Abstract

The hydrothermal synthesis and optical properties of undoped and Sb3+-doped lithium metasilicate and lithium disilicate nanomaterials were investigated. The microstructures and morphologies of the synthesized Li2−2xSb2xSiO3 and Li2−2xSb2xSi2O5 nanoparticles were studied with powder X-ray diffraction and scanning electron microscopy techniques, respectively. The synthesized undoped and doped lithium metasilicate and lithium disilicate nanomaterials, respectively, are isostructural with the standard bulk Li2SiO3 (space group Cmc21) and Li2Si2O5 (space group Ccc2) materials. The electronic absorption and photoluminescence spectra of the synthesized materials are studied. The measured optical properties show dependence on the dopant amounts in the structure.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Background

Lithium ceramics are of research interest because of their technological applications. Among these ceramics, lithium silicates have been investigated as breeder materials for nuclear fusion reactors and as carbon dioxide absorbents in addition to other more well-known applications such as in thermal expansion of glass ceramics used in ceramic hobs[1–6]. Since the tetrahedral silicate ion (SiO42−) provides good mechanical resistance and stability, lithium metasilicate, and lithium disilicate are used as pyroelectric materials in optical waveguide devices[7–12].

Previously, some research groups have reported the synthesis of lithium silicate doped with La3+, Sm3+, Gd3+, Ho3+, Dy3+[13–16], Nd3+[17], Eu3+, and Tb3+[18] ions. Also, Cr4+-doped[19], Al3+-doped[20], and Na+-doped[21] lithium silicates have been synthesized. Moreover, Rodriguez et al have reported the synthesis of Cr3+-and Tm3+-doped alkaline silicate glasses[22]. On the other hand, Cu2+-doped[23] and V5+-doped[24] lithium disilicate glasses have been reported previously. However, to our best knowledge, no work has been devoted to antimony-doped lithium silicates. Catalytic activity[25], photo-induced superhydrophilicity[26], and optoelectronic properties[27] are observed in Sb3+-doped materials. Sb3+-doped semiconductors exhibit increased electrical conductivity compared to the undoped materials[28, 29]. The doping of Sb3+ also causes a p-type connection and pins the Fermi level in metal-semiconductor interface[30, 31].

In this context, we sought to reexamine the chemistry of lithium silicates. Herein, we report the hydrothermal synthesis of the Sb3+-doped lithium metasilicate (Li2−2xSb2xSiO3) and lithium disilicate (Li2−2xSb2xSi2O5) nanoparticles. The effect of the dopant concentration on the morphology of the synthesized materials is investigated. Moreover, the optical properties of the synthesized Li2−2xSb2xSiO3 and Li2−2xSb2xSi2O5 nanomaterials are studied.

Methods

The phase identifications were performed on a powder X-ray diffractometer Siemens D5000 (Siemens AG, Munich, Germany) using Cu-Kα radiation. The morphology of the obtained materials was examined by a Philips XL30 scanning electron microscope (Royal Philips Electronics, Amsterdam, The Netherlands). Absorption and photoluminescence spectra were recorded on a Analytik Jena Specord 40 (Analytik Jena AG Analytical Instrumentation, Jena, Germany) and a Perkin Elmer LF-5 spectrometer (PerkinElmer Inc., Waltham, MA, USA), respectively.

All the reagents used in the experiments were of analytical grade and used as received without further purification. The Li2−2xSb2xSiO3 and Li2−2xSb2xSi2O5 nanomaterials are synthesized in a one-step hydrothermal process.

Synthesis of lithium metasilicate

LiNO3 (2 mmol) was added to a solution of silicic acid (4 mmol) in 30 mL of hot 0.01 M aqueous solution of NaOH while stirring. The resultant solution was stirred for further 15 min and then diluted to 60 mL. The obtained mixture was transferred to a 100-mL Teflon-lined stainless steel autoclave and heated for 48, 72, or 96 h at 180°C. The resulting nanomaterials of Li2SiO3 were filtered and dried at 110°C.

