Abstract

Microwave energy based chemical synthesis has several merits and is important from both scientific and engineering standpoints. Microwaves have been applied in numerous inorganic and organic chemical syntheses; perhaps, from the time their ability to work as heat source was discovered. Recent laboratory scale microwave applications in biodiesel production proved the potential of the technology to achieve superior results over conventional techniques. Short reaction time, cleaner reaction products, and reduced separation-purification times are the key observations reported by many researchers. Energy utilization and specific energy requirements for microwave based biodiesel synthesis are reportedly better than conventional techniques. Microwaves can be very well utilized in feedstock preparation, extraction and transesterification stages of the biodiesel production process. Although microwave technology has advanced in other food, pharmaceutical and polymer chemistry related research and industry, it has yet to prove its potential in the biodiesel industry at large scale applications. This paper reviews principles and practices of microwave energy technology as applied in biodiesel feedstock preparation and processing. Analysis of laboratory scale studies, potential design and operation challenges for developing large scale biodiesel production systems are discussed in detail.

Similar content being viewed by others

Introduction

Renewable energy research is receiving increased attention in recent years. Main reasons for this evolution are energy, economic and environmental security related concerns. It is reported that the present petroleum consumption is 105 times faster than the nature can create [1] and at this rate of consumption, the world’s fossil fuel reserves will be diminished by 2050 [2]. Apart from this, the fuel consumption is expected rise by 60% or so in the next 25 years [3]. To reduce dependency on the fossil fuel sources and imports from oil-rich countries and maintain environmental sustainability, many countries have committed to renewable energy production increases and/or greenhouse gas emission reductions at national and international levels [4]. Policy amendments and changes in energy management strategies have been considered as well.

Among many renewable energy sources solar thermal and photovoltaic collectors are still not mature and are cost-prohibitive. For instance, energy conversion efficiency of the photovoltaic modules available in the market is at the maximum of 15%. Photovoltaic cells are also referred to as solar energy harvesting factories with an input to output ratios of 1:7. The return energy production rate from the photovoltaic modules is slow over 20-25 years [5]. Wind and geothermal sources have limitations such as location, availability, and intensity. Since most of the transportation and industrial sectors need liquid fuels to drive the machinery and engines, more emphasis is needed on alternative fuel sources such as biodiesel [6]. Biodiesel is composed of methyl or ethyl esters produced from vegetable oil or animal oil and has fuel properties similar to diesel fuel which renders its use as biofuel. Biodiesel offers many benefits: (a) serves as alternative to petroleum-derived fuel, which implies a lower dependence on crude oil foreign imports; (b) provides favorable energy return on energy invested; (c) reduces greenhouse emissions in line with the Kyoto Protocol agreement; (d) lowers harmful gaseous emissions; (e) biodegradable and nontoxic fuel, being beneficial for reservoirs, lakes, marine life, and other environmentally sensitive areas [7–9]. It has been realized that local biodiesel production can address challenges related to energy independence, economic prosperity, and environmental sustainability in any nation. Towards this end, the United States (US) and Europe have encouraged large scale industrial biodiesel production. For example, biodiesel production in the US has increased from 75 million gallons in 2005 to 250 million gallons in 2006 and 450 million gallons in 2007, with an expected total capacity of well over 1 billion gallons in the next few years [10, 11]. Also, the federal government has passed the energy independence and security act (EISA) in 2007 which requires a gradual increase in the production of renewable fuels to reach 36 billion gallons per year by 2022. Furthermore, 28 states have passed their own mandatory renewable energy legislation. For example, Arizona and California will replace 15% and 20% of their electricity sales with renewable energy by 2020, respectively. Texas has a mandate for 5880 MW of renewable electricity capacity by 2015. Other states have mandates to reduce greenhouse gas (GHG) emissions. For instance, Minnesota’s strategic goal is to reduce GHG emissions by 80% between 2005 and 2050 [8, 9].

Local biodiesel production holds great promise to solve the above mentioned energy and environmental related concerns; however there are two major challenges that inhibit biodiesel production: 1) cost of the feedstock; and 2) conversion process of oils to biodiesel. While using low cost feedstock and recycling waste cooking oils and animal fats can be an alternative to reduce the feedstock costs; process improvements and optimization help reduce the biodiesel conversion process costs. Biodiesel production involves two main steps: 1) extraction of oils from the feedstock, and 2) conversion (transesterification) of oils (fatty acids) to biodiesel (alkyl esters). Without these steps biodiesel production is not possible, as such, these two steps play important role and need detailed attention. Common methods employed to demonstrate these two steps simultaneously or in series include conventional heating, high pressure and temperature reactions such as thermal liquefaction and pyrolysis. These methods are employed based on the feedstock type and quality [11]. These methods are not energy-efficient and are expensive and offer scope for further improvements. Several process modification and improvements were performed both at laboratory research and industrial levels [11–13]. In this category, the effect of radiofrequency and ultrasound waves has been tested [4, 7]. Ultrasonic production has shown improvements in extraction and transesterification processes; however, the technology may require longer reaction times and larger volumes of solvents possibly with excess energy consumption compared to microwave based process [12]. Recently, microwaves have received increased attention due to their ability to complete chemical reactions in very short times. Microwaves have revolutionized the way chemical reactions can be performed with unexplainable results. This amazed the entire scientific and industrial community and resulted in “curious chemists” who applied microwaves in different areas of chemistry to benefit from these results. Few advantages with microwave processing can be listed as: rapid heating and cooling; cost savings due to energy, time and work space savings; precise and controlled processing; selective heating; volumetric and uniform heating; reduced processing time; improved quality (“reportedly”) and properties; and effects not achievable by conventional means of heating [14–20]. Microwaves have been used by many researchers around the world in many organic and inorganic syntheses at exploratory levels [14–20]. Recently, many industries have successfully implemented microwave based processes, examples include: ceramic/ceramic matrix composite sintering and powder processing, polymers and polymer-matrix composites processing, microwave plasma processing of materials, and minerals processing [14]. Microwaves have the ability to induce reactions even in solvent-free conditions offering “Green Chemistry” solutions to many environmental problems related to hazardous and toxic contaminants [19]. Due to these advantages, microwaves provide for tremendous opportunities to improve biodiesel conversion processes from different feedstock and oils. The intention of this review is to provide the basics of microwave energy applications specific to biodiesel preparation and processing, preliminary understanding and explanation of microwave effect on the chemical reactions (extraction and transesterification), update on process utilization and improvements, and information related to different process configurations and reactor designs available for biodiesel production. This review paper provides basic information related to microwave based biodiesel processing for novice researchers and those actively practicing in the biodiesel industry.

Microwave characteristics

Microwave irradiation is the electromagnetic irradiation with frequency range of 0.3-300 GHz. They lie in the electromagnetic spectrum between infrared waves and radio waves with wavelengths between 0.01 and 1 m. Commercial microwave ovens approved for domestic applications operate at a frequency of 2.45 GHz to avoid interference with telecommunication and cellular phone frequencies. Typical bands approved for industrial applications are 915 and 2450 MHz. Most of the reported microwave chemistry experiments are conducted at 2450 MHz (the corresponding wavelength is 12.24 cm) since this frequency is approved worldwide and used in currently available commercial microwave chemistry equipment. One reason is that near to this frequency, the microwave energy absorption by liquid water is maximal. Interaction of dielectric materials with microwaves leads to what is generally described as dielectric heating due to a net polarization of the substance [21–24]. There are several mechanisms which are responsible for this, including electronic, ionic, molecular (dipole), and interfacial (space-charge) polarization which will be discussed further [25].

