Abstract

Background

The chemical composition of the crude waxes extracted from three different seed oils (sunflower, canola, and cottonseed) was studied using chromatographic techniques.

Results

Greater amount of wax (0.45% ± 0.13%) was found in the crude oil of sunflower followed by cottonseed (0.07% ± 0.01%), and then canola (0.03% ± 0.01%). Wax ester and fatty hydrocarbon fractions were separated by thin layer chromatography. Fatty hydrocarbon fraction was analyzed by gas chromatography and mass spectrometry (GC-MS) to confirm the presence of C19-C35 fatty hydrocarbons. Wax ester fraction indicated distribution of esters from C34 to C54, while C42-C48 fraction was found to be predominant. For constituents of fatty acid, methyl esters and fatty alcohol acetates were carried out by GC-MS after the saponification and derivatization of wax esters. GC-MS analysis indicated the presence of saturated methyl esters from Cl4-C30, whereas C24 methyl ester was found to be predominant. The alcohol portion contained saturated chain lengths between C14-C30; the main component was saturated C22 and C24 alcohol.

Conclusions

GC-MS was used for the characterization of the various classes of three different seed oil waxes. The results indicated that seed oil wax has the potential to be used in the cosmetic and pharmaceutical industry due to its better composition of long chain fatty acids and fatty alcohols.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Background

The major portion of edible oils contained triacyl-glycerols (95% to 98%), and the minor fraction contained (2% to 5%) complex mixtures of minor compounds such as free fatty acids, mono-, di-, and tri-acylglycerides, tocopherols, sterols, phospholipids, pigmented compounds, waxes. etc. [1]. Edible oils usually contain small amount of high-melting waxes, which must be removed to avoid cloudiness and settling problem [2]. Waxes and non-glycerol esters have been found in many seed oils [3]. Usually, natural waxes are lipids in nature and mainly contain a wide variety of lipid components, such as hydrocarbons, esters, fatty alcohols, ketones, mono-, di-, tri-acylglycerols, and sterol esters [4]. The seed oil waxes are composed of mainly long-chain fatty acids with long-chain linear or branched alcohols.

Among the various techniques available for the characterization of waxes, chromatographic and spectroscopic techniques are considered to be very efficient. Spectroscopic technique such as FT-IR, [5] have been used to characterize waxes, but this kind of method only permits to distinguish among characteristic groups. Separation methods such as supercritical gas chromatography [6], liquid chromatography [7], gas chromatography-flame ionization detection (GC-FID) [8], or pyrolysis gas chromatography [9] have been used. Gas chromatography (GC) and mass spectrometry (MS) has proved an effective combination for chemical analysis, in order to carry out simultaneous identification and quantification of the various components of complex mixture [9]. For some wax components, derivatization is required; as fatty acids and fatty alcohols are not volatile, derivatization is necessary [10] but fatty hydrocarbons are volatile and can be analyzed without derivatization [11]. In the present study, chromatographic techniques were used for the characterization of sunflower wax (SFW), cottonseed wax (CSW), and canola wax (CW) extracted from their respective crude oils.

Methods

Gas chromatography of wax esters

The separation of individual wax ester was carried out on a PerkinElmer Clarus gas chromatograph (Massachusetts, USA) equipped with a flame ionization detector. A DB-1 fused-silica capillary column (15 m × 0.32 mm, film thickness 0.25 μm; J&W Scientific, Folsom, USA) was used. The sample (1 μL) was injected at 75°C; the oven was then heated to 230°C at a rate of 25°C/min and from 230°C to 340°C at a rate of 10°C/min. The final temperature was held for 10 min. Hydrogen was used as a carrier gas at a constant flow rate of 1.8 mL/min. The injector and detector temperatures were 300°C and 350°C, respectively. Identification was based on comparison with authentic standards.

Separation of various fractions of waxes by thin-layer chromatography

The wax removed and purified as above was subjected to thin-layer chromatography (TLC) to separate it into wax esters and fatty hydrocarbons fraction. Separations were done on twenty 20-cm glass plates coated with a silica gel (Merck, Darmstadt, Germany) layer of 0.25-mm thickness. Waxes dissolved in chloroform were applied onto the plates using capillary tubes. The plates were developed using the solvent system, toluene/chloroform (7:3). Fractionation of these constituents was achieved, based on earlier reported procedures [12]. Spots were visualized by placing the plate in a chamber, saturated with iodine for identification of spots. The spots were identified with simultaneous running of authentic standards. The preparative TLC was carried out for the separation and elution of wax esters. The separated constituents were eluted with chloroform from adsorbent and dried under a stream of nitrogen.