Synthesis of lithium disilicate

The preparation of Li2Si2O5 was similar to that of Li2SiO3, except that LiNO3 (2 mmol) and silicic acid (6 mmol) were used. The obtained mixture was transferred to a 100-mL Teflon-lined stainless steel autoclave and heated for 48, 72, 96, or 120 h at 180°C. The resulting nanomaterials of compound Li2Si2O5 were filtered and dried at 110°C.

Synthesis of Sb3+-doped lithium metasilicate (x = 0.01, 0.0125, and 0.015)

Appropriate molar amounts of LiNO3 (7.9, 5.87, or 5.90 mmol), SiO2.H2O (15.88, 11.82, or 11.91 mmol, respectively), and Sb2O3 (0.0387, 0.0398, or 0.0449 mmol, respectively) were dissolved in 60 mL of hot NaOH solution (0.53, 0.40, or 0.40 M, respectively) under magnetic stirring at 80°C. The resultant solution was transferred into a 100-mL Teflon-lined stainless steel autoclave. The autoclave was sealed and maintained at 180°C for 48 h then allowed to cool naturally to room temperature, and the resulting white precipitate was recovered.

Synthesis of Sb3+-doped lithium disilicate (x = 0.005, 0.0075, and 0.01)

Appropriate molar amounts of LiNO3 (13.9, 9.9, or 7.92 mmol), SiO2.H2O (41.8, 29.81, or 23.92 mmol, respectively), and Sb2O3 (0.035, 0.0377, or 0.0549 mmol, respectively) were dissolved in 60 mL of hot NaOH solution (1.40, 0.99, or 0.80 M, respectively) under magnetic stirring at 80°C. The resultant solution was transferred into a 100-mL Teflon-lined stainless steel autoclave. The autoclave was sealed and maintained at 180°C for 48 h then allowed to cool naturally to room temperature, and the resulting white precipitate was recovered.

Results and discussion

Powder X-ray diffraction analysis

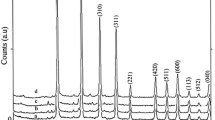

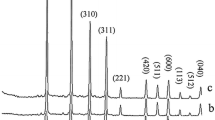

The crystal phases of the synthesized samples were examined by powder X-ray diffraction technique. Figures1 and2 show the powder X-ray diffraction (PXRD) patterns of the Sb3+-doped lithium metasilicate and lithium disilicate, respectively. Also, the measured PXRD data for hydrothermally synthesized undoped lithium metasilicate and lithium disilicate nanoparticles are summarized in Tables1 and2 respectively. The measured powder XRD data are in good agreement with those of standard pure lithium metasilicate (JCPDS 29-0829) and lithium disilicate (JCPDS 15-0637), and the obtained stable phases are isostructural with Li2SiO3 (space group Cmc21)[32–41] and Li2Si2O5 (space group Ccc2)[42–44]. Moreover, the intense sharp diffraction patterns suggest that the as-synthesized products are well crystallized. The doping limitations are 0-0.75 and 0-1.25 mole% of Sb3+ for lithium metasilicate and lithium disilicate, respectively. However, for excess mole% concentration of the dopant agent in the reaction mixture, the impurity peaks were observed in the XRD patterns. The diffraction lines at 2θ ≈ 13°, 26° and 49° are assigned by their peak positions to the excess Sb2O3[35]. As shown in Figures1 and2, the formation of the other phases of lithium silicates and raw materials was already detected for higher mole percentage concentration of the dopant agent in the reaction mixture[41, 42].

