Abstract

Background

Inhibition effect of 1-((4-chlorophenyl)(2-hydroxynaphtalen-1-yl)(phenyl)methyl)urea (CPHU) and 1-((2-hidroxynaphtalen-1-yl)(4-methoxyphenyl)methyl)urea (HNMU) in 1 M HCl solution on mild steel was investigated using weight loss and potentiostatic polarization techniques.

Results

It is found that the studied compounds exhibit a good performance as inhibitors for mild steel corrosion in acid solutions. The inhibition efficiency increased with decreasing temperature and increasing concentration of the inhibitors. Potentiostatic polarization measurements indicate that these compounds act as mixed-type inhibitors. The values of activation energy and the thermodynamic parameters, such as adsorption equilibrium constant, adsorption free energy, adsorption heat, and adsorption entropy values, were calculated and discussed. The scanning electron microscopy analysis indicated the existence of an adsorbed film on the steel surface in the presence of the inhibitors. The results obtained from infrared spectra confirmed adsorption of the inhibitor on the metal surface after immersion in acidic solution containing CPHU.

Conclusions

The adsorption of the inhibitors on the surface obeys the Langmuir adsorption isotherm. The percentage of inhibition efficiency values obtained from polarization measurements show good agreement with those obtained from weigh loss experiments. The overall results revealed that the investigated compounds are efficient inhibitors of corrosion in mild steel in 1 M hydrochloric acid solution, and CPHU showed better performance.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Background

Corrosion inhibitors are widely used in the industry to prevent/reduce the corrosion rates of metallic materials in reducing acid media [1, 2]. Hydrochloric acid solutions are widely used for acid clearing, industry cleaning, acid descaling, oil-well acidizing, etc. Therefore, corrosion inhibitors for metals in hydrochloric acid have attracted more attention because of its wide application [3–8]. Compounds with nitrogen and oxygen function group as well as multiple bonds or aromatic rings are considered to be one of the effective chemicals for inhibiting the corrosion of metals [9–11].

Earlier reports [12] showed that inhibition efficiency of organic compounds containing heterocyclic nitrogen increases with the number of aromatic systems and the availability of electronegative atoms in the molecule. These compounds can absorb on the metal surface and block the active sites on the surface, thereby reducing the corrosion rate [13]. The adsorption of organic molecules at the metal/solution interface is of great interest in surface science and can markedly change the corrosion-resisting properties of metals.

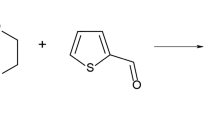

In continuation of the work on acid corrosion inhibitors [14, 15] and since two organic compounds containing nitrogen, oxygen, and aromatic rings (Figure 1), namely 1-((4-chlorophenyl)(2-hydroxynaphtalen-1-yl)(phenyl)methyl)urea (CPHU) and 1-((2-hidroxynaphtalen-1-yl)(4-methoxyphenyl)methyl)urea (HNMU), which have been studied earlier [16] to prevent the corrosion of mild steel in sulfuric acid medium, revealed reasonable inhibiting effects, due to the wide applications of corrosion inhibitors in hydrochloric acid, the usage of these compounds as corrosion inhibitors in 1 M hydrochloric acid solution was undertaken.

Weight loss and polarization methods were employed to evaluate the corrosion rate of mild steel and the inhibition efficiency of the inhibitors. The mild steel surface was also examined by scanning electron microscopy (SEM), and films on the surface in the presence of CPHU inhibitor were analyzed by infrared spectroscopy. Fourier transform infrared spectroscopy (FTIR) was used to identify whether there was adsorption and also to provide new bonding information of the adsorption process.

Methods

Weight loss measurements

Mild steel sheets of 0.5 cm × 0.5 cm × 0.5 cm were used for the weight loss technique. Before each experiment, the samples were abraded using emery papers (grades 200 to 2,500), washed with distilled water and then acetone, and finally dried at room temperature. The initial weight of each specimen was noted before immersion using an analytical balance (precision: ±0.1 mg). Then, the specimens were immersed in 100 mL of 1 M hydrochloric acid solutions without and with different concentrations of the inhibitors. After 24 h of immersion, the specimens were washed and reweighed. The experiments were done in triplicate, and the average value of the weight loss was considered. The corrosion rates of the mild steel were determined using Equation 1.

where ∆ m is the mass loss, s is the area of the specimen (versus cm2), and t is the immersion time (versus s) [17].