Gas chromatography and mass spectrometry

GC-MS instrumentation

An Agilent 6890 N gas chromatography instrument coupled with an Agilent MS-5975 inert XL mass selective detector and an Agilent auto sampler 7683-B injector (Agilent Technologies, Little Fall, NY, USA) was used. A capillary column HP-5MS (5% phenyl methylsiloxane) with dimension of 30 m, 0.25 mm i.d, 0.25 μm film thickness (Agilent Technologies, Palo Alto, CA, USA) was used.

Results and discussion

The present study was carried out to explore the quantity and quality of various seed oil waxes. The wax samples were coded as SFW, CSW, and CW for sunflower, cottonseed, and canola wax, respectively. The waxes that were extracted, purified, and weighed from SFW, CW, and CSW is presented in Figure 1. Greater mean value of the waxes in percent (0.45% ± 0.13%) was observed in the sunflower oil, then followed by cottonseed (0.07% ± 0.01%) and then canola (0.03% ± 0.01%) oil.

After the separation and purification of the waxes, they were subjected to TLC to separate fractions of wax esters and fatty hydrocarbons of waxes. Fractionation of these constituents was achieved by thin-layer chromatography. Among the solvent systems, toluene/chloroform (7:3 v/v) was used, and the order of movement of hydrocarbons and wax esters is indicated by the retention values of 0.94 and 0.90 respectively. The seed oil waxes consisted of wax esters, fatty hydrocarbons, and traces of triacylglycerides (Table 1). The reported procedure was used for TLC, and good recovery up to 98% was achieved for each fraction.

The presence of eight fatty hydrocarbons (Table 2) was identified by GC-MS analysis, which ranged between C19 to C35. The major fatty hydrocarbon was C28 which is 1-octacosene for all seed oils waxes.

Further adequate separation and resolution has been obtained for wax ester up to C54 under the gas chromatographic conditions employed. The gas chromatographic analysis of the wax ester fraction provides a separation of saturated even- and odd-numbered wax esters within a run time of 55 min. On the capillary column DB-1, the wax esters were separated according to their boiling points. Odd chain saturated long-chain esters are present in lower concentrations than even long-chain saturated esters.

Individual separation of wax esters was carried out by GC-FID (Table 3). The results indicated that the long chain esters were ranged between C34 to C54. The major wax esters were C44 to C48, constituting more than 50% of the total wax esters. Among the wax esters present, C44 was predominant; this clearly shows that esters are mainly formed from C22-C24 acids and C22-C24 alcohols.

Saponification wax ester released long fatty acids and long chain fatty alcohols. The assignment of the components was performed by GC-MS analysis and is given in detail below.

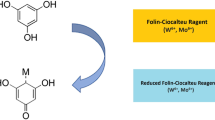

The wax ester fraction of seed oil waxes is composed of esters of long fatty acids and long chain fatty alcohols (Figure 2). The structures of wax esters are represented as R1-COO-R2, where R1 is the acidic moiety and R2 is the alcoholic moiety. Totally, 23 compounds were separated and identified, of which 10 were fatty acids and 13 were fatty alcohols. The studies revealed that overall, the quantity of fatty alcohols is greater in all analyzed wax samples, then followed by fatty acid. The results are shown in Table 4.

These results are comparable with the reported values in which many researchers have carried out the characterization of different seed oil waxes, and present research results are in range for SFW, CW, and CSW compared with other seed oil waxes [13–15]. Fatty alcohols and fatty acids separated were found to contain saturated even-numbered carbon chain, ranging from C14 to C30 (Table 4) as analyzed by GC-MS as fatty alcohol acetates and fatty acids methyl esters. The major FAL acetate present in the seed oil wax ester is from C20 to C28, and high percent of FALs were present in SFW 60% as compared to the other three seed oil waxes. For all the waxes, lignoceryl acetate was the major FAL acetate. The major fatty acids present in the seed oil wax ester are from C20 to C28, and the two major fatty acids present in the SFW, CW and CSW (behenic and lignoceric acids) were identified as methyl behenate and methyl lignocerate with molecular weights of 354 and 386, respectively.