Compared to those of the nanoparticles of pure lithium silicates, the diffraction lines in the powder XRD patterns of the nanoparticles of Sb3+-doped lithium silicates shift to lower 2θ values (Δ 2θ = 26.99 (pure) – 26.81 (doped) = 0.15° and Δd = 3.322 Å (doped) − 3.304 Å (pure) = 0.018 Å for Sb3+-doped lithium metasilicate; and Δ2θ = 24.78 (pure) − 24.68 (doped) = 0.1°, Δd = 3.603 Å (doped) 3.589 Å (pure) = 0.014 Å for Sb3+-doped lithium disilicate are calculated via Bragg’s law (n λ = 2dhkl sin θ)). Since the ionic radius of the Sb3+ (0.76 Å[45]) is closer to the ionic radius of Li+ (0.59 Å[45]) rather than the Si4+ (0.26 Å[45]), in the Sb3+-doped lithium metasilicate and lithium disilicate, it may be expected that the dopant ion will replace with Li+ ions. The larger radius of the dopant ion, as compared to the Li+, may cause an expansion of the lattice parameter in the Sb3+-doped lithium silicate nanomaterials. Since both ionic radii and charges are not the same for the dopant and Li+ ions, it is also possible that the dopant ion takes an interstitial position in lattice rather than replaces any Li+ ions, where additional patterns will be observed in XRD pattern[26]. However, here, the doped samples show similar powder XRD patterns without any residual or impurity phase formation. The powder XRD patterns of the doped samples suggest the fact that the dopant ions are indeed going to lattice positions rather than to interstitial positions. Moreover, when replacing Li+ ions, the dopant ions are bound to create some oxygen-related defect centers or Li+ vacancies for charge compensation. Therefore, it is believed that the dopant ions will be in a structurally disordered environment.

Morphology analysis

The scanning electron microscopy (SEM) images of the synthesized Li2SiO3 nanomaterials are given in Figure3. After 48 h, nonuniform sheet like nanoparticles of Li2SiO3 are obtained (Figure3a). The thickness, widths, and lengths of the resultant sheets are approximately 100 nm, 600 nm, and 2 μm respectively. With increasing the reaction time to 72 h, the morphology of the obtained materials has been changed to the very compact sheets with heterogeneous morphology (Figure3b). This is while, with the reaction time of 96 h, uniform flower like nanoparticles are obtained (Figure3c).

Figure4 represents the SEM images of the synthesized Li2Si2O5 nanomaterials. After 48 h, the morphology of the obtained material is sponge-like, consisting of sheet-like and flower-like nanoparticles (Figure4a). With the increasing the reaction time to 72, 96, and 120 h, the morphology of the obtained materials has been changed to the rectangular sheets and high homogeny in the size is achieved. Using field emission scanning electron microscopy, the microstructure analysis of as-synthesized samples was investigated.

SEM images of the synthesized Sb3+-doped lithium metasilicates (Li1.98Sb0.02SiO3) and (Li1.975Sb0.025SiO3) are given in Figures5 and6 respectively. In Figure5a, with low magnification, it is revealed that the sample is composed of two dimensional continuous networks of nanosheet structures. With high magnification in Figure5b,c, it is clear that the length of the sheets are about 1 μm and the thickness of the sheets is about 100 nm. With high magnification, as shown in Figures6b,c, there are two types of flower-like structures (showing nonuniformity of the morphology). Low magnification in Figure6a,b,c shows that the size of each flower is about 3-5 μm and the thickness of the sheets is about 100 nm.

Figures7 and8 show the SEM images of the synthesized Sb3+-doped lithium disilicate (Li1.99Sb0.01Si2O5) and (Li1.985Sb0.015Si2O5) respectively. Low magnification in Figure7a shows that the sample is composed of a large quantity of individual plates. High magnification images in Figure7b,c shows that the plates cut each other. The length of each plate is about 300-350 nm, and the thickness is 80-100 nm. The plates have regular multigonal shapes that are arisen from a substrate.

Figure8a shows that with increasing the concentration of Sb3+ from 0.5 to 0.75 mole%, the morphology of the samples change from nanoplates to nanoflower structures. The synthesized products are composed of a large quantity of individual nanobelts that form highly uniform 3-D flower-like structures. Each nanobelt has a width of about 500 nm and a length of about 2 μm. It seems that numerous nanodot particles cover all over the surface of each nanobelt.

