Abstract

Background

Pectate lyases (PELs) play an important role in the infection process of plant pathogens and also have a commercial significance in industrial applications. Most of the PELs were expressed as soluble recombinant proteins, while a few recombinant proteins were insoluble. The production of a large-scale soluble recombinant PEL would allow not only a more detailed structural and functional characterization of this enzyme but also may have important applications in the food industry.

Results

We cloned a new pectate lyase gene (Pcpel2) from Phytophthora capsici. Pcpel2 was constructed by pET system and pMAL system, and both constructs were used to express the PCPEL2 in Escherichia coli BL21 (DE3) pLysS. The expressed products were purified using affinity chromatography and gel filtration chromatography. The purity, specific activity and pathogenicity of the purified PCPEL2 expressed by the pMAL system were higher than the purified PCPEL2 expressed by the pET system. In addition, some other characteristics of the purified PCPEL2 differed from the two systems, such as crystallographic features. Purified PCPEL2 expressed by the pMAL system was crystallized by the hanging-drop vapour-diffusion method at 289 K, and initial crystals were grown.

Conclusion

The two different methods and comparison presented here would be highly valuable in obtaining an ideal enzyme for the downstream experiments, and supply an useful alternative to purify some insoluble recombinant proteins.

Similar content being viewed by others

Background

Phytophthora capsici is a phytopathogenic oomycete that causes severe disease in a wide variety of plant species. During infection, pathogens produce a diverse range of cell wall-degrading enzymes, including cellulases, hemicellulases and pectinases [1]. Pectinases can degrade pectin which is a major component of the primary cell wall and middle lamella of plants. According to the action mode, pectinase can be divided into three different types: polygalacturonase, pectin methyl esterase and pectate lyase (EC 4.2.2.2) [2].

Pectate lyases (PELs), which cleave glycosidic bonds of pectate or low methylated pectin by a trans-eliminative mechanism to yield unsaturated products, are widely distributed among microorganisms, such as P. capsici[3, 4]. PELs are enzymes which specifically catalyze the cleavage of the α-1,4-glycosidic linkages in the unesterified polygalacturonic acid (PGA) regions of plant cell walls and produce an unsaturated bond between C4 and C5 of each d-galacturonic acid unit [5, 6], resulting in tissue maceration and cell death due to osmotic fragility [7]. Polysaccharide lyases are classified into 15 different families, including five families of PELs identified as family number 1, 2, 3, 9, and 10 [8, 9]. PELs are distinguished by both specificity for a glycosidic linkage and different optimal pH [10]. Most PELs are active in the pH range 8-11, and Ca2+ is required for enzymatic activity [11, 12], while some members depend on Co2+, Mn2+, and Ni2+[13].

Besides playing an important role in the infection process of various pathogens and fruit ripening, PELs have great commercial significance in industrial applications, such as extraction and clarification of fruit juices [14, 15], maceration of vegetables, scoring of cotton fabric, and retting of flax [16]. There is a high interest to improve the quality and efficiency of the PELs for industrial applications.

Genes encoding PELs have been cloned from a variety of species, including Erwinia chrysanthemi[17], Zinnia elegans[18], Meloidogyne javanica[19], Strawberry [20], etc. Some have been further characterized by tertiary structure of the protein sequence and biochemical properties of the enzyme [21, 22]. Most of the PELs were expressed as soluble recombinant proteins, such as PelW [23] and PelC [24] expressed in prokaryotic organism, and Pel1 [25] expressed in eukaryotic cells. A few recombinant proteins were insoluble [26], and the inclusion bodies required solubilization in 8 M urea.

Preparation of large-scale soluble protein can provide a basis for detailed structural and functional studies and ultimately improve our understanding of PEL. In the present study, we report the expression and purification of a new PEL from P. capsici using the pET and the pMAL systems. We identified important differences in the characteristics of the recombinant PELs produced by these two methods.