Experimental

Samples, reagents, and solvents

The seeds of sunflower, canola, and cottonseed were collected from Karachi Pakistan (three different locations); the seeds were ground and their oil extracted with n-hexane (boiling point 68°C to 72°C) in a Soxhlet apparatus following the IUPAC standard method 1.122 [16]. The hexane was evaporated on rotary evaporator. The extraction procedure was done in triplicate, and the quantity of the oil obtained was calculated. The following reagents have been used for the treatment of the samples: the standards of wax esters are myristic acid arachidyl ester (99%), atearic acid stearyl ester (99%), aonadecanic acid stearyl ester (99%), arachidic acid oleoyl ester (99%), aenicosanoic acid stearyl ester, arachidic acid arachidyl ester (99%), henicosanoic acid arachidyl ester (99%), arachidic acid behenyl ester (99%), behenic acid behenyl ester (99%), heptacosanyl stearyl ester(99%), hehenic acid lignoceryl ester (99%), lignoceryl acid lignoceryl ester (99%); fatty acid methyl esters (FAMEs): methyl myristic, methyl palmitate, methyl oleate, methyl stearate, methyl nonadecanate, methyl arachidate, methyl heneicosanate, methyl behenate, methyl lignocerate, methyl cerotate, methyl montanate; methyl melissylate fatty alcohols: myristyl acetate, cetyl acetate, stearyl acetate, arachidyl acetate, heneicosanyl acetate, behenyl acetate, lignoceryl acetate, cerotyl acetate, heptacosanyl acetate, montanyl acetate, melissyl acetate; and fatty hydrocarbons: nonadecene, eicosene, heneicosene, docosene, hexacosene, octacosene, 9-tricontene, pentatricontene with a purity of almost 99% were purchased from Sigma Chemical Co. (Balcatta, USA), Aldrich Chemical Company, Inc. (Milwaukee, USA), and E. Merck (Darmstadt, Germany). Acetic anhydride (purity >98%), pyridine, benzene and n-hexane (analytical grade) were purchased from E. Merck. Chloroform, methanol, ethanol (purity >98%) were obtained from Thermo Fisher Scientific, Inc. (Loughborough, UK). Acetone (HPLC grade), hydrochloric acid, and potassium hydroxide (analytical grade) were obtained from Fluka Chemical Corporation (St. Louis, USA). Millipore water purified in a Milli-Q system (EMD Millipore Corporation, Billerica, USA) was used, and the resistivity of the millipore water was 20 MΩ cm.

Separation of waxes from the oils

For the separation of waxes, crude seed oils to be analyzed were subjected to cool at 4°C for 24 h; the crystallized waxes were removed by centrifugation followed by filtration. Centrifugation was carried out at 3,000/minute revolution at 10°C for 3 min.

Purification of waxes

Waxes were purified by dissolving waxes in acetone/n-hexane (5:1, 6 ml) followed by heating the solution in a centrifuge tube up to its boiling temperature. The resultant solution was cooled at room temperature. By slow cooling at room temperature, stable β crystals of waxes were formed. The sample was then centrifuged for 3 min and the supenatant liquid was removed. Again, crystals were dissolved in 5 ml of hot acetone to crystallize at room temperature. The solution was centrifuged and the supenatant liquid was removed. Re-crystallization three times with 5 ml acetone ensured the complete removal of any residual triglyceride. Finally, the crystals were filtered through a Buchner funnel to obtain the pure waxes [13].

Separation of various fractions of waxes by thin-layer chromatography

The wax removed and purified as above was subjected to thin-layer chromatography (TLC) to separate it into wax esters and fatty hydrocarbons fraction. Separations were done on twenty 20-cm glass plates coated with a silica gel (Merck, Darmstadt, Germany) layer of 0.25-mm thickness. Waxes dissolved in chloroform were applied onto the plates using capillary tubes. The plates were developed using the solvent system, toluene/chloroform (7:3). Fractionation of these constituents was achieved, based on earlier reported procedures [12]. Spots were visualized by placing the plate in a chamber, saturated with iodine for identification of spots. The spots were identified with simultaneous running of authentic standards. The preparative TLC was carried out for the separation and elution of wax esters. The separated constituents were eluted with chloroform from adsorbent and dried under a stream of nitrogen.

Gas chromatography of wax esters

The separation of individual wax ester was carried out on a PerkinElmer Clarus gas chromatograph (Massachusetts, USA) equipped with a flame ionization detector. A DB-1 fused-silica capillary column (15 m × 0.32 mm, film thickness 0.25 μm; J&W Scientific, Folsom, USA) was used. The sample (1 μL) was injected at 75°C; the oven was then heated to 230°C at a rate of 25°C/min and from 230°C to 340°C at a rate of 10°C/min. The final temperature was held for 10 min. Hydrogen was used as a carrier gas at a constant flow rate of 1.8 mL/min. The injector and detector temperatures were 300°C and 350°C, respectively. Identification was based on comparison with authentic standards.

