Abstract

Background

The modern society primarily relies on petroleum and natural gas for the production of fuels and chemicals. One of the major commodity chemicals 1,2-propanediol (1,2-PDO), which has an annual production of more than 0.5 million tons in the United States, is currently produced by chemical processes from petroleum derived propylene oxide, which is energy intensive and not sustainable. In this study, we sought to achieve photosynthetic production of 1,2-PDO from CO2 using a genetically engineered cyanobacterium Synechococcus elongatus PCC 7942. Compared to the previously reported biological 1,2-PDO production processes which used sugar or glycerol as the substrates, direct chemical production from CO2 in photosynthetic organisms recycles the atmospheric CO2 and will not compete with food crops for arable land.

Results

In this study, we reported photosynthetic production of 1,2-PDO from CO2 using a genetically engineered cyanobacterium Synechococcus elongatus PCC 7942. Introduction of the genes encoding methylglyoxal synthase (mgsA), glycerol dehydrogenase (gldA), and aldehyde reductase (yqhD) resulted in the production of ~22mg/L 1,2-PDO from CO2. However, a comparable amount of the pathway intermediate acetol was also produced, especially during the stationary phase. The production of 1,2-PDO requires a robust input of reducing equivalents from cellular metabolism. To take advantage of cyanobacteria’s NADPH pool, the synthetic pathway of 1,2-PDO was engineered to be NADPH-dependent by exploiting the NADPH-specific secondary alcohol dehydrogenases which have not been reported for 1,2-PDO production previously. This optimization strategy resulted in the production of ~150mg/L 1,2-PDO and minimized the accumulation of the incomplete reduction product, acetol.

Conclusion

This work demonstrated that cyanobacteria can be engineered as a catalyst for the photosynthetic conversion of CO2 to 1,2-PDO. This work also characterized two NADPH-dependent sADHs for their catalytic capacity in 1,2-PDO formation, and suggested that they may be useful tools for renewable production of reduced chemicals in photosynthetic organisms.

Similar content being viewed by others

Background

Many natural metabolites containing bi-functional groups such as succinate, lactate, and 3-hydroxybutaoate can be used as monomers to make polymers, and have long been produced biologically by fermentation processes. However, production of diols from renewable source represents unique challenges partially because they are not typical fermentation products and that they are more reduced compared to the average carbon redox state in biological systems [1]. Over the past decade, progress in synthetic biology and metabolic engineering have enabled substantial achievements in diol production [1–4], mostly from sugars, glycerol, or biomass feedstocks. Direct production of chemicals from CO2 in photosynthetic organisms [5–7] and lithoautotrophic organisms [8–10] have been proposed to be advantageous in particular situations. This work aims to produce 1,2-propanediol (1,2-PDO) directly from CO2 by an engineered cyanobacterium, Synechococcus elongatus PCC 7942.

The racemic 1,2-PDO can find applications in antifreeze and heat transfer fluids, plasticizers and thermoset plastics, and cosmetics [11]. 1,2-PDO is naturally produced by anaerobic microorganisms such as Thermoanaerobacterium thermosaccharolyticum[12]. It has also been produced by engineered E.coli[3, 11, 13], Corynebacterium glutamicum[14], Saccharomyces cerevisiae[15, 16], and Pichia Pastoris[17] from glycerol or sugar. Consistent with the fermentative nature of the pathway in its native host, 1,2-PDO production in heterologous hosts only achieved relatively high titer (4.5 ~ 6.5g/L) in anaerobic fermentation. However, cyanobacterium S. elongatus produces O2 in the light reaction of photosynthesis (Figure 1A) and does not perform fermentation in light. Moreover, CO2 is a more oxidized substrate than sugar or glycerol and therefore requires more energy and reducing equivalents to be converted to the product. Here we report introduction of the heterologous 1,2-PDO production pathway into S. elongatus and subsequent tailoring of the pathway to fit in the metabolism of this photosynthetic CO2-fixing host.