Microwave energy

Energy associated with microwaves is lower than the energy of Brownian motion which is not strong enough to even break chemical bonds as such microwaves cannot induce chemical reactions. The influence of microwave energy on chemical or biochemical reactions is both thermal and non-thermal. The microwave energy quantum is given by the well-known equation, W = hν. Within the frequency domain of microwaves and hyper-frequencies (300 MHz - 300 GHz), the corresponding energies are 1.24 × 10-6 -1.24 × 10-3 eV, respectively. These energies are much lower than ionization energies of biological compounds (13.6 eV), of covalent bond energies such as OH- (5 eV), hydrogen bonds (2 eV), van der Waals intermolecular interactions (lower than 2 eV) and even lower than the energy associated with Brownian motion at 37°C (2.7 10-3eV) [26–28]. Microwaves, as an energy source, produce heat by their interaction with the materials at molecular level without altering the molecular structure [29, 30]. Microwave heating offers several advantages over conventional heating such as non-contact heating (reduction of overheating of material surfaces), energy transfer instead of heat transfer (penetrative radiation), reduced thermal gradients, material selective and volumetric heating, fast start-up and stopping and reverse thermal effect, i.e. heat starts from the interior of material body. In terms of biodiesel production, the resultant value could include: more effective heating, fast heating of catalysts, reduced equipment size, faster response to process heating control, faster start-up, increased production, and elimination of process steps [28].

Microwave heat transfer mechanism

Microwave heating mechanism is complex. The microwave method of heating can be illustrated as shown in Figure 1. A comparison with conventional heating method would provide a base to compare the differences in heating mechanisms and further realize the advantages associated with microwave heating.

In conventional heating as well as supercritical methods, heat transferred to the sample volume is utilized to increase the temperature of the surface of the vessel followed by the internal materials. This is also called “wall heating”. Therefore, a large portion of energy supplied through conventional energy source is lost to the environment through conduction of materials and convection currents. Heating effect in the conventional method is heterogeneous and dependent on thermal conductivity of materials, specific heat, and density which result in higher surface temperatures causing heat transfer from the outer surface to the internal sample volume as seen in Figure 2. As a result, non-uniform sample temperatures and higher thermal gradients are observed [31, 32].

Figure 2a shows the temperature profiles for a 5 mL sample of ethanol boiled at 160°C in a single mode closed vessel microwave irradiation and open vessel oil bath heating conditions. The temperature profiles show that microwave heating method allows for rapid increase of solvent temperature and quick cooling as well, whereas in conventional heating (oil bath) rate of heating and cooling are very slow. Figure 2b shows thermal behavior of microwave versus oil bath heating. Temperature gradients shown in Figure 2b suggest that microwave irradiation rises the temperature of the whole volume evenly and simultaneously whereas in oil bath heating the reaction mixture in contact with the vessel wall is heated first. Inverted thermal gradient differences can be observed between the two heating methods [33–35]. The advantages of this enabling technology have more recently also been exploited in the context of multistep total synthesis and medicinal chemistry/ drug discovery and have additionally penetrated fields such as polymer synthesis,6 material sciences, nanotechnology, and biochemical processes [36].

Materials in general can be classified into three categories based on their interaction with microwaves: (1) materials that reflect microwaves, which are bulk metals and alloys, e.g. copper; (2) materials that are transparent to microwaves, such as fused quartz, glasses made of borosilicate, ceramics, Teflon, etc.; and (3) materials that absorb microwaves which constitute the most important class of materials for microwave synthesis, e.g. aqueous solutions, polar solvent, etc. Dissipation factor (often called the loss tangent, tan δ), a ratio of the dielectric loss (loss factor) to the dielectric constant, is used to predict material’s behavior in a microwave field. The microwave absorption ability of a material is directly proportional to its dissipation factor [34].

Microwaves transfer energy into materials by dipolar polarization, ionic conduction and interfacial polarization mechanisms to cause localized and rapid superheating of the reaction materials (Figure 3). If a molecule possesses a dipole moment, when it is exposed to microwave irradiation, the dipole tries to align with the applied electric field. Since the electric field is oscillating, the dipoles constantly try to realign to follow this movement. At 2.45 GHz, molecules have time to align with the electric field but not to follow the oscillating field exactly (Figure 4). This continual reorientation of the molecules results in friction and thus heat. If a molecule is charged, then the electric field component of the microwave irradiation moves the ions back and forth through the sample while also colliding them into each other. This movement again generates heat. In addition, because the energy is interacting with the molecules at a very fast rate, the molecules do not have time to relax and the heat generated can be, for short times, much greater than the overall recorded temperature of the bulk reaction mixture. In essence, there will be instantaneous localized superheating. Thus, the bulk temperature may not be an accurate measure of the temperature at which the actual reaction is taking place. The interfacial polarization method can be considered as a combination of the conduction and dipolar polarization mechanisms. It is important for heating systems that comprise a conducting material dispersed in a non-conducting material such as metal oxides in polar solvents [25, 28, 30, 32]. Figure 4 shows the range of microwave frequency and the variations of ionic conduction and dipolar polarization with the microwave frequency [233].

Microwave role in biodiesel production

Biodiesel production technologies

Currently, commercial biodiesel production processes are based on either conventional or supercritical heating methods. Commonly used methods are: 1) Pyrolysis, 2) Micro-emulsions, 3) Dilution, and 4) Transesterification of oils to esters [37–41]. Among these methods, transesterification has proven to be the simplest and the most economical route to produce biodiesel, with physical characteristics similar to fossil diesel and little or no deposit formation when used in diesel engines. Transesterification of oils from any feedstock is to simply reduce the viscosity of the oils derived from them. Transesterification is a process in which an alcohol (methanol or ethanol) in the presence of a catalyst (acid or alkali or enzyme) is used to chemically break the molecule of the vegetable oils or animal fats into methyl or ethyl esters of the renewable fuel.

The overall transesterification process is a sequence of three consecutive and reversible reactions, in which di and monoglycerides are formed as intermediates, yielding one ester molecule in each step. The stoichiometric reaction requires 1 mole of a triglyceride and 3 moles of the alcohol. However, excess amount of alcohol is used to increase the yields of the alkyl esters by shifting the equilibrium towards the formation of esters and to allow its phase separation from the glycerol formed as a by-product. The product of transesterification process is known as “biodiesel”.

While transesterification of oils to produce biodiesel is a well-established method, there exist conversion and energy utilization inefficiencies in the process which result in the high cost of biodiesel. These are mainly associated with the heating method employed in the process. Transesterification of organic feedstock to yield biodiesel can be performed by the following methods: 1) conventional heating with acid, base catalysts and co-solvents [42–51]; 2) sub- and super-critical methanol conditions with co-solvents and without catalyst [52–57]; 3) enzymatic method using lipases [58–63]; and 4) microwave irradiation with acid, base and heterogeneous catalysts [64–67]. Among these methods, conventional heating method requires longer reaction times with higher energy inputs and losses to the ambient [66]. Super and sub-critical methanol process operates in expensive reactors at high temperatures and pressures resulting in higher energy inputs and higher production costs [53, 67–69]. The enzymatic method, though operates at much lower temperatures, requires much longer reaction times [40]. Microwave-assisted transesterification, on the other hand, is energy-efficient and quick process to produce biodiesel from different feedstocks [65, 66].

The production methods include pyrolysis, thermochemical liquefaction, supercritical reactors, oil and sand baths, and jacket type heating. Ultrasound treatment was also favored in some processes. In recent years, many researchers have tested application of microwaves in biodiesel production and optimization studies with various feedstocks. Microwave energy, a non-conventional heating method is utilized in biodiesel production in two main stages: 1) oil extraction and 2) chemical transesterification reaction. It can be beneficial to combine the above two steps to perform a single-step extractive transesterification reaction as discussed later. Biodiesel production involves mixing of appropriate ratios of oil, methanol (solvent) and catalysts as shown in Figure 5. The mixture is then processed through a microwave reactor followed by separation of products to yield biodiesel and glycerin.

