Abstract

Background

While the increase in the number of coconut-based industries in Malaysia supports economic growth positively, it affects the environment negatively by generating large amounts of coconut wastes. This study has endeavored to assess the possibility of vermicomposting different types of coconut wastes and, in doing so, evaluated the potential of using the African nightcrawler (Eudrilus eugeniae) to decompose coconut wastes. The study was conducted over a 50-day duration using two different types of coconut wastes: coconut husk (CH) and spent coconut flakes (SCF). The nutrient content of the vermicompost at various stages of treatments was determined. Three different percentage ratios were used: {C1-W or B1-W (100% waste), C2-W or B2-W (70% waste + 30% goat manure), and C3-W or B3-W (50% waste + 50% goat manure)}. Twenty healthy adult E. eugeniae (each 0.02 to 0.03 kg) were introduced to each treatment.

Results

Results showed that the degradation process was very fast in the spent coconut flakes which needed only 16 days for complete decomposition, while that in the coconut husk needed 2 months. Available phosphorous (P) and total potassium (TK) values declined in CH. The available P and TK in C3-W (50% waste + 50% goat manure) were less than the initial values by 26.6% and 53.69%, respectively. Moreover, P and TK values increased in SCF at the final stage as in B2-W (70% waste + 30% goat manure) which was 69.3% more than the initial level. The weights of the worms were recorded throughout the experimental period.

Conclusions

The study showed that vermicomposting could be an efficient method to convert coconut wastes into a valuable by-product.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Background of the study

Waste is an inevitable by-product that arises from various anthropogenic activities; it is also considered as one of the major sources of environmental degradation as it causes air, land, and water pollution and contributes to global warming (Peter2010). Different kinds of industries, change of lifestyle, and population growth are assumed to be among the main factors that increase the rate of waste generation globally and locally. Hence, proper waste management options are vitally important in terms of cost-effectiveness and environmental sustainability.

Malaysia, like many developing countries, is facing an increase in the generation of waste and problems associated with waste disposal (Lina2004). The Malaysian population was approximately 28.96 million in 2010, based on a projection growth with an average of 1.6% per year compared to that in 2009 which was 28.31 million (Malaxi2010). As such, waste generation has increased by 3% annually, and recent studies showed that increased solid waste generation has alarmed waste managers (Fauziah and Agamuthu2009). The national average of waste generation at 1.3 kg/capita is expected to be increasing linearly, reaching to 2.23 kg/capita by 2024 (Mohamad et al.2009). Approximately 30,000 tonnes of municipal solid waste is generated daily, covering 83% of the country’s waste generation which includes agrowastes. About 95% of the total wastes are sent to the landfill for disposal (Fauziah and Agamuthu2009). Clearly, the way to limit the impact on the environment is by reducing the amount of waste that is generated. Failing this, waste must be recycled, composted, or reused. When these options are unsuitable, waste must be incinerated for the purpose of harvesting energy for heating houses or generating electricity, and only as a last resort, should landfills be utilized (Antonio and Domenico2008).

Globally, 998 million tonnes of agricultural waste is produced in a year, and in Malaysia, 1.2 million tonnes of agricultural waste is disposed into landfills annually. In Malaysia, coconut is the fourth most important crop in terms of acreage, after oil palm, rubber, and paddy. Moreover, coconut has significant socioeconomic implications as it is estimated to provide a source of revenue for 80,000 households. It is important that new methods for treating agro-residues are being adopted and considered in order to achieve sustainable management of agricultural waste. The coconut-based industry in Malaysia has been considered as part of the country’s economic sector for a considerably long time and has efficiently developed in recent years. In addition, large amounts of coconut waste are also generated which end up being dumped into the landfills, thereby taking up landfill space.

Objectives of the study

This study was carried out toward the purpose of achieving the following objectives:

-

(1)

To assess the possibility of vermicomposting of different types of coconut wastes

-

(2)

To evaluate the potential of Eudrilus eugeniae to vermicompost coconut wastes

-

(3)

To generate comparative data on the degradability of the various types of coconut wastes

Methods

Collections and culturing of earthworm

The earthworm E. eugeniae which is commonly known as the African nightcrawler was used in this study and was obtained from a commercial supplier. The worms were cultured in large plastic containers that contained partially decomposed farm soil mixed with goat manure (GM) under laboratory conditions which maintained a temperature between 25°C to 28°C, as this worm cannot easily tolerate low temperatures.