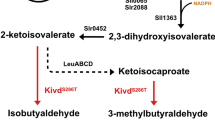

The pathway for 1,2-Propanediol (1,2-PDO) production from CO 2 in Synechococcus elongatus PCC 7942. A) Light reaction of photosynthesis generates ATP and reducing equivalents NADPH, which power the CO2 fixation through Calvin cycle and the synthetic 1,2-PDO production pathway. gldA, yqhD and mgsA are from E.coli. Secondary alcohol dehydrogenases (sADHs) are from C. beijerinckii and T. brockii. DHAP, dihydroxyacetone phosphate. GAP, glyceraldehyde-3-phosphate. F6P, fructose-6-phophate. B) Two possible pathways for 1,2-Propanediol synthesis from methylglyoxal.

Results and discussion

Designing of the 1,2-PDO production pathway

In light conditions, cyanobacteria fix CO2 via the Calvin-Benson-Bassham (CBB) cycle which is powered by ATP and NADPH generated by the photosystems (Figure 1A). Two CBB cycle intermediates, fructose-6-phosphate (F6P) and glyceraldehydes-3-phosphate (GAP), serve as the branch points of carbon leaving the CBB cycle to the central metabolism for glycogen synthesis and glycolysis, respectively. While glycogen synthesis is the major carbon and energy storage pathway, glycolysis and TCA cycle produce building blocks for cell growth. The synthesis of 1,2-PDO, on the other hand, starts from another CBB cycle intermediate, dihydroxyacetonephosphate (DHAP). The introduction of one extra branch point can potentially increase the flux of output carbon from the CBB cycle, which has been suggested to be beneficial for increasing photosynthesis efficiency in higher plants [18, 19], but may also disrupt the normal flux distribution in the cell.

To synthesize 1,2-PDO, DHAP is first converted to methylglyoxal (Figure 1A) by methylglyoxal synthase (encoded by mgsA in E. coli). Methyglyoxal is very toxic to the cells [11] and needs to be efficiently utilized by downstream enzymes. Two different metabolic routes have been shown to synthesize 1,2-PDO from methyglyoxal (Figure 1B) [11]. The first involves reduction of methyglyoxal by the glycerol dehydrogenase (encoded by gldA in E. coli) to lactaldehyde, which is further reduced by the 1,2-propanediol reductase (encoded by fucO in E.coli) to yield the final product. The second route includes an alcohol dehydrogenase (such as the broad-substrate range aldehyde reductase encoded by yqhD in E. coli) to produce acetol as the intermediate, which is then converted to 1,2-PDO by gldA. The latter route was chosen to introduce into S. elongatus because yqhD gene has been previously overexpressed in this organism for biofuel production and showed relatively good performance, possibly due to its NADPH-specific cofactor preference.

Introduction of the 1,2-PDO biosynthesis genes

As described above, the genes mgsA, yqhD, and gldA from E. coli are needed to construct the 1,2-PDO biosynthesis pathway in S. elongatus from the CBB cycle intermediate DHAP (Figure 1A, B). These genes were cloned into an artificial operon driven by the Ptrc promoter under the control of lacO (Figure 2A). The operon was inserted into the S. elongatus chromosome by homologous recombination at the Neutral Site I (NSI). A lacI gene and a spectinomycin resistant gene were also inserted together with the operon to achieve inducible gene expression (Additional file 1: Figure S2) and facilitate antibiotics selection, respectively. The resulting strain was named LH21.

Construction of the 1,2-propanediol pathways. (A) Illustration of artifical operons inserted into the Synechococcus elongatus PCC 7942 Neutral Site I (NSI) to build strains LH21, LH22, and LH23. gldA, yqhD and mgsA are from E.coli. Secondary alcohol dehydrogenases (sADHs) are from C. beijerinckii and T. brockii. (B) Test of the total RNA quality and the RT-PCR system using housekeeping gene rnpB. (C) Verification of the heterologous gene expression in engineered cyanobacteria strains by RT-PCR.