Optical properties

The optical properties of the as-synthesized materials were measured at room temperature. Figure9 shows photoluminescence spectra of the synthesized Sb3+-doped lithium metasilicate nanoflowers (λex = 232 nm). It is well known that the emission peak positions remain almost unchanged under different excitation wavelengths, showing that it is an intrinsic property of the compound[44]. Under excitation with light at 232 nm, as shown in Figure9, the main emission peaks are located at 310 and 362 nm with a shoulder at 425 nm. The peak that appeared at 310 nm is assigned to the band edge emission. Also, the broad band with maxima at 362 nm is assigned to the trap state emission of the nanocrystals. With increasing dopant concentration, the intensity of the shoulder at 425 nm also increases. Considering that the energy gap of bulk lithium silicates is above 3.3 eV, the purple-blue photoluminescence at 425 nm (approximately 2.92 eV) is probably due to a triplet to ground state transition of a neutral oxygen vacancy defect, as suggested by ab initio molecular orbital calculations for many other well-studied metal oxides[46, 47]. The defects create some dangling bands. Therefore, the energy levels between conduction and valence bands (trap states) would contribute in the band structure, which result in a broad band at visible range.

The photoluminescence spectra of the synthesized Sb3+-doped lithium disilicate nanoflowers (λex = 227 nm) is given in Figure10. Compared to the described antimony-doped lithium metasilicate nanomaterials, the band edge emission of the synthesized Sb3+-doped lithium disilicate nanomaterials occurred at 310 nm upon excitation at 227 nm. Also, the trap state emission of the compound is observed as a weak band at 360 nm under this excitation wavelength. Moreover, compared to the synthesized antimony-doped lithium metasilicate nanomaterials, the emission band which is attributed to the oxygen-related defects in Sb3+-doped lithium disilicate nanoflowers (appeared as a shoulder at 425 nm) shows a decreasing intensity with the increasing dopant concentration. Electronic absorption spectra of the as-synthesized Sb3+-doped Li2SiO3 and Li2Si2O5 nanomaterials have been given in Figure11a,b. With increasing the dopant concentration in the structure of both of the synthesized Sb3+-doped lithium silicates, the band gap slightly shifts to lower energies. A band gap of 4.17 eV for Li1.98Sb0.02SiO3 and 4.13 eV for Li1.975Sb0.025SiO3 is calculated from the absorption spectroscopy. Also, a band gap of 4.49 eV and 4.46 eV, respectively, was measured for Li1.99Sb0.01Si2O5 and Li1.985Sb0.015Si2O5 from the electronic absorption spectroscopy.

Conclusions

In summary, nanolayers and nanoflowers of Sb3+-doped lithium metasilicate and lithium disilicate were synthesized successfully by employing a simple hydrothermal method. We found that the dopant concentration affects the morphology and crystal phase of the final product. As shown by SEM images, with increasing the dopant concentration, layered and flake-like nanocrystals change to flower-like nanomaterials. We found that compared to those of the nanoparticles of pure lithium silicates, the diffraction lines in the powder XRD patterns of the nanoparticles of Sb3+-doped lithium silicates shift to lower 2θ values. The shift in the diffraction lines might be attributed to the larger radius of the dopant ion, compared to the ionic radius of the Li+, which may cause an expansion of the lattice parameters in the Sb3+-doped lithium silicate nanomaterials. The synthesized nanomaterials exhibited emerging photoluminescence and electronic absorption optical properties in the UV-visible region, which show dependence on the dopant amounts in the structure. These materials are expected to have a potential application in light-emitting devices and as catalysts.

Authors’ information

SK got his B.S. degree from the University of Birjand in the field of applied chemistry in 2007. He got his M. Sc degree from the University of Tabriz in the field of inorganic chemistry in August 2010. AA got his B.S. and M. Sc. degree from the University of Tabriz, Iran in the field of chemistry in 1972 and 1974, respectively. She got her Ph. D degree from the University of Paris, France in the field of inorganic chemistry in 1978. He is now a professor in inorganic chemistry at University of Tabriz, Iran. MD got her B.S. and M. Sc. degree from the University of Tabriz, Iran in the field of chemistry and inorganic chemistry in 2004 and 2006, respectively. She got her Ph. D degree from the University of Tabriz, Iran in the field of inorganic-solid state chemistry in 2010. She is now post doctorate student and associate professor in the research group of Prof. Dr. Rostami at School of Engineering-Emerging Technologies, University of Tabriz, Iran. AB got his B.S. and M. Sc. degree from the University of Urmia, Iran and from the University of Tabriz in the field of chemistry and inorganic chemistry in 2004 and 2006, respectively. She got her Ph. D degree from University of Tabriz, Iran in the field of inorganic chemistry in 2010.