Collection of coconut wastes and experimental setup

The used coconuts were obtained from different sources, while the feed materials such as farm soil and goat dung were obtained from the goat farm at University of Malaya campus. Whereas, the spent coconut flakes (SCF) were obtained from a local market; the coconut husk (CH) was obtained from Kapar Coconut Industry Sdn. Bhd (Selangor, Malaysia). The experiments were conducted in plastic containers which were 20 × 14 × 15 cm (length × width × depth), and the tops of the containers were perforated for aeration. A total of 24 plastic containers were used for both types of coconut wastes. The containers were divided into three different sets, and each set was composed of nine containers for the SCF, CH, and controls (without any earthworm). Each experimental percentage was run in triplicates to minimize any experimental error. E. eugeniae earthworms (0.02 to 0.03 kg) numbering 20 were randomly picked and introduced into each treatment. The different percentage ratios were utilized (Table S1.1 in Additional file1). The layering system that was used in this study is illustrated in Figure1.

Chemical and physical analyses

The experiment was analyzed for pH, C:N ratio, N, P, K, weight loss, and degradation rate. Samples were taken for day 0 (starting day) and the final stage (when the experiments totally degraded) for determining the trends with time. In addition, physical parameters, namely, conductivity, salinity, and color change, were observed. Total nitrogen and total organic carbon were detected by CHNS elemental analysis, while the total phosphorus was determined by ICPMS. The multipurpose Hach Sension 7 Benchtop conductivity meter (Thomas Scientific, Swedesboro, NJ, USA) was used to measure the conductivity and salinity of the samples.

Results and discussion

The physical and chemical parameters were determined for the starting day (day 0) and final day of degradation. The time taken for the degradation process to be complete was 50 days for CH compared to only 16 days for SCF. The color of the CH began to change after 12 days which was probably due to the initial stages of the degradation process by microorganisms as well as the action of the earthworms. The experiment’s color completely changed to brown at the final stage. For SCF, the color of the coconut flakes changed from white to yellow after 5 days and turned completely brown after 16 days.

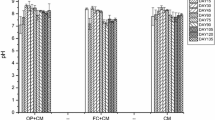

pH

For CH, the pH values of all the experiments from the first day (zero 0) were slightly acidic in C1-W (5.2 ± 0.1), C2-W (5.8 ± 0.6), and C3-W (5.9 ± 0.1) as shown in Figure2A. The pH values in SCF were slightly alkaline from the first day (day 0). The pH values in B1-W were 6.8 ± 1.0, whereas B2-W and B3-W recorded pH values of 7.6 ± 0.1 and 7.8 ± 0.1, respectively (Figure2B). The pH values at the final stage increased in all types of coconut waste setups. These increased pH values at the final stage of vermicomposting can be attributed to the decomposition of nitrogenous substrates, resulting in the production of ammonia which formed a large proportion of the nitrogenous matter excreted by the earthworms (Muthukumaravel et al.2008).

pH values. (A) The pH values during the vermicomposting process of coconut husk. Note: C1, CH (100); C2, GM:CH (30:70); C3, GM:CH (50:50); W, with worm; and CTRL, without worm. (B) The pH values during the vermicomposting process of SCF. Note: B1, SCF (100); B2, GM:SCF (30:70); B3, GM:SCF (50:50); W, with worm; and CTRL, without worm.

Total phosphorus

The highest reduction at the final stage of the P value in CH was in C3-W from (18.42 mg/l to 8.53 mg/l) (Figure3A). The P value increased in SCF at the final stage, and the highest increase was in B2-W from (10.02 mg/l to 16.40 mg/l) (Figure3B). The highest reduction of the P value was in C3-CTRL and was possibly due to the presence of GM which enhanced the mineralization and mobilization of phosphorus. However, the increase of the P value in SCF may be due to the high ratio of phosphorus present in the vermibed or the physical breakdown of the materials by the worms. The further release of P might be attributed to the P-solubilizing microorganisms present in worm casts (Edwards and Bohlen1972; Suthar2008).