To check if all the genes were successfully introduced and transcribed, reverse transcription polymerase chain reaction (RT-PCR) was performed. After induction with Isopropyl β-D-1-thiogalactopyranoside (IPTG), total RNA was extracted from LH21 and wildtype S. elongatus PCC 7942. RT-PCR of the house keeping gene rnpB, whose transcription product is the RNA component of RNase P, was performed to verify the RT-PCR system. Using the rnpB specific primers, PCR products were obtained using cDNA synthesized from both wildtype and LH21 total RNA (Figure 2B). On the other hand, the no-reverse-transcriptase (NRT) controls did not yield any products, suggesting that the genomic DNA contamination during the total RNA extraction was minimal and that the positive signals of RT-PCR are representative for the transcription of the target genes. Using the verified system, mgsA, yqhD, and gldA genes from E. coli were tested and showed to have expression in LH21 under inductive condition (Figure 2C). Activity assays using cell lysate further suggested that these heterologous enzymes were functional in cyanobacterial cells (Figure 3A, B, Additional file 1: Figure S1).

Optimization of the 1,2-Propanediol production by exploiting different acetol-reducing enzymes. LH22 and LH23 were constructed which harbored C. beijerinckii and T. brockii. sADH. A) methylglyoxal synthase activities were measured using cell lysate of LH21, LH22, and LH23, showing that mgsA was functionally overexpressed in all three strains. To confirm the functional expression of yqhD, NADPH-dependent methylglyoxal reduction activities were also measured (See Additional file 1: Figure S1 and text in supporting material), although assay method with higher specificity needs to be developed. (B), (C) NADPH- and NADH-dependent acetol reduction activities measured using cell lysates of the wildtype Synechococcus elongatus PCC 7942 and engineered strains that overexpress gldA from E.coli (LH21), adh from C. beijerinckiiadh (LH22), and adh from T. brockiadh (LH23). (D) Acetol and 1,2-Propanediol accumulated by different strains after 10 days of production.

Production of 1,2-PDO

1,2-PDO production by LH21 was performed under high light condition (100 μE/s/m2) with 50mM bicarbonate supplementation in the medium. After induction, LH21 produced around 16mg/L 1,2-PDO in 4 days, with the highest production rate of 7mg/L/day. However, although no defect in cell growth was seen, the production rate decreased rapidly and the total titer was only around 22mg/L after 10 days (Figure 4A, B). The drastically decreased and eventually ceased production by LH21 led to one hypothesis: key substrate(s) might become limited at certain stage of cell growth which decreased the flux of the synthetic 1,2-PDO production pathway. Three substrates are needed to produce 1,2-PDO in LH21: NADPH, NADH, and DHAP (Figure 1A, B). Among these substrates, NADPH and DHAP are made through photosynthesis light and dark reactions (Figure 1A), respectively, and could be continuously generated under light condition. However, NADH may mainly be generated by the NADH-dependent glyceraldehyde-3-phosphate dehydrogenase in the glycolysis [20]. And the reaction catalyzed by the putative NADH-dependent malate dehydrogenase in TCA cycle may also contribute to the cellular NADH level. It has been suggested that the main function of glycolysis and TCA cycle in cyanobacteria is to generate essential metabolites for biomass synthesis under light conditions, rather than to produce reducing equivalents and energy [21]. As such, when the growth rate of LH21 cells slowed down in the stationary phase, the activities of these NADH generating pathways may also decrease.

If NADH is really the limiting factor in our production scenario, the partially reduced intermediate acetol may accumulate. In fact, at the end of the production, around 16mg/L acetol was accumulated, which was comparable to the level of 1,2-PDO (~22mg/L) (Figure 3D). In addition, acetol was only detected after 4 days and kept accumulating during the late stage of production (data not shown). These results are consistent with the above-mentioned hypothesis and suggest that the NADH-dependent reduction of acetol catalyzed by gldA might be the limiting step in the 1,2-PDO production pathway.

Improving 1,2-PDO production using NADPH-dependent secondary alcohol dehydrogenases

To overcome the bottleneck of the 1,2-PDO production in LH21, one possible strategy is to overexpress the soluble transdehydrogenase (STH) which produces NADH at the expense of NADPH. However, genes encoding this enzyme have not been found in S. elongatus genome. Heterologous overexpression of the Pseudomonas aeruginosasth gene in cyanobacteria has been shown to be instable and caused growth defect [22].