Thermodynamic justification

The advantage of microwave assisted reactions clearly reflects in short reaction times by rapid heating and cooling. Perhaps, the motivation for microwave reactions was derived from the desire to reduce reaction times and produce cleaner reaction products. A very high increase in (5-1000 times) reaction rates was reported by early researchers [53, 70–73]. It is also possible to observe different product composition under microwave and conventional heating. Probable explanation for this phenomenon is that microwave heating significantly increases the reaction temperature and it is possible that the reaction temperature (due to dielectric heating) could exceed the ignition temperature for an additional reaction, which is not possible at the lower temperatures achieved by conventional heating. Many theories attempt to elaborate on the special microwave effects of heating. Since reactions involve thermodynamics of materials, fundamental thermodynamic equation (the Arrhenius equation) for reactions can be taken as a basis to explain the special microwave heating effect [74]:

From the above equation, it can be noted that there are only two possible ways to increase the rate of reaction. First, by increasing the pre-exponential factor “A” which is the molecular mobility that depends on frequency of the vibrations of molecules at the reaction interface [75]. This relates to the microwave effects of dipolar polarization and ionic conduction mechanisms explained earlier. The pre-exponential factor “A” is expressed as :

where γ = number of neighbor jump sites, λ = jump distance, and Γ = jump frequency [76].

The other way is to decrease the activation energy, ΔG, which is given in terms of enthalpy and entropy (ΔG = ΔH – TΔS). In microwave assisted reactions, entropy generation is higher due to quick and random dipolar movement and molecular level microwave interactions which increases the value of second term in the equation. The expedited superheating can also contribute to reduction in activation energy [75]. Kappe mentioned that non-thermal effects essentially result from a direct interaction of the electric field with specific molecules in the reaction medium. It has been argued that the presence of an electric field leads to orientation effects of dipolar molecules and hence changes the pre-exponential factor A or the activation energy (entropy term) in the Arrhenius equation. A similar effect should be observed for polar reaction mechanisms, where the polarity is increased going from the ground state to the transition state, thus resulting in an enhancement of reactivity by lowering the activation energy [35, 77].

Microwave effects result from material-wave intractions and due to the dipolar polarization phenomenon, the greater the polarity of a molecule (such as the solvent) the more pronounced the microwave effect when the rise in temperature is considered [77]. In terms of reactivity and kinetics, the specific effect has therefore to be considered according to the reaction mechanism and particularly with regard to how the polarity of the system is altered during the progress of the reaction. When polairty is increased during the reaction from the ground state towards the transition state, specific microwave effects can be expected for the polar mechanism. The outcome is essentially dependent on the medium and the reaction mechanism. If stabilization of the transition state (TS) is more effective than that of the ground state (GS), this results in an enhancement of reactivity by a decrease in the activation energy (Figure 6a, 55). Alteration of esterification kinetics under microwave irradation was reported by Jermolovicius et al [78].

In biodesel transesterication reactions, the solvent used mostly is methanol. Methanol is known to have high microwave absorption capacity and is an organic solvent with high polarity. It can therefore be understood that oil-methanol-catalyst involved transesterification reaction can be enhanced by microwave interactions through dipolar polarization and ionic conduction. In water containing feedstock biodiesel reactions, microwave assisted supercritical reactions can turn the water as organic solvent because water molecules possess a dipole moment. A dipole is sensitive to external electrical fields and will attempt to align itself with the field by rotation to generate local superheating (Figure 6b, 74).

Microwave based biodiesel production

Microwave applications in biodiesel production can be separated based on different feedstock types. Many reports include research on microwave-enhanced transesterification of 1) edible oils, 2) non-edible oils, and 3) oils from algae and other cellulose based renewable feedstock.

-

i)

Edible oils (first generation)

Rudolph diesel has first tested the engine by using the peanut oil and discovered that the vegetable oils can serve as engine fuels after further treatment. Edible oils commonly used as feedstock for the biodiesel production have been soybean, canola, corn, coconut, palm tree, rapeseed, rice bran, sunflower, safflower, camelina and cottonseed oils to just name a few. Among these, soybean oil is the dominant feedstock and palm tree produces highest quantity of oils per cultivated area [79, 80]. Rapeseed and sunflower oils are predominant in the European Union. Although use of vegetable oils to prepare biodiesel was well received in the early stage, soon it turned out be a food versus fuel issue. This conflict arose due to increase in vegetable oil demands and prices.

-

ii)

Non-edible oils (second generation)

Among possible alternative biodiesel feedstocks are oils of non-edible crops such as jatropha, castor, neem, karanja, rubber seed, used frying oils (waste cooking oil), animal fats, beef and sheep tallow [81]. pongamia pinnata, maize, yellow grease, poultry fat, castor, and Chinese tallow tree. While these feedstock do not conflict with food interest, they conflict with other commercial products such as cosmetics and industrial products.

-

iii)

Algae and other feedstock (third generation)

Third generation biodiesel feedstock are those that do not conflict with any food, feed or cosmetic related human consumption interests. Macro and microalgae, cyanobacteria, wastewater treatment plant activated sludge, switch grass and other microbial communities belong to this type. Among these, algae seem to be a superior feedstock and offer several advantages as follows: 1) Algae can utilize non-arable land; 2) oil content in algae is orders of magnitude higher than from other feedstocks such as corn, sugar cane, jatropha, etc.; 3) Algae need CO2 to photosynthesize and can be used to sequester CO2 from industrial sources of flue and flaring gas; 4) Algae-based fuels are carbon-neutral or even more carbon-capturing than releasing; 5) Algae can be used to remediate high-nutrient water sources such as sewage treatment plant and agricultural runoff; 6) End-products include biodiesel and/or other higher value feed (protein), pharmaceutical, and health-related products. 7) Different species of algae can be grown in polluted, saline, brackish, and freshwater; 8) Co-location of algal ponds with industrial production plants for potential recycling of CO2 and impaired waters. Algal biofuels are thus renewable, sustainable, and environmentally-benign [82–85].

Microwave-assisted oil extraction

Microwaves can be used either as a thermal pretreatment or process enhancement technique for extraction of oils and lipids from biodiesel feedstock [86]. Microwave extraction is more efficient than other conventional extraction methods in many ways. Microwaves allow for rapid and selective extraction of organic compounds with low solvent and energy consumptions [87, 88]. In conventional extraction the extractability of different components depends mainly on the solubility of the compound in the solvent, mass transfer kinetics of the product and matrix interactions [89], whereas under microwave-assisted extraction localized superheating rate plays an important role in extraction efficiency. This heating rate is influenced by factors such as microwave power level, frequency, initial temperature and design of microwave applicator, and can be selected for a particular processing application. Microwaves have been successfully applied for the extraction of natural compounds from foodstuffs like flavonoids and polyphenols compounds from tea [90] and grape seeds [91], constituents from herbals [92], pigments from paprika [93], antioxidants from rice bran [94], isoflavones from soybeans [95, 96] and also for trace analysis of organic compounds in solid and liquid samples [97–99]. Microwaves may also allow for solvent free extraction of essential oils from plant materials [100].

Selection of solvent is another important consideration in microwave extraction. Microwaves are effective on materials that have high dielectric properties, an intrinsic property of the material that requires empirical measurement but is mostly influenced by the moisture liquid/solid mixture content and spatial distribution of the water and other polar/ionic compound in the matrix. The dielectric properties of materials are defined in terms of their relative complex permittivity. For a solvent/matrix to heat up rapidly under the microwave radiation, it has to have a high dielectric constant, associated with the potential for electrical energy storage in the material, and a high dielectric loss which is related to the electrical energy dissipation in the material [101]. The heating of a dielectric material in the presence of an electromagnetic field is based on intermolecular friction that arises via ionic conduction and dipolar rotation [102]. N-hexane is widely used as solvent for extraction with other commonly used solvents such as isopropanol, methanol, ethanol, acetone and water [89, 90, 103, 104].