Values of phosphorus. (A) Value of phosphorus during vermicomposting of coconut husk. Note: C1, CH (100); C2, GM:CH (30:70); C3, GM:CH (50:50); W, with worm; and CTRL, without worm. (B) Value of phosphorus during vermicomposting of SCF. Note: B1, SCF (100); B2, GM:SCF (30:70); B3, GM:SCF (50:50); W, with worm; and CTRL, without worm.

Total potassium

The total potassium (TK) values decreased in CH at the final stage of vermicomposting (Figure4A), while in SCF, the TK values for B1-W, B2-W, and B3-W increased (Figure4B). These reductions in TK values in CH at the final stage of vermicomposting were possibly due to the leaching of this soluble element through the action of excess water draining through the mass. However, the TK value increased in SCF, and the increase could be attributed to the acid production during the decomposition process by the microorganisms for the solubilization of insoluble K. The TK values of SCF controls (without worms) at the final stage increased.

Values of total potassium. (A) The value of total potassium during vermicomposting of coconut husk. Note: C1, CH (100); C2, GM:CH (30:70); C3, GM:CH (50:50); W, with worm; and CTRL, without worm. (B) The value of total potassium during vermicomposting of spent coconut flakes. Note: B1, SCF (100); B2, GM:SCF (30:70); B3, GM:SCF (50:50); W, with worm; and CTRL, without worm.

Total organic carbon

The total organic carbon (TOC) values of the CH experiments (with worm) decreased at the final stage of vermicomposting (Table S2A in Additional file1). The highest reduction of TOC was in C3-W from 10.477% to 3.621%, and the lowest reduction was in C1-W from 4.856% to 3.481%. For SCF, the TOC values also in all of the experiments declined at the final stage of vermicomposting as shown in (Table S2B in Additional file1). The final reduction in TOC values of all types of coconut wastes was possibly due to the rapid respiration rate that leads to the loss TOC in terms of CO2 or was probably due to the fact that the organic carbon was utilized as by the worms and resulted to TOC reduction.

Total nitrogen

The total nitrogen (TN) values of the CH experiments (with worm) decreased at the final stage of vermicomposting (Table S3A in Additional file1). For SCF, the TN value increased at the final stage in B2-W and B3-W (from 0.394% to 0.556% and from 0.371% to 0.437%, respectively) (Table S3B in Additional file1). However, the TN value decreased in B1-W from 0.396% to 0.288%. The reduction of TN values at the final stage of vermicomposting in CH experiments was possibly due to the mineralization of the nitrogen, and the increase of pH in the final stage was assumed to be the significant factor for losing nitrogen as volatile ammonia (Ndegwa and Thompson2000). However, the TN values increased at the final stage in SCF experiments, and it could be attributed to the initial presence (physicochemical properties) in the substrates and the mineralization process of nitrogen by microbial and enzyme activity in the gut of the worms.

Carbon-to-nitrogen ratio

The carbon-to-nitrogen ratio (C/N) decreased at the final stage of vermicomposting in CH and SCF. The highest reduction of C/N in CH experiments was in C3-W, while the lowest reduction was in C2-W (Table S4A in Additional file1). For SCF, the highest reduction of C/N was in B1-W, while the lowest reduction was in B3-W (Table S4B in Additional file1). The reduction of C/N at the final stage of vermicomposting for CH and SCF was possibly due to the decline of TOC through the degradation process via the release of CO2 with a decrease of TN via the release of volatile ammonia. The C/N was within the acceptable range for the vermicompost which was addressed by the EPA that preferred C/N at a ratio of less than 20:1 (Adi and Noor2009). Moreover, the final C/N declined in the control setups of all types of coconut wastes (except in B2-CTRL which was increased). The highest reduction of C/N in CH controls was in C1-CTRL from 14.9% to 11.4%, and the lowest was in C2-CTRL from 13.5% to 11.3%. For SCF, the C/N declined in B1-CTRL, from 45.8% to 22.9%, and B3-CTRL, from 31.2% to 13.6%. The reduction of C/N in all types of coconut waste control setups was possibly due to the reduction of TOC via the respiration process in the form of CO2.