Alternatively, it could be beneficial to find the NADPH-dependent counterpart of gldA. To convert acetol to 1,2-PDO, a hydroxyl group on the secondary carbon has to be made, which can be catalyzed by the secondary alcohol dehydrogenase (sADH) family of enzymes. Several sADHs have been characterized previously that are NADPH-dependent [4], including the sADH encoded by the adh gene in Thermoanaero bacterbrockii[23] and Clostridium beijerinckii[24]. To test their catalytic activity for the substrate acetol, these two sADHs as well as the E. coli gldA were purified and their kinetics parameters were measured (Table 1). The kinetics studies showed that the C. beijerinckii sADH has the highest K cat among all three enzymes tested. However, the large K m value of C. beijerinckii sADH suggested that the enzyme has relatively low affinity to the substrate acetol. On the other hand, the T. bacterbrockii sADH has the highest acetol affinity and a two-fold higher K cat than that of the gldA enzyme, which is the most commonly used enzyme for this reaction step in previous studies. In summary, these two sADH have distinct kinetic features and both showed activity towards the substrate acetol, which suggested that they may be used in cyanobacterial cells for 1,2-propanediol production in vivo.

C. beijerinckii and T. brockii adh were cloned and introduced into the cyanobacterial genome to replace gldA. The resulting strains are named LH22 and LH23, respectively (Figure 2A). RT-PCR was also performed to verify the expression of these genes (Figure 2B, C). Enzyme assays with crude cell extract of LH22 and LH23 further verified that both C. beijerinckii and T. brockii sADH were functionally overexpressed and showed higher activities of NAD(P)H-dependent acetol reduction compared to that in LH21. Especially, the C. beijerinckii sADH overexpression in LH22 delivered the highest activity (Figure 3B, C).

Production using strains LH22 and LH23 yielded significantly higher 1,2-PDO titer (~150 and 80mg/L, respectively) compared to that of LH21 (Figure 4B). Notably, the high production rate was maintained through the 10 days of production. In consistent with the hypothesis mentioned in the previous section, the high level of NADPH-dependent acetol reduction activity in LH22 and LH23 also significantly reduced the accumulation of the intermediate acetol (Figure 3D).

Despite its great significance to metabolic engineers, the information on intracellular NAD(P)H level during different growth phases and growth conditions in cyanobacteria is very limited. Although it is believed that NADPH is more abundant than NADH in cyanobacteria [25], only a few studies discussed its role in biofuel/biochemical synthesis from CO2[6, 22]. The science behind efficient conversion of CO2 to chemicals and fuels is still in its infancy and the NADPH driving force theory still needs to be extensively tested, which requires the accumulation of empirical evidence in more production scenario, as well as fundamental studies on NAD(P)H levels and their regulation. In our case, other factors may also contribute to the difference between the production levels of the NADH and NADPH-dependent pathways. For example, the NADPH-dependent enzymes may be better folded and more active when expressed in cyanobacteria. And different level of physiological fitness may be caused by overespression of different enzymes, although all production strains showed the same growth phenotype as the wildtype.

Conclusion

In this work, we demonstrated the 1,2-PDO production from CO2 for the first time by the engineered cyanobacterium S. elongatus PCC 7942. By exploiting sADHs which have not been reported for 1,2-PDO production previously, a completely NADPH dependent pathway was built to channel the CBB cycle intermediate DHAP for 1,2-PDO production without accumulating the pathway intermediate, acetol. The best strain LH22, which harbors mgsA and yqhD both from E. coli and the adh from C. beijerinckii, produced ~150mg/L 1,2-PDO.

This work revealed the great potential of the vast NADPH pool in photosynthetic cyanobacteria as a robust driving force for the production of chemicals. Among the chemicals that have been produced biologically in industrial scale, a significant number of them are synthesized by NADPH consuming pathways. For example, in amino acid production, studies have shown that increasing the NADPH pool can improve the production performance [26, 27]. However, in most of the heterotrophic microorganisms, NADPH is mainly generated through the pentose phosphate pathway and TCA cycle and its pool size is relatively small compared to that of the NADH. On the other hand, photosynthetic organisms maintain high intracellular NADPH level. The unique metabolic feature of photosynthetic organisms provides great opportunities for the production of chemicals through NADPH dependent pathways.

Methods

Chemicals and reagents

All chemicals were purchased from Sigma-Aldrich (St. Louis, MO) or Fisher Scientifics (Pittsburgh, PA). Restriction enzymes were purchased from New England BioLabs (Ipswich, MA). The Rapid DNA ligation kit was from Roche (Mannheim, Germany). KOD DNA polymerase was from EMD Chemicals (San Diego, CA). Oligonucleotides were purchased from IDT (San Diego, CA).