References

Kudo H, Okuno K, Ohira S: Tritium release behavior of ceramic breeder candidates for fusion reactors. J. Nucl. Mater. 1988, 155: 524.

Wen G, Zheng X, Song L: Effects of P 2 O 5 and sintering temperature on microstructure and mechanical properties of lithium disilicate glass-ceramics. Acta. Mater. 2007, 55: 3583. 10.1016/j.actamat.2007.02.009

Yamaguchi T, Nair BN, Nakagawa K: Membranes for high temperature CO 2 separation: part II - lithium silicate based membranes. J. Membr. Sci. 2007, 294: 16. 10.1016/j.memsci.2007.01.028

Essaki K, Kato M, Nakagawa K: CO 2 removal at high temperature using packed bed of lithium silicate pellets. J. Ceram. Soc. Japan 2006, 114: 739. 10.2109/jcersj.114.739

Pfeiffer H, Bosch P, Bulbulian S: Synthesis of lithium silicates. J. Nucl. Mater. 1998, 257: 309. 10.1016/S0022-3115(98)00449-8

Mosqueda HA, Vazquez C, Bosch P, Pfeiffer H: Chemical sorption of carbon dioxide (CO 2 ) on lithium oxide (Li 2 O). Chem. Mater. 2006, 18: 2307. 10.1021/cm060122b

Ilyushin GD: Phase relations in the LiOH-TiO 2 -SiO 2 -H 2 O system at 500°C and 0.1 GPa. J. Inorg. Mater. 2002, 9: 927.

Kumar GB, Buddhudu S: Synthesis and emission analysis of RE3+ (Eu3+ or Dy3+):Li 2 TiO 3 ceramics. Ceram. Int. 2009, 35: 521. 10.1016/j.ceramint.2007.09.107

Romanowski WR, Sokolska I, Dsik GD, Golab S: Investigation of LiXO 3 (X = Nb, Ta) crystals doped with luminescent ions: recent results. J. Alloys Compd. 2000, 300301: 152.

Hreniak D, Speghini A, Bettinelli M, Strek W: Spectroscopic investigations of nanostructured LiNbO3 doped with Eu3+. J. Lumin. 2006, 119–120: 219.

Yang X, Ning G, Li X, Lin Y: Synthesis and luminescence properties of a novel Eu3+-doped γ-LiAlO 2 phosphor. Mater. Lett. 2007, 61: 4694. 10.1016/j.matlet.2007.03.011

Ignatovych M, Holovey V, Vidczy T, Baranyai P: Spectral study on manganese- and silver-doped lithium tetraborate phosphors. Radiat. Phys. Chem. 2007, 76: 1527. 10.1016/j.radphyschem.2007.02.066

Ganesan M: Li 1−x Sm 1+x SiO 4 as solid electrolyte for high temperature solid-state lithium batteries. Ionics 2007, 13: 379. 10.1007/s11581-007-0110-2

Ganesan M, Dhananjeyan MVT, Sarangapani KB, Renganathan NG: Lithium ion conduction in sol-gel derived lithium samarium silicate solid electrolyte. J. Alloy Comp. 2008, 450: 452. 10.1016/j.jallcom.2006.10.126

Ganesan M: Synthesis and characterization of lithium holmium silicate solid electrolyte for high temperature lithium batteries. J Appl. Electrochem. 2009, 39: 947. 10.1007/s10800-008-9754-5

Ganesan M: A new promising high temperature lithium battery solid electrolyte. Electrochem. Commun. 2007, 9: 1980. 10.1016/j.elecom.2007.05.012

