals such as Cd in fertilisers were missing [66, 85, 86]. To address these issues, the Commission published its first Circular Action Plan in 2015. The Circular Action Plan included a revision of the EU Fertiliser Regulation with measures to facilitate the EU wide recognition of organic and waste-based fertilisers [63]. In preparation of the revised regulation, an impact assessment was performed. This assessment states that “[t]he general objective [of the new fertiliser regulation] is to incentivise large scale fertilising products production in the EU from domestic organic or secondary raw materials by creating a regulatory framework granting such fertilisers access to the internal market and to address the well-recognised issue of soil contamination by contaminants present in fertilisers” [11]. Ultimately, the new regulation was adopted in June 2019. It applies to EU fertilising products which are defined as “a substance, mixture, micro-organism or any other material, applied or intended to be applied on plants or their rhizosphere or on mushrooms or their mycosphere, or intended to constitute the rhizosphere or mycosphere, either on its own or mixed with another material, for the purpose of providing the plants or mushrooms with nutrient or improving their nutrition efficiency” (Art. 2 (1) FPR).

The regulation establishes obligations for economic operators which include manufacturers (Arts. 6–7 FPR), importers (Art. 8 FPR) and distributors (Art. 9 FPR). For example, manufacturers have to ensure that fertilising products comply with the requirements of the product function and component material categories (see below). They do also have to perform the conformity assessment (Art. 6 (1) and (2) FPR). Importers have to ensure that, before placing a fertilising product on the EU market, products from third countries comply with the regulation, i.e., that the manufacturer in the third country has done the prescribed conformity assessment procedure (Art. 8 (2) FPR). Distributors have to ensure that the fertilising products are equipped with the required documentation (Art. 9 (2) FPR). Penalties for infringements with this regulation are established by the member states (Art. 48 FPR). Besides, surveillance, control and safeguarding procedures for dealing with potentially harmful EU fertilising products are established (Art. 37–41 FPR).

If the fertilising products comply with the requirements of the regulation, they can be placed on the internal market of the EU (Art. 5 FPR) and the CE marking indicates the conformity with the regulation (recital 41 FPR). The regulation enables the marketing of products with different functions and components (Fig. 1). To this end, product function categories with individual product safety and quality requirements (Annex I FPR), and different component categories with individual process requirements and control mechanisms are established (Annex II FPR). An EU fertilising product has one product function and can be composed of several component materials. Each material has to comply with the requirements of the corresponding component material category/categories. For fertilising products with multiple functions, a separate product function category ‘fertilising product blend’ is created (Annex I FPR). In addition to these requirements, an EU fertilising product must comply with labelling requirements (Art. 4 (1) lit. (c) FPR).

Where a fertilising product complies with other standards of EU regulation, it is assumed to also comply with the FPR (Art. 13 (1) FPR). For all other fertilising products, conformity assessment procedures are established in Annex IV. Depending on the product function category and the component material category, different procedures—called ‘modules’—have to be applied. These modules are adopted from EU Decision No 768/2008/EC. Some modules require a third-party conformity assessment body; others can be performed internally by the manufacturer (Art. 32 and Annex IV FPR). Conformity assessment bodies have to be notified by the member states to the Commission (Art. 20 FPR). To ensure a level playing field, the regulation establishes mandatory requirements for all assessment bodies (Art. 24 and recital 43 FPR). This includes having to have a legal personality and employees with sound technical training and being independent of the assessed fertilising product [Art. 24 (1)–(11) FPR]. Ultimately, where a fertilising product contains waste material and is compliant with the requirements of the FPR, that material is no longer considered waste material (‘end of waste status’) (Art. 19 FPR).

To keep up with technological process and to enable market access for new fertilising products, the Commission can adopt delegated acts to amend the annexes of the regulation. National authorities and stakeholders can submit proposals for new fertilising products [87]. The proposed fertilising products (1) must have the potential to be widely traded on the internal market, and come with scientific evidence that they (b) do not cause a risk to human, animal or plant health, to safety or to the environment, and that shows their agronomic efficiency (Art. 42 (1) FPR). Exempted from the Commission’s empowerment is a change in Cd limit values (Art. 42 FPR).

Bone char fertilisers under the EU Fertilising Products Regulation

This section assesses if the FPR contains a legal pathway to put bone char fertilisers on the internal market of the EU. Research on bone char primarily focusses on its fertilising characteristics, but an application as soil improver also appears feasible (Sect. 3.2). Still, this article focusses on bone char as recycling fertiliser.

Annex I of the FPR establishes the product function category ‘fertiliser’ (Fig. 2) (Annex I Part II pp. 33–43 FPR).

A fertiliser has to provide nutrients to plants or mushrooms. Fertilisers are distinguished into (1) organic fertilisers, (2) organo-mineral fertilisers and (3) inorganic fertilisers. Bone char can be categorised as inorganic fertiliser that supplies P to plants. According to the FPR, an inorganic fertiliser has to contain or release nutrients in a mineral form. Bone char contains calcium phosphate which is a mineral form. The FPR further distinguishes between inorganic macronutrient fertilisers and inorganic micronutrient fertilisers. As a P (and S) supplying fertiliser, bone char is an inorganic macronutrient fertiliser. For this fertiliser category, the FPR establishes contaminant limit values, including Cd. The Cd limit value depends on the total P content of the fertiliser. If the total P content is below 5% phosphorus pentoxide (P2O5)-equivalent by mass, Cd content must be below 3 mg/kg dry matter. If P content exceeds the 5% threshold value, Cd content must be below 60 mg/kg phosphorus pentoxide (P2O5). Bone char does not contain heavy metals, such as Cd and no organic contaminants (Sect. "Recycling P fertilisers and bone char"). The Regulation then distinguishes between solid and liquid inorganic macronutrient fertilisers. Bone char is solid (Sect. "Recycling P fertilisers and bone char"). Finally, solid inorganic macronutrient fertilisers are divided into straight solid inorganic macronutrient fertilisers and compound solid inorganic macronutrient fertilisers. The allocation of a fertilising product towards either category depends on the declared nutrient content (Fig. 3). It appears feasible that bone char could be allocated towards straight solid inorganic macronutrient fertilisers: declared nutrient could either be only one macronutrient (P) or one primary macronutrient (P) with one secondary macronutrient (S).