The inhibition efficiencies were calculated using Equation 2 [18].

where Wcorr and Winh are the corrosion rates of mild steel without and with inhibitors, respectively.

Potentiostatic polarization measurements

Potentiostatic polarization measurements were carried out in a three-electrode cell using BHP 2063 + electrochemical analysis system instrument (Behpajooh, Isfahan, Iran). A saturated calomel electrode was used as a reference electrode, and a Pt electrode was used as a counter electrode. The working electrode was prepared from a cylindrical mild steel such that the exposed area was 1 cm2. Before each polarization test, the open-circuit potential was stabled within 30 min. The cell was equipped so that the temperature during each experiment was kept constant and measurable. The polarization curves obtained in the potential range from −700 to −350 mV with a scan rate of 1 mV s−1. The inhibition efficiency for each concentration of inhibitors was calculated using Equation 3 [19].

where Icorr and Iinh are the corrosion current densities calculated from the extrapolation of Tafel slopes without and with inhibitors. Then, surface coverage was calculated by the equation below.

Fourier transform infrared spectroscopy and SEM

FTIR spectra were recorded in a TENSOR 27 Bruker spectrophotometer (Bruker, Ettlingen, Germany), which extended from 700 to 4,000 cm−1, using a KBr disk technique. The pure CPHU was mixed with the KBr and disk made; then, the mild steel specimen was prepared as described for the weight loss technique. After 24 h of immersion in 1 M hydrochloric acid in the presence of CPHU, the specimen was cleaned with distilled water and dried at room temperature. Then, the thin adsorbed film formed on the mild steel surface was rubbed with a small amount of KBr powder, and a KBr disk was prepared using this powder.

Scanning electron microscopy

The morphology of the mild steel surface after polarization test in acidic solutions containing optimum concentration (8 ppm) of inhibitors was examined by a Philips XL30 scanning electron microscope (Philips, Amsterdam, Netherlands).

Results and discussions

Weight loss measurements

The results of weight loss measurements are listed in Table 1. As it is seen, the percentage of inhibition efficiency (IE%) increases with increasing inhibitor concentration. In most cases, the inhibition efficiencies obtained from weight loss measurements are lower than those from electrochemical experiments; this phenomenon is attributed to the fact that weight loss experiments give average corrosion rates, whereas the electrochemical experiments give instantaneous corrosion rates [20]. The highest inhibition efficiency is related to the CPHU inhibitor, which reaches a maximum value of 80% at 8 ppm concentration.

Potentiostatic polarization measurements

The effect of increasing the concentration of the inhibitors on the polarization curves are shown in Figure 2. The electrochemical parameters such as corrosion current density (Icorr), corrosion potential (Ecorr), cathodic and anodic Tafel slopes (βc, βa), and inhibition efficiency (IE%) are given in Table 1. Increasing the concentration of the inhibitors decreases the corrosion current densities but does not affect the corrosion potentials noticeably. Both anodic and cathodic Tafel slopes increase slightly, and both the anodic and cathodic current densities decrease, indicating that the inhibitors suppressed both the anodic and cathodic reactions. The overall results suggest that both investigated inhibitors act as mixed-type inhibitors [21, 22]. It is observed that the inhibition efficiency increases with increasing concentration of the inhibitors. The highest inhibition efficiency reaches a maximum value of 82% at an optimum concentration (8 ppm) of the CPHU inhibitor.

Effect of temperature

The effect of temperature on the polarization curves and corrosion parameters (Ecorr, Icorr, IE, and θ) in the presence of optimum concentration of the inhibitors was studied. The polarization curves are illustrated in Figure 3, and the corrosion parameter values at different temperatures are listed in Table 2. The results obtained from the polarization curves show increase in current density and decrease in IE% with increasing temperature. The corrosion potential almost remained unchanged with increasing temperature. The dependence of corrosion rate on temperature can be expressed by the Arrhenius equation [23]:

where Icorr is the corrosion current density, A is the frequency factor, Ea is the activation energy of the metal dissolution reaction, R is the gas constant, and T is the absolute temperature. The Ea values can be determined from the slopes of Arrhenius plots (ln Icorr versus 1/T (Figure 4)). Calculated activation energies for the corrosion process in the absence and presence of inhibitors are given in Table 3.

