Abstract

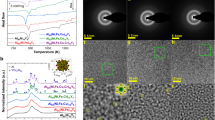

This study evaluated the structural changes of Al–Ni–(Fe,Cr,Cu)–Y alloys induced by different cooling states. The aim was to determine the role of Fe, Cr, and Cu addition as well as cooling rate on the structure, hardness and anticorrosion properties of crystalline and nanocrystalline Al–Ni–Y alloys. The impact of the preparation method on the structure of alloys was observed by the broadening of the X-ray diffraction peaks of the alloys in the form of plates, which indicated structure fragmentation at a high cooling rate. The TEM images showed the formation of a structure composed of homogeneously dispersed α-Al nanograins. Phase analysis performed using X-ray diffraction method and Mössbauer spectroscopy revealed that the slowly cooled master alloys were mainly composed of Al23Ni6Y4, Al10Fe2Y, and α-Al phases. The Al10Fe2Y structure was the main Fe-bearing phase in all investigated master alloys. A crystallization mechanism was proposed based on the DTA heating and cooling curves. The pitting corrosion type was identified based on morphology observations after electrochemical tests. Rapid solidification and the addition of chromium and copper improved the microhardness as well as corrosion resistance. The high increase of hardness (289 HV0.1) and corrosion resistance (Ecorr = − 0.629 V vs. SCE, jcorr = 2.19 μA cm−2, vcorr = 0.07 mm/year) was noted for the Al85Ni2.5Fe2.5Cr2.5Cu2.5Y5 alloy in a plate form.

Similar content being viewed by others

References

Jindal R, Raja VS, Gibson MA, Styles MJ, Bastow TJ, Hutchinson CR. Effect of annealing below the crystallization temperature on the corrosion behavior of Al-Ni-Y metallic glasses. Corros Sci. 2014;84:54–65. https://doi.org/10.1016/j.corsci.2014.03.015.

Inoue A, Kimura H. Fabrications and mechanical properties of bulk amorphous, nanocrystalline, nanoquasicrystalline alloys in aluminum-based system. J Light Met. 2001;1:31–41. https://doi.org/10.1016/S1471-5317(00)00004-3.

Inoue A. Bulk amorphous and nanocrystalline alloys with high functional properties. Mater Sci Eng A. 2001;304–306:1–10. https://doi.org/10.1016/S0921-5093(00)01551-3.

Abrosimova G, Aronin A. Amorphous and Nanocrystalline Metallic Alloys. In: Glebovsky V, editor. Progress in Metallic Alloys. London: IntechOpen; 2016. https://doi.org/10.5772/64499.

Seikh AH, Baig M, Ammar HR, Alam MA. The influence of transition metals addition on the corrosion resistance of nanocrystalline al alloys produced by mechanical alloying. Metals (Basel). 2016;6:8–13. https://doi.org/10.3390/met6060140.

Liu L, Li Y, Wang F. Electrochemical corrosion behavior of nanocrystalline materials—a review. J Mater Sci Technol. 2010;26:1–14. https://doi.org/10.1016/S1005-0302(10)60001-1.

Shen Y, Perepezko JH. Al-based amorphous alloys: glass-forming ability, crystallization behavior and effects of minor alloying additions. J Alloys Compd. 2017;707:3–11. https://doi.org/10.1016/j.jallcom.2016.11.079.

Kiminami CS, Bassim ND, Kaufman MJ, Amateau MF, Eden TJ, Galbraith JM. Challenges in the development of aluminium-based bulk amorphous alloys. Key Eng Mater. 2001;189–191:503–8. https://doi.org/10.4028/www.scientific.net/kem.189-191.503.

Das SK, Davis LA. High performance aerospace alloys via rapid solidification processing. Mater Sci Eng. 1988;98:1–12. https://doi.org/10.1016/0025-5416(88)90116-4.

Rizzi P, Baricco M, Borace S, Battezzati L. Phase selection in Al-TM-RE alloys: nanocrystalline Al versus intermetallics. Mater Sci Eng A. 2001;304–306:574–8. https://doi.org/10.1016/S0921-5093(00)01537-9.

Gupta RK, Fabijanic D, Zhang R, Birbilis N. Corrosion behaviour and hardness of in situ consolidated nanostructured Al and Al-Cr alloys produced via high-energy ball milling. Corros Sci. 2015;98:643–50. https://doi.org/10.1016/j.corsci.2015.06.011.