Medium and culture condition

All S. elongatus PCC 7942 strains were grown on BG-11 medium (Sigma-Aldrich) containing 50mM NaHCO3 in shake flasks. Plates contain 1.5% (w/v) agar. For 1,2-PDO production, 50mL culture was grown in 250mL shake flasks under 100 μE/s/m2 light supplied by four Lumichrome F30W-1XX 6500K 98CRI light tubes, at 30°C. Cell growth was monitored by measuring OD730. 1mM IPTG was added to induce the gene expression at OD730 of around 1. Daily, samples were taken for analysis and 50mM NaHCO3 was added. IPTG concentration in the culture was maintained to 1mM by adding appropriate amount of fresh IPTG to compensate the IPTG lost from sampling. Spectinomycin was added for LH21, LH22, and LH23 at a final concentration of 20mg/L. E. coli strains were grown in LB medium. And a spectinomycin concentration of 50mg/L was used where appropriate.

Plasmid construction

All cloning and plasmid preparation were done using E. coli XL1-blue cells (Stratagene, La Jolla, CA). Detained information about plasmids and primers used in this study can be found in Table 2 and Table 3.

Briefly, to construct plasmid GYM, gldA, mgsA, and yqhD were amplified from E. coli genomic DNA using primer pairs gldA SpeI fwd/gldA_YqhD rev, gldA_YqhD fwd/YqhD_mgsA rev, and YqhD_mgsA fwd/mgsA NotI rev, respectively. The PCR products were purified and linked into an artificial operon using Splicing by overhang extension (SOE) PCR using primers gldA SpeI fwd/mgsA NotI rev. The PCR product was digested with restriction enzymes SpeI and NotI and then inserted into the NSI targeting vector pAM2991. The CYM and TYM plasmids were constructed similarly. The C. beijerinckii adh and T. brockii adh genes were amplified from plasmids pZE12-alsS-alsD-CBADH and pZE12-alsS-alsD-TBADH [4], respectively, using primer pairs CBSADH SpeI fwd/CBSADH_yqhD rev and TBSADH SpeI fwd/TBSADH_yqhD rev, respectively. In order to amplify yqhD gene that have overlapping region with the C. beijerinckii adh and T. brockii adh, the forward primer for yqhD amplification was CBSADH_yqhD fwd and TBSADH_yqhD fwd, respectively.

To purify the 6xHis-tagged gldA and secondary alcohol dehydrogenases, plasmids his-gldA, his-CB, and his-TB were constructed. Briefly, the T5 promoter/lacO and 6xHis tag fragment of pQE-9 (Qiagen) was amplified using primers pQE XhoI fwd and pQE Acc65I rev and then digested and inserted at XhoI/Acc65I sites of the plasmid pZElac [29]. The resulted plasmid was named pZElac-his. To insert the E. coli gldA, C. beijerinckii adh and T. brockii adh genes in pZElac-his, the isothermal DNA assembly method [30] was used. The primers his ad up rev and his ad down fwd were used to amplify the vector backbone using pZElac-his as template. And the primer pairs his ad up_gldA fwd/his ad down_gldA rev, his ad up_CB fwd/his ad down_CB rev, and his ad up_TB fwd/his ad down_TB rev were used to amplify the corresponding genes. The gene amplification products were assembled with the backbone.

Protein purification and enzyme kinetics study

The plasmid his-gldA, his-CB, and his-TB were transformed into BL21 cells. The transformants were cultured in 40 mL LB medium containing 100mg/L ampicillin. After the cells reached mid-log phase, 1mM IPTG was added to induce protein expression followed by incubation at 30°C overnight. The cells were collected by centrifugation and the recombinant proteins were purified using His-Spin Protein Miniprep kit (Zymo research Corporation, CA) according to the manufacturer’s instructions. The purified proteins were checked by SDS-PAGE for homogeneity and quantified by Bradford assay (Bio-Rad, Hercules, CA).