Results and discussion

Expression and purification of 6 × His-PCPEL2

The mature fragment of Pcpel2 (1137 bp) without introns was obtained and cloned into a pET28a expression vector. The recombinant plasmid was transformed into E. coli BL21 (DE3) pLysS cells, following by induction under the T7 promoter with 1 mM IPTG for 20 h at 16°C. The predicted molecular mass of the recombinant protein 6 × His-PCPEL2 is 44 kDa. After being lysed by sonication, there was little target protein (6 × His-PCPEL2) in supernatant at pH 7.0-9.0 buffer (10 mM Tris-HCl, 150 mM NaCl) (Figure 1, Lanes 1 and 2). The insoluble particles were solubilized with buffer A (10 mM Tris-HCl pH 10.3 containing 150 mM NaCl, 2 M urea, 10 mM imidazole and 5 mM β-mercaptoethanol), and then most of the expressed recombinant proteins were soluble (Figure 1, Lane 3). Both the higher pH (pH 10.3) and the urea were essential for the solubilization of the recombinant protein 6 × His-PCPEL2. After a series of purification steps (Table 1), the purified protein was more than 90% purity by SDS-PAGE stained with Coomassie brilliant blue (Figure 2A, Lane 1). Analysis by SDS-PAGE showed a significant amount of a 44 kDa protein containing a 6 × His tag at the N-terminus of PCPEL2, in agreement with the predicted molecular weight for this protein. The protein was also recognized by western blot analysis (Figure 2B, Lane 1).

Solubilization of PCPEL2 expressed by pET system. Lane M, molecular mass marker; lanes 1 and 2, the supernatant of fusion protein after ultrasonication at pH 7.0 and 9.0 buffer (10 mM Tris-HCl, 150 mM NaCl); lane 3, the supernatant of fusion protein after ultrasonication with suspending buffer (10 mM Tris-HCl pH 10.3 containing 150 mM NaCl, 2 M urea, 10 mM imidazole and 5 mM β-mercaptoethanol). The over-expressed protein is indicated by the arrow.

Expression and purification of MBP-PCPEL2

PCPEL2 was over-expressed as a soluble protein in E. coli using pMAL expression system. It is shown from SDS-PAGE analysis that cell lysate dominantly reveals a 86 kDa band (Figure 3, Lane 2), corresponding 42 kDa MBP plus 44 kDa PCPEL2. The expressed MBP-PCPEL2 comprised 40% of the total protein, most of which was soluble. The soluble fusion protein dissolved in buffer 1 (10 mM Tris-HCl pH 7.5 containing 150 mM NaCl and 5 mM β-mercaptoethanol) was firstly purified by Amylose Resin column based on MBP affinity (Figure 3, Lane 3). To remove the affinity tag from fusion protein MBP-PCPEL2, an enzymatic cleavage procedure was conducted with human rhinovirus 3C protease, a protease specific for a spacer sequence between MBP and PCPEL2. The result implies that the human rhinovirus 3C protease can efficiently cleave the corresponding tag fused to the target protein. To separate the PCPEL2 from the enzymatic mixture of MBP-PCPEL2, we tried a method of amylose re-affinity. The PCPEL2 purity was about 95% and showed a significant amount of a 44 kDa protein, as analyzed by SDS-PAGE (Figure 2A, Lane 2). The protein was further verified by western blot analysis (Figure 2B, Lane 2).

Expression and purification of fusion protein expressed by pMAL system. Lane M, molecular mass marker; lanes 1, un-induced bacterial lysate; lane 2, IPTG-induced culture; lane 3, product eluted from the Amylose Resin column (arrow indicates a 86 kDa purified fusion protein, corresponding to the 42 kDa MBP plus 44 kDa PCPEL2).

In vitro and in vivoactivity assay

The activity of the purified PCPEL2 was analyzed both in vitro and in vivo. The specific activity towards Polygalacturonic Acid of the purified PCPEL2 that was produced using the pET system and the pMAL system was 750 U/mg and 860 U/mg, respectively. In the in vivo activity assay, the presence of lesions in the positive control leaves (Figure 4A) was regarded as a typical disease symptom compared with the treated leaves. The treated leaves began to display small necrotic spots at the second day after treatment (dat) with PCPEL2, and the necrotic lesions expanded gradually and visible necrotic lesions appeared after 4 dat (Figure 4B and 4C). In addition, the mean lesion area treated with the purified PCPEL2 expressed by the pMAL system was significantly bigger (Figure 4C) than that of treated with the purified PCPEL2 expressed by the pET system, in agreement with the specific activities. PCPEL2 could induce necrotic lesions on the pepper leaves, resulting in pathogenic symptoms. The results confirm that PCPEL2 is likely to soften pepper tissues and may cause death of plant cells, and might be one of the pathogenicity factors during infection of P. capsici.