Adsorption isotherm

In general, inhibitors can function either by physical (electrostatic) or chemical adsorption on the metal surface [24]. Basic information on the interaction between the inhibitors and the mild steel surface can be provided by the adsorption isotherm [25, 26]. Totally, adsorption isotherms provide information about the interaction among the adsorbed molecules themselves and also their interactions with the electrode surface [27].

In order to obtain a suitable adsorption isotherm, Langmuir, Temkin, and Freundluich adsorption isotherms were tested. Langmuir adsorption isotherm, which is given by Equation 6 [28], was found to be more suitable.

where C is the inhibitor concentration, K is the adsorption equilibrium constant, and θ is the surface coverage which is given by Equation 4.

Straight lines were obtained when Cinh/θ were plotted against Cinh (Figure 5). The linear relationships suggest that the adsorption of inhibitors obey the Langmuir adsorption isotherm [27]. The straight line has an intercept of 1/K.

Thermodynamic parameters

The relation of constant K with the standard free energy can be determined by Equation 7.

where 55.5 is the molar concentration of water and ∆ Gads is the adsorption free energy [29]. The negative values of ∆ Gads (Table 3) indicate that the adsorption of the inhibitors on the metal surface is spontaneous. Generally, values of ∆ Gads around −20 kJ mol−1 or lower are consistent with the electrostatic interaction between charged molecules and the charged metal surface (physisorption); those around −40 kJ mol−1 or higher involve charge sharing or transfer from organic molecules to the metal surface to form a coordinate type of metal bond (chemisorption) [30]. The obtained values for ∆ Gads are less than −40 kJ mol−1; such values are commonly interpreted with the presence of physical adsorption [30, 31], but some researchers have reported [16, 27] that for these values, the adsorption of inhibitor molecules is not merely physisorption or chemisorption but obeying a comprehensive adsorption (physical and chemical adsorption).

The Langmuir adsorption isotherm may be expressed by Equation 8:

where T is the temperature, A is the independent constant, C is the inhibitor concentration, R is the gas constant, ΔHads is the heat of adsorption, and θ is the surface coverage by the inhibitor molecules. The plots of log (θ/(1–θ)) versus 1/T at the optimum concentration of inhibitors are shown in Figure 6. The slope of the linear part of the curves is equal to ΔHads/2.303R, from which the average ΔHads was calculated, and their values are given in Table 3. The negative values of ΔHads reflect the exothermic behavior of the inhibitors on the mild steel surface.

Adsorption entropy (ΔSads) can be calculated from the equation below [16]:

The negative values of the calculated adsorption entropy (Table 3) mean that the adsorption process is accompanied by a decrease in entropy.

Scanning electron microscopy

Representative SEM obtained from the mild steel surface after polarization test in hydrochloric acid in the absence and presence of 8 ppm of inhibitors are shown in Figure 7. In the absence of inhibitors in hydrochloric acid, the mild steel surface was highly corroded with areas of pitting corrosion. In the presence of HNMU compound, it can be seen that the rate of corrosion is suppressed, and there is little acid corrosion product on the steel surface. Figure 7c clearly shows that the presence of the CPHU inhibitor leads to the formation of a stiffly stuck surface cover with irregular cracks (probably due to the drying up of the hydrated compound); such results have been reported previously [16, 32]. In order to evaluate this protective layer, FTIR study was done.

Fourier transform infrared spectroscopy

The FTIR spectrum of pure CPHU is shown in Figure 8a. The sharp peaks at 1,640 cm−1 is attributed to C=O stretching vibrations, and the peak at 3,000 cm−1 is related to C-H stretching vibrations in aromatic rings [33]. Double sharp peak at 3,300 to 3,500 cm−1 are assigned to N-H stretching vibrations. The broad peak under the other peaks at 2,900 to 3,500 cm−1 is related to O-H stretching vibrations. The FTIR spectrum of the adsorbed protective layer formed on the surface after immersion in 1.0 M hydrochloric acid containing 8 ppm CPHU is shown in Figure 8b. The band around 1,650 cm−1 is attributed to C=O stretching vibrations. Appearance of this peak in the adsorbed layer indicates that oxygen atom and carbonyl group did not contribute to the adsorption process. The weak peaks around 3,000 cm−1 are assigned to C-H stretching vibrations in aromatic rings. The broad band at 3,422 cm−1 is attributed to O-H stretching, which indicates that the protective film contains H2O [34]. N-H and O-H stretching vibrations disappeared in Figure 8b, revealing that nitrogen and oxygen atoms act as active centers in the adsorption. This means that these atoms contribute to the formation of complex with steel surface atoms [34]. An overall investigation of the results suggests that CPHU is adsorbed on the mild steel surface.