Annex II currently establishes 15 different component material categories (CMC) which can be used for fertilising products. To be included in the FPR, animal by-products or derived products such as bone chars have to leave the scope of the Animal by-products (ABP) Regulation: Art. 1 FPR states that the regulation applies to EU fertilising products and not to animal by-products or derived products which are subject to the requirements of the ABP Regulation (Art. 1 (1) lit. a FPR). To leave the scope of the ABP Regulation, animal by-products or derived products have to reach an end point in the manufacturing chain (Art. 5 (2) ABPR). Against this backdrop, the FPR contains an obligation for the Commission to determine end points for certain animal by-products and hence amend the ABP Regulation. Once this has been accomplished, these materials will be included in the FPR (Art. 42 (5) FPR). While the Commission has recently adopted a (delayed) delegated regulation,Footnote 8 which determines end points for meat-and-bone meal under certain conditions (Art. 4 (1) lit d Delegated Regulation), the final inclusion of these materials still requires an amendment of the FPR. Thus, currently, animal by-products and derived products such as bone chars cannot be included in fertilising products.

Still, as the Commission is working to include these materials into the FPR, we will discuss two CMCs which could be relevant for bone char fertilisers once they have been incorporated into the FPR. The first potential candidate is CMC 10. CMC 10 covers derived products as covered by the ABP Regulation. The second potential candidate is CMC 14 which covers pyrolysis and gasification materials. CMC 10 requires derived products to have reached an end point in the manufacturing chain and be listed in a table in Annex II of the FPR. However, that table has not been included into the Annex so far (see above). Hence, up to this point, legal provisions for CMC 10 are not established and cannot be used as pathway for placing bone char fertilisers on the market.

As an alternative to CMC 10, CMC 14 enables the input of animal by-products or derived products upon the condition that (1) again, an end point in the manufacturing chain has been determined and (2) they comply with certain manufacturing and material requirements. CMC 14 limits input material to Category 2 and Category 3 material as defined by the ABP Regulation. The ABP Regulation establishes three categories with increasing public and animal health risk levels (Arts. 7–10 APBR). Category 1 material covers material with the highest risk level. This includes, e.g., entire animal bodies and all body parts which are suspected of or confirmed to be infected with a transmissible spongiform encephalopathy (TSE), contaminated animal by-products, catering waste from international transport and mixtures of Category 1 material with either Category 2 material or Category 3 material or both (Art. 8 ABPR). Category 2 material covers, e.g., manure, Category 3 carcases and parts of animals slaughtered for human consumption but removed for commercial reasons (Arts. 9–10 ABPR). Manufacturing requirements of CMC 14 include, for example, a reactor temperature of at least 180 °C for a minimum of 2 s and prohibition of physical contact of input and output material. Besides, pyrolysis materials, i.e., the bone meal/chips/grist, have to be registered under the REACH Regulation.Footnote 9 Despite containing more details than CMC 10, CMC 14 also currently does not provide a legal pathway to put bone char fertilisers on the market for the same reason as CMC 10. Still, principally, the FPR contains the legal frame to market bone char fertilisers on the internal market of the EU. However, the incorporation into the FPR of animal by-products and derived products is a bottle neck that urgently needs to be addressed.

Discussion

Critical review of the Fertilising Products Regulation

This subsection begins with a discussion on the strengths and benefits of the FPR and proceeds with its limitations, including the lengthy policy process, restrictions of the input material and contamination issues.

Replacing finite resources with recycling and alternative materials is urgent to achieve the goal of the Convention on Biological Diversity. Still, it took 10 years from a Parliament resolution calling for nutrient recycling from waste streams to the entering into force of the FPR [88]. Despite the lengthy policy process, the FPR now finally closes an important regulatory gap for the marketing of organic and recycling P fertilisers in the EU. The FPR removes legal barriers for using recycled materials by granting an end of waste status. Besides, the adoption of the FPR is expected contribute to replace non-renewable resources, such as rock phosphate in fertiliser production [89]. In doing so, an important step towards operationalising the circular economy for P [90] and achieving the goal of the Convention on Biological Diversity is taken. Finally, in the past, researchers have called for harmonised procedures to assess potentials risks of recycling fertilisers when applied on soils, so that costs for fertiliser producers, farmers and public administration could be decreased [86]. The FPR now establishes such harmonised procedures and hence simplifies market access and observation and thereby policy enforcement.