Dehydrogenase activity was measured by monitoring the absorbance decrease of NADH or NADPH at wavelength of 340 nm. To determine the kinetic parameters, the assay reaction was prepared with Tris-HCl buffer (50 mM, pH = 7.5) containing 200 μM of NADH or NADPH and various concentration of acetol ranging from 0.05 mM to 20 mM at room temperature. The K m and K cat values were obtained by non-linear fitting with the Michaelis–Menten equation.

Transformation and selection

S. elongatus PCC7942 cells transformed as described [31]. The transformed cells were spread on BG-11 plates with 20mg/ml spectinomycin and incubated in light to select for recombinants. Colonies were verified by PCR and inoculated into liquid BG-11 medium with 20 mg/ml spectinomycin for further tests.

Enzyme assays

For sADH enzyme assays, different cyanobacterial strains were grown in 30mL BG-11 medium in 125mL shake flask under light condition and induced with 1mM IPTG at the OD730 of around 1. After overnight induction, cells were harvested and resuspended in 1mL Buffer A (100mM Tris-HCl, pH = 8.0). Cell lysates were prepared by bead beating followed by centrifugation at 10,000 × g for 20min at 4°C. Cell. 10μL cell lysate was used in 200μL reaction system which also contained 100mM Tris-HCl, pH = 8.0, 200μL NAD(P)H, and 20mM acetol (or no substrate for negative control). The reaction was started by adding the substrate, and the OD340 was monitored. The soluble protein concentrations in cell lysates were quantified using Quick Start Bradford Protein Assay (Bio-Rad, CA) according to manufacturer’s instructions. Similar method was used to determine the activity of methylglyoxal reduction.

The activity of methylglyoxal synthase was determined by the previously reported method [32]. Briefly, the reaction mixture at 30°C contained, in 0.5 ml: Tris-HCl buffer, pH7.5 (50mM), dihydroxyacetone phosphate (20mM) and cell lysate. The reaction was allowed to proceed for 10min. The methylglyoxal formed was measured colorimetrically by taking 0.1 ml samples into 0.33 ml of 2,4-dinitrophenylhydrazine reagent (0.1% 2,4-dinitrophenylhydrazine in 2M-HCI) plus 0.9ml of water. After incubation at 30°C for 15min, 1.67ml of 2.5M NaOH was added and the OD555 measured after a further 15min. A molar extinction coefficient of 4.48 × 104 was used to convert the readings into nmol of methylglyoxal.

RT-PCR

For RT-PCR enzyme assays, different cyanobacterial strains were grown in 30mL BG-11 medium in 125mL shake flask under light condition and induced with 1mM IPTG at the OD730 of around 1. After overnight induction, total RNA was extracted using RiboPure-Bacteria Kit (Life Technologies, NY). RNA was quantified using Nanodrop. After treatment with the TURBO DNA-free kit (Life Technologies, NY), cDNA was synthesized using iScript cDNA Synthesis kit (Bio-Rad, CA). PCR was performed using the specific primers listed in Table 2. The PCR product was then checked by electrophoresis on 2% agarose gel and stained with ethidium bromide.

Quantification of 1,2-PDO and acetol

1mL samples were taken daily from production culture. After centrifugation, the supernatant was taken for 1,2-PDO and acetol analysis by Agilent 1200 highpressure liquid chromatography (HPLC) system equipped with an autosampler (Agilent Technologies),a Bio-Rad (Bio-Rad Laboratories, Hercules, CA) Aminex HPX87 column (5 mM H2SO4, 0.6 mL/min, column temperature at 35°C) and a refractive index detector (RID) module.

References

Yim H, Haselbeck R, Niu W, Pujol-Baxley C, Burgard A, Boldt J, Khandurina J, Trawick JD, Osterhout RE, Stephen R, et al: Metabolic engineering of Escherichia coli for direct production of 1, 4-butanediol. Nat Chem Biol. 2011, 7 (7): 445-452. 10.1038/nchembio.580

Nakamura CE, Whited GM: Metabolic engineering for the microbial production of 1, 3-propanediol. Curr Opin Biotechnol. 2003, 14 (5): 454-459. 10.1016/j.copbio.2003.08.005

Altaras NE, Cameron DC: Metabolic engineering of a 1, 2-propanediol pathway in Escherichia coli. Appl Environ Microbiol. 1999, 65 (3): 1180-1185.