Crystallization of PCPEL2

The purified PCPEL2 obtained by the two different ways was used for the crystallization trials. Initial crystals of PCPEL2 (Figure 5) appeared using the purified protein expressed by the pMAL system. The lower pH and higher purity of the PCPEL2 produced by the pMAL system compared to the purified protein expressed by the pET system may have contributed to the good crystallization of the former PCPEL2. The crystals were grown in drops with 0.1 M HEPES (pH 7.5), 10% (w/v) Polyethylene glycol 6000, 5% (v/v) (±)-2-Methy-2,4-pentanediol. High quality crystals of PCPEL2 would be necessarily optimized in order to get a good X-ray diffraction data set for the structure determination. The work is in progress.

Characterization comparison of the two purified PCPEL2

The buffer dissolved the PCPEL2 and the purity of the purified PCPEL2 differed from the two systems. As far as PCPEL2 expressed by the pET system, the higher pH (pH 10.3) and the urea (2 M) were essential during the purification steps, and the urea could be removed gradually by dialysis. The above steps were unnecessary for the PCPEL2 expressed by the pMAL system since the MBP tag can increase the solubility of target protein. Specific activities of purified PCPEL2 compared favorably at 750 and 860 U/mg protein, respectively (Tables 1 and 2). In addition, both the two purified PCPEL2 were able to induce necrotic lesions on the pepper leaves, but the necrotic lesions were different from the typical Phytophthora foliar blight symptoms as observed in the positive control. The different symptoms are possibly because P. capsici is likely to be producing a series of pathogenesis-related enzymes to initiate host cell death, while the PCPEL2 is a single pathogenicity factor to soften pepper tissues. The two purified PCPEL2 showed differences in infectious characteristic, the mean lesion area treated with the higher activity PCPEL2 was distinctly bigger than that of treated with the lower activity protein, suggesting the virulence of PCPEL2 enzyme is related to its activity. Crystals of PCPEL2 were grown using the purified protein expressed by the pMAL system, while no crystals appeared using the purified PCPEL2 expressed by the pET system. In conclusion, the purified PCPEL2 expressed by the pMAL system contributed to the higher specific activity, pathogenicity and crystallization.

Conclusions

In summary, we cloned a new pectate lyase gene (Pcpel2) from P. capsici. PCPEL2 was expressed by two different systems, pET and pMAL systems. The recombinant products were purified using affinity chromatography and gel filtration chromatography. The purity, specific activity and pathogenicity of the purified PCPEL2 expressed by the pMAL system were higher than the purified PCPEL2 expressed by the pET system. In addition, some other characteristics of the purified PCPEL2 differed from the two systems, such as crystallographic features. Using different methods and comparison of the products would be highly valuable in obtaining an ideal enzyme for the downstream experiments.

Methods

Strains, plasmids and chemicals

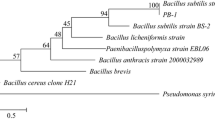

The pectate lyase gene Pcpel2 [GenBank Accession No. FJ213435] was obtained by screening the genomic library of P. capsici by our lab [27]. DH5α Chemically Competent Cell (TransGen) was used as a host strain for manipulation. E. coli BL21 (DE3) pLysS (TransGen) was used as expression strain. The pET28a Expression kit was obtained from Novagen. The pET28a vector contains the T7 promoter and allows expression of the recombinant protein fused to His-tag at the N-terminus. Vector pMAL-p4X, purchased from New England Biolabs, was reconstructed by our lab. The human rhinovirus 3C protease was expressed and purified as previously described [28]. Restriction enzymes, T4 DNA ligase, Pfu polymerase and protein marker were purchased from TaKaRa (Dalian, China). All chemicals were obtained from Sigma-Aldrich unless otherwise specified.