These promising developments are dampened by several outstanding policy issues. The long process of integrating animal by-products and derived products such as bone char into the FPR hinders their use in recycling fertilisers—an issue that has repeatedly been picked up by the industry and other stakeholders [91, 92]. Quick legislation adoption is needed. Still, in the meantime, a fertiliser producer could access the internal market of the EU through a national market application and the Mutual Recognition Regulation. The Mutual Recognition Regulation enables the marketing of a product that is marketed in one member state to be also marketed in another member state. Benefits include a shorter application process in comparison with the application process under the past fertiliser regulation. Besides, authorities have more decision flexibility and the burden of proof in case of non-approval lies with them. Shortfalls include that the (additional) application procedure increases the administrative burden for fertiliser producers [66]. In addition, shifting effects which counteract achieving the goal of the Convention on Biological Diversity appear likely. For example, poor quality fertilisers may be approved in a national market with little legal requirements but would fail approval in a member state with higher legal requirements. These fertilisers could still enter the market with higher legal requirements through the Mutual Recognition Regulation [66]. Hence, again, fast adoption of outstanding legislation to enable marketing of bone char through the FPR is needed.

Once the FPR enables the use of animal by-products and derived products in fertilising products, input material is limited to Category 2 and Category 3 materials (Sect. "Bone char fertilisers under the EU Fertilising Products Regulation"). The exclusion of Category 1 material is a wasted opportunity. In its report, that serves as a basis to include new materials into the FPR, the Joint Research Centre of the Commission quotes numbers of the European Fat Processors and Renderers Association. According to these numbers, approximately one quarter of the material that is annually processed, is classified as Category 1 material [93]. Hence, one quarter of potential bone feedstock cannot be used for fertiliser production. It would thus be useful if the Commission mandated a risk assessment of Category 1 material also with a view to animal diseases, such as TSE—a step it did not do in the past [93, 94]. In addition, in fact, it seems that the Commission is considering such an assessment but cautions that this process is going to be lengthy [95].

Another risk of (recycling) fertilisers pose contaminants, such as Cd. In this context, the proposal of the FPR established that one of the two policy objectives of the proposal aims at the introduction of harmonised Cd limits [96]. However, no comprehensive Cd limit has been established (Sect. "Bone char fertilisers under the EU Fertilising Products Regulation"). Hence, while nearly closing an important regulatory gap—the previous fertiliser regulation did not contain any threshold value for Cd [see also 9, 66]—current provisions still offer a substantial shortcoming. In doing so, the FPR fails to exercise an effective steering effect and to adopt the precautionary principle as established in EU primary law [97, 98 instead argues for risk assessment-based requirements]. These inadequacies also counteract achieving the goal of the Convention on Biological Diversity as soil contamination is not adequately addressed.

Finally, the FPR misses an opportunity to enhance the competitive position of recycling fertilisers, such as bone char, by not increasing the cost of mineral fertilisers due to Cd-removal. In fact, low prices for (fossil-based) P raw materials are a primary market barrier for recycling products [98,99,100]. Still, the fertiliser industry lobby and the EU farmers association were opposed to the Cd threshold limits [101]. To enhance the economic viability of P recycling outside the FPR, different proposals have been made. For example, Jupp et al. [9] propose to implement a ban on all routes which do not recycle P, such as landfilling and incineration of meat and bone meal in cement works (p. 98). Others propose recycling quotas and targets [66, 98, 99] as, for example, established in the reformed German sewage sludge ordinance (AbfKlärV). Besides that, a supportive effect could be achieved if voluntary industry certificates included bone chars into their certification schemes (see, e.g., positive list of the European Biochar Certificate) [102]. Finally, including biochars from animal materials into the scope of organic farming could increase their application. To date, organic farming only allows the application of biochar from plant materials (Annex II Regulation EU 2021/1165 i.c.w. Art. 24 (1) lit. b Regulation EU 2018/848). All of these measures could provide incentives establish bone char production in the EU, which is currently non-existent.

Taking a step back to the impact assessment of the FPR which established two general objectives, namely, pushing large scale recycling fertiliser production and addressing soil contamination (Sect. "Aims and general provisions"), the assessment of this article finds that first important steps have been made to achieve these objectives but further regulatory action is needed as soon as possible.

P recycling in a greater context

Promoting recycling fertilisers such as bone char contributes to close P cycles and, in doing so, to achieve the objectives of the Circular Economy Action Plan and the Convention on Biological Diversity. However, this push—as done through the FPR—alone does not solve the issues of unsustainable fertilisation practices, P losses into the environment through, e.g., soil erosion and waste accumulation through mining [103, 104]. Consequently, P recycling is just one element in the transition to a circular economy and the adoption of the FPR does not replace the necessity to (1) promote site-adapted and efficient fertilisation, (2) target regional P surpluses, (3) minimise mined P fertilisers and (4) transform the entire agricultural sector to be in line with global environmental goals. For example, the agricultural sector of the EU is characterised by regionally very high livestock densities [105]. If these densities remained high, large P import dependency, inefficient P use and regional nutrient surpluses would continue to exist. The FPR exercises no steering effect on these issues. Hence, a comprehensive transformation is needed and it is the interlinkage of the environmental problems that makes this comprehensive transformation essential.

The example above indicates that a comprehensive transformation for P management (including P recycling) and the entire agricultural sectors cannot be achieved by solely addressing P. Instead, the major drivers of global environmental issues, namely, livestock farming and fossil fuels, have to be targeted [36, 37, different argument by 106]. Yet, aligning livestock farming with global environmental goals such as those of the Convention on Biological Diversity and the Paris Agreement would directly impact the production of bone char fertilisers as animal numbers would have to decline and hence the supply of animal bones. In addition, even without more ambitious climate policies, beef and pig meat production are expected to shrink in the EU [107]. This highlights again the necessity to make best use of all available resources, including Category 1 of the ABP regulation. Finally, recycling fertilisers have to be produced with renewable energy. This includes bone char fertiliser production. Pyrolysis of biomass can have a positive energy balance [Sect. "Recycling P fertilisers and bone char" and 73] but an expansion of renewable energy and technological efficiency as well as frugality will play a key role in the transformation [40, 44]. Overall, this article finds that the promotion and use of recycling fertilisers is a necessary but complementary approach for the circular economy.