Mechanism of corrosion inhibition

A clarification of the mechanism of inhibition requires full knowledge of the interaction between the protective compound and the metal surface. Corrosion inhibition of mild steel in hydrochloric acid solution by inhibitors can be explained on the basis of molecular adsorption. The adsorption process is influenced by the chemical structures of organic compounds, the distribution of charge in molecule, the nature and surface charge of metal, and the type of aggressive media [35].

If one considers the structures of the investigated compounds (Figure 1), many potential sources of inhibitor-metal interaction can be identified. It is apparent from the molecular structure that the compounds are able to absorb on the metal surface through the lone pair of electrons of N and O and the π electrons of the benzene rings or as a protonated species. The cationic species may adsorb on the cathodic sites of the mild steel and reduce the evolution of hydrogen [36]. The FTIR results show that nitrogen atoms act as adsorption centers. Therefore, the lower inhibition efficiency of HNMU in comparison to CPHU can be related to the higher electronegativity of oxygen atom (methoxy group) than chlorine atom that attracts electrons from the vicinity of adsorption centers.

Experimental

Fresh solutions of 1 M hydrochloric acid were prepared for each experiment using analytical grade of hydrochloric acid (37%) and distilled water. The concentration range of the inhibitors was 2 to 8 ppm. The specimen was a rectangular coupon cut from a mild steel rod, with the composition (in wt.%) C 0.17, Si 0.5, Mn 1.4, S 0.045, and Fe 97.885, that was used as working electrode.

Conclusion

After the experiment, the following points were obtained:

-

1.

The results revealed that the investigated compounds are efficient inhibitors of corrosion of mild steel in 1 M hydrochloric acid solution, and CPHU showed better performance.

-

2.

These inhibitors showed good inhibition efficiencies in low concentrations, and the IE% increased by increasing the inhibitor concentration.

-

3.

Both of the compounds act as mixed-type inhibitors.

-

4.

The adsorption of both inhibitors on the mild steel surface obey Langmuir adsorption isotherm.

-

5.

The negative values of ∆ G ads reveal the spontaneous adsorption of inhibitor on the metal surface, and the negative values of ∆ H ads and ∆ S ads show that the adsorption process is exothermic and accompanied by a decrease in entropy.

-

6.

The SEM and FTIR results clearly indicate the presence of a protective surface layer over the mild steel surface.

References

Hosseini SMA, Salari M, Ghasemi M: Mater Corros. 2009, 60: 963. 10.1002/maco.200905214

Bilgic S, Sahin M: Mater Chem Phys. 2001, 7: 290.

Lalitha A, Ramesh S, Rajeswari S: Electrochim Acta. 2005, 51: 47. 10.1016/j.electacta.2005.04.003

Sherif EM, Park SM: Electrochim Acta. 2006, 51: 4665. 10.1016/j.electacta.2006.01.007

Quraishi MA, Sardar R: Corrosion. 2002, 58: 103. 10.5006/1.3277308

Karakus M, Sahin M, Bilgic S: Mater Chem Phys. 2005, 92: 565. 10.1016/j.matchemphys.2005.02.010

Ashassi-Sorkhabi H, Ghalebsaz-Jeddi N, Hashemzadeh F, Jahani H: Electrochim Acta. 2006, 51: 3848. 10.1016/j.electacta.2005.11.002

Abdel-Rehim SS, Khaled KF, Abd-Elshafi NS: Electrochim Acta. 2006, 51: 3269. 10.1016/j.electacta.2005.09.018

Ali SA, Saeed MT, Rahman SU: Corros Sci. 2003, 45: 253. 10.1016/S0010-938X(02)00099-9

Yildirim A, Cetin M: Corros Sci. 2008, 50: 155. 10.1016/j.corsci.2007.06.015

Bartos M, Hackerman N: J Electrochem Soc. 1992, 139: 3428. 10.1149/1.2069095

Bentiss F, Traisnel M, Gengembre L, Lagrenee M: Appl Surf Sci. 1999, 152: 237. 10.1016/S0169-4332(99)00322-0

Qu Q, Hao Z, Li L, Bai W, Liu Y, Ding Z: Corros Sci. 2009, 51: 569. 10.1016/j.corsci.2008.12.010

Hosseini SMA, Bahrami MJ, Dorehgiraee A: Mater Corros. 2011, 62: No. 9999.