Takeda N, Itagaki Y, Sadaoka Y: Ionic conductivity of Li x La 10−x (SiO 4 ) 6 O 3−x sinters. J. Cer. Soc. Japan 2008, 116: 803. 10.2109/jcersj2.116.803

Naik YP, Mohapatra M, Dahale ND, Seshagiri TK, Natarajan V, Godbole SV: Synthesis and luminescence investigation of RE3+ (Eu3+, Tb3+ and Ce3+)-doped lithium silicate (Li 2 SiO 3 ). J. Lumin. 2009, 129: 1225. 10.1016/j.jlumin.2009.06.001

Deng D, Xu S, Ju H, Zhao S, Wang H, Li C: Broadband near-infrared emission from Cr4 + - doped transparent glass-ceramics based on lithium silicate. Chem. Phys. Lett 2010, 486: 126. 10.1016/j.cplett.2009.12.063

Nakazawa T, Yokoyama K, Noda K: Ab initio MO study on hydrogen release from surface of lithium silicate. J. Nucl. Mater. 1998, 258–263: 571.

Victoria L, Trejo M, Fregoso-Israel E, Pfeiffer H: Textural, structural, and CO 2 chemisorption effects produced on the lithium orthosilicate by its doping with sodium (Li 4−x NaxSiO 4 ). Chem. Mater. 2008, 20: 7171. 10.1021/cm802132t

Rodriguez VD, Rodriguez-Mendoza UR, Martin IR, Lavin V, Nunez P: Site distribution in Cr3+ and Cr3+- Tm3+-doped alkaline silicate glasses. J. Lumin. 1997, 72–74: 446.

Elbatal HA, Mandouh Z, Zayed H, Marzouk SY, Elkomy G, Hosny A: Gamma ray interactions with undoped and CuO-doped lithium disilicate glasses. Physica B: Cond. Mat. 2010, 405: 4755. 10.1016/j.physb.2010.08.071

Abd E, All S, Ezz-Eldin FM: Beam interactions with materials and atoms. Nucl. Instrum. Methods Phys. Res., B 2010, 268: 49. 10.1016/j.nimb.2009.09.038

Yang W, Cai-mei F, Bo H, Hai LZ, Pin SY: Photoelectrocatalytic activity of two antimony doped SnO 2 films for oxidation of phenol pollutants. Trans. Nonferrous Met. Soc. China 2009, 19: 778. 10.1016/S1003-6326(08)60349-0

Sen RD, Min BZ, Li H, Jie S, Li CX, Ling YX, Jian ZZ: The effect of dopant Sb on the superhydrophilicity and the microstructure of the nanoscale TiO 2 thin film. Acta Phys. Chim. Sin. 2004, 20: 414.

Mandalapu LJ, Yang Z, Xiu FX, Zhao DT, Liu JL: Homojunction photodiodes based on Sb-doped p-type ZnO for ultraviolet detection. Appl. Phys. Lett. 2006, 88: 092103. 10.1063/1.2178470

Hu Y, Hou SH: Preparation and characterization of Sb-doped SnO 2 thin films from colloidal precursors. Mater. Chem. Phys. 2004, 86: 21. 10.1016/j.matchemphys.2004.01.039

Lee SY, Park B: Structural, electrical and optical characteristics of SnO 2 :Sb thin films by ultrasonic spray pyrolysis. Thin Solid Films 2006, 510: 154. 10.1016/j.tsf.2006.01.001

Lupan O, Chow L, Ono LK, Cuenya BR, Chai G, Khallaf H, Park S, Schulte A: Synthesis and characterization of Ag- or Sb-doped ZnO nanorods by a facile hydrothermal route. J. Phys. Chem. 2010, 114: 12401.