Conclusions

Recycling P fertilisers such as bone char fertilisers contribute to close P circles and establish a circular economy. Hence, in creating a legal pathway to market these fertilisers on the internal market of the EU, the FPR is an important measure to not only achieve global environmental goals of the Convention on Biological Diversity and Paris Agreement but also to contribute to the objectives of the Green Deal, the Circular Economy Action Plan and the Farm to Fork Strategy. However, outstanding legislation hinders the marketing of bone char fertilisers and inadequate Cd threshold values endanger soil health and biodiversity. Quick adoption of outstanding legislative acts and stricter threshold limits are, therefore, warranted. A bird's-eye view finally finds that, to achieve comprehensive changes in the agricultural sector, replacing mineral P fertilisers with recycling fertilisers is just one element amongst many.

Availability of data and materials

Not applicable.

Change history

01 February 2024

A Correction to this paper has been published: https://doi.org/10.1186/s12302-024-00847-3

Notes

Directive 2010/75/EU of the European Parliament and of the Council of 24 November 2010 on industrial emissions (integrated pollution prevention and control).

Regulation (EU) 2021/2115 of the European Parliament and of the Council of 2 December 2021 establishing rules on support for strategic plans to be drawn up by Member States under the common agricultural policy (CAP Strategic Plans) and financed by the European Agricultural Guarantee Fund (EAGF) and by the European Agricultural Fund for Rural Development (EAFRD) and repealing Regulations (EU) No 1305/2013 and (EU) No 1307/2013.

Regulation (EU) 2019/1009 of the European Parliament and of the Council of 5 June 2019 laying down rules on the making available on the market of EU fertilising products and amending Regulations (EC) No 1069/2009 and (EC) No 1107/2009 and repealing Regulation (EC) No 2003/2003.

Regulation (EC) No 2003/2003 of the European Parliament and of the Council of 13 October 2003 relating to fertilisers.

Regulation (EU) 2019/515 of the European Parliament and of the Council of 19 March 2019 on the mutual recognition of goods lawfully marketed in another Member State and repealing Regulation (EC) No 764/2008.

Regulation (EC) No 1069/2009 of the European Parliament and of the Council of 21 October 2009 laying down health rules as regards animal by-products and derived products not intended for human consumption and repealing Regulation (EC) No 1774/2002 (Animal by-products Regulation).

Agronomic efficiency describes yield changes in relation to nutrient application (Fixen et al. 2015).

Commission Delegated Regulation (EU) 2023/1605 of 22 May 2023 supplementing Regulation (EC) No 1069/2009 of the European Parliament and of the Council as regards the determination of end points in the manufacturing chain of certain organic fertilisers and soil improvers (Delegated Regulation).

Regulation (EC) No 1907/2006 of the European Parliament and of the Council of 18 December 2006 concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH), establishing a European Chemicals Agency, amending Directive 1999/45/EC and repealing Council Regulation (EEC) No 793/93 and Commission Regulation (EC) No 1488/94 as well as Council Directive 76/769/EEC and Commission Directives 91/155/EEC, 93/67/EEC, 93/105/EC and 2000/21/EC.

References

Asimov I (1959) Life’s Bottleneck. The Magazine of Fantasy and Science Fiction 31–40.

Schoumans OF, Bouraoui F, Kabbe C et al (2015) Phosphorus management in Europe in a changing world. Ambio 44:180–192. https://doi.org/10.1007/s13280-014-0613-9

Leinweber P, Bathmann U, Buczko U et al (2018) Handling the phosphorus paradox in agriculture and natural ecosystems: scarcity, necessity, and burden of P. Ambio 47:3–19. https://doi.org/10.1007/s13280-017-0968-9

Nedelciu CE, Ragnarsdottir KV, Schlyter P, Stjernquist I (2020) Global phosphorus supply chain dynamics: assessing regional impact to 2050. Glob Food Sec 26:100426. https://doi.org/10.1016/j.gfs.2020.100426

Panagos P, Köningner J, Ballabio C et al (2022) Improving the phosphorus budget of European agricultural soils. Sci Total Environ 853:158706. https://doi.org/10.1016/j.scitotenv.2022.158706

Vaccari DA, Powers SM, Liu X (2019) Demand-driven model for global phosphate rock suggests paths for phosphorus sustainability. Environ Sci Technol 53:10417–10425. https://doi.org/10.1021/acs.est.9b02464

Nanda M, Kansal A, Cordell D (2020) Managing agricultural vulnerability to phosphorus scarcity through bottom-up assessment of regional-scale opportunities. Agric Syst 184:102910. https://doi.org/10.1016/j.agsy.2020.102910

Jama-Rodzeńska A, Białowiec A, Koziel JA, Sowiński J (2021) Waste to phosphorus: A transdisciplinary solution to P recovery from wastewater based on the TRIZ approach. J Environ Manage 287:112235. https://doi.org/10.1016/j.jenvman.2021.112235

Jupp AR, Beijer S, Narain GC et al (2021) Phosphorus recovery and recycling – closing the loop. Chem Soc Rev 50:87–101. https://doi.org/10.1039/D0CS01150A

United States Geological Survey (USGS) (2022) Mineral commodity summaries. USGS, Reston, United States.