Yan Y, Lee C-C, Liao JC: Enantioselective synthesis of pure (R, R)-2, 3-butanediol in Escherichia coli with stereospecific secondary alcohol dehydrogenases. Org Biomol Chem. 2009, 7 (19): 3914-3917. 10.1039/b913501d

Atsumi S, Higashide W, Liao JC: Direct photosynthetic recycling of carbon dioxide to isobutyraldehyde. Nat Biotechnol. 2009, 27 (12): 1177-1180. 10.1038/nbt.1586

Lan EI, Liao JC: ATP drives direct photosynthetic production of 1-butanol in cyanobacteria. Proc Natl Acad Sci U S A. 2012, 109 (16): 6018-6023. 10.1073/pnas.1200074109

Ducat DC, Way JC, Silver PA: Engineering cyanobacteria to generate high-value products. Trends Biotechnol. 2011, 29 (2): 95-103. 10.1016/j.tibtech.2010.12.003

Nevin KP, Woodard TL, Franks AE, Summers ZM, Lovley DR: Microbial electrosynthesis: feeding microbes electricity to convert carbon dioxide and water to multicarbon extracellular organic compounds. MBio. 2010, 1 (2): e00103-10.

Hawkins AS, Han Y, Lian H, Loder AJ, Menon AL, Iwuchukwu IJ, Keller M, Leuko TT, Adams MWW, Kelly RM: Extremely thermophilic routes to microbial electrofuels. ACS Catalysis. 2011, 1 (9): 1043-1050. 10.1021/cs2003017. 10.1021/cs2003017

Li H, Opgenorth PH, Wernick DG, Rogers S, Wu TY, Higashide W, Malati P, Huo YX, Cho KM, Liao JC: Integrated electromicrobial conversion of CO2 to higher alcohols. Science. 2012, 335 (6076): 1596-, 10.1126/science.1217643

Clomburg JM, Gonzalez R: Metabolic engineering of Escherichia coli for the production of 1, 2-propanediol from glycerol. Biotechnol Bioeng. 2011, 108 (4): 867-879. 10.1002/bit.22993

Cameron DC, Cooney CL: A novel fermentation: the production of R(-)-1, 2-propanediol and acetol by clostridium thermosaccharolyticum. Nat Biotech. 1986, 4 (7): 651-654. 10.1038/nbt0786-651. 10.1038/nbt0786-651

Altaras NE, Cameron DC: Enhanced production of (R)-1, 2-propanediol by metabolically engineered Escherichia coli. Biotechnol Prog. 2000, 16 (6): 940-946. 10.1021/bp000076z

Niimi S, Suzuki N, Inui M, Yukawa H: Metabolic engineering of 1, 2-propanediol pathways in Corynebacterium glutamicum. Appl Microbiol Biotechnol. 2011, 90 (5): 1721-1729. 10.1007/s00253-011-3190-x

Jeon E, Lee S, Kim D, Yoon H, Oh M, Park C, Lee J: Development of a Saccharomyces cerevisiae strain for the production of 1, 2-propanediol by gene manipulation. Enzyme Microb Technol. 2009, 45 (1): 42-47. 10.1016/j.enzmictec.2009.03.009. 10.1016/j.enzmictec.2009.03.009

Jung JY, Yun HS, Lee J, Oh MK: Production of 1, 2-propanediol from glycerol in Saccharomyces cerevisiae. J Microbiol Biotechnol. 2011, 21 (8): 846-853. 10.4014/jmb.1103.03009

Barbier GG, Ladd JL, Campbell ER, Campbell WH: Genetic modification of Pichia Pastoris for production of propylene glycol from glycerol. International Journal of Genetic Engineering. 2011, 1 (1): 6-13.

Ducat DC, Avelar-Rivas JA, Way JC, Silver PA: Rerouting carbon flux to enhance photosynthetic productivity. Appl Environ Microbiol. 2012, 78 (8): 2660-2668. 10.1128/AEM.07901-11

Miyagawa Y, Tamoi M, Shigeoka S: Overexpression of a cyanobacterial fructose-1, 6-/sedoheptulose-1, 7-bisphosphatase in tobacco enhances photosynthesis and growth. Nat Biotechnol. 2001, 19 (10): 965-969. 10.1038/nbt1001-965

Koksharova OA, Brandt U, Cerff R: The gap1 operon of the cyanobacterium Synechococcus PCC 7942 carries a gene encoding glycogen phosphorylase and is induced under anaerobic conditions. Mikrobiologiia. 2004, 73 (3): 388-392.