Extraction of lipids and oils from plant leaves and seeds depend on the microwave penetration ability. Disruptions of the oilseed cells take place when temperature of water molecule inside the cells reach the boiling point leading to high pressure gradients and rupture of cell walls, causing migration of selected compounds from sample matrix into the extraction solvent [98]. This particularity makes the technology appealing for biodiesel, as biodiesel is produced from vegetable oil. The microwave thermal effects (localized microscopic super heating) naturally match the requirements for the disruption process of tissues and could be used to induce rupture of cells for efficient extraction of oils and other components from plants. The above mechanism of extraction applies to algal cells as well. In a recent study, lipid extraction from microalgae was tested by various methods including autoclaving, bead-beading, microwaves, sonication, and a 10% NaCl solution. Microwave based extraction proved to be the most simple, easy and effective method for disruptive extraction of lipids from Botryococcus sp., Chlorella vulgaris, and Scenedesmus sp. [105].

Extraction by microwaves can be fast and simple. Kanitkar conducted microwave assisted extraction of oils from soybeans, rice bran and Chinese tallow tree seeds. About 95% of recoverable oils were extracted from these seeds by microwave extraction process in just 20 minutes which would otherwise have taken hours of processing using other solvent and mechanical extraction methods. It was observed that the enhanced extraction was due to the specific interaction of the microwave field with the solvent-feedstock matrix, where higher temperature and pressure gradients develop at the microscopic level, leading to enhanced mass transfer coefficients [106].

Extraction kinetics can be explained using the Arrhenius equation. An explanation provided by Cooney is as follows. Solvent extraction of bio-oils from biomass is a process whereby the target analyte is transferred from one phase (e.g., a solid phase in the case of dried biomass and an aqueous liquid phase in the case of wet biomass) to a second immiscible phase (e.g., an alcohol such as methanol or an alkyl halide such as chloroform). In other words, the analyte (i.e., lipid) molecule must dissolve into the solvent and form a solution. The solubility of the analyte in the solvent is governed by the Gibbs free energy of the dissolution process, which is directly related to the equilibrium constant governing the concentration of the analyte in either phase.

As more of the analyte dissolves into the solvent phase, the natural logarithm of the quotient becomes positive and the Gibbs free energy for this reaction becomes negative, indicating that the reaction has proceeded more favorably in the direction of the analyte dissolving into the solvent. As the analyte fully dissolves into the solvent phase, the quotient approaches infinity and the equilibrium lies totally to the right, and the target analyte (i.e., lipid) is considered fully extracted into the solvent phase.

The solubility of the target analyte in various solvents is governed by two independent parameters (which may, or may not, work together): the enthalpy of mixing (ΔH) and the entropy of mixing (ΔS). The solubilization of the analyte in the solvent is therefore favored when the dissolution process gives off energy (i.e., ΔH) and/or when the dissolution process increases entropy (ΔS). Since these two properties are interdependent, a favorable change in one may (or may not) offset an unfavorable change in the other. How the analyte molecule chemically interacts with the selected solvent will dictate whether the change in enthalpy is positive or negative, whether the change in entropy is positive or negative, and whether their combined sum yields a favorable Gibbs free energy of dissolution. The overall sum of these two terms is defined by the total relative contribution of all intermolecular forces that occur between the analyte and solvent molecules: Electrostatic, London forces, hydrogen bonds, and hydrophobic bonding. Consequently, the development of any solvent based extraction process must comprise a choice of solvent (or co-solvent mixture) that yields a set of chemical interactions between the analyte and solvent molecules that is more favorable than the chemical interactions between (i) the solvent molecules themselves (i.e., self association), and (ii) the analyte with the matrix it was already associated with. As a general rule analytes that strongly self associate dissolve best in strongly associated solvents, while analytes that weakly associate dissolve best in weakly associated solvents. In other words, polar solutes will dissolve in similarly polar solvents and non-polar solutes will dissolve better in similarly non-polar solvents [107].

An improved process of Soxhlet extraction assisted by microwave, called microwave-integrated Soxhlet (MIS) was tested for the extraction of oils and fats from different food matrixes such as oleaginous seeds, meat and bakery products. Results have shown that MIS parameters do not affect the composition of the extracts. For the generalization of the study with several food matrices, MIS extraction results obtained were then compared to conventional Soxhlet extraction in terms of crude extract and fatty acid composition and shown that the oils extracted by MIS were quantitatively and qualitatively similar to those obtained by conventional Soxhlet extraction. MIS labstation can be considered as a new and general alternative for the extraction of lipids by using microwave energy [108].

Microwave-enhanced transesterification

The chemical conversion of the oil to its corresponding fatty ester (biodiesel) is called transesterification. Transesterification is the process of using a monohydric alcohol in the presence of an alkali catalyst, such as sodium hydroxide (NaOH) or potassium hydroxide(KOH), to break chemically the molecule of the raw renewable oil into methyl or ethyl esters of the renewable oil with glycerol as a byproduct [109]. Microwave effect on the transesterification reaction can be two-fold: 1) enhancement of reaction by a thermal effect, and 2) evaporation of methanol due to the strong microwave interaction of the material [110, 111]. The microwave interaction with the reaction compounds (triglycerides and methanol) results in large reduction of activation energy due to increased dipolar polarization phenomenon [112]. This is achieved due to molecular level interaction of the microwaves in the reaction mixture resulting in dipolar rotation and ionic conduction [74, 96, 113]. The amount, by which the activation energy is reduced, is essentially dependent on the medium and reaction mechanism [112]. Methanol is a strong microwave absorption material and in general, the presence of an -OH group attached to a large molecule behaves as though it were anchored to an immobile raft and the more localized rotations result in localized superheating which assists the reaction to complete faster (Figure 6b) [114]. For this reason, methanol is preferred over ethanol for microwave-assisted transesterification process [115]. Comparison between three heating methods for biodiesel preparation through transesterification reaction is shown in Table 1. Supercritical conditions (high pressure and temperatures) eliminate the need for catalyst and provide for quick transesterification of oils and biomass lipids while the most commonly used conventional heating methods are slow and energy consuming.

Camelina Sativa oil as a feedstock was evaluated by Patil et al. [118, 119]. These studies included different methods of heating such as conventional, supercritical and microwave methods. Among which the microwave method proved to be superior due to inherent advantages of shorter reaction time and lower energy requirements. Microwave assisted reactions not only reduce the reaction time and increase the biodiesel yield but also reduce the product separation time significantly [66]. It was reported that the product separation in conventional heating method required 480 minutes which was around 30 minutes in microwave assisted heating method. Microwave irradiation resulted in reduction of the reaction time by about 97% and the separation time by about 94% [120]. Saifuddin and Chua [121] reported that the separation time was between 45-60 min for ethyl esters.

Continuous preparation of fatty acid ethyl esters (FAEE) from coconut, rice bran and used frying (palm) oils in a modified conventional microwave oven (800 Watts) were reported by Lertsathapornsuk et al. In a continuously mixed batch reactor system, rapid reaction rate and higher conversion yield of FAEE in the presence alkali catalyst of three vegetable oils was observed with excess amounts of alcohol. The reaction time was reduced to 30 - 60 seconds which was 30 - 60 times higher when compared with conventional and super critical methods [122, 123]. Refaat and Sheltawy reported that microwave irradiation also allows for use of high free fatty acid (FFA) containing feed stocks, including animal fats and used cooking oils, in existing transesterification processes by promoting the removal of the fatty acid. Radio frequency microwave energy further improves product recovery in the separation of the biodiesel product from alcohol and glycerin in the reaction mixture [124].