European Commission (2016) Circular Economy Package. Commission Staff Working Document. Impact Assessment. Accompanying the document Proposal for a Regulation of the European Parliament and of the Council laying down rules on the making available on the market of CE marked fertilising products and amending Regulations (EC) No 1069/2009 and (EC) No 1107/2009 {COM(2016) 157 final} {SWD(2016) 65 final} [SWD(2016) 64 final].

European Commission (2014) Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions on the review of the list of critical raw materials for the EU and the implementation of the Raw Materials Initiative [COM(2014) 297 final].

European Commission (2014) Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions on the 2017 list of Critical Raw Materials for the EU [COM(2017) 490 final].

European Commission (2020) Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. Critical Raw Materials Resilience: Charting a Path towards greater Security and Sustainability [COM(2020) 474 final].

European Commission (2022) Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. Ensuring availability and affordability of fertilisers [COM(2022) 590 final].

Kuokkanen A (2022) The next-generation of sustainable fertilisers: a win-win solution. European Commission, Petten.

Kratz S, Schick J, Schnug E (2016) Trace elements in rock phosphates and P containing mineral and organo-mineral fertilizers sold in Germany. Sci Total Environ 542:1013–1019. https://doi.org/10.1016/j.scitotenv.2015.08.046

Khan MN, Mobin M, Abbas ZK, Alamri SA (2018) Fertilizers and Their Contaminants in Soils, Surface and Groundwater. In: Encyclopedia of the Anthropocene. Elsevier, pp 225–240.

de Boer MA, Wolzak L, Slootweg JC (2019) Phosphorus: reserves, production, and applications. In: Ohtake H, Tsuneda S (eds) Phosphorus recovery and recycling. Springer, Singapore, pp 75–100

Gray CW, McDowell RW, Condron LM, McLenaghen RD (2020) Changes in soil cadmium concentrations with time following cessation of phosphorus fertilizer inputs. J Environ Qual 49:1054–1061. https://doi.org/10.1002/jeq2.20086

Bracher C, Frossard E, Bigalke M et al (2021) Tracing the fate of phosphorus fertilizer derived cadmium in soil-fertilizer-wheat systems using enriched stable isotope labeling. Environ Pollut 287:117314. https://doi.org/10.1016/j.envpol.2021.117314

Roy ED (2017) Phosphorus recovery and recycling with ecological engineering: a review. Ecol Eng 98:213–227. https://doi.org/10.1016/j.ecoleng.2016.10.076

International Resource Panel (2019) Global resources outlook 2019: natural resources for the future a report of the international resource panel. United Nations Environment, Geneva

Mayer N, Kaltschmitt M (2022) Closing the phosphorus cycle: current P balance and future prospects in Germany. J Clean Prod 347:131272. https://doi.org/10.1016/j.jclepro.2022.131272

Huygens D, Saveyn HGM (2018) Agronomic efficiency of selected phosphorus fertilisers derived from secondary raw materials for European agriculture. A meta-analysis Agron Sustain Dev 38:52. https://doi.org/10.1007/s13593-018-0527-1

Scholz RW, Wellmer F (2019) Although there is no physical short-term scarcity of phosphorus, its resource efficiency should be improved. J Ind Ecol 23:313–318. https://doi.org/10.1111/jiec.12750

Tonini D, Saveyn HGM, Huygens D (2019) Environmental and health co-benefits for advanced phosphorus recovery. Nat Sustain 2:1051–1061. https://doi.org/10.1038/s41893-019-0416-x

Garske B, Ekardt F, Stubenrauch J (2023) Phosphorus, Human Rights, and Distributive Justice [Working Paper]. Research Unit Sustainability and Climate Policy, Leipzig.

Carpenter SR, Bennett EM (2011) Reconsideration of the planetary boundary for phosphorus. Environ Res Lett 6:014009. https://doi.org/10.1088/1748-9326/6/1/014009

Steffen W, Richardson K, Rockström J et al (2015) Planetary boundaries: guiding human development on a changing planet. Science 347:1259855. https://doi.org/10.1126/science.1259855

Schindler DW, Carpenter SR, Chapra SC et al (2016) Reducing phosphorus to curb Lake Eutrophication is a success. Environ Sci Technol 50:8923–8929. https://doi.org/10.1021/acs.est.6b02204

Bloem E, Haneklaus S, Schnug E (2020) Regulatory scenarios to counteract high phosphorus inputs into the Baltic sea. In: Negm AM, Zelenakova M, Kubiak-Wójcicka K (eds) Water resources quality and management in baltic sea countries. Springer International Publishing, Cham, pp 127–140

Beaulieu JJ, DelSontro T, Downing JA (2019) Eutrophication will increase methane emissions from lakes and impoundments during the 21st century. Nat Commun 10:1375. https://doi.org/10.1038/s41467-019-09100-5

Li Y, Robinson SVJ, Nguyen LH, Liu J (2023) Satellite prediction of coastal hypoxia in the northern Gulf of Mexico. Remote Sens Environ 284:113346. https://doi.org/10.1016/j.rse.2022.113346

Lun F, Liu J, Ciais P et al (2018) Global and regional phosphorus budgets in agricultural systems and their implications for phosphorus-use efficiency. Earth Syst Sci Data 10:1–18. https://doi.org/10.5194/essd-10-1-2018

Weishaupt A, Ekardt F, Garske B et al (2020) Land use, livestock, quantity governance, and economic instruments—sustainability beyond big livestock herds and fossil fuels. Sustainability 12:2053–2080. https://doi.org/10.3390/su12052053