Zhang S, Bryant DA: The tricarboxylic acid cycle in cyanobacteria. Science. 2011, 334 (6062): 1551-1553. 10.1126/science.1210858

Angermayr SA, Paszota M, Hellingwerf KJ: Engineering a cyanobacterial cell factory for the production of lactic acid. Appl Environ Microbiol. 2012, 78 (19): 7098-106. 10.1128/AEM.01587-12

Lamed RJ, Zeikus JG: Novel NADP-linked alcohol–aldehyde/ketone oxidoreductase in thermophilic ethanologenic bacteria. Biochem J. 1981, 195 (1): 183-190.

Ismaiel AA, Zhu CX, Colby GD, Chen JS: Purification and characterization of a primary-secondary alcohol dehydrogenase from two strains of Clostridium beijerinckii. J Bacteriol. 1993, 175 (16): 5097-5105.

Tamoi M, Miyazaki T, Fukamizo T, Shigeoka S: The Calvin cycle in cyanobacteria is regulated by CP12 via the NAD(H)/NADP(H) ratio under light/dark conditions. Plant J. 2005, 42 (4): 504-513. 10.1111/j.1365-313X.2005.02391.x

Takeno S, Murata R, Kobayashi R, Mitsuhashi S, Ikeda M: Engineering of Corynebacterium glutamicum with an NADPH-generating glycolytic pathway for L-lysine production. Appl Environ Microbiol. 2010, 76 (21): 7154-7160. 10.1128/AEM.01464-10

Marx A, Hans S, Mockel B, Bathe B, de Graaf AA, McCormack AC, Stapleton C, Burke K, O’Donohue M, Dunican LK: Metabolic phenotype of phosphoglucose isomerase mutants of Corynebacterium glutamicum. J Biotechnol. 2003, 104 (1–3): 185-197.

Ivleva NB, Bramlett MR, Lindahl PA, Golden SS: LdpA: a component of the circadian clock senses redox state of the cell. EMBO J. 2005, 24 (6): 1202-1210. 10.1038/sj.emboj.7600606

Zhang K, Li H, Cho KM, Liao JC: Expanding metabolism for total biosynthesis of the nonnatural amino acid L-homoalanine. Proc Natl Acad Sci U S A. 2010, 107 (14): 6234-6239. 10.1073/pnas.0912903107

Gibson DG, Young L, Chuang RY, Venter JC, Hutchison CA, Smith HO: Enzymatic assembly of DNA molecules up to several hundred kilobases. Nat Methods. 2009, 6 (5): 343-345. 10.1038/nmeth.1318

Golden SS, Brusslan J, Haselkorn R: Genetic engineering of the cyanobacterial chromosome. Methods Enzymol. 1987, 153: 215-231.

Hopper DJ, Cooper RA: The purification and properties of Escherichia coli methylglyoxal synthase. Biochem J. 1972, 128 (2): 321-329.

Acknowledgement

We thank Dr. Yajun Yan for helpful discussion and the plasmids pZE12-alsS-alsD-CBADH and pZE12-alsS-alsD-TBADH. We thank Dr. Wendy Higashide for assistance on experiments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contribution

HL designed and performed the experiments and analyzed the data. HL and JCL prepared the manuscript. Both authors read and approved the final manuscript.

Electronic supplementary material

12934_2012_796_MOESM1_ESM.docx

Additional file 1: Measurement of the NADPH-dependent methylglyoxal reduction activity in production strains and inducibility of the synthetic pathways. (DOCX 22 KB)

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

This article is published under license to BioMed Central Ltd. This is an Open Access article distributed under the terms of the Creative Commons Attribution License (http://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Li, H., Liao, J.C. Engineering a cyanobacterium as the catalyst for the photosynthetic conversion of CO2 to 1,2-propanediol. Microb Cell Fact 12, 4 (2013). https://doi.org/10.1186/1475-2859-12-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/1475-2859-12-4