Mazzocchia et al. have shown that microwave irradiation is a fast and energy saving method compared to the conventional transesterification method for biodiesel production from different feedstocks. It was reported that microwave irradiation method prevented product degradation, when barium hydroxide was employed as a catalyst. The separation of the reaction products was quick and increased with Ba(OH)2 H2O when anhydrous and barium hydroxide is employed [125]. The total microwave irradiation power on the non-catalytic reaction indicated conversion up to 60% in 60 min of reaction in the esterification of oleic acid (C18). The effects of alcohol type (methanol or ethanol), temperature (150-225°C) and molar ratio of alcohol/fatty acid (3.5-20) on the ester yield were studied in detail [67]. To enhance the synthesis process for biodiesel from castor oil (fatty acid methyl ester, FAME), microwave absorption solid acid catalysts (H2SO4/C) were used for transesterification under microwave radiation. A maximum yield of 94% was obtained using 12:1 (MeOH to Oil ), 5 wt % catalyst , and 55 wt % H2SO4 loading amounts of catalyst at 338 K under microwave radiation after 60 min [111].

An efficient microwave-assisted transesterification (MAT) technique was developed by Zhang and co-workers to prepare biodiesel from yellow horn (Xanthoceras sorbifolia) oil with a heteropolyacid (HPA) catalyst namely Cs2.5H0.5PW12O40. A conversion yield higher than 96% was achieved by using a lower catalyst amount (1% w/w of oil) with a lower molar ratio of methanol/oil (12:1) in a relatively shorter reaction time (10 min) at 60°C [126]. The transesterification of high FFA jatropha curcas oil was carried out using microwave irradiation with homogenous catalyst. Biodiesel with 99% conversion can be achieved at 7 minutes reaction time [127]. It was studied that rapeseed oil can be converted to fatty acid butyl esters by means of microwave irradiation without using a catalyst or supercritical conditions of the alcohol [128]. The microwave assisted solvent extraction was studied effectively for Tallow tree. The major advantage of this implemented process was the reduced time of extraction required to obtain total recoverable lipids, with corresponding reduction in energy consumption costs per unit of lipid extracted [113].

Moseley and Woodman reported the energy efficiency of microwave- and conventionally heated reactors compared at meso scale for organic reactions. The results obtained from the study showed that at meso scale, microwave heating is generally more energy-efficient than conventional heating [129]. Barnard et al. developed a continuous-flow approach for the preparation of biodiesel using microwave heating. The methodology used for this process allows for the reaction to be run under atmospheric conditions and performed at flow rates of up to 7.2 L/min using a 4 L reaction vessel. This study assessed a range of different processing techniques for the scale-up of microwave-promoted reactions, taking them from the milligram to at least the multigram level for batch and continuous flow processing [130, 131]. Microwave assisted extraction and transesterification was performed using various types of feedstock ranging from edible oils to non-edible and waste frying oils. The experimental studies are summarized in Table 2[64, 106, 111, 118, 120–125, 127, 130, 132–139],[141–155].

Catalyst and alcohol-oil ratio

Among the most commonly used alkaline catalysts in the biodiesel industry are potassium hydroxide (KOH) and sodium hydroxide (NaOH) flakes which are inexpensive, easy to handle in transportation and storage, and are preferred by small producers. Alkyl oxide solutions of sodium methoxide or potassium methoxide in methanol, which are now commercially available, are the preferred catalysts for large continuous-flow production processes. However, both NaOH and KOH catalysts cause separation and purification a difficult process due to their high solubility in the both biodiesel and glycerin [109, 156, 157]. Biodiesel with the best properties was obtained using sodium hydroxide as catalyst in many studies. On the other hand, many other studies achieved best results using potassium hydroxide [120]. Refaat used 500 mL reactor at a reaction temperature of 65°C with a microwave power of 500 W controlled by microprocessor. A methanol/oil molar ratio of 6:1 was employed, and potassium hydroxide (1%) was used as a catalyst. Barium hydroxide was also used a homogeneous catalyst. the range of homogeneous catalysts applied was between 0.1 and 5% (Table 2) [132]. Slightly higher concentrations of KOH will be required compared to NaOH catalyst due to its higher molecular weight. For feedstock containing high free fatty acid content such as animal fats and used vegetable oils, KOH proved to be a better performer [120, 158]. Transesterification reaction depends on the type of oil and catalyst applied and the effects of catalysts vary with types of oils.

Although homogeneous catalysts are advantageous in terms of fast reaction rates, the drawback of this application is that the reaction products require longer separation and purification times. Use of heterogeneous catalysts can be advantageous in microwave-enhanced transesterification reactions since the catalyst can provide locations for hotspots for rapid heating. In addition, they are recyclable and reusable with acceptable performance. Patil et al. employed heterogeneous catalysts such as BaO, CaO, MgO, and SrO for transesterification of Camelina Sativa oil into biodiesel. They reported the kinetic rate constants for different catalysts. Two orders of magnitude of difference in the kinetic rate constants between the conventional heating method and microwave heating methods was reported in their study [159]. Sol gel type catalysts were also developed and tested by the same group of researchers. Heterogeneous catalysts also reportedly provide for cleaner products and easier separation of the end products. Variety of heterogeneous catalysts were tested. Few examples include: diphenylammonium salts - DPAMs (mesylates), DPABs (benzenesulfonate), DPATs (tosylate), sulfated zirconia, ZnO/ La2O2CO3, TiO2/SO4, heteropolyacids, aluminum oxides with sulfuric acid. whether reactions involving homogeneous or heterogeneous catalysts, when the reaction is carried out under microwaves, transesterification is efficiently activated, with short reaction times, and as a result, a drastic reduction in the quantity of by-products and a short separation time is obtained (> 90% reduction in separation time), and all with a reduced energy consumption [66, 136]. The rate acceleration in solid-state catalytic reactions, on exposure to microwave radiation, is attributed to high temperatures on the surface of the catalyst. The increase in the local surface temperature of the catalyst results in enhancement of the catalytic action, leading to an enhanced rate of reaction. It has been observed that when the catalyst is introduced in a solid granular form, the yield and rate of the heterogeneous oxidation, esterification and hydrolysis reactions increases with microwave heating, compared to conventional heating under the same conditions [160]. Solid base catalysts are more efficient than solid-acid catalysts. The advantage with the solid catalysts is that they are not sensitive to the presence of water in the reactants [25]. Breccia et al. reported on the use of a domestic microwave apparatus for the synthesis of biodiesel by reaction between methanol and commercial seed oils [161]. In this work, they found that the reaction was complete in less than 2 min under microwave irradiation. Activities of several catalysts such as sodium methylate, sodium hydroxide, sodium carbonate, sulfuric acid, benzensulfonic acid and boron carbide were also briefly discussed in their study.

The transesterification reaction is governed by the amount and type of alcohol participating in the reaction. Considering the type of the alcohol, the use of methanol is advantageous as it allows the simultaneous separation of glycerol. The same reaction using ethanol is more complicated as it requires a water-free alcohol, as well as an oil with a low water content, in order to obtain glycerol separation [162]. Methanol is the most commonly used reactant both in conventional and microwave assisted transesterification reactions. Ethanol is more sensitive to the presence of moisture content in the oil causing soap formation and has less dielectric constant compared to methanol. Ethanolysis proceeds at a slower rate than methanolysis because of the higher reactivity of the methoxide anion in comparison to ethoxide. As the length of the carbon chain of the alkoxide anion increases, a corresponding decrease in nucleophilicity occurs, resulting in a reduction in the reactivity of ethoxide in comparison to methoxide [163]. An example of this phenomenon is the transesterification (at 25°C) of canola oil with a 1:1 mixture of ethanol and methanol (to provide an overall molar ratio of alcohol to oil of 6:1) that results in 50% more methyl than ethyl esters [164, 165]. Therefore, for microwave assisted reactions, it is more favorable to use methanol as a solvent. On the other hand, ethanol has environmental acceptance due to its environmental friendly production from biomass. Since the transesterification reaction is an equilibrium reaction, excess amounts of alcohols need to be added to drive the reaction to completion within reasonable time. Alcohol-oil ratios of wide ranges (30:1) have been tested by many researchers with most common ratio being 9:1.