Garske B, Ekardt F (2021) Economic policy instruments for sustainable phosphorus management: taking into account climate and biodiversity targets. Environ Sci Eur 33:56. https://doi.org/10.1186/s12302-021-00499-7

Borrelli P, Robinson DA, Panagos P et al (2020) Land use and climate change impacts on global soil erosion by water (2015–2070). Proc Natl Acad Sci USA 117:21994–22001. https://doi.org/10.1073/pnas.2001403117

Alewell C, Ringeval B, Ballabio C et al (2020) Global phosphorus shortage will be aggravated by soil erosion. Nat Commun 11:4546. https://doi.org/10.1038/s41467-020-18326-7

Stubenrauch J, Ekardt F, Heyl K et al (2021) How to legally overcome the distinction between organic and conventional farming—governance approaches for sustainable farming on 100% of the land. Sustain Prod Cons 28:716–725. https://doi.org/10.1016/j.spc.2021.06.006

United Nations (2015) Paris Agreement [FCCC/CP/2015/L.9/Rev.1]. United Nations, New York.

Ekardt F, Rath T, Vöhler T (2021) Die UN sustainable development goals und das Sozialrecht—unter besonderer Berücksichtigung der Rentenversicherung. Soziales Recht 2:60–75

United Nations Environment Programme (UNEP) (2022) Kunming-Montreal Global biodiversity framework Draft decision submitted by the President [CBD/COP/15/L.25]. UNEP, Montreal.

Ekardt F (2020) Sustainability transformation, governance, ethics, law. Springer International Publishing, Cham

European Commission (2020) Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. A Farm to Fork Strategy for a fair, healthy and environmentally-friendly food system [COM(2020) 381 final].

Heyl K, Ekardt F, Roos P, Garske B (2023) Achieving the nutrient reduction objective of the Farm to Fork Strategy. An assessment of CAP subsidies for precision fertilization and sustainable agricultural practices in Germany. Front Sustain Food Syst 7:1088640. doi:https://doi.org/10.3389/fsufs.2023.1088640.

European Commission (2019) Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions: The European Green Deal [COM(2019) 640 Final].

European Commission (2020) Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. A new Circular Economy Action Plan For a cleaner and more competitive Europe [COM/2020/98 final].

Commission E (2018) A sustainable bioeconomy for Europe: strengthening the connection between economy, society and the environment. Publications Office of the European Union, Luxemburg, Updated Bioeconomy Strategy

Stubenrauch J, Ekardt F, Hagemann K, Garske B (2022) Forest governance: overcoming trade-offs between land-use pressures. Springer International Publishing, Cham, Climate and Biodiversity Protection

Garske B, Stubenrauch J, Ekardt F (2020) Sustainable phosphorus management in European agricultural and environmental law. RECIEL 29:107–117. https://doi.org/10.1111/reel.12318

United Nations (1992) Convention on biological diversity [1760 UNTS 79; 31 ILM 818]. United Nations, New York

Heyl K, Ekardt F (2021) Barriers and methodology in transitioning to sustainability: analysing web news comments concerning animal-based diets. J Clean Prod. https://doi.org/10.1016/j.jclepro.2021.129857

Graça J, Calheiros MM, Oliveira A (2014) Moral disengagement in harmful but cherished food practices? An exploration into the case of meat. J Agric Environ Ethics 27:749–765. https://doi.org/10.1007/s10806-014-9488-9

Russell SV, Young CW, Unsworth KL, Robinson C (2017) Bringing habits and emotions into food waste behaviour. Resour Conserv Recycl 125:107–114. https://doi.org/10.1016/j.resconrec.2017.06.007

Fanghella V, Faure C, Guetlein M-C, Schleich J (2023) What’s in it for me? Self-interest and preferences for distribution of costs and benefits of energy efficiency policies. Ecol Econ 204:107659. https://doi.org/10.1016/j.ecolecon.2022.107659

Kollmuss A, Agyeman J (2002) Mind the gap: why do people act environmentally and what are the barriers to pro-environmental behavior? Environ Educ Res 8:239–260. https://doi.org/10.1080/13504620220145401

Bartiaux F (2008) Does environmental information overcome practice compartmentalisation and change consumers’ behaviours? J Clean Prod 16:1170–1180. https://doi.org/10.1016/j.jclepro.2007.08.013

Weingarten N, Meraner M, Bach L, Hartmann M (2022) Can information influence meat consumption behaviour? An experimental field study in the university canteen. Food Qual Pref 97:104498. https://doi.org/10.1016/j.foodqual.2021.104498

Ekardt F, Jacobs B, Stubenrauch J, Garske B (2020) Peatland governance: the problem of depicting in sustainability governance, regulatory law, and economic instruments. Land 9:83. https://doi.org/10.3390/land9030083

Bastviken D, Wilk J, Duc NT et al (2022) Critical method needs in measuring greenhouse gas fluxes. Environ Res Lett 17:104009. https://doi.org/10.1088/1748-9326/ac8fa9

Keith DA, Ferrer-Paris JR, Nicholson E et al (2022) A function-based typology for earth’s ecosystems. Nature 610:513–518. https://doi.org/10.1038/s41586-022-05318-4

European Commission (2015) Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. Closing the loop - An EU action plan for the Circular Economy [COM(2015) 614 final].