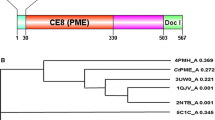

Construction of plasmids pET28-Pcpel2 and pMAL-Pcpel2

A signal peptide of 22 amino acids of Pcpel2 was predicted by the SignalP program [29]. The N-terminal signal peptide sequence was omitted. The mature fragment of Pcpel2 was amplified by PCR using sense 5'-CGCGGATCCCTCTCCACGGGTACGGCACCAG-3' and antisense 5'-CCGGAATTCTTAGTTGGACAGGACACCCAC-3' primers (Invitrogen), containing BamHI and EcoRI restriction sites (underlined), respectively. After initial denaturation at 95°C for 2 min, the PCR reaction was carried out using TransStart FastPfu DNA Polymerase (TransGen). The conditions for each cycle were as follows: denaturation at 95°C for 20 s, annealing at 63°C for 30 s, and extension at 72°C for 20 s. A final extension step at 72°C for 5 min was added at the end of the 35 cycles. The purified PCR product was digested with BamHI and EcoRI, and ligated into the BamHI-EcoRI site of the expression vectors pET28a and reconstructed pMAL-p4X, generating pET28-Pcpel2 and pMAL-Pcpel2 plasmids. The recombinant plasmids were transformed into E. coli BL21 (DE3) pLysS cells for inducible expression. The recombinant plasmid pET28-Pcpel2 has a 6 × His tag at the N-terminus, while the recombinant plasmid pMAL-Pcpel2 has a malE gene, which encodes maltose-binding protein (MBP).

Expression and purification of 6 × His-PCPEL2

Cells carrying the recombinant 6 × His-PCPEL2 were grown at 37°C in LB medium containing 50 ug/ml kanomycin until they reached an optical density at 600 nm of 0.5, and then the cells were induced with 1 mM IPTG for 20 h at 16°C. Cells were harvested, resuspended in buffer A (10 mM Tris-HCl pH 10.3 containing 150 mM NaCl, 2 M urea, 10 mM imidazole and 5 mM β-mercaptoethanol) and lysed by sonication. The lysate was centrifuged at 15,000 g for 30 min at 4°C, and the supernatant was loaded onto a Ni-NTA Superflow column (GE Healthcare) equilibrated with buffer A. The column was washed with buffer B (buffer A containing 20 mM instead of 10 mM imidazole), buffer C (buffer B containing 0.5% (v/v) tween-20) and buffer D (buffer B containing 0.5% (v/v) ethanol). The proteins were eluted with buffer E (buffer A containing 100 mM instead of 10 mM imidazole). The solution was concentrated in a centrifugal concentrator (Millipore) and applied onto a Superdex-200 gel-filtration column equilibrated in 10 mM Tris-HCl pH 10.3, 150 mM NaCl, 2 M urea and 1 mM DTT. Fractions were collected according to their UV absorption peaks. Major peak fractions containing PCPEL2 were pooled and dialyzed overnight against buffer F (10 mM Tris-HCl pH 10.3 containing 150 mM NaCl and 1 mM DTT). The sample was then concentrated to 2 mg/ml according to the Bradford assay. The molecular mass and the purification steps of PCPEL2 were determined using SDS-PAGE (12% polyacrylamide).

Expression and purification of MBP-PCPEL2

The conditions of the fermentation and induction with the cells carrying the recombinant MBP-PCPEL2 were the same as those of the recombinant 6 × His-PCPEL2 described above. Cells were harvested, resuspended in buffer 1 (10 mM Tris-HCl pH 7.5 containing 150 mM NaCl and 5 mM β-mercaptoethanol) and lysed by sonication. The lysate was centrifuged at 15,000 g for 30 min at 4°C, the supernatant was loaded onto an Amylose Resin column (New England Biolabs) which pre-equilibrated with buffer 1. To remove non-specifically bound proteins, the column was washed with buffer 1, buffer 2 (buffer 1 containing 0.5% (v/v) tween-20) and buffer 3 (buffer 1 containing 1% (v/v) triton X-100). The fusion protein was eluted with buffer 4 (10 mM Tris-HCl pH 7.5 containing 150 mM NaCl, 1 mM DTT and 10 mM maltose). The purity of the MBP-PCPEL2 was determined by SDS-PAGE. To separate MBP from PCPEL2, the purified fusion protein was digested with human rhinovirus 3C protease at the weight ratio of 50:1 (substrate/enzyme). The released enzyme was purified with an Amylose Resin column to retain MBP protein.