Saponification of wax esters

Commonly, for the determination of the constituents of wax esters, saponification is needed, but usually the waxes were very resistant to saponification. The saponification of waxes was carried by modified procedure of Morrison and Smith [17], dissolving the waxes (0.25 g) in benzene/methanol (1:1, 10 ml), followed by the addition of 95% ethanol (25 ml) and 60% aqueous potassium hydroxide (5 ml) and refluxed for 8 h [15, 17].

Acetylation and esterification

Acetylation of fatty alcohols was carried out by adding 1 ml of acetic anhydride and 1 ml of anhydrous pyridine to the saponified residue, and contents were well-mixed and kept overnight at room temperature. The precipitate formed was filtered and dried [17]. Finally, the product was subjected to esterification by IUPAC standard method 2.301 in which 100 mg of sample was dissolved in 20 ml of methanol, and 1 N solution of KOH was added to the sample which was then refluxed for 1 h. After that, 10 ml of hexane was added to separate the organic layer [16]. The final product was dissolved in chloroform for analysis by gas chromatography and mass spectrometry (GC-MS).

Gas chromatography and mass spectrometry

GC-MS instrumentation

An Agilent 6890 N gas chromatography instrument coupled with an Agilent MS-5975 inert XL mass selective detector and an Agilent auto sampler 7683-B injector (Agilent Technologies, Little Fall, NY, USA) was used. A capillary column HP-5MS (5% phenyl methylsiloxane) with dimension of 30 m, 0.25 mm i.d, 0.25 μm film thickness (Agilent Technologies, Palo Alto, CA, USA) was used.

GC-MS programming of fatty hydrocarbons analysis

Chromatographic conditions for hydrocarbons: the oven temperature was programmed at 70°C for 2 min, ramped to 150°C at 25°C/min, then to 200°C at 3°C/min, and then to 280°C at 8°C/min and held for 10 min. The injection port temperature was 300°C. The injection volume was 2 μL, with carrier gas helium at constant flow rate (1 ml/min). The MS was operated in electron ionization mode at 70 eV with a transfer line temperature of 280°C, ion source at 230°C, and quadrupole temperature at 150°C. Solvent delay was set to 4 min. Selected ion monitoring mode was used for the qualitative and quantitative determination of fatty hydrocarbons. Agilent Chemstation with Retention Time Locking software was used for instrumental control and chromatographic data processing.

GC-MS programming of fatty alcohol acetates and FAMEs

The GC-MS analysis was performed on the saponified and esterified component of wax esters; the oven temperature was programmed from 150°C to 200°C at 5°C/min and then at 325°C at ramp 3°C; hold at this temperature for 20 min. The split ratio was 1:10, and helium was used as a carrier gas with the flow rate of 0.8 ml/min, with the injector set at 300°C transfer line set at 325°C. MS conditions: mass range 50 to 550 m/z, electron multiplier 70 eV, relative. All the compounds were identified by NIST and Wiley GC-MS Libraries.

Calculations and statistical analyses

Peak identification of the fatty acids methyl esters, fatty alcohol acetate (FALs), and fatty hydrocarbons in the analyzed wax samples was carried out by comparing the retention time and mass spectra with the respective standards. Also, their relative amounts (%) calculated from the peak areas, taking as a reference the peak area of the most abundant compound for each wax, and the RSDs of the amounts present are shown. All quantitative data given in this work are the average of the two samples of each wax and were collected, and each sample was analyzed thrice. The data obtained were put in to Origin 7 program and reported as mean (n = 2 × 3).

Conclusions

The main objective of the present study was to explore valuable lipid components present in seed oil waxes sunflower, canola, and cottonseed through different chromatographic techniques. Quantitative determination of different seed oil waxes showed highest amount of wax present in SFW, CSW, then CW, respectively. Both even- and odd-numbered fatty hydrocarbons were present and ranged between C19 and C35. Wax esters comprised more than 70% of all seed oil waxes; among them, C44 wax ester was predominant. Even-numbered wax esters are major wax esters than odd-numbered wax chain. A total of 23 compounds were characterized through GC-MS from wax esters after saponification, acetylation, and esterification. Methyl lignocerate was the main fatty acid present in all seed oil waxes. The quantity of even-numbered fatty alcohols was more than that of fatty acids.