Cordell D, White S (2015) Tracking phosphorus security: indicators of phosphorus vulnerability in the global food system. Food Sec 7:337–350. https://doi.org/10.1007/s12571-015-0442-0

Powers SM, Chowdhury RB, MacDonald GK et al (2019) Global opportunities to increase agricultural independence through phosphorus recycling. Earth Future 7:370–383. https://doi.org/10.1029/2018EF001097

Hukari S, Hermann L, Nättorp A (2016) From wastewater to fertilisers—Technical overview and critical review of European legislation governing phosphorus recycling. Sci Total Environ 542:1127–1135. https://doi.org/10.1016/j.scitotenv.2015.09.064

Kratz S, Schick J, Shwiekh R, Schnug E (2014) Abschätzung des Potentials erneuerbarer P-haltiger Rohstoffe in Deutschland zur Substitution rohphosphathaltiger Düngemittel. J für Kulturpflanzen. https://doi.org/10.5073/JFK.2014.08.01

van Dijk KC, Lesschen JP, Oenema O (2016) Phosphorus flows and balances of the European union member states. Sci Total Environ 542:1078–1093. https://doi.org/10.1016/j.scitotenv.2015.08.048

Someus E, Pugliese M (2018) Concentrated phosphorus recovery from food grade animal bones. Sustainability 10:2349. https://doi.org/10.3390/su10072349

Ashley K, Cordell D, Mavinic D (2011) A brief history of phosphorus: from the philosopher’s stone to nutrient recovery and reuse. Chemosphere 84:737–746. https://doi.org/10.1016/j.chemosphere.2011.03.001

Möller K (2015) Assessment of Alternative Phosphorus Fertilizers for Organic Farming: Meat and Bone Meal. University of Hohenheim, ETH Zürich, Research Institute of Organic Agriculture, Bioforsk, University of Natural Resources and Life Sciences, Newcastle University and University of Copenhagen, Stuttgart.

Siebers N, Leinweber P (2013) Bone char: a clean and renewable phosphorus fertilizer with cadmium immobilization capability. J Environ Qual 42:405–411. https://doi.org/10.2134/jeq2012.0363

Huang C, Mohamed BA, Li LY (2022) Comparative life-cycle assessment of pyrolysis processes for producing bio-oil, biochar, and activated carbon from sewage sludge. Res Conserv Recycl 181:106273. https://doi.org/10.1016/j.resconrec.2022.106273

Panten K, Leinweber P (2020) Agronomische Bewertung nach fünfjähriger Phosphordüngung mit Knochenkohle. J für Kulturpflanzen. https://doi.org/10.5073/JFK.2020.12.02

Grafe M, Kurth JK, Panten K et al (2021) Effects of different innovative bone char based P fertilizers on bacteria catalyzing P turnover in agricultural soils. Agric Ecosyst Environ 314:107419. https://doi.org/10.1016/j.agee.2021.107419

Morshedizad M, Zimmer D, Leinweber P (2016) Effect of bone chars on phosphorus-cadmium-interactions as evaluated by three extraction procedures. J Plant Nutr Soil Sci 179:388–398. https://doi.org/10.1002/jpln.201500604

Leinweber P (2017) Pyrolyse von Schlachtknochen – ein attraktiver Ansatz im Phosphorrecycling. In: Sauermann U, Klätte M (Eds) Thermolyphos. Dokumentationsband zur Forumsveranstaltung am 4. und 5. Oktober 2016 in Halle (Saale). Stuttgart, pp 59–65.

Leinweber P, Hagemann P, Kebelmann L et al (2019) Bone char as a novel phosphorus fertilizer. In: Ohtake H, Tsuneda S (eds) Phosphorus recovery and recycling. Springer, Singapore, pp 419–432

Morshedizad M, Leinweber P (2017) Leaching of phosphorus and cadmium in soils amended with different bone chars: soil. Clean Soil Air Water 45:1600635. https://doi.org/10.1002/clen.201600635

Zimmer D, Panten K, Frank M et al (2019) Sulfur-enriched bone char as alternative p fertilizer: spectroscopic, wet chemical, and yield response evaluation. Agriculture 9:21. https://doi.org/10.3390/agriculture9010021

Postma J, Nijhuis EH, Someus E (2010) Selection of phosphorus solubilizing bacteria with biocontrol potential for growth in phosphorus rich animal bone charcoal. Appl Soil Ecol 46:464–469. https://doi.org/10.1016/j.apsoil.2010.08.016

World Health Organization (2019) Preventing disease through healthy environments. Exposure to cadmium: a major public health concern [WHO/CED/PHE/EPE/19.4.3]. World Health Organization, Geneva

Siebers N, Godlinski F, Leinweber P (2014) Bone char as phosphorus fertilizer involved in cadmium immobilization in lettuce, wheat, and potato cropping. Z Pflanzenernähr Bodenk 177:75–83. https://doi.org/10.1002/jpln.201300113

Terra Humana (2020) REFERTIL. Reducing mineral fertilisers & chemicals use in agriculture by recycling treated organic waste as compost and bio-char products. http://www.refertil.info/. Accessed 31 Aug 2023.

Centre for Strategy & Evaluation Services (2010) Evaluation of Regulation (EC) 2003/2003 relating to Fertilisers. Final Report. Publications Office of the European Union, Luxemburg.

Silva FC, Cruz NC, Tarelho LAC, Rodrigues SM (2019) Use of biomass ash-based materials as soil fertilisers: critical review of the existing regulatory framework. J Clean Prod 214:112–124. https://doi.org/10.1016/j.jclepro.2018.12.268

European Commission (2023) EU survey on possible future development of the FPR. https://ec.europa.eu/eusurvey/runner/possible_future_development_of_the_FPR. Accessed 31 Aug 2023.

European Parliament (2012) European Parliament resolution of 19 January 2012 on the farm input supply chain: structure and implications [2011/2114(INI)]. https://www.europarl.europa.eu/doceo/document/TA-7-2012-0011_EN.html?redirect. Accessed 31 Aug 2023.