Direct extractive-transesterification of microalgae

In certain applications, it can be advantageous to perform extraction and transesterification reactions simultaneously. Biodiesel production from microalgae requires extraction of oils and lipids from the cellular mass prior to their transesterification. Microwaves can be used as efficient medium to perform these two tasks simultaneously. Algal biodiesel production essentially involves the following steps (Figure 7): 1) genetic development, 2) cultivation, 3) harvesting, 4) processing, and 5) separation of products [166–168]. Microwaves can be utilized in processing stage of the process i.e. for extraction and transesterification of oils.

High lipid yielding microalgae are cultivated and grown either in open or closed raceway ponds or in photobioreactors. Photobioreactors are designed to maximize the lipid yield and to minimize contamination and to improve the efficiency of the process. Algae are harvested by coagulation, flocculation, sedimentation and filtration methods followed by extraction and transesterification steps. The algal culture is usually concentrated to 15-20% by volume from its original concentration of 0.02-05% concentration in the cultivation ponds. One can notice that all of the above steps require large quantities of energy.

There are three well-known methods to extract the oil from algae: (1) mechanical expeller/press, (2) solvent extraction with hexane, and (3) supercritical fluid extraction. A simple process is to use a press to extract a large percentage (70–75%) of the oils out of algae. However, this method requires large volumes of samples. Algal oil can be extracted using chemicals. The most popular chemical for solvent extraction is hexane, which is relatively inexpensive. To be successful, any extracting solvent must be able to (1) penetrate through the matrix enclosing the lipid material, (2) physically contact the lipid material, and (3) solvate the lipid. As such the development of any extraction process must also account for the fact that the tissue structure and cell walls may present formidable barriers to solvent access. This generally requires that the native structure of the biomass must be disrupted prior to extraction [169]. Supercritical fluid extraction is far more efficient than traditional solvent separation methods. Supercritical fluids are selective, thus providing the high purity and product concentrations. This can extract almost 100% of the oils all by itself. In the supercritical fluid carbon dioxide (CO2) extraction, CO2 is liquefied under pressure and heated to the point that it has the properties of both a liquid and gas. This liquefied fluid then acts as the solvent in extracting the oil [170].

In general, two basic mechanisms by which extraction of a lipid can possibly occur: (1) diffusion of lipids across the cell wall, if the algal biomass is suspended in the solvent with higher selectivity and solubility (or large partition coefficient) for lipids and (2) disruption of the cell wall with release of cell contents in the solvent. The relative contribution of each of these mechanisms depends on the extraction technique. It could be easily perceived that diffusive mechanism will have less efficiency (in terms of long extraction time and smaller yield of lipid) due to the slow diffusion of lipid molecules across the cell wall. On the other hand, a disruptive mechanism is likely to cause faster extraction of lipids with high yields, as it involves the direct release of the lipid droplets in cytoplasm in to the bulk liquid with rupture of cell wall [171]. Diffusive mechanism is more predominant in extraction methods such as solvent extraction, soxhlet extraction and others. Disruptive mechanism refers to mechanical breakdown of the cell as in mechanical pressing and supercritical high pressure and high temperature treatment. However, it has been reported that mechanical pressing is inefficient method of extraction for algal biomass due to their rigid wall structure.

Even though dried plant material is used for extraction in most cases, but still plant cells contain minute microscopic traces of moisture that serves as the target for microwave heating. The moisture when heated up inside the plant cell due to microwave effect, evaporates and generates tremendous pressure on the cell wall due to swelling of the plant cell. The pressure pushes the cell wall from inside, stretching and ultimately rupturing it, which facilitates leaching out of the active constituents from the ruptures cells to the surrounding solvent thus improving the yield of phytoconstituents. This phenomenon can even be more intensified if the plant matrix is impregnated with solvents with higher heating efficiency under microwave (higher tan value) [172]. A microwave assisted straining method was developed to determine the amount of neutral lipids in microalgae. The microwave pretreatment and straining process only took 50 and 60 seconds respectively. Microwaves are suitable for this application since the conventional fluorescence method is unsuccessful in algae with thick, rigid cell walls [173].

Supercritical conditions can be applied in direct extractive-transesterification of vegetable oils and algal oils. Water at supercritical conditions can act as organic solvent and thus eliminating the need for solvent use. many studies have focused on this method to extract and transesterify bio-oils from different feedstock. The process operates at high temperatures and high pressures close to sub and supercritical conditions of water or solvent. In these studies, it was observed that higher temperatures favored extraction and transesterification process, however, at certain temperatures decomposition of biomass was inevitable [174–184]. Apart from it, safety of pressurized vessels is another concern. Advantages of this process are high quality extracts and end products which require easy separation [107].

Direct transesterification of freeze-dried microalgae in various solvents and using various catalysts was conducted by Cooney and co-workers under various experimental conditions. A 100% conversion of lipids (triglycerides) to FAMEs was observed. The same group has also executed this reaction in a novel ionic liquid based co-solvent that replaces the organic (i.e., chloroform) of the Bligh and Dyer co-solvent system with a hydrophilic ionic liquid (e.g., 1-ethyl-3-methylimidazolium methyl sulfate). It is proposed that the methanol facilitates the permeabilization of the cell wall and intracellular extraction of the lipids, while the ionic liquid facilitates the auto partitioning of the lipids to a separate immiscible phase [107, 167, 185]. Johnson and Wen have attempted extraction and transesterification of oils from Schizochytrium limacinum, heterotrophic microalga. They conducted their experiments by two methods: 1) oil extraction followed by transesterification (a two-stage method) or direction transesterification of algal biomass (a one-stage method). When freeze-dried biomass was used as feedstock, the two-stage method resulted in 57% of crude biodiesel yield (based on algal biomass) with a fatty acid methyl ester (FAME) content of 66.37%. The one-stage method (with chloroform, hexane, or petroleum ether used in transesterification) led to a high yield of crude biodiesel, whereas only chloroform-based transesterification led to a high FAME content. When wet biomass was used as feedstock, the one-stage method resulted in a much-lower biodiesel yield. The biodiesel prepared via the direct transesterification of dry biomass has met the ASTM standards. Different schemes using different solvents for one stage and two stage methods were also presented [186].

Aresta et al. conducted thermochemical liquefaction using wet algal biomass and supercritical CO2 extraction using dry algal biomass for direct transterification of bio-oils. Both of the processes seem to be energy intensive by the reaction conditions they reported (thermochemical liquefaction conditions: 250–395°C for 1 h and supercritical CO2 extraction conditions: 50°C, 2.60 MPa for 7 h). The two technologies resulted in different extraction capacities; the extraction with sc-CO2 allows to obtain a higher amount of long chain FA, while the liquefaction gives a higher amount of oily material. Also, the isolated yield of poly-unsaturated species (18.2, 20:4, 20:5) is higher with the sc-CO2 extraction compared to thermochemical liquefaction. Thermochemical liquefaction requires temperature around 350 and 395°C in order to have the optimal amount of extracted oil. However, as explained earlier, its composition depends on the working temperature and the content of long chain FA is higher at lower temperature as decomposition may occur at higher temperatures. Between these two technologies, the thermochemical liquefaction seems to be more efficient than the extraction with sc-CO2 from the quantitative point of view (as expected) but decomposition of the FA may occur under the operative conditions [187].