Western blot analysis

The purified PCPEL2 was used to prepare antibody in New Zealand white rabbits [30]. The antibody preparation, purification and antiserum titer determination were done as previously described [31]. The proteins purified by the two different ways were transferred to a polyvinylidene fluoride (PVDF) membrane after SDS-PAGE. The membrane was blocked with 5% (w/v) non-fat dry milk diluted in TBS buffer (10 mM Tris-HCl, pH 7.0, 100 mM NaCl) for 1 h, and then rinsed with TBS and placed in 1:500 antibody for 2 h by constant shaking. The membrane was then washed with washing buffer (TBS buffer containing 0.5% (v/v) tween-20) three times (5 min each) and incubated with 1:1000 diluted HRP-labeled goat anti-rabbit IgG (Glostrup, Denmark) in TBS buffer for 1 h. Immune complexes were detected by enhanced chemiluminescence according to the manufacturer's specifications (Santa Cruz, CA, USA).

Enzyme activity assay

The purified PCPEL2 was used to determine the pectate lyase activity by adding 20 μl (2 mg/ml) protein solution to 980 μl of reaction buffer (0.2% Polygalacturonic Acid, 100 mM Tris-HCl, pH 8.5, and 1 mM CaCl2) and kept at 40°C for 10 min. Then, 250 μl of 50 mM HCl was added to stop the enzymatic reaction and absorbance at 232 nm was measured with a U-2100 spectrophotometer (Amersham Biosciences). The enzymatic activity was defined as the amount of enzyme that produced a change in absorbance of 0.001 at 232 nm/min [32], as determined by the formation of unsaturated uronide [33].

Treatment of pepper leaves with PCPEL2

Prior to inoculation, seedlings of Pepper Kexing 3 were maintained at 100% humidity at 28°C for 24 h to maximize leaf opening during the fifth to sixth-leaf stage. To evaluate the impact of the purified PCPEL2 on leaves, the seedlings were spot inoculated with 2.5 μl (2 mg/ml) protein solution using a microsyringe. Inoculations were carried out on three of the uppermost leaves. A second set of leaves inoculated with zoospore suspensions (1 × 105/ml) served as a positive control while the heat-inactivated protein and distilled water served as negative controls. Following inoculation, seedlings were maintained at 100% humidity at 28°C for 7 days.

Crystallization of PCPEL2

The purified PCPEL2 was concentrated to 5 mg/ml in 10 mM Tris-HCl, pH 7.5, 150 mM NaCl and 1 mM DTT. The Crystal Screen I and Screen II (Hampton Research) sets of screening conditions were used for the first screening. Initial crystallization conditions were established using 16-well Linbro plates. Purified PCPEL2 was initially crystallized using the hanging-drop vapour-diffusion method at 289 K with 1 μl protein solution and 1 μl mother liquor and the mixture was equilibrated against 200 μl reservoir solution, following by a refinement of the conditions through the variation of precipitants, pH, protein concentrations and additives. Initial crystals appeared after 5 days.

References

Walton JD: Deconstructing the cell wall. Plant Physiol. 1994, 104: 113-1118.

Yadav PK, Singh VK, Yadav S, Yadav KDS, Yadav D: In silico analysis of pectin lyase and pectinase sequences. Biochemistry (Mosc). 2009, 74: 1049-1055. 10.1134/S0006297909090144.

Barras F, Gijsegem FV, Chatterjee AK: Extracellular enzymes and pathogenesis of soft-rot Erwinia. Annu Rev Phytopathol. 1994, 32: 201-234. 10.1146/annurev.py.32.090194.001221.

Herron SR, Benen JAE, Scavetta RD, Visser J, Jurnak F: Structure and function of pectic enzymes: virulence factors of plant pathogens. Pro Natl Acad Sci USA. 2000, 97: 8762-8769. 10.1073/pnas.97.16.8762.