Commission E (2018) Circular economy: agreement on commission proposal to boost the use of organic and waste-based fertilisers [press release]. European Commission, Brussels

Marshall R, Lag-Brotons AJ, Inam EJ et al (2019) From bioenergy by-products to alternative fertilisers: pursuing a circular economy. In: Macaskie LE, Sapsford DJ, Mayes WM (eds) Green chemistry series. Royal Society of Chemistry, Cambridge, pp 287–314

European Sustainable Phosphorus Platform (2021) Animal By Product End-Points for EU Fertilising Products Regulation “STRUBIAS” materials [Letter]. https://www.phosphorusplatform.eu/images/download/ESPP_-_SANTE_-_GROW_ABP_End-Points__STRUBIAS_16_4_2021.pdf . Accessed 31 Aug 2023.

Sukalac K (2022) Letter to Mr. Reviriego Gordejo | Animal By-Products. https://phosphorusplatform.eu/images/download/EBIC%20ESPP%20etc%20joint%20letter%20ABPs%20in%20FPR%2011_3_22%201.pdf. Accessed 31 Aug 2023.

Huygens D, Saveyn H, Tonini D et al (2019) Technical proposals for selected new fertilising materials under the fertilising products regulation (regulation (EU) 2019/1009). Publications Office of the European Union, Luxemburg

EFSA Panel on Biological Hazards (BIOHAZ), Koutsoumanis K, Allende A et al (2021) Inactivation of indicator microorganisms and biological hazards by standard and/or alternative processing methods in category 2 and 3 animal by-products and derived products to be used as organic fertilisers and/or soil improvers. EFS2. https://doi.org/10.2903/j.efsa.2021.6932

Gallina S (2022) Letter to Cssrs concerning safe recycling of nutrients in Animal By-Products (ABPs) and manures. https://www.phosphorusplatform.eu/images/download/SANTE_Gallina_reply_ESPP_ABPs_ash_31_5_22.pdf. Accessed 31 Aug 2023.

European Commission (2016) Circular Economy Package. Proposal for a Regulation of the European Parliament and of the Council laying down rules on the making available on the market of CE marked fertilising products and amending Regulations (EC) No 1069/2009 and (EC) No 1107/2009 [COM(2016) 157 final].

Marini M, Caro D, Thomsen M (2020) The new fertilizer regulation: a starting point for cadmium control in European arable soils? Sci Total Environ 745:140876. https://doi.org/10.1016/j.scitotenv.2020.140876

Kabbe C (2019) Circular economy: bridging the gap between phosphorus recovery and recycling. In: Ohtake H, Tsuneda S (eds) Phosphorus recovery and recycling. Springer, Singapore, pp 45–57

Schipper W (2019) Success factors for implementing phosphorus recycling technologies. In: Ohtake H, Tsuneda S (eds) Phosphorus recovery and recycling. Springer, Singapore, pp 101–130

Rosemarin A, Macura B, Carolus J et al (2020) Circular nutrient solutions for agriculture and wastewater – a review of technologies and practices. Curr Opin Environ Sustain 45:78–91. https://doi.org/10.1016/j.cosust.2020.09.007

Halleux V (2019) EU fertilising products. Briefing. EU Legislation in Progress [PE 582.010]. European Parliamentary Research Service, Brussels and London.

Meyer S, Genesio L, Vogel I et al (2017) Biochar standardization and legislation harmonization. J Environ Eng Landsc 25:175–191. https://doi.org/10.3846/16486897.2016.1254640

Withers P, Doody D, Sylvester-Bradley R (2018) Achieving sustainable phosphorus use in food systems through circularisation. Sustainability 10:1804. https://doi.org/10.3390/su10061804

United States Environmental Protection Agency (2021) TENORM: Fertilizer and Fertilizer Production Wastes. https://www.epa.gov/radiation/tenorm-fertilizer-and-fertilizer-production-wastes. Accessed 31 Aug 2023.

Eurostat (2019) Agri-environmental indicator - livestock patterns. https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Agri-environmental_indicator_-_livestock_patterns. Accessed 31 Aug 2023.

Wassen MJ, Schrader J, Eppinga MB et al (2022) The EU needs a nutrient directive. Nat Rev Earth Environ 3:287–288. https://doi.org/10.1038/s43017-022-00295-8

Commission E (2021) EU agricultural outlook for markets, income and environment, 2021–2031. Publications Office of the European Union, Luxemburg

Acknowledgements

We would like to thank Peter Leinweber for comprehensive feedback on an earlier draft of this manuscript and Ludwig Hermann and Chris Thornton for their shared knowledge on the Fertilising Products Regulation.

Funding

Open Access funding enabled and organized by Projekt DEAL. This research was funded by the German Federal Ministry of Education and Research (BMBF) within the BonaRes project InnoSoilPhos (No. 031B0509).

Author information

Authors and Affiliations

Contributions

All authors contributed to the manuscript. Article conceptualisation, analysis of the Fertilising Products Regulation and the discussion were performed by KH. She also wrote Sect. "Materials and methods". The overview of recycling fertilisers was contributed by BG as was the introduction. The method is based on research of FE, who supervised the project. All authors commented on previous versions of the manuscript and provided additional ideas and arguments. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Heyl, K., Garske, B. & Ekardt, F. Using bone char as phosphate recycling fertiliser: an analysis of the new EU Fertilising Products Regulation. Environ Sci Eur 35, 109 (2023). https://doi.org/10.1186/s12302-023-00819-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s12302-023-00819-z