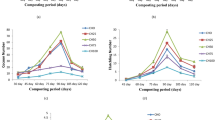

Degradation of coconut wastes

The complete degradation of the C3-W setup was 42 days, while C2-W and C1-W were totally degraded after 45 and 49 days, respectively. Also, the time needed for degradation of the spent coconut flake setups, namely, B3-W, B2-W, and B1-W, was 11, 12, and 16 days, respectively. The degradation of the various types of coconut wastes is shown in Figure5. Faster degradation in spent coconut flake setups was possibly due to the size of the spent coconut flake particles which were smaller and softer than those of the coconut husk. Additionally, spent coconut flakes also contained high moisture content (52.6%) compared to the coconut husk (14.3%). Spent coconut flakes were also less fibrous compared to coconut husk. (Michael2006) had reported similar findings where spent coconut flakes were found to contain low fiber (4 g/100 g SCF), while coconut husk contained high lignin at 43.0%. Therefore, it is possible that the presence of lignin and fiber may have slowed the degradation rates. This indicates that the higher the ligno-cellulose contents of the waste, the slower the vermicomposting process.

Weight losses in the vermicomposting setups

For the coconut husk, the final weight loss was highest in C3-W (33.6%), followed by C2-W (29.4%) and C1-W (21.7%) as shown in Figure6A. However, in SCF, the weight loss was higher in B3-W (29.4%) than in B2-W (28.9%) and B1-W (19.6%) (Figure6B). The distinct weight losses between these experiments were possibly due to the presence of goat manure which catalyzed microbial degradation of the waste. Such activities encourage the release of CO2 via the mineralization process of organic matter and the release of moisture through evaporation. The weight losses in CH and SCF experiments with worms were higher than those in the controls (without worms). The presence of worms in the system demonstrated the enhancement of the biological processes, leading to higher weight loss compared to setups without worms. Also, the worms’ physical activities like the blending and mixing of the waste increased the surface area exposed to microorganisms, hence creating more favorable conditions for microbial activities and faster decomposition.

Weight loss at the final stage. (A) Weight loss of the CH at the final stage. Note: C1, CH (100); C2, GM:CH (30:70); C3, GM:CH (50:50); W, with worm; and CTRL, without worm. (B) Weight loss of the SCF at the final stage. Note: B1, SCF (100); B2, GM:SCF (30:70); B3, GM:SCF (50:50); W, with worm; and CTRL, without worm.

Multiplication of earthworms (weights and numbers) in different experiments

After 50 days of vermicomposting the coconut husk, the highest earthworm weight gain was in C1-W (3.39 ± 0.71 g), and the lowest weight gain was in C2-W (−0.57 ± 0.72 g). The number of earthworms declined at the final stage of vermicomposting, and the highest reduction was in C1-W (9.0 ± 2.0 g), while the lowest reduction was in C3-W (4.0 ± 3.0 g) as shown in Table S5A in Additional file1. For the spent coconut flakes, the highest weight gain was in B2-W (7.67 ± 1.6 g), and the lowest was in B1-W (1.99 ± 0.2 g). The number of worms declined at the final stage of vermicomposting spent coconut flakes. The highest reduction in worm numbers was in B1-W (8.0 ± 2.0), and the lowest decline in worm numbers was in B3-W (4.0 ± 1.0) as shown in Table S5B in Additional file1.

The final earthworm weight gains were possibly due to the availability of adequate nutrients in the vermibeds for the worms, particularly inside the mixture of waste with GM. Moreover, GM also may have played an important role in earthworm weight gain by providing more nutrients. Additionally, the earthworms may have utilized microorganisms present in their substrates as a food source and could digest them selectively (Suthar2009;Singh and Sharma2002).

The final number of worms decreased in all types of coconut wastes. The reduction of the worm’s numbers was possibly due to the change of pH (acidic condition) because this type of earthworm is very sensitive to pH change. Also, the texture and hardness of the waste may have had an impact on the worms’ reproduction. In addition, the decrease in worm numbers was probably due to the high level of protein that can cause rapid disrepair and heating which often results in creating an environment that is unsuitable to worm production (Adi and Noor2009).