Authors’ information

STHS is a professor at the National Centre of Excellence in Analytical Chemistry, University of Sindh, Jamshoro, Pakistan. He holds a Ph.D. from the same institution. After his Ph.D., he started his carrier in edible oil industries and worked from 1997 to 2004 at responsible posts. He was the general manager in an edible oil industry when he left the industry and joined the National Centre of Excellence in Analytical Chemistry in 2004. During 2006, he completed his postdoctoral work in McGill University, Canada under the supervision of Dr. Frederik van de Voort. Who is a well-known scientist in the field of FT-IR spectroscopy. He presented his research work in many international conferences and published many papers in peer review international journals. RKS is a lecturer. She holds a Ph.D. from the National Centre of Excellence in Analytical Chemistry, University of Sindh, Jamshoro, Pakistan under the supervision of Dr. Syed Tufail Hussain Shah. She presented her research work in many conferences and also published papers in peer review international journals.

References

Aragón A, Cortés JM, Toledano RM, Vázquez A: Analysis of wax esters in edible oils by automated on-line coupling liquid chromatography–gas chromatography using the through oven transfer adsorption desorption (TOTAD) interface. J Chrom A 2011, 1218: 4960–4965. 10.1016/j.chroma.2010.12.042

Grob K, Lanfranchi M, Marian C: Evaluation of olive oils through the fatty alcohols, the sterols and their esters by coupled LC-GC. J Am Oil Chem Soc 1990, 67: 626–634. 10.1007/BF02540412

Moulton KJ: Turbidimetric measurement of wax in sunflower oil. J Am Oil Chem Soc 1988, 65: 367–368. 10.1007/BF02663078

Kolattukudy PE: Chemistry and biochemistry of natural waxes. Elsevier, Amsterdam; 1976.

Odlyha M: Investigation of the binding media of paintings by thermoanalytical and spectroscopic techniques. Thermochimi Acta 1995, 269: 705–727.

Hamilton RJ: Waxes: chemistry, molecular biology and functions. The Oily Press, Dundee; 1995.

Asperger A, Engewald W, Fabian G: Thermally assisted hydrolysis and methylation – a simple and rapid online derivatization method for the gas chromatographic analysis of natural waxes. J Anal Appl Pyrol 2001, 61: 91–109. 10.1016/S0165-2370(01)00116-4

Marinach C, Papillon MC, Pepe C: Identification of binding media in works of art by gas chromatography–mass spectrometry. J Cult Herit 2004, 5: 231–240. 10.1016/j.culher.2003.12.002

Regert M, Colinart S, Degrand L: Characterization of wax works of art by gas chromatographic procedures. J Chromatogr A 2005, 1091: 124–136. 10.1016/j.chroma.2005.07.039

Asperger A, Engewald W, Fabian G: Analytical characterization of natural waxes employing pyrolysis–gas chromatography–mass spectrometry. J Anal Appl Pyrol 1999, 103: 103–115.

Grob K, Giuffré AM, Leuzzi U, Mincione B: Recognition of adulterated oils by direct analysis of the minor components. Fat Sci Tech 1994, 98: 286–290.

Holloway PJ, Challen SB: Thin layer chromatography in the study of natural waxes and their constituents. J Chrom 1966, 25: 336–346.

Isbell TA, Carlson KD, Abbott TP, Phillips BS, Erhan SM, Kleiman R: Isolation and characterization of wax esters in meadowfoam oil. Ind Crops Prod 1996, 5: 239–243. 10.1016/0926-6690(96)89456-8

Sindhu Kanya TC, Jaganmohan Rao L, Shamanthaka Sastry MC: Characterization of wax esters, free fatty alcohols and free fatty acids of crude wax from sunflower seed oil refineries. Food Chem 2007, 101: 1552–1557. 10.1016/j.foodchem.2006.04.008

Rizwana KS, Sherazi STH: Spectroscopic and chromatographic evaluation of the wax ester fraction of Adenanthera pavonina oil. Ind Crops Prod 2012, 36: 294–298. 10.1016/j.indcrop.2011.10.012

IUPAC: Standards methods for the analysis of oils, fats and derivatives. Pergamon Press, Oxford, UK; 1979:96–98.

Morrison WR II, Smith LM: Preparation of fatty acids, methyl esters and dimethyl acetates from lipids with boron trifluoride–methanol. J Lip Res 1964, 5: 600–608.

Acknowledgment

This work has been sponsored by the National Center of Excellence in Analytical Chemistry University of Sindh Jamshoro for the financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interest

The authors declare that they have no competing interests.

Authors’ contributions

RKS and STHS analyzed the data and drafted the manuscript. All authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Soomro, R.K., Sherazi, S.T.H. Extraction and characterization of seed oil waxes by using chromatographic techniques. Int J Ind Chem 4, 9 (2013). https://doi.org/10.1186/2228-5547-4-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2228-5547-4-9