Soriano M, Blanco A, Diaz P, Pastor FI: An unusual pectate lyase from a Bacillus sp. with high activity on pectin: cloning and characterization. Microbiology. 2000, 146: 89-95.

Sukhumsiirchart W, Kawanishi S, Deesukon W, Chansiri K, Kawasaki H, Sakamoto T: Purification, characterization, and overexpression of thermophilic pectate lyase of Bacillus sp. RN1 isolated from a hot spring in Thailand. Biosci Biotechnol Biochem. 2009, 73: 68-273. 10.1271/bbb.80287.

Kaewnum S, Prathuangwong S, Burr TJ: A pectate lyase homolog, xagP, in Xanthomonas axonopodis pv. glycines is associated with hypersensitive response induction on tobacco. Phytopathology. 2006, 96: 1230-1236. 10.1094/PHYTO-96-1230.

Sakai T, Sakamoto T, Hallaert J, Vandamme EJ: Pectin, pectinase and protopectinase: production, properties, and applications. Adv Appl Microbiol. 1993, 39: 213-294. full_text.

Ogawa A, Sawada K, Saito K, Hakamada Y, Sumitomo N, Hatada Y, Kobayashi T, Ito S: A new high-alkaline and high-molecular-weight pectate lyase from a Bacillus isolate: enzymatic properties and cloning of the gene for the enzyme. Biosci Biotechnol Biochem. 2000, 64: 1133-1141. 10.1271/bbb.64.1133.

Abbott DW, Boraston AB: A family 2 pectate lyase displays a rare fold and transition metal-assisted beta-elimination. J Biol Chem. 2007, 282: 35328-35336. 10.1074/jbc.M705511200.

Alkorta I, Garbisu C, Llama M, Serra JL: Industrial applications of pectic enzymes: a review. Process Biochem. 1998, 33: 21-28. 10.1016/S0032-9592(97)00046-0.

Benen JA, Visser J: Pectate and pectin lyases. Handbook of food enzymology New York. Edited by: Whitaker JR, Voragen A, Wong DWS, Dekker. 2003, 1029-1041.

Henriksson G, Akin DE, Hanlin RT, Rodriguez C, Archibald DD, Rigsby LL, Eriksson KL: Identification and retting efficiencies of fungi isolated from dew-retted flax in the United States and Europe. Appl Environ Microbiol. 1997, 63: 3950-3956.

Henrissat B: A classification of glycosyl hydrolases based on amino acid sequence similarities. Biochem J. 1991, 280: 309-316.

Henrissat B, Davies G: Structural and sequence-based classification of glycoside hydrolases. Curr Opin Struc Biol. 1997, 7: 637-644. 10.1016/S0959-440X(97)80072-3.

Pilnik W: Pectin: a many splendoured thing. Gums and stabilizers in the food industry. Edited by: Wedlock DJ, Willima PA. 1990, Oxford: Oxford university press, 209-211.

Keen NT, Dahlbeck D, Staskawicz B, Belser W: Molecular cloning of pectate lyase genes from Erwinia chrysanthemi and their expression in Escherichia coli. J Bacteriol. 1984, 159: 825-831.

Domingo C, Roberts K, Stacey NJ, Connerton I, Teran FR, Mccann MC: A pectate lyase from Zinnia elegans is auxin inducible. Plant J. 1998, 13: 17-28. 10.1046/j.1365-313X.1998.00002.x.

Doyle EA, Lambert KN: Cloning and characterization of an Esophageal-gland-specific pectate lyase from the Root-knot nematode Meloidogyne javanica. Mol Plant Microbe Interact. 2002, 15: 549-556. 10.1094/MPMI.2002.15.6.549.

Burraco AB, Portales RB, Nevado JR, Bellido ML, Moyano E, Caballero J, Blanco JM: Cloning and characterization of two ripening-related strawberry pectate lyase genes. J Exp Bot. 2003, 54: 633-645. 10.1093/jxb/erg065.

Popeijus H, Overmars H, Jones J, Blok V, Goverse A: Degradation of plant cell walls by a nematode. Nature. 2000, 406: 36-37. 10.1038/35017641.