Prof. Deng’s research group has demonstrated simultaneous extraction and transesterification (in situ transesterification) of the wet algal biomass in supercritical methanol conditions [188]. In a microwave-assisted extraction and transesterification process, as it has been demonstrated in many organic and biodiesel synthesis studies, it is anticipated that the reaction can be conducted at atmospheric pressures and temperatures merely close to the boiling point of methanol with much shorter reaction time [64, 66, 118, 130, 136, 150]. The same group also performed direct extractive-transesterification of dry algal biomass and optimized process parameters using microwave heat source. Response surface methodology (RSM) was used as an optimization technique to analyze the influence of the process variables (dry algae to methanol (wt/vol) ratio, catalyst concentration, and reaction time) on the fatty acid methyl ester conversion. From experimental results and RSM analysis, they reported the optimal conditions as: dry algae to methanol (wt/vol) ratio of around 1:12, catalyst concentration about 2 wt.%, and reaction time of 4 min. The algal biodiesel samples were analyzed by GC–MS and thin layer chromatography (TLC) methods. Transmission electron microscopy (TEM) images of the algal biomass samples before and after the extraction/transesterification reaction were also presented which are shown in Figure 8[188–190].

Koberg and co-workers at Bar-Ilan University (Israel), together with their industrial research collaborators have demonstrated the direct production (extraction and transesterifcation) of biodiesel from Nannochloropsis. The marine algae was cultivated using carbon dioxide liberated from industrial flue gas emissions (coal burning power station). direct conversion of algal oil into biodiesel in a single step or by following two steps was conducted. two new innovative heating methods, namely, microwave irradiation and ultrasonication were used. These two techniques were compared to identify the most effective bio-diesel production method. Based on their studies, it was concluded that the microwave oven method was the most simple and efficient method for the one-stage direct transesterification of the as-harvested Nannochloropsis algae [191].

Microwave based biodiesel properties

The use of 100% pure vegetable or animal fats to power diesel engines is not permissible due to several drawbacks such as high fuel viscosity, low power output, thickening or gelling of the lubricating oil, oxidative stability, and low volatility resulting in carbon deposits by incomplete combustion. When biodiesel is used in its 100% purity, it is referred to as B100 or “neat” fuel. Blended biodiesel means pure biodiesel is blended with petrodiesel. Biodiesel blends are referred to as BXX. The XX indicates the amount of biodiesel in the blend (i.e., a B80 blend is 80% biodiesel and 20% petrodiesel) [44]. Commercially, these blends are named as B5, B20 or B100 to represent the volume percentage of biodiesel component in the blend with petro diesel as 5, 20 and 100 vol.%, respectively. Biodiesel obtained by microwave heating process very well compares with that obtained by other conventional methods of production. A summary of 1st generation, second generation biodiesel properties obtained by microwave processing are shown in Table 3[126, 140, 141, 144, 192–194]. Also shown in Table 3 are fuel properties of algal biodiesel from a conventional process for a comparison.

Energy needs

Energy scenario of biodiesel production

A viable alternative fuel as a substitute to fossil fuel (ex: biodiesel) will not only provide comparable or superior environmental performance but also will result in an energy gain in the overall process [195, 196]. For instance, among current food-based biofuels, biodiesel provides 93% more usable energy than the fossil energy needed for its production, reduces greenhouse gas emissions by 41% compared with diesel, reduces several major air pollutants, and has minimal impact on human and environmental health through N, P, and pesticide release. Sustainability of biodiesel production can be evaluated by a new concept called “Net energy balance” ratio. Net energy balance simply means the ratio of energy derived from the renewable feedstock (energy-out) to the energy invested (energy-in) in the process. The following expression can be used to represent the net energy balance (NEB) ratio [168]. The overall savings in energy and greenhouse gas emissions over the lifecycle of the biofuel may be less than anticipated; for example for biodiesel from oilseed rape and soya the input of energy required over the life-cycle is_50% of the energy contained in the fuel (Scott 2010).

Since the energy invested in the biodiesel production (energy required for farming, harvesting, processing, transport, etc) is derived from non-renewable energy sources such as fossil fuels, the net energy balance can also be written as follows [81]:

Sheehan reported that the fossil energy ratio of biodiesel is equal to 3.2. In other words, biodiesel yields 3.2 units of energy for every unit of fossil energy consumed over its life cycle. In comparison, it was found that petroleum diesel’s life cycle yielded only about 0.84 units of energy per unit of fossil energy consumed [197]. Few other studies have reported similar results as in [198, 199]. It may be more appealing and sustainably acceptable alternative if renewable energy sources can be utilized to produce biodiesel. this means the fossil energy input can be replaced by other renewable sources such as solar thermal, photovoltaic, geothermal and wind energy. the substitution can be in part or as a whole wherever applicable.

A life cycle analysis of microalgal biomass production was conducted between open raceway ponds and tubular photobioreactors [200]. The net energy ratio for the photobioreactor reactor proved to be a negative value considering energy requirements in its construction and material production. Net energy ratio depends on many factors such as the cultivation, harvesting, production and processing methods and can vary from each process [201]. For instance, the US DOE reported in the algal biodiesel production roadmap as follows: The energy content of most algae cells is of the order of 5 watt-hours/gram if the energy content of lipids, carbohydrates, and proteins and the typical percentage of each in algae are considered [202]. It is possible to estimate the energy requirements in watt-hours/gram of algae for harvesting, de-watering, and drying as a function of the volume percentage of algae in harvested biomass. The energy requirements for flocculation and sedimentation and the belt filter press are expected to be minimal. However, based on the latent heat of vaporization of water at 0.54 watt-hours/gram, energy balance can become an issue in systems that propose to take algal biomass and concentrate / dry it to enable downstream processing and extraction because of the high volumes of water that must be evaporated away. In spite of gaps in data precluding more detailed analyses, algal biofuel production schemes at scale will likely need to implement innovative technologies and integrated systems in order to overcome this challenge. Possible approaches may include developing strains of algae with much higher energy content than available today, along with innovative solutions to lower the energy intensity of harvesting and drying algae [168, 203, 204].

Microwave energy efficiency and requirements

Energy generation efficiency of microwaves from electrical energy is in the range of 50-65%. This means 35-50% of electrical energy is not converted into microwave energy. Again, in chemical reactions, it is an assumption that all of the microwave energy has been absorbed by the materials participating in reaction. Although microwaves have shown to increase reaction rates by 1000 times in particular chemical synthesis, the downside of it is that the energy generation process is not competitive with conventional steam based production plants with energy conversion efficiencies in the range of 65% - 90% (Electricity to steam conversion - 90%; fossil fuel to steam - 65%) [129].

The energy efficiency of a microwave assisted reaction can be calculated using the following equations. Eq. 1 represents the heat energy supplied by the microwaves which is given in terms of the power dissipation and the time of exposure. The power dissipation level of the microwave device is usually reported by the manufacturer. Eq. 4 quantifies the thermal effect caused by the microwave radiation in the sample volume (i = reactant; ex: oil, catalyst, and solvent) which is simply the product of the mass of the sample multiplied the specific heat of the material and the temperature gain during the reaction. Energy efficiency of the microwave energy is the ratio of the observed resultant temperature effect to the total energy supplied to the sample as in Eq. 3 [102].

The energy efficiency of the microwave assisted reactions depends on several factors such as the sample volume, nature of the medium (solvents), dissipation level of the microwave device and the penetration depth of the microwaves required in the reaction sample volume. Poor efficiencies can be observed when a high power microwave device is used for a very small sample volume. It is very important to consider the effective level of power dissipation in microwave assisted chemical synthesis to eliminate the energy losses to the surroundings. Patil et al found that transesterification of the Camelina Sativa oil was even successful at reduced microwave power levels using domestic microwave unit. This observation suggests that effective utilization of microwave power can lead to process energy savings [118].