Fathy A, El-Kady O, Mohammed MMM, Effect of iron addition on microstructure, mechanical and magnetic properties of Al-matrix composite produced by powder metallurgy route, Trans. Nonferrous Met. Soc. China. 2015;25:46–53. https://doi.org/10.1016/S1003-6326(15)63577-4

Vargel C. The metallurgy of aluminium. In: Corrosion of aluminium. 2nd ed. New York: Elsevier; 2004. p. 23–57. https://doi.org/10.1016/b978-008044495-6/50008-2.

Rana RS, Purohit R, Das S. Reviews on the Influences of Alloying elements on the Microstructure and Mechanical Properties of Aluminum Alloys and Aluminum Alloy Composites. Int. J. Sci. Res. Publ. 2012;2:1–7.

Li Q, Li B, Li J, Zhu Y, Xia T. Effect of yttrium addition on the microstructures and mechanical properties of hypereutectic Al-20Si alloy. Mater Sci Eng A. 2018;722:47–57. https://doi.org/10.1016/j.msea.2018.03.015.

Zhang LM, Zhang SD, Ma AL, Hu HX, Zheng YG, Yang BJ, Wang JQ. Thermally induced structure evolution on the corrosion behavior of Al-Ni-Y amorphous alloys. Corros Sci. 2018;144:172–83. https://doi.org/10.1016/j.corsci.2018.08.046.

Babilas R, Młynarek K, Łoński W, Lis M, Łukowiec D, Kądziołka-Gaweł M, Warski T, Radoń A. Analysis of thermodynamic parameters for designing quasicrystalline Al-Ni-Fe alloys with enhanced corrosion resistance. J Alloys Compd. 2021;868: 159241. https://doi.org/10.1016/j.jallcom.2021.159241.

Inoue A, Horio Y, Masumoto T. New amorphous Al-Ni-Fe and Al-Ni-Co Alloys. Mater Trans JIM. 1993;34:85–8. https://doi.org/10.2320/matertrans1989.34.85.

Babilas R, Spilka M, Młynarek K, Łoński W, Łukowiec D, Radoń A, Kądziołka-Gaweł M, Gębara P. Glass-forming ability and corrosion resistance of Al88Y8-xFe4+x (x= 0, 1, 2 at.%) alloys. Materials (Basel). 2021;14:1–12.

Sasaki TT, Ohkubo T, Hono K. Microstructure and mechanical properties of bulk nanocrystalline Al–Fe alloy processed by mechanical alloying and spark plasma sintering. Acta Mater. 2009;57:3529–38. https://doi.org/10.1016/j.actamat.2009.04.012.

Kuball A, Stolpe M, Busch R. Crystallization behavior of the Al86Ni8Y6 metallic glass forming alloy upon rapid cooling. J Alloys Compd. 2018;737:398–404. https://doi.org/10.1016/j.jallcom.2017.12.044.

Inoue A, Ohtera K, Tsai AP, and Masumoto T, Aluminum-Based Amorphous Alloys with Tensile Strength above 980 MPa (100 kg/mm2), Jpn. J. Appl. Phys. 1988;27:L479-L482. https://doi.org/10.1143/JJAP.27.L479

Yang BJ, Yao JH, Chao YS, Wang JQ, Ma E. Developing aluminum-based bulk metallic glasses. Philos Mag. 2010;90:3215–31. https://doi.org/10.1080/14786435.2010.484401.

Raggio R, Borzone G, Ferro R. The Al-rich region in the Y-Ni-Al system: microstructures and phase equilibria. Intermetallics. 2000;8:247–57. https://doi.org/10.1016/S0966-9795(99)00100-4.

Vasiliev AL, Aindow M, Blackburn MJ, Watson TJ. Phase stability and microstructure in devitrified Al-rich Al-Y-Ni alloys. Intermetallics. 2004;12:349–62. https://doi.org/10.1016/j.intermet.2003.11.007.

Raghavan V. Al-Ni-Y (Aluminum-Nickel-Yttrium). J Phase Equilibria Diffus. 2010;31:57–8. https://doi.org/10.1007/s11669-009-9625-8.

Yang BJ, Lu WY, Zhang JL, Wang JQ, Ma E. Melt fluxing to elevate the forming ability of Al-based bulk metallic glasses. Sci Rep. 2017;7:1–16. https://doi.org/10.1038/s41598-017-11504-6.