Hosseini SMA, Azimi A: Corros Sci. 2009, 51: 728. 10.1016/j.corsci.2008.11.019

Hosseini SMA, Bahrami MJ, Pilvar P: Corros Sci. 2010, 52: 2793. 10.1016/j.corsci.2010.04.024

Abboud Y, Abourriche A, Saffaj T, Berrada M, Charrouf M, Bennamara A, Al Himidi N, Hannache H: Mater Chem Phys. 2007, 105: 1. 10.1016/j.matchemphys.2007.03.037

Quraishi MA, Shukla SK: Mater Chem Phys. 2009, 113: 685. 10.1016/j.matchemphys.2008.08.028

Qu Q, Jiang S, Li L, Bai W, Zhou J: Corros Sci. 2008, 50: 35. 10.1016/j.corsci.2007.06.008

Li W, He Q, Pei C, Hou B: Electrochim Acta. 2007, 52: 6386. 10.1016/j.electacta.2007.04.077

Scendo M: Corros Sci. 2007, 49: 373. 10.1016/j.corsci.2006.06.022

Behpour M, Ghoreishi SM, Salavati-Niasari M, Ebrahimi B: Mater Chem Phys. 2008, 107: 153. 10.1016/j.matchemphys.2007.06.068

Hosseini SMA, Azimi A: Mater Corros. 2008, 59: 41. 10.1002/maco.200704101

Ismail KM: Electrochim Acta. 2007, 52: 7811. 10.1016/j.electacta.2007.02.053

Bouklah M, Hammouti B, Lagrenee M, Bentiss F: Corros Sci. 2006, 48: 2831. 10.1016/j.corsci.2005.08.019

Khaled KF, Al-Qahtani MM: Mater Chem Phys. 2009, 113: 150. 10.1016/j.matchemphys.2008.07.060

Noor EA, Al-Moubaraki AH: Mater Chem Phys. 2008, 110: 145. 10.1016/j.matchemphys.2008.01.028

Abdallah M: Corros Sci. 2002, 44: 717. 10.1016/S0010-938X(01)00100-7

Fuchs-Godec R: Electrochim Acta. 2009, 54: 2171. 10.1016/j.electacta.2008.10.014

Hosseini SMA, Salari M, Ghasemi M, Abaszadeh M: Z Phys Chem. 2009, 223: 769. 10.1524/zpch.2009.5441

Solmaz R, Kardas G, Culha M, Yazici B, Erbil M: Electrochim Acta. 2008, 53: 5941–5952. 10.1016/j.electacta.2008.03.055

Sahin M, Bilgic S, Yilmaz H: Appl Surf Sci. 2002, 195: 1. 10.1016/S0169-4332(01)00783-8

Qu Q, Jiang S, Bai W, Li L: Electrochim Acta. 2007, 52: 6811. 10.1016/j.electacta.2007.04.114

Li X, Deng S, Fu H, Mu G: Corros Sci. 2009, 51: 620. 10.1016/j.corsci.2008.12.021

Maayta AK, Al-Rawashdeh NAF: Corros Sci. 2004, 46: 1129. 10.1016/j.corsci.2003.09.009

Oguzie EE, Li Y, Wang FH: J Colloid Interf Sci. 2007, 310: 90. 10.1016/j.jcis.2007.01.038

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

MJB carried out the weight loss and polarization experiments, participated in the sequence alignment, and drafted the manuscript. SMAH carried out the scanning electron microscopy and Fourier transform infrared spectroscopy, studied the mechanism of corrosion inhibition, and edited the manuscript. All authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Bahrami, M.J., Hosseini, S.M.A. Electrochemical and thermodynamic investigation of the corrosion behavior of mild steel in 1 M hydrochloric acid solution containing organic compounds. Int J Ind Chem 3, 30 (2012). https://doi.org/10.1186/2228-5547-3-30

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2228-5547-3-30