Energy calculations for microwave based process need to consider the actual microwave power applied into the process. Leadbeater conducted batch and continuous flow microwave experiments using 4.6 L batch vessel and flow rates 2 L/min, 7.2 L/min. Energy consumption rates reported from this study are comparable to energy consumption by conventional method. Process energy requirements were calculated based on both actual power consumed and actual microwave power delivered (65% of the power setting) by the system. Overall conversion (oil to FAMEs) rates of 97.9 and 98.9% were reported for these tests. For instance, considering preliminary analysis for 2 L continuous flow conditions, the initial assumption was that the microwave unit would operate at an average of 66% of maximum power (1100 W microwave input; power consumed 2600 W) as observed when the reaction was performed. On the basis of this, energy consumption would be 60.3 kJ/L of biodiesel prepared. If the microwave was operating at full power (1600 W; power consumed 2600 W), energy consumption would be 92.3 kJ/L of biodiesel prepared. For a batch process, calculations were based on the process to heat a 4.6 L reaction mixture to the target temperature of 50°C which takes 3.5 min using a microwave power of 1300 W. With a hold time of 1 min at 50°C, a total reaction time of 4.5 min is given. Assuming that the microwave power remains constant at 1300 W throughout the process, the energy consumption would be 90.1 kJ/L of biodiesel prepared. In reality, the power drops once the target temperature is reached. Thus, this is an overestimation of energy consumption [110].

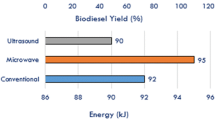

While few other studies attempted to report the energy efficiency and requirements for the microwave based biodiesel production, they are based on some rudimentary assumptions and calculations [133]. Some energy requirements are based on milliliter volumes without a measure of scale in laboratory studies [205]. This is one of the most serious drawbacks for the microwave based biodiesel process. A pilot scale demonstration study at a biodiesel production capacity of 1 ton/d may provide an estimate of actual energy requirements of the process. Results compiled from recent studies are shown in Table 4. Chand et al conducted biodiesel conversion process using ultrasonication method. They estimated an energy consumption of 91-100 kJ/L for the transesterification process with total energy requirements around 137.5 kJ/L. Their estimates at a large scale level are comparable to the conventional method [206].

Current status and potential for large scale industrial application

General microwave reactor concerns

One of the main limitations of the microwave technology reported by many experts is its inability to penetrate through large sample volumes. This limitation challenges the scalability of microwave applications from laboratory small-scale synthesis (millimolar level) to industrial multikilogram production (kmolar level). The replacement of conventional processes by microwave has several limitations. Measurement and control of temperature are difficult and temperature distribution is non-uniform in large batch reactors, it may indeed simulate thermal currents similar to conventional heating. Microwaves generally have a few centimeters depth of penetration capacity into the absorbing materials depending on their dielectric properties. As such, in large batch type reactors, the microwave power density varies greatly from outside surface to inside sample material. Therefore, materials in the center of the reaction vessel are heated only by convection and not by microwave dielectric heating. When trying to heat large quantities of materials, additional problems arise. As the volume of the mixture increases, the energy required for heating it also increases and higher radiation intensity is needed. Safety of the pressurized vessel with large quantities of batch operation needs to be considered as well.

The dissipation factor or penetration capacity of the microwave radiation depends on the factors such as ion concentration, the ions size, the dielectric constant and viscosity of the reacting medium and the microwave frequency. The dissipation factor of water and most organic solvents decreases with increasing temperature, i.e. the absorption of microwave radiation in water decreases at higher temperatures. In turn, the penetration depth of microwaves increases [102]. For some heterogeneous reactions, the microwaves may not be able to penetrate through large sample volumes. An important characteristic of microwave heating is the phenomenon of ‘hotspot’ formation, whereby regions of very high temperature form due to non-uniform heating [207]. This thermal instability arises because of the non-linear dependence of the electromagnetic and thermal properties of the material on temperature [208]. The formation of standing waves within the microwave cavity results in some regions being exposed to higher energy than others. This results in an increased rate of heating in these higher energy areas due to the non-linear dependence. Cavity design is an important factor in the control, or the utilization of this hotspot phenomenon. Considering high production flow rates, it is beneficial to design the reactor in a fashion that simulates the plug flow reactor. In this case, the sample volume exposed to microwave field can be sized to the power dissipation capacity of microwave heat source. Plug flow reactors or small quantities of batch reactions in a continuous chain type operation mode can be designed to enhance the utilization of microwave energy [209–211].

Microwave reactor design

Microwave ovens operating at 2450 MHz are common appliances in the households of USA and around the world. Hundreds of 2450 and 915 MHz systems between 10 to 200 kW heating capacities are used in the food industry for precooking bacons (e.g., used in Subways restaurants), tempering deep frozen meats when making meat patties, and precooking many other foods products. When evaluating an extraction process it is important to consider the various factors affecting it during scale up to commercial operations. In microwave processing this usually means a change in frequency from 2450 MHz to 915 MHz. Microwaves at 915 MHz (used industrially) have much higher penetration depths into the material as compared to the higher frequency of 2450 MHz commonly used in laboratory sized equipment. The higher penetration depths allow for much larger diameter tubes and processing flow rates, and microwave generators can be built for significantly higher power and efficiencies when compared to smaller generators.

Proper application of microwave energy may result in greater benefits in terms of energy efficiency and reaction product quality. Understanding the characteristics of the reactants and nature of the reactions desired is critical in many applications. In certain polymerization reactions where the reaction temperatures change with nature of the reactions (endothermic versus exothermic), a better control of the microwave power dissipation is desired. In these applications, pulsed type microwave heating rather than continuous heating might result in improved energy efficiencies without affecting the quality of the reaction products due to too high or too low reaction temperatures [31]. In some applications, the organic chemicals under study may not have the capacity to absorb the microwave energy. In such cases, it is beneficial to introduce materials that have strong microwave absorption capability. This helps initiate the desired chemical reactions using organic chemicals. Here, the materials introduced whether it is a solvent or metal particle acts both as a chemical catalyst as well as an energy converter. Also, by using a proper microwave pulse train, it is further possible to control the desired selectivity in the products formed.

Microwave reactors can be designed to function in two different modes: multimode and monomode (also referred to as single-mode) reactors. In multimode reactor instruments (which is similar to a domestic oven in concept), the microwaves that enter the cavity are reflected by the walls and the load over the typically large cavity. In most instruments a mode stirrer ensures that the field distribution is as homogeneous as possible. In the much smaller monomode cavities, the electromagnetic irradiation is directed through an accurately designed rectangular or circular wave guide onto the reaction vessel mounted at a fixed distance from the radiation source, thus creating a standing wave. The key difference between the two types of reactor systems is that in multimode cavities several reaction vessels can be irradiated simultaneously in multi vessel rotors (parallel synthesis), in monomode systems only one vessel can be irradiated at any time. In the latter case high throughput can be achieved by integrated robotics that move individual reaction vessels in and out of the microwave cavity [133].

Most instrument companies offer a variety of diverse reactor platforms with different degrees of sophistication with respect to automation, database capabilities, safety features, temperature and pressure monitoring, and vessel design. Importantly, single-mode reactors processing comparatively small volumes also have a built-in cooling feature that allows for rapid cooling of the reaction mixture with compressed air after completion of the irradiation period (see Figure 2). The dedicated single-mode instruments available today can process volumes ranging from 0.2 to about 50 mL under sealed vessel conditions (250°C, ca. 20 bar), and somewhat higher volumes (ca. 150 mL) under open-vessel reflux conditions. In the much larger multimode instruments several liters can be processed under both open- and closed-vessel conditions. Continuous-flow reactors are currently available for both single- and multimode cavities that allow the preparation of kilograms of materials by using microwave technology.