Mandalapu LJ, Xiu FX, Yang Z, Liu JL: Al/Ti contacts to Sb-doped p -type ZnO. J. Appl. Phys. 2007, 102: 023716. 10.1063/1.2759874

Gutiérrez GM, Cruz D, Pfeiffer H, Bulbulian S: Low temperature synthesis of Li2SiO3: effect on its morphological and textural properties. J. Res. Lett. Mater. Sci. 2008. 10.1155/2008/908654

Zhang B, Easteal AJ: Effect of HNO 3 on crystalline phase evolution in lithium silicate powders prepared by sol-gel processes. J. Mater. Sci. 2008, 43: 5139. 10.1007/s10853-008-2736-5

Fuss T, Moguš-Milanković A, Ray CS, Lesher CE, Youngman R, Day DE: In-situ crystallization of lithium disilicate glass: effect of pressure on crystal growth rate. J. Non-Cryst. Sol. 2006, 352: 4101. 10.1016/j.jnoncrysol.2006.06.038

Soares PC, Zanotto ED, Fokin VM, Jain H: TEM and XRD study of early crystallization of lithium disilicate glasses. J. Non-Cryst. Sol. 2003, 331: 217. 10.1016/j.jnoncrysol.2003.08.075

Zheng X, Wen G, Song L, Huang X: Effects of P 2 O 5 and heat treatment on crystallization and microstructure in lithium disilicate glass ceramics. Acta Mater. 2008, 56: 549. 10.1016/j.actamat.2007.10.024

Mahmoud MM: Crystallization of lithium disilicate glass using variable frequency microwave processing. Blacksburg, Virginia; 2007.

Ge S, Wang Q, Li J, Shao Q, Wang X: Controllable synthesis and formation mechanism of bow-tie-like Sb 2 O 3 nanostructures via a surfactant-free solvothermal route. J. All. Comp. 2010, 494: 169. 10.1016/j.jallcom.2010.01.064

Deng Z, Chen D, Tang F, Ren J, Muscat AJ: Synthesis and purple-blue emission of antimony trioxide single-crystalline nanobelts with elliptical cross section. Nano. Res. 2009, 2: 151. 10.1007/s12274-009-9014-y

Grund CS, Hanusch K, Breunig JH, Wolf HU: Antimony and antimony compounds. In Ullmann's Encyclopedia of Industrial Chemistry. Weinheim, Wiley-VCH; 2006.

De Jong BHW, Beerkins RGC, van Nijnatten PA, Bourhis EL: Glass. In Ullmann's Encyclopedia of Industrial Chemistry. Weinheim, Wiley-VCH; 2005.

Peiniger M, Piel H: A superconducting Nb3Sn coated multicell accelerating cavity. J. Nucl. Sci. 1985, 32: 3610.

Moura S, Hernane R: Melting and purification of niobium. In Single Crystal - Large Grain Niobium Technology: AIP Conference Proceedings. American Institution of Physics, Melville 927; 2007:165.

Ye C: Low temperature growth and photoluminescence of well-aligned zinc oxide nanowires. Chem. Phys. Lett. 2002, 363: 134. 10.1016/S0009-2614(02)01145-4

Lide DR: CRC Handbook of Chemistry and Physics. 87th edition. Boca Raton: Taylor and Francis; 2006.

Hsu J, Tallant DR, Simpson RL, Missert NA, Copel RG: Luminescent properties of solution-grown ZnO nanorods. Appl. Phys. Lett. 2006, 88: 252103. 10.1063/1.2214137

Her YC, Wu JY, Lin YR, Tsai SY: Low-temperature growth and blue luminescence of SnO 2 nanoblades. Appl. Phys. Lett. 2006, 89: 043115. 10.1063/1.2235925

Acknowledgment

The authors express their sincere thanks to the authorities of University of Tabriz for financing the project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interest.

Authors’ contributions

All authors participated in the experiments, read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License ( https://creativecommons.org/licenses/by/2.0 ), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Alemi, A., Khademinia, S., Dolatyari, M. et al. Hydrothermal synthesis, characterization, and investigation of optical properties of Sb3+-doped lithium silicates nanoparticles. Int Nano Lett 2, 20 (2012). https://doi.org/10.1186/2228-5326-2-20

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2228-5326-2-20