Creze C, Castang S, Derivery E, Haser R, Pattat N, Shevchik VE, Gouet P: The crystal structure of pectate lyase Pel1 from soft rot pathogen Erwinia chrysanthemi in complex with its substrate. J Biol Chem. 2008, 283: 18260-18268. 10.1074/jbc.M709931200.

Vladimir ES, Guy C, Janine RB, Nicole HCP: The exopolygalacturonate lyase PelW and the oligogalacturonate lyase Ogl, two cytoplasmic enzymes of pectin catabolism in Erwinia chrysanthemi 3937. J Bacteriol. 1999, 181: 3912-3919.

Margarita S, Pilar D, Francisco IJP: Pectate lyase C from Bacillus subtilis: a novel endo-cleaving enzyme with activity on highly methylated pectin. Microbiology. 2006, 152: 617-625. 10.1099/mic.0.28562-0.

Elizabeth AD, Kris NL: Cloning and characterization of an esophageal-gland-specific pectate lyase from the root-knot Nematode meloidogyne javanica. Mol Plant Microbe Interact. 2002, 15: 549-556. 10.1094/MPMI.2002.15.6.549.

Taisei K, Hajime S, Takuya A, John TJ: Cloning and characterization of pectate lyases expressed in the esophageal gland of the pine wood Nematode Bursaphelenchus xylophilus. Mol Plant Microbe Interact. 2006, 19: 280-287. 10.1094/MPMI-19-0280.

Sun WX, Jia YJ, Feng BZ, O'Neill NR, Zhu XP, Xie BY, Zhang XG: Functional analysis of Pcipg2 from the straminopilous plant pathogen Phytophthora capsici. Genesis. 2009, 47: 535-544. 10.1002/dvg.20530.

Li HJ, Wang WJ, Shi R: Gene cloning, expression, purification and activity of human rhinovirus 3C protease. Chin J Biolocals. 2007, 20: 240-243.

Nielsen H, Engelbrecht J, Brunak S, Heijne G: Identification of prokaryotic and eukaryotic signal peptides and prediction of their cleavage sites. Protein Eng. 1997, 10: 1-6. 10.1093/protein/10.1.1.

Kothari H, Kumar P, Singh N: Prokaryotic expression, purification, and polyclonal antibody production against a novel drug resistance gene of Leishmania donovani clinical isolate. Protein Expr Purif. 2006, 45: 15-21. 10.1016/j.pep.2005.10.002.

Yang J, Guo SY, Pan FY, Geng HX, Gong Y, Lou D, Shu YQ, Li CJ: Prokaryotic expression and polyclonal antibody preparation of a novel rab-like protein mRabL5. Protein Expr Purif. 2007, 53: 1-8. 10.1016/j.pep.2006.10.025.

Matsumoto H, Jitareerat P, Baba Y, Tsuyumu S: Comparative study of regulatory mechanisms for pectinase production by Erwinia carotovora subsp. carotovora and Erwinia chrysanthemi. Mol Plant Microbe Interact. 2003, 16: 226-237. 10.1094/MPMI.2003.16.3.226.

Liao CH, Hung HY, Chatterjee AK: An extracellular pectate lyase is the pathogenicity factor of the soft-rotting bacterium Pseudomonas viridiflava. Mol Plant Microbe Interact. 1988, 1: 199-206. 10.1094/MPMI-1-199.

Acknowledgements

This research was supported by 973 Program of the Ministry of Science and Technology of China (2009CB119000).

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors' contributions

XGZ conceived and designed the experiment. HZW and LF performed the experiments. HZW analyzed the data. HZW and XGZ wrote the paper. All authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is published under license to BioMed Central Ltd. This is an Open Access article is distributed under the terms of the Creative Commons Attribution License ( https://creativecommons.org/licenses/by/2.0 ), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Wang, H., Fu, L. & Zhang, X. Comparison of expression, purification and characterization of a new pectate lyase from Phytophthora capsiciusing two different methods. BMC Biotechnol 11, 32 (2011). https://doi.org/10.1186/1472-6750-11-32

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/1472-6750-11-32