Conclusion

This study concludes that the two types of coconut wastes utilized, which were coconut husk and spent coconut flakes, can be composted within different periods of time (50 and 16 days, respectively). Degradation processes were faster in SCF than in CH. The vermicompost of coconut wastes can be utilized as an organic fertilizer instead of being disposed in landfills. The results also showed that the smaller the size of the shredded waste, the more rapid the decomposition process. The success of E. eugeniae to vermicompost coconut wastes was also studied, and it was found that, generally, the number of worms declined during the process.

References

Adi A, Noor Z: Waste recycling: utilization of coffee grounds and kitchen waste in vermicomposting. Bioresour Technol 2009,100(2):1027–1030. 10.1016/j.biortech.2008.07.024

Antonio M, Domenico P: Municipal waste management in Sicily: practices and challenges. Waste Manag 2008,28(7):1201–1208. 10.1016/j.wasman.2007.05.003

Edwards C, Bohlen P: Biology and ecology of earthworms, 3rd edn, vol 3. Chapman and Hall, London; 1972:305.

Fauziah SH, Agamuthu P: Sustainable household organic waste management via vermicomposting. Malaysian Journal of Science 2009,28(22):135–142.

Lina L: Case study on the management of waste materials in Malaysia. 2004. . Accessed on 15 March 2011 http://www.geooekologie.de/download_forum/forum_2004_2_spfo042b.pdf . Accessed on 15 March 2011

Malaxi: Malaysian population. 2010. . Accessed on 5 January 2011 http://www.malaxi.com . Accessed on 5 January 2011

Michael F: Coconut shell composition. 2006. . Accessed on 12 January 2011 http://www.mail-archive.com/vortexl@eskimo.com/msg16649.html . Accessed on 12 January 2011

Mohamad O, Mohd Nasir H, Abdul Mujeebu M: Assessment of municipal solid waste generation and recyclable materials potential in Kuala Lumpur, Malaysia. Waste Manag 2009,29(7):2209–2213. 10.1016/j.wasman.2009.02.017

Muthukumaravel K, Amsath A, Sukumaran M: Vermicomposting of vegetable wastes using cow dung. E-Journal of Chemistry 2008,5(4):810–813. 10.1155/2008/572431

Ndegwa P, Thompson S: Effects of C-to-N ratio on vermicomposting of biosolids. Bioresour Technol 2000,75(1):7–12. 10.1016/S0960-8524(00)00038-9

Peter H American Association for the Advancement of Science. Population and environment. Population, waste and chemicals 2010. . Accessed on 14 January 2011 http://atlas.aaas.org/index.php?part=2&sec=waste . Accessed on 14 January 2011

Singh A, Sharma S: Composting of a crop residue through treatment with microorganisms and subsequent vermicomposting. Bioresour Technol 2002,85(2):107–111. 10.1016/S0960-8524(02)00095-0

Suthar S: Bioconversion of post harvest crop residues and cattle shed manure into value-added products using earthworm Eudrilus eugeniae Kinberg. Ecol Eng 2008,32(3):206–214. 10.1016/j.ecoleng.2007.11.002

Suthar S: Vermicomposting of vegetable-market solid waste using Eisenia fetida : impact of bulking material on earthworm growth and decomposition rate. Ecol Eng 2009,35(5):914–920. 10.1016/j.ecoleng.2008.12.019

Acknowledgments

The authors are thankful to UM-IPPP for the financial support. Also, the authors would like to thank Mike Creager, Emenike Chijioke, Omer Almuktar, Shamini Karishian, and Muhammad Javanmeri for providing the necessary experimental facilities and their valuable comments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

TAT is the main author, did the field and laboratory task, and drafted the manuscript. FSH designed the experiment, gave supervision, drafted the proposal, and participated in the correction of the manuscript. Both authors read and approved the final manuscript.

Electronic supplementary material

40093_2012_7_MOESM1_ESM.rtf

Additional file 1: Supplementary tables. A file showing five tables with different data and results during vermicomposting of spent coconut flakes and coconut husk. (RTF 246 KB)

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Tahir, T.A., Hamid, F.S. Vermicomposting of two types of coconut wastes employing Eudrilus eugeniae: a comparative study. Int J Recycl Org Waste Agricult 1, 7 (2012). https://doi.org/10.1186/2251-7715-1-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2251-7715-1-7