Babilas R, Łoński W, Młynarek K, Bajorek A, Radoń A. Relationship between the thermodynamic parameters, structure, and anticorrosion properties of Al-Zr-Ni-Fe-Y alloys. Metall Mater Trans A. 2020;51:4215–27. https://doi.org/10.1007/s11661-020-05833-x.

Dunlap R, Dahn J, Eelman D, MacKay G. Microstructure of supersaturated fcc Al–Fe alloys: a comparison of rapidly quenched and mechanically alloyed Al98Fe2. Hyperfine Interact. 1998;116:117–26. https://doi.org/10.1023/A:1012685713970.

Waerenborgh J, Salamakha P, Sologub O, Serio S, Godinho M, Goncalves A, Almeida M. Y-Fe–Al ternary system: partial isothermal section at 1070 K powder X-ray diffraction and mossbauer spectroscopy study. J Alloy Compd. 2001;323:78–82. https://doi.org/10.1016/S0925-8388(01)00990-2.

van der Woude F, Schurer P. A study of quasi-crystalline Al-Fe alloys by Mossbauer-effect spectroscopy and diffraction techniques. Can J Phys. 1987;65:1301–8. https://doi.org/10.1139/p87-205.

Bėčytė L, Mažeika K, Juškėnas R. Study of the iron atom clustering in mechanically alloyed Al-rich Fe-Al mixture. Lith J Phys. 2014;54:199–203. https://doi.org/10.3952/physics.v54i3.2960.

Sitek J, Degmová J. Aluminium-based amorphous and nanocrystalline alloys with Fe impurity. Czechoslov J Phys. 2006;56:17–22. https://doi.org/10.1007/s10582-006-0467-x.

Srinivas V, Dunlap RA. Structural and electrical properties of AlCuFe quasicrystals. Philos Mag B. 1991;64:475–84. https://doi.org/10.1080/13642819108215270.

Derman MN, Jeffry MR, Kumar R. Corrosion behavior of Al-Cu-Ni-Y alloys. Adv Mater Res. 2013;795:535–9. https://doi.org/10.4028/www.scientific.net/AMR.795.535.

Grilli R, Baker MA, Castle JE, Dunn B, Watts JF. Localized corrosion of a 2219 aluminium alloy exposed to a 3.5% NaCl solution. Corros Sci. 2010;52:2855–66. https://doi.org/10.1016/j.corsci.2010.04.035.

Arthanari S, Jang JC, Shin KS. Corrosion behavior of high pressure die cast Al-Ni and Al-Ni-Ca alloys in 3.5% NaCl solution. Corros Sci Technol. 2017;16:100–8. https://doi.org/10.14773/CST.2017.16.3.100.

Singh G, Singh D, Dhindsa GS, Singh G, Singh P. Corrosion in aircraft components: types, impacts and protection measures. Int J Adv Sci Technol. 2020;29:4891–6.

Lachowicz MM, Jasionowski R. Effect of cooling rate at the eutectoid transformation temperature on the corrosion resistance of Zn-4Al alloy. Materials (Basel). 2020;13:19–21. https://doi.org/10.3390/ma13071703.

Zhang LM, Ma AL, Hu HX, Zheng YG, Yang BJ, Wang JQ. Effect of microalloying with Ti or Cr on the corrosion behavior of Al-Ni-Y amorphous alloys. Corrosion. 2018;74:66–74. https://doi.org/10.5006/2451.

Ribeiro TM, Catellan E, Garcia A, dos Santos CA. The effects of Cr addition on microstructure, hardness and tensile properties of as-cast Al-3.8 wt%Cu-(Cr) alloys. J Mater Res Technol. 2020;9:6620–31. https://doi.org/10.1016/j.jmrt.2020.04.054.

Funding

The work was supported by the National Science Centre of Poland under research project no. 2018/29/B/ST8/02264.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All the authors of the article declare that during the implementation of the research presented in the article there was no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Babilas, R., Młynarek-Żak, K., Łoński, W. et al. Influence of Fe, Cr, and Cu addition on the microstructure, hardness, and anticorrosion properties of Al–Ni–Y alloys. Archiv.Civ.Mech.Eng 22, 82 (2022). https://doi.org/10.1007/s43452-022-00404-